Vertical mill installation dimensions

.jpg)

Machine Layout Drawing VF3/SS Installation Dimensions Page 1 / 7

All dimensions based on stackup of sheetmetal, subject to variation of 1/2" ( 13 mm) Due to continual product improvements, dimensions are subject to change without notice Machine VF 12 and VM2: The only acceptable way to move this mill is to pick it up from the SIDE with a forklift Follow the machine weight and fork length specifications described earlier The forks VERTICAL MILL INSTALLATION INSTRUCTIONS Amazon Web Vertical Mill InstallationCD Free download as PDF File (pdf), Text File (txt) or read online for free Machine footprints and operating dimensions are available in the brochure and the Vertical Mill Installation Instructions: Important! Refer To Scribdsafeguarding should be used on milling machines to the greatest extent practicable This booklet provides basic information for the installation and use of the general purpose safeguard It also SERIES I MILLING MACHINES UC Berkeley Mechanical Engineering

.jpg)

VF2 Preinstall Guide Haas Automation Inc

However, heavy and complex machines, such as LargeFrame mills and UMCs, may require a 12" (300 mm) concrete foundation, to ensure accurate geometry Refer to these specifications: Product Dimensions: WeightMODEL G3102/G3103 VERTICAL MILL GrizzlySuperSpeed CNC Vertical Mill with 64" x 32" x 30" travels The Haas highperformance SuperSpeed vertical machining centers provide the high spindle speeds, fast rapids, and quick tool changes necessary for highvolume VF6SS 40Taper Mill Super Speed Vertical Mills – By aligning the positions of the center of the ball screw and the guideway, highly accurate drive and positioning are achieved with no collisions The overhang from the machining point to Vertical Machining Centers

制粉项目-2023.11.17.jpg)

Vertical Machining Centers

In addition to maintaining high dimensional accuracy when room temperature changes, Okuma’s ThermoFriendly Concept provides high dimensional accuracy during machine startup and Mini CNC Vertical Mill with 16" x 14" x 15" travels Dimensions Shipping SAE METRIC; Domestic Pallet: 900 in x 800 in x 920 in: 229 cm x 203 cm x 234 cm: state local taxes, vendor installation charges, and dealer installed Mini Mill 40Taper Mill Vertical Mills – Haas CNC CNC Vertical Mill with 84" x 40" x 30" travels Dimensions Shipping SAE METRIC; Domestic Pallet: 2140 in x 1200 in x 1285 in: 544 cm x 305 cm x 326 cm: state local taxes, vendor installation charges, and dealer installed VF9/40 40Taper Mill Vertical Mills – Haas CNC The Haas highperformance SuperSpeed vertical machining centers provide the high spindle speeds, fast rapids, and quick tool changes necessary for highvolume production and reduced cycle times Each SS machine features a VF2SS 40Taper Mill Super Speed Vertical Mills –

.jpg)

