Environmental brick grinding equipment produced with fly ash

New technology and application of brick making with coal fly ash

2015年4月1日 This paper introduces an experimental research on how to recycle fly ash effectively, a kind of new technology of making bricks by which fly ash content could be 2024年4月10日 Considering the current scenario, by replacing 1–2% of brunt clay bricks with agroforestry waste, CD waste based fly ash bricks can potentially reduce 05–15 million Large CO2 reduction and enhanced thermal performance of agro 2017年9月28日 Fly ash was acquired from the coal power plant Manufacturing of brick specimens was done in a local brick industry The main variable in this study was the Production of sustainable clay bricks using waste fly ash: 2024年11月26日 The source material chosen for geopolymer production has a significant effect on its properties [4]A material (fly ash, silica fume, kaolinite, etc) rich in amorphous silica and Development of Fillerfree and Ambientcured Fly Ash Based

Examining the endpoint impacts, challenges, and opportunities of

2023年10月25日 Fly ash has been widely used as a cement substitute to improve the sustainability of concrete Although the advantages of fly ash have been extensively Two Indians have invented a climatefriendly technology that produces bricks without using any coal whatsoever The new fly ash brick technology has the potential to completely eliminate carbon emissions from India’s large brick Fly Ash Bricks Reduce Emissions World Bank Group2023年3月24日 We’ve reviewed various tests which determine the properties of AFQ Bricks like compressive strength, soundness, water absorption rate, efflorescence, crushing strength, etc Bricks made with fly ash A review of recent developments2024年8月29日 By substituting fly ash (FA) for cement it is possible to significantly lower the finished concrete product's overall CO footprint and associated environmental costs Enhancing Sustainable Concrete Production by Utilizing Fly Ash

Flyashbased bricks: an environmental savior—a critical review

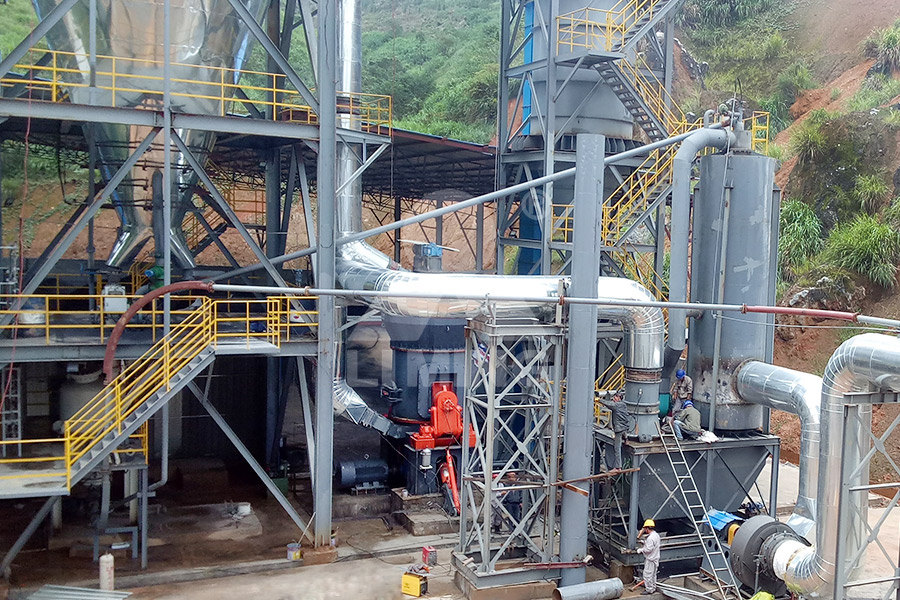

2022年5月28日 The primary focus of this review article is to promote research on flyashbased bricks for the brick industry and provide safe and costeffective sustainable materials to The fly ash processing plant produced by AGICO includes a ball mill grinding system, The fly ash ball mill is the special equipment for fly ash grinding, be made into different types of concrete blocks through batching, mixing, Fly Ash Processing Plant Cement Equipment Value in Waste: Fly Ash Reuse and Recovery Opportunities Fly ash has proven to offer a wide range of benefits when used as a LWA, to the extent that it has become a key material in the construction industry; the use of fly ash as a LWA can provide economic benefits such as reduced structural, shipping, and handling costs, as well as environmental benefits that come along fly ash handling equipment2022年12月1日 Methods of sampling fly ash: 2021: Japan: JIS A 6201: Fly ash for use in concrete: 2015: United Kingdom: BS EN 4501: Fly ash for concrete Definition, specifications and conformity criteria: 2012: BS EN 4502: Fly ash for concrete Conformity evaluation: 2005: PD CEN/TR 15840: Evaluation of conformity of fly ash for concrete Guidelines for Fly ash for sustainable construction: A review of fly ash concrete

.jpg)

Fly Ash: Production and Utilization in India An Overview

2020年5月23日 Global fly ash generation is about 800 million tons, and India produced 21704 million tons from 2018 to 2019 [9] The utilization of fly ash in India for 2018 to 2019 is 16840 million tons [10] 2009年1月1日 Environmental Properties of Fly Ash Bricks January 2009; Authors: were manufactured using pilot size equipment strong fly ash brick can be produced at compaction pressure of 3,000 psi, Environmental Properties of Fly Ash Bricks Request PDF2017年6月27日 Coarse ash particles, referred to as bottom ash or slag, fall to the bottom of the combustion chamber, while the lighter fine ash particles, termed fly ash, remain suspended in the flue gas Prior to exhausting the flue gas, fly ash is removed by particulate emission control devices, such as electrostatic precipitators or filter fabric baghouses (see Figure 11)Chapter 1 Fly Ash An Engineering Material Fly Ash Facts for 2015年4月1日 China has ranked first in the coal fly ash emission in the world The multipurpose use of the fly ash from power plant waste is always an important topic for the Chinese environmental protection New technology and application of brick making with coal fly ash

LifeCycle Assessment of Municipal Solid Waste Incineration Fly Ash

2023年6月29日 The recovery of municipal solid waste incineration (MSWI) fly ash is currently considered to be the most viable solution for its management However, in developing resource recovery technologies, it is crucial to consider the overall environmental impact This study employed a lifecycle assessment (LCA) to compare environmentally friendly red bricks 2019年5月23日 524 Composition of Fly Ash Particles The fly ash particