Raymond mill vibration cause analysis

.jpg)

Composite control for raymond mill based on model

2016年3月28日 In this work, based on a raymond mill control system in a silicon carbide powder factory, a DOBMPC scheme is proposed to improve the 2018年6月12日 The Raymond Mill produces vibrations for the following reasons: First, the impact of the grinding roller on the grinding ring; the feeding should be uniform, and the empty Analysis of Causes of Vibration Occurred during Use of Raymond Vibration analysis in machinery is a critical aspect of the field of Mechanics of Machines in Engineering The study of vibration involves understanding the forces that cause oscillations and the response of the system to these forces Vibration Analysis in Machinery: Causes and Control2021年6月15日 Vibration produced by the vertical mill not only damages the equipment, but also causes the instability of the table time and affects the output due to frequent rollup and rolloffCharacteristics and Cause Analysis of Vibration in

Composite control for raymond mill based on model predictive

2016年3月28日 In the raymond mill grinding process, precise control of operating load is vital for the high product quality However, strong external disturbances, such as variations of ore size 2020年11月1日 In this paper, a new framework for mill vibration monitoring and a datadriven mill vibration earlywarning method for a cold rolling mill is proposed SVR, an NNbased Prediction and analysis of cold rolling mill vibration based on a 2017年10月5日 Three typical causes of vibration were analyzed Based on these results, the cause of the vibrations that occur during changes in the processing conditions in a CEM can Investigation of the cause of the chatter and physical behavior of a 2016年3月28日 In the raymond mill grinding process, precise control of operating load is vital for the high product quality However, strong external disturbances, such as variations of ore size Composite control for raymond mill based on model predictive

.jpg)

Research on vibration characteristics of mill rolls based on

2021年4月1日 According to the actual parameters of rolling mill, the influence of the nonlinear stiffness of the hydraulic cylinder and external force on the amplitudefrequency response of 2019年7月1日 We developed a simulation model for the vibration of a mill wall to better understand the relationship between the operating conditions and wall vibration characteristicsVibration characteristics of an operating ball mill2016年3月28日 In order to address this issue, a widely used method in raymond mill control system is to use a programmable logic controller (PLC), electromagnetic vibration feeder, and current sensor to form a feedback Composite control for raymond mill based on model 2012年6月1日 In this article the vibration analysis of a two stand tandem mill is presented Vibration monitoring and chatter detecting systems were used to analyze the rolling standFrequency analysis of chatter vibrations in tandem

