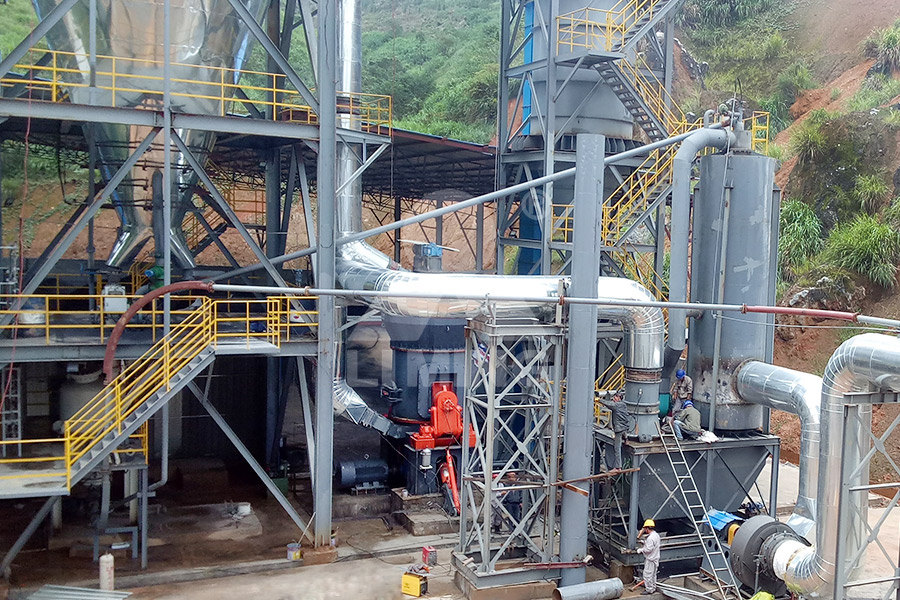

Raw material mill for cement plant

Raw mill Cement Plant

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plant In the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the Cement crusher refers to the stone crusher in the cement industry, as a part of the Cement CrusherCement ball mill and cement vertical mill are two raw mills commonly used in cement plants As the main cement equipment in the cement production line, the two cement raw mills have different characteristicsRaw Mill – Raw Mill In Cement Plant AGICO Cement Providing a comprehensive guide to the entire cement production process from raw material extraction to the finished product, the industry’s favourite technical reference book is now fully The Cement Plant Operations Handbook International Cement

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process In recent years, the VRM cement mill has been equipped in more and more cement A raw mill with a superior fineness and wellcontrolled chemical composition using as advanced control system can improve the cement quality and define critical cement craft parameters Amrit Cement uses the best of raw materials and Raw Mill in Cement Plant Cement Manufacturing Raw Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plant Vertical raw mill is an ideal grinding mill that crushing, drying, grinding, Vertical raw mill Cement PlantThe raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing Mixing: according to the requirement of clinker, compound desired raw material for cement production Preparation Of Cement Raw Material Cement Mill,

OK™ Raw and Cement Mill

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It The main difference to cement mill operation is the need to dry rawfeed and assure transport of stightly moist materialwithin a mill Also, many raw materials are softer than clinker, and operations must avoid coarse residues in kiln feed Raw milling and blending INFINITY FOR CEMENT The planned new plant is located nearly 500 km south of Cairo in Sohag The LOESCHE scope of delivery includes a raw material mill with a capacity of 540 t/h of cement raw meal, a cement mill with an output of 350 t/h of clinker as well Cement Raw Material LoescheA cement plant in the Middle East faced issues with high moisture content in its raw materials, leading to frequent mill stoppages and reduced output By installing a rotary dryer before the raw mill, the plant reduced moisture levels by 15%, Raw Mill Moisture Content Management: A

.png)

Cement Mill Cement Ball Mill Vertical Cement Mill Factory

As a trusted cement plant manufacturer of China, AGICO Cement can provide highquality cement mill and other kinds of cement equipment at competitive prices Wide product range: For meeting various requirements from different clients, our cement mill range from cement ball mill, vertical cement mill, Raymond mill, coal mill in cement plant, etc2024年2月23日 It is a crucial component of cement plants, as it is employed to grind raw materials such as limestone, clay, and other substances into fine powders suitable for cement manufacturing The raw materials are fed into the mill and then crushed by multiple grinding wheels or rollers The resulting powder is used for cement productionHow Does a Raw Mill Work in a Cement IndustryCement manufacturing: components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc For information on materials, including reactions in the kiln, see the ' Clinker ' pagesCement manufacturing components of a cement plant Understanding Cement2024年11月23日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by Cement Extraction, Processing, Manufacturing Britannica