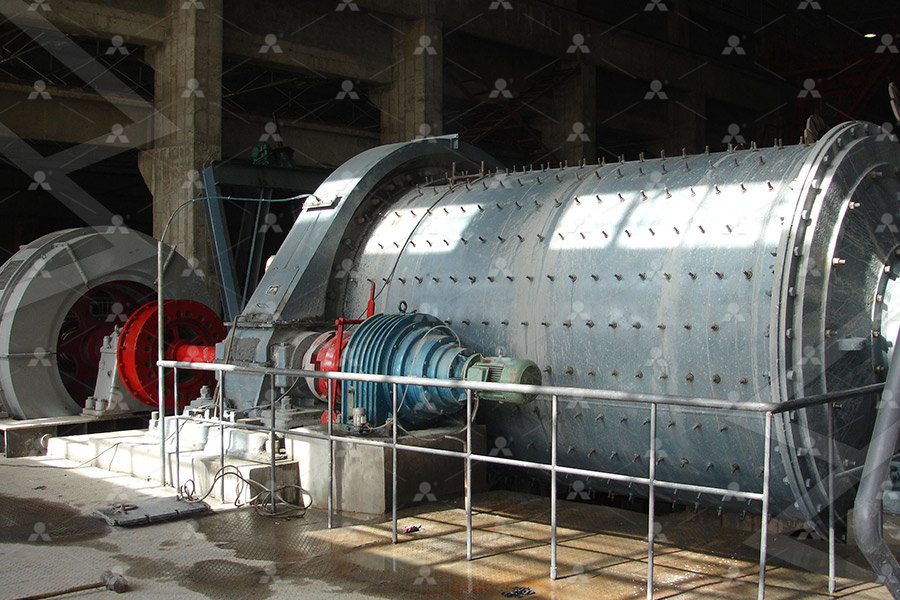

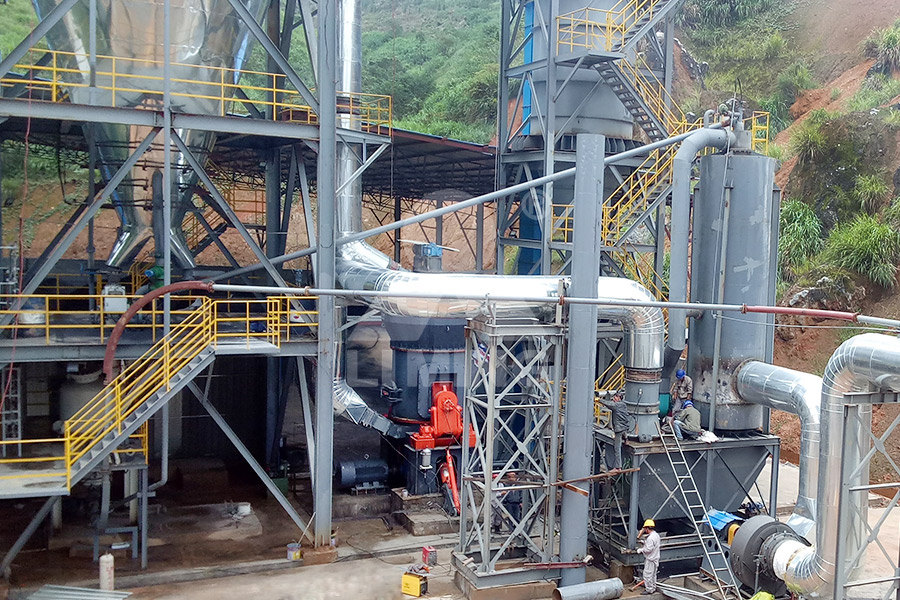

Christian Pfeiffer VEM Vertical mill Christian Pfeiffer

The vertical mill vem for wet material grinding more than 100 ball mill installations worldwide Why do ball mills have different dimensions? The diameter of a ball mill has a great influence on the power consumption of the mill and thus on the possible production outputî äò—úÿümýf*˜"Çé ón ž®'³‘ ’Ÿ´Ä9÷]{ŸÿÂÍN(Ù\3`r„i¯7 p¬g,¢ sb*âtgre ¬£ôyE?%Ž¢í†»vþª+• ²ƒ àÄ!¶ð˜#š›é)Îa8Ý VF10/40 40Taper Mill Vertical Mills – Haas CNC MachinesVERTICAL MILL INSTALLATION INSTRUCTIONS Machine RequiReMents Machine footprints and operating dimensions are available in the brochure and the anchoring addendum GeneRal RequiReMents Operating Temperature Range 41°F to 104°F (5 to 40°C) Storage Temperature Range 4°F to 158°F (20 to 70°C)VERTICAL MILL INSTALLATION INSTRUCTIONSCNC Vertical Mill with 30" x 20" x 20" travels Dimensions Shipping SAE METRIC; Domestic Pallet: 1060 in x 1013 in x 1010 in: 269 cm x 257 cm x 257 cm: state local taxes, vendor installation charges, and dealer installed accessories are not included Not responsible for misprints or typographical errors Machines shown with VF2YT 40Taper Mill Vertical Mills – Haas CNC Machines

Conventional Vertical Milling Machines KNUTH Machine Tools

Oil, Coolants and Lubricants SmartFactory Roller Conveyor Lathes accessories Milling machine accessories Installation, the vertical mill, or knee mill, Table dimensions: 1235x460 mm 2000x500 mm KB 2100Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetimeVertical roller mills FLSmidth CementVertical Mills ; VF Series; Universal Machines; VR Series; VP5 Prismatic; PalletChanging VMCs; Mini Mills; Mold Machines; HighSpeed Drill Centers; Drill/ Tap/ Mill SeriesVR5 5Axis Mill 30Taper Vertical Mills – Haas CNC MachinesWhile only a few installations with drive capacities above 10,000 kW exist, The motor as well as the gearing are wearfree and the entire drive is built in the same dimensions as conventional gearboxes It is suitable for replacements of Drive Systems for Vertical Roller Mills

.jpg)