Analysis of Causes of Vibration Occurred during Use of Raymond Mill

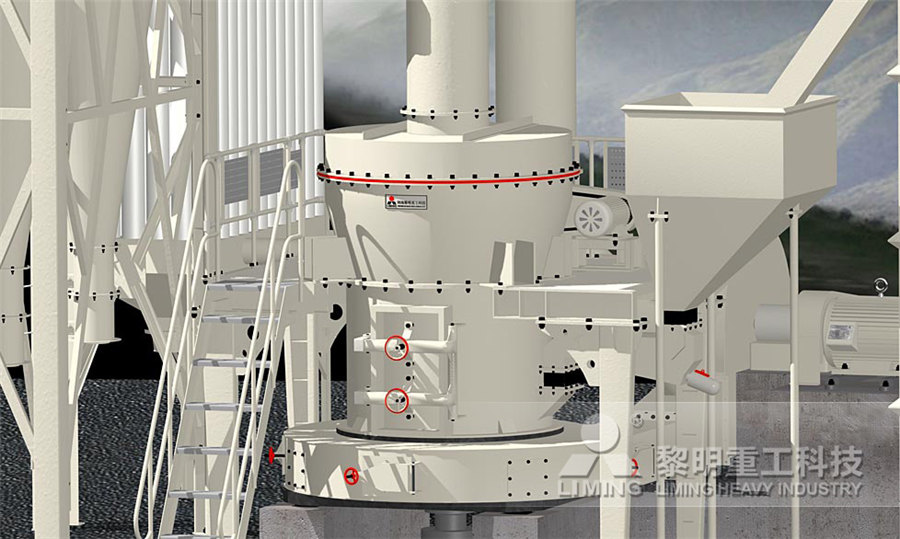

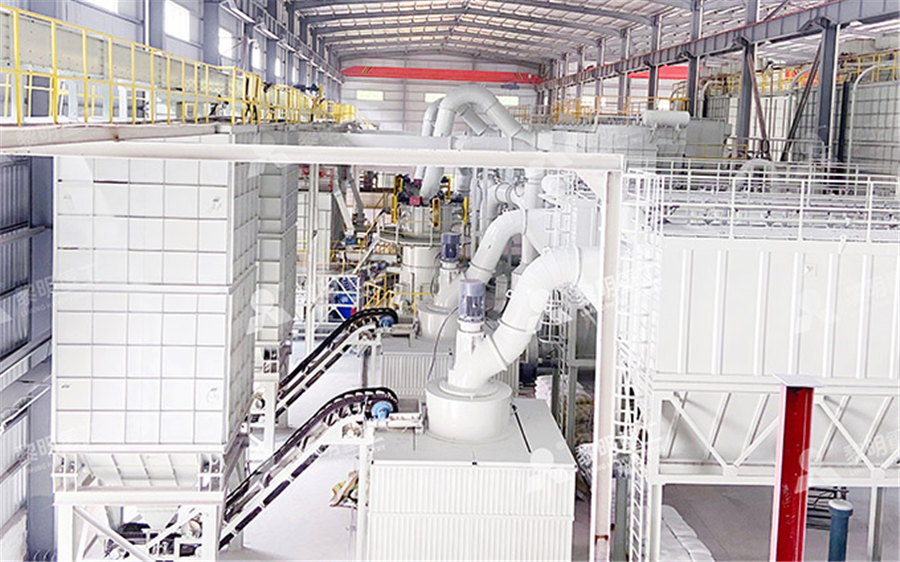

2018年6月12日 Raymond Mill's main machine is divided into three parts, the bottom spiral inlet, Analysis of Causes of Vibration Occurred during Use of Raymond Mill Report this articleHomeDry Mortar MachineRaymond Mill Machine Raymond Mill Machine Manufacturing As a production line for grinding nonmetallic minerals, the Raymond mill machine is commonly used in coal mines, metallurgy, and mines with a Mohs hardness Raymond Mill Machine Manufacturing Dura Mortar2016年1月5日 In the raymond mill grinding system, the raw silicon carbide ores are first fed into the tank of the raymond mill by the vibration feeder and then are grinded into the silicon carbide powders using the grinding rollers and grinding rings The air blower supplies the wind into the tank of the raymond mill and then the silicon Figure posite control for raymond mill based on model predictive 2023年7月26日 Cause Analysis of Rolling Mill Vibration Faults Release time: 20230726 Different types of failures will occur when the steel rolling machinery is in the production and operation state for a long time, which will have a negative impact on the stable operation of the equipment, normal production, and product qualityCause Analysis of Rolling Mill Vibration Faults Judian

AN EXPERIMENTAL ANALYSIS OF VIBRATION OF A BALL MILL

recognized much easier in the spectra of vibration measured at the lower load of the ball mil 6 REFERENCES [1] Rahmanović S, Dolecek V: Identification of Causes of a Ball Mill Drive Vibration Using Signature Analysis in Time and Frequency Domain, The 12th International Conference on Problems of MaterialWe therefore analyze the “type” of vibration to identify its cause and take appropriate repair action When analyzing vibration we look at two components of the vibration signal, its amplitude and its frequency Frequency is the number of times an event occurs in a given time period (the event being one vibration cycle)Vibration Diagnostic Guide SKFThe YGM highpressure Raymond grinding mill represents a significant improvement over the R series Raymond mill With increased grinding roller centrifugal force achieved through highpressure spring pressure, YGM Raymond mill is wellsuited for processing nonflammable and explosive minerals with a Mohs hardness level of 7 and humidity below 6%YGM Raymond Roller Mill2024年4月1日 Due to the importance of vibration analysis, many researchers have drawn attention to this field Randall et al [19] demonstrated the effectiveness of vibration analysis in diagnosing bearing faults in helicopter gearboxes Orhan et al [20] detected the bearing failure by comparing the failure frequencies with the ball passing frequency in the outer raceDiagnosis and root cause analysis of bearing failure using vibration

How to Maintain My Raymond Mill to Improve the

2019年9月9日 Raymond grinding mill is to grind the material through the grinding of the rollers and rings If the feed quantity is too small, there cannot form a material cushion between the highspeed rotating roller and the ring The 2015年1月20日 (1), because the machine is the use of the roller, impact and abrasive grinding ring between the friction material crushing leaving, so the machine running vibration and noise are larger, but the sound is uniform, there should be no abnormal sound, If it is found abnormal sound or a sudden increase in the current host for a long time but do not fall down, you should Raymond Mill Operation Specification (b)2020年11月1日 The most general methods for mill vibration research are mechanistic model analysis of mill chatter and the datadriven rolling mill vibration analysis methods In the mechanistic models of rolling mill vibrations, the most typical models are multipledegreeoffreedom mass–spring structure models, finite element method (FEM) models, and transfer Prediction and analysis of cold rolling mill vibration based on 2020年11月1日 The most general methods for mill vibration research are mechanistic model analysis of mill chatter and the datadriven rolling mill vibration analysis methods In the mechanistic models of rolling mill vibrations, the most typical models are multipledegreeoffreedom mass–spring structure models, finite element method (FEM) models, and transfer Prediction and analysis of cold rolling mill vibration based on

.jpg)

Rolling process and its influence analysis on hot continuous

2016年11月9日 Rolling mill vibration is a worldwide problem, although it has been found that the mill structure defects are the main cause of vibration, but the inhibition measures are difficult to implementSemantic Scholar extracted view of "VIBRATION ANALYSIS IDENTIFIES THE CAUSES OF MILL CHATTER" by J Gasparic Skip to search form Skip to main content Skip to @article{Gasparic1991VIBRATIONAI, title={VIBRATION ANALYSIS IDENTIFIES THE CAUSES OF MILL CHATTER}, author={Jure Gasparic}, journal={Ironsteel Engineer}, year={1991 VIBRATION ANALYSIS IDENTIFIES THE CAUSES OF MILL CHATTER2020年1月28日 Start the Raymond mill host, and the electromagnetic vibration feeder will start immediately after starting the host At this time, the grinding work of Raymond Mill is started 3 The main working process of Raymond mill The working process of the main engine is to drive the central shaft to rotate by means of the transfer support equipmentHow Does Raymond Mill Work?2023年6月12日 Overview of Raymond Mill Raymond mill is one the most commonly used grinding mill in China's grinding industry It has been widely used in the milling and processing fields of more than 280 kinds of materials in the industries of nonflammable and nonexplosive minerals, chemicals, construction, etc, such as barite, calcite, potash feldspar, talc, marble, 6 Aspects For You to Understand Raymond Mill

Schematic diagram of a raymond mill system ResearchGate

In the raymond mill grinding process, precise control of operating load is vital for the high product quality However, strong external disturbances, such as variations of ore size and ore 2023年11月21日 In the present incident, one of the rollers of grinding mill in cement plant failed during operation, exhibiting longitudinal cracking over inner surface Deposition welding was carried out just before the incident to match the wornout profile of the roller Investigation revealed that the subsurface of the cracked region contained discontinuities like blow holes Operational Failure of Vertical Roller Attached to a Grinding Mill 2021年9月11日 Vibration measurement using (a) piezoelectric accelerometer by means of adhesive mounting and (b) velocity transducer, studmounted on the machine’s surface(PDF) Vibration Analysis for Machine Monitoring 2021年12月29日 We produce four kinds of grinding mills: Raymond mill, highpressure grinding mill, highstrength grinding mill, and ultrafine grinding mill You can choose the most suitable mill according to your material, fineness, and output requirements Raymond Mill Get a quotation High Pressure Grinding Mill Get a quotationRaymond Mill : The Ultimate FAQ Guide Dry Mortar Plant

How to maintain the vulnerable parts for Raymond Mill?

2020年4月27日 However, during the longterm use of Raymond Mill, the anchor bolts may loosen due to longterm vibration, thus irregular vibrations occur, and the main engine wears out for a long time, causing the main engine and the The Raymond mill, also called Raymond roller mill, combines grinding, classifying, and if necessary, drying, in one machine to produce precisely sized powders to meet exact production specificationsIt is an efficient fine grinding machine for largescale powder production Applied materials: various nonflammable and explosive minerals such as gypsum, talc, calcite, Raymond Mill2006年10月24日 In this study, experimental analysis is performed for the purpose of clarifying the cause of the mill vibration From the obtained characteristics of the mill vibration, it is denoted that the materials have a negativedamping property relative to the table speed in the fundamental experiment concerning friction characteristicsUnstable vibration of roller mills ScienceDirect2019年6月21日 Grinding pressure is too high or the material layer is too thin will cause the vertical roller mill vibration problem Common types of grinding mills include ball mill, Raymond mill, vertical roller mill and ultrafine mill, each with unique advantages for specific applicationsReasons of Vertical Roller Mill Vibration Zenith Crusher