Vertical Cement Mill

The vertical cement mill is largescale cement grinding machine With advantages of energyefficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic mining industry and etc As a typical type of Cement Mill, vertical cement mill set crushing, drying, grinding, grading transportation in one, it grind Lime Component Limestone: Common forms of calcium carbonate used as raw material for cement manufacturing are limestone and chalkLimestone is of predominantly fine grained crystalline structure, its hardness is between 18 to 30 of the Mohs scale of hardness and specific gravity 2 To 28 Limestone usually contains admixtures of clay substance or iron compounds, Raw materials for cement manufacturing Cement Plant Raymond mill can be used in cement plant and lime calcination plant AGICO CEMENT supplies Raymond mill with customization service and factory price, feel FREE to ask! Skip to content +86 s about blog contact Home > Raw Material Production > Cement Mill > Raymond mill Capacity: 8176t Feeding Size Raymond Mill, Raymond Mill For Sale For Cement and Lime PlantIntroduction Setting up a cement plant involves numerous components and stages, each contributing significantly to the overall cost This detailed guide will break down the costs associated with each component and stage of a cement The Comprehensive Guide to Cement Plant Costs: An

.jpg)

PROCESS TRAINING for operators of Vertical RAW Mills

For drying the wet raw material it is necessary that prior to the mill start up the grinding plant isheated for some timeOtherwise the cold grinding plant would take away too much heat from the drying process and the finish product would A mediumsized dry process roller mill A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement millThe raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the Rawmill Wikipedia2019年4月23日 Introduction Portland cement underpins modern global development As such, it is the most abundantly produced material in the world (Deolalkar Citation 2016)The world has an abundance of the primary raw materials for cement manufacturing and, compared to other construction materials, cement’s cost is low and it has good durability (Hewlett Citation 2003)An overview of alternative raw materials used in cement and 2019年9月27日 Cement mill Cement mill is another necessary cement equipment of the cement plant After raw material crushing, cement mill plays vital role in the further cement manufacturing process Cement ball mill, vertical cement mill, and cement roller press are common types of cement grinding plantCement Euipment Overview Cement Making Machines Cement Plant

.jpg)

Cement Ball Mill Ball Mill For Sale Cement Mill 15100t/h

Home > Raw Material Production > Cement Mill > Cement Ball Mill Ball mill for sale Production Capacity: 15100t/h Feeding Size: ≤25mm you can send the drawing to s Detailed information is greatly helpful for us to give you the bestcustomized offer/quotation at the soonest timeRoller grinding mill Ball mill Raw meal silos Cyclone preheater Calciner Preheater kiln Grate preheater Lepol kiln Clinker Raw meal silos The crushed material is transported into the raw material storage of the cement plant by conveyorbelts, cableways or railways and also in exceptional cases with trucksFrom raw materials to cementPreheater exit gases are distributed based on requirement of Vertical Roller Mills for Raw Material Grinding and Vertical Roller Mill for Coal grinding For the operation of the Raw Mill (Vertical Roller Mill), existing system was 2fan circuit The existing system consisted of Gas Conditioning Tower (GCT) Like in any cement plant, Raw Mill – Kiln Application in Cement Industry ThermaxAfter monitoring and controlling the quality of incoming raw material, the area of high activity for quality department to ensure quality mix for smooth production of high quality of cement is “mill feeding system” The system consists of material hoppers/bins, weighing, conveying, venting and mill feeding gate Mill Feeding HoppersRaw Mill Feeding Cement Plant Optimization

Vertical roller mill for raw Application p rocess materials

As of 2002, this system is used at four plants in Japan Mill Fig1 Flow of Conventional Vertical Mill Grinding System Mill Kiln IDF (Kiln gas exhaust fan) Fig2 Flow of direct dust collection system The basic management of the components of cement raw materials is to set the mixing2024年3月4日 Optimisation of Pfeiffer raw mill for cement plant Download as a PDF or view online for free Grindability of Raw Material •Grinding Fineness •Classifier Design •Grinding Bed Height / Variations •Dam Ring Height •Air Optimisation of Pfeiffer raw mill for cement plantThe proportioning of cement raw materials is not all the same but should be determined according to the actual situation The proportion of raw materials of different specifications of cement is also different Generally, the proportion of How Is Cement Produced in Cement Plants Cement SINOMALY produces cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d and 8000t/d The vertical grinding Vertical Roller Mill for Cement Raw Material

.jpg)