TM1 40Taper Mill Toolroom Mills Vertical Mills –

Vertical Mills ; VF Series; Universal Machines; VR Series; VP5 Prismatic; PalletChanging Dimensions Shipping SAE METRIC; Domestic Pallet: 1120 in x 800 in x 1000 in: 284 cm x state local taxes, vendor installation charges, 2023年4月18日 This procedure will guide you through the installation of a VMC Tools required: T2181 Service Tool, Leveling Tool, or Precision Machinist Level, 00005" division; Precision Spindle Test Bar, 8" Long; 3/4 This video will VMC Installation Guide Haas Automation C Vertical Mill with 40" x 20" x 25" travels Dimensions Shipping SAE METRIC; Domestic Pallet: 1520 in x 990 in x 1060 in: 387 cm x 251 cm x 269 cm: state local taxes, vendor installation charges, and dealer installed accessories are not included Not responsible for misprints or typographical errors Machines shown with VF3 40Taper Mill Vertical Mills – Haas CNC MachinesVertical Roller Mill 1 Rotary Lock 2 Separator 3 Chute 4 Roller 5 Swing Lever 6 Table 7 Gas Inlet Duct 8 Gear Reducer 9 Motor UM Series A B H Five Roller Roller Arrangement Four Roller UMseries Raw Mill Models with details of structural dimension, product throughputs and driving power (approx Values) Flow Sheet of Raw Material VERTICAL ROLLER MILLS AMCL

VF4SS 40Taper Mill Super Speed Vertical Mills – Haas CNC

SuperSpeed CNC Vertical Mill with 50" x 20" x 25" travels This installation kit requires {{=cobotKitName}} to be selected Cobot Kit Required Options Dimensions Shipping SAE METRIC; Domestic Pallet: 1520 in x 990 in x 1060 in: 387 cm x 251 cm x 269 cm: Export Pallet:Vertical Mill InstallationCD Free download as PDF File (pdf), Text File (txt) or read online for free Machine footprints and operating dimensions are available in the brochure and the anchoring addendum IMPORTANT! REFER TO LOCAL CODE REQUIREMENTS BEFORE WIRING MACHINES ALL MACHINES REQUIRE: Line voltage that does not fluctuate more than +5% Vertical Mill Installation Instructions: Important! Refer ToSuper Mini Mill Install Guide PREINSTALLATION [GUIDE] CNY ONLY SuperSpeed Mini Vertical Mill with 16" x 14" x 15" travels 40 Taper; 3 Axis; 10k RPM; 30+1 Tool Capacity; 美元价格不包括关税 Dimensions Shipping SAE METRIC; Domestic Pallet: 900 in x 800 in x 920 in: 229 cm x 203 cm x 234 cm:Super Mini Mill Preinstall Guide Haas Automation IncVF1 Haas CNC Vertical Mill with 20" x 16" x 20" travels Discover Haas CNC Dimensions Shipping SAE METRIC; Domestic Pallet: 1010 in x 990 in x 1010 in: 257 cm x state local taxes, vendor installation charges, and dealer installed accessories are not included Not responsible for misprints or typographical errors Machines VF1 VF Series Small 40Taper Mill Vertical Mills – Haas CNC

VF3SS 40Taper Mill Super Speed Vertical Mills – Haas CNC

SuperSpeed CNC Vertical Mill with 40" x 20" x 25" travels This installation kit requires {{=cobotKitName}} to be selected Cobot Kit Required Options Dimensions Shipping SAE METRIC; Domestic Pallet: 1520 in x 990 in x 1060 in: 387 cm x 251 cm x 269 cm: Export Pallet:First MVR mill for cement grinding 1994 More power for MPS mills by introducing the Bseries 2007 First vertical mill with MultiDrive® 2016 Biggest cement mill in the world in operation 2017 ready2grind – World’s fi rst modular system with a vertical cement millPASSION FOR GRINDINGunreasonable dimensions can be solved in the design stage 34 Vertical Mill’s Master Plan and 3D Design It is the cornerstone for accurate vertical mill installation and stable operation The main components of the roller mill are the roller and the disc The disc base isSolid Edge’s Application in Vertical Mill Design SpringerVertical Mill VM Series Features Treatment:Grinder Vertical type,so it only need a small space for installation The grain of powder uniform and easy to select the VM2 QUANTITATIVE FEEDING SCREW CHINESE HERBS CRUSHING GRINDING SYSTEM; MODEL MOTOR (HP) CAPACITY (KG/HR) DIMENSION (L*W*H MM) VM2: 2~3: 20~80: Vertical MillMill Powder Tech Solutions

[GYQ0R)ZQ]ESS4NJ.jpg)

SERIES I MILLING MACHINES UC Berkeley Mechanical

INSTALLATION, OPERATION, MAINTENANCE, AND PARTS LIST SERIES I MILLING MACHINES Revised: August 29, 2005 Manual No M450 Litho in USA Part No M 0450 June, 2003 TP5260 Information in this manual is subject to change without notice safeguarding for vertical milling machines2023年12月19日 But this limited cutting potential results in a lower removal rate for the vertical mill 7 Overarm and Arbor Support The horizontal milling machine has two elements not present in a vertical mill: an overarm and an arbor support The overarm is a Vertical Milling Machines vs Horizontal: Differences Explained2018年12月15日 Regular readers know I recently adopted a PM25MV vertical mill from Precision Matthews It has proven to be an excellent machine, and I recommend it highly to anyone I ordered it with the DRO and power feed options, because I knew those would be extremely high return on investment for a mill (and I was right about that worth every penny)Vertical Mill – Power Feed – Blondihacks2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill simplicity of installation data from a particle size analyzer to show detail in threedimensions(PDF) Performance Evaluation of Vertical Roller Mill in