.jpg)

Stability analysis of the rolling mill multiplemodalcoupling

2015年9月30日 Considering the unstable oscillation in the rolling process caused by the lubrication conditions change, a dynamic rolling process model considering the nonlinear friction is built using the BlandFordHill rolling force model In addition, based on the structure model which can characterize the coupling vibration of rolling mill, and taking the dynamic variations of 2014年7月25日 In this paper, vibration characteristics of a Vertical Roller Mill (VRM) are studied by using physical parameters of an operating VRM The mathematical model is derived and simulated for a set of Vibration Analysis of a Vertical Roller Mill: Modeling and Validation2024年6月30日 In order to clarify the vibration suppression effect of each parameter of the DVA, the timedomain curve, amplitudefrequency curve and phase diagram are carried out for the horizontal and vertical vibration of the work rolls on the mill The vibration suppression effect before and after the installation of the DVA is analyzedCoupling vibration characteristics and vibration suppression of 2016年1月5日 In the raymond mill grinding system, the raw silicon carbide ores are first fed into the tank of the raymond mill by the vibration feeder and then are grinded into the silicon carbide powders using the grinding rollers and grinding rings The air blower supplies the wind into the tank of the raymond mill and then the silicon Figure posite control for raymond mill based on model predictive

.jpg)

Composite control for raymond mill based on model

2016年3月28日 In order to address this issue, a widely used method in raymond mill control system is to use a programmable logic controller (PLC), electromagnetic vibration feeder, and current sensor to form a feedback 2012年6月1日 In this article the vibration analysis of a two stand tandem mill is presented Vibration monitoring and chatter detecting systems were used to analyze the rolling standFrequency analysis of chatter vibrations in tandem 2018年6月12日 Raymond Mill's main machine is divided into three parts, the bottom spiral inlet, Analysis of Causes of Vibration Occurred during Use of Raymond Mill Report this articleAnalysis of Causes of Vibration Occurred during Use of Raymond MillHomeDry Mortar MachineRaymond Mill Machine Raymond Mill Machine Manufacturing As a production line for grinding nonmetallic minerals, the Raymond mill machine is commonly used in coal mines, metallurgy, and mines with a Mohs hardness Raymond Mill Machine Manufacturing Dura Mortar

Composite control for raymond mill based on model predictive

2016年1月5日 In the raymond mill grinding system, the raw silicon carbide ores are first fed into the tank of the raymond mill by the vibration feeder and then are grinded into the silicon carbide powders using the grinding rollers and grinding rings The air blower supplies the wind into the tank of the raymond mill and then the silicon Figure 12023年7月26日 Cause Analysis of Rolling Mill Vibration Faults Release time: 20230726 Different types of failures will occur when the steel rolling machinery is in the production and operation state for a long time, which will have a negative impact on the stable operation of the equipment, normal production, and product qualityCause Analysis of Rolling Mill Vibration Faults Judianrecognized much easier in the spectra of vibration measured at the lower load of the ball mil 6 REFERENCES [1] Rahmanović S, Dolecek V: Identification of Causes of a Ball Mill Drive Vibration Using Signature Analysis in Time and Frequency Domain, The 12th International Conference on Problems of MaterialAN EXPERIMENTAL ANALYSIS OF VIBRATION OF A BALL MILL We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action When analyzing vibration we look at two components of the vibration signal, its amplitude and its frequency Frequency is the number of times an event occurs in a given time period (the event being one vibration cycle)Vibration Diagnostic Guide SKF

.jpg)

YGM Raymond Roller Mill

The YGM highpressure Raymond grinding mill represents a significant improvement over the R series Raymond mill With increased grinding roller centrifugal force achieved through highpressure spring pressure, YGM Raymond mill is wellsuited for processing nonflammable and explosive minerals with a Mohs hardness level of 7 and humidity below 6%2024年4月1日 Due to the importance of vibration analysis, many researchers have drawn attention to this field Randall et al [19] demonstrated the effectiveness of vibration analysis in diagnosing bearing faults in helicopter gearboxes Orhan et al [20] detected the bearing failure by comparing the failure frequencies with the ball passing frequency in the outer raceDiagnosis and root cause analysis of bearing failure using vibration