OK RAW AND CEMENT MILL

to be the most efficient cement VRM available with the highest reliability and ease of operation In 2017, we introduced the OK raw mill, which is designed with the same proven technology and modular design as the OK cement mill Along with our proven highefficiency RAR separator, the OK raw mill also incorporates the best VRM features in oneCement conveyor refers to a belt conveyor in cement plant, which is necessary accessory equipment in the cement production line A belt conveyor is a kind of material handling equipment with strong adaptability, applied for conveying bulk density less than 167t / m³, it is mostly used for powder, granular, small lump materials, and bagged materials, such as sand, ore, coal, Cement Conveyor Belt Conveyor In Cement Plant AGICOBall mill in operation at a cement plant The mill shell was protected against wear by liner plates bolted to it Brundick, H, “Drying and grinding of extremely moist cement raw materials in the Loesche mill,” ZKG International, No2, 1998, pages 64 Everything you need to know about cement Materials Preparation and Raw The cement raw material mixtures are ground, dried, and classified in the Pfeiffer vertical roller mill For drying the material, hot gases are directed into the mill Product fineness can be adjusted within a wide range (0063 to 02 mm)Raw mills for all requirements Gebr Pfeiffer

.jpg)

8 Tips For Cement Plant Design

2023年11月1日 The design of the raw material grinding system should focus on the energysaving, vertical mill grinding system because of its powersaving, simple process to become a large cement plant, the use of a ball mill grinding system is no more than two reasons: first, the raw material is difficult to grind, such as high quartz sandstone content, the second is the 2024年8月20日 Step 4: Cement grinding and storageThe cooled clinker with gypsum is finely ground in a cement mill to form the hard cement The other raw materials are added during the grinding process The raw material added during the grinding process defines the quality of the cement Therefore, the raw materials determine the cement grade Let us discuss Understanding the Raw Materials for Manufacturing CementRaw mill is the grinding equipment applied in the raw material preparation processIn the wet process of cement production, raw materials should be ground into raw slurry with a water content of 30% – 40% While in the dry process of cement production, they will be ground into dry powder in a cement raw millCement Mill Cement Grinding Machine AGICO Cement Grinding MillThe main difference to cement mill operation is the need to dry rawfeed and assure transport of stightly moist materialwithin a mill Also, many raw materials are softer than clinker, and operations must avoid coarse residues in kiln feed Raw milling and blending INFINITY FOR CEMENT

Cement Raw Material Loesche

The planned new plant is located nearly 500 km south of Cairo in Sohag The LOESCHE scope of delivery includes a raw material mill with a capacity of 540 t/h of cement raw meal, a cement mill with an output of 350 t/h of clinker as well A cement plant in the Middle East faced issues with high moisture content in its raw materials, leading to frequent mill stoppages and reduced output By installing a rotary dryer before the raw mill, the plant reduced moisture levels by 15%, Raw Mill Moisture Content Management: A As a trusted cement plant manufacturer of China, AGICO Cement can provide highquality cement mill and other kinds of cement equipment at competitive prices Wide product range: For meeting various requirements from different clients, our cement mill range from cement ball mill, vertical cement mill, Raymond mill, coal mill in cement plant, etcCement Mill Cement Ball Mill Vertical Cement Mill Factory 2024年2月23日 It is a crucial component of cement plants, as it is employed to grind raw materials such as limestone, clay, and other substances into fine powders suitable for cement manufacturing The raw materials are fed into the mill and then crushed by multiple grinding wheels or rollers The resulting powder is used for cement productionHow Does a Raw Mill Work in a Cement Industry

Cement manufacturing components of a cement plant Understanding Cement

Cement manufacturing: components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc For information on materials, including reactions in the kiln, see the ' Clinker ' pages2024年11月23日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by Cement Extraction, Processing, Manufacturing BritannicaThe vertical cement mill is largescale cement grinding machine With advantages of energyefficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic mining industry and etc As a typical type of Cement Mill, vertical cement mill set crushing, drying, grinding, grading transportation in one, it grind Vertical Cement MillLime Component Limestone: Common forms of calcium carbonate used as raw material for cement manufacturing are limestone and chalkLimestone is of predominantly fine grained crystalline structure, its hardness is between 18 to 30 of the Mohs scale of hardness and specific gravity 2 To 28 Limestone usually contains admixtures of clay substance or iron compounds, Raw materials for cement manufacturing Cement Plant

.jpg)

Raymond Mill, Raymond Mill For Sale For Cement and Lime Plant

Raymond mill can be used in cement plant and lime calcination plant AGICO CEMENT supplies Raymond mill with customization service and factory price, feel FREE to ask! Skip to content +86 s about blog contact Home > Raw Material Production > Cement Mill > Raymond mill Capacity: 8176t Feeding Size