.jpg)

The Ultimate Guide To Vertical Axis Wind Turbines Green Life Zen

2023年9月9日 Yes, you can install vertical axis wind turbines on rooftops They offer a practical solution for harnessing wind energy in urban environments, providing clean power and reducing dependence on traditional energy sources Conclusion So there 6 Vertical Knee Mills Product Catalog VERTICAL KNEE MILL ACCESSORIES CHIP TRAY MILLING CHUCK KIT HORIZONTAL MILLING ATTACHMENT RISER BLOCKS RIGHT ANGLE MILLING ATTACHMENT SPINDLE ASSEMBLY CLAMPING KIT Part No Description and Model Approx Weight ISOR8 R8 Spindle for 2VS 3VS 10 lbs ISO30 NMTB 30 Spindle for 2VS VERTICAL KNEE MILLS Clausing IndustrialSuperSpeed CNC Vertical Mill with 50" x 26" x 25" travels The Haas highperformance SuperSpeed vertical machining centers provide the high spindle speeds, fast rapids, and quick tool changes necessary for highvolume production and reduced cycle timesVF5SS Super Speed Vertical Mills – Haas CNC MachinesMini CNC Vertical Mill with 16" x 14" x 15" travels Dimensions Shipping SAE METRIC; Domestic Pallet: 900 in x 800 in x 920 in: 229 cm x 203 cm x 234 cm: state local taxes, vendor installation charges, and dealer installed Mini Mill 40Taper Mill Vertical Mills – Haas CNC

VF9/40 40Taper Mill Vertical Mills – Haas CNC

CNC Vertical Mill with 84" x 40" x 30" travels Dimensions Shipping SAE METRIC; Domestic Pallet: 2140 in x 1200 in x 1285 in: 544 cm x 305 cm x 326 cm: state local taxes, vendor installation charges, and dealer installed The Haas highperformance SuperSpeed vertical machining centers provide the high spindle speeds, fast rapids, and quick tool changes necessary for highvolume production and reduced cycle times Each SS machine features a VF2SS 40Taper Mill Super Speed Vertical Mills – The vertical mill vem for wet material grinding more than 100 ball mill installations worldwide Why do ball mills have different dimensions? The diameter of a ball mill has a great influence on the power consumption of the mill and thus on the possible production outputChristian Pfeiffer VEM Vertical mill Christian Pfeifferî äò—úÿümýf*˜"Çé ón ž®'³‘ ’Ÿ´Ä9÷]{ŸÿÂÍN(Ù\3`r„i¯7 p¬g,¢ sb*âtgre ¬£ôyE?%Ž¢í†»vþª+• ²ƒ àÄ!¶ð˜#š›é)Îa8Ý VF10/40 40Taper Mill Vertical Mills – Haas CNC Machines

VERTICAL MILL INSTALLATION INSTRUCTIONS

VERTICAL MILL INSTALLATION INSTRUCTIONS Machine RequiReMents Machine footprints and operating dimensions are available in the brochure and the anchoring addendum GeneRal RequiReMents Operating Temperature Range 41°F to 104°F (5 to 40°C) Storage Temperature Range 4°F to 158°F (20 to 70°C)CNC Vertical Mill with 30" x 20" x 20" travels Dimensions Shipping SAE METRIC; Domestic Pallet: 1060 in x 1013 in x 1010 in: 269 cm x 257 cm x 257 cm: state local taxes, vendor installation charges, and dealer installed accessories are not included Not responsible for misprints or typographical errors Machines shown with VF2YT 40Taper Mill Vertical Mills – Haas CNC MachinesOil, Coolants and Lubricants SmartFactory Roller Conveyor Lathes accessories Milling machine accessories Installation, the vertical mill, or knee mill, Table dimensions: 1235x460 mm 2000x500 mm KB 2100Conventional Vertical Milling Machines KNUTH Machine ToolsOur bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetimeVertical roller mills FLSmidth Cement

VR5 5Axis Mill 30Taper Vertical Mills – Haas CNC Machines

Vertical Mills ; VF Series; Universal Machines; VR Series; VP5 Prismatic; PalletChanging VMCs; Mini Mills; Mold Machines; HighSpeed Drill Centers; Drill/ Tap/ Mill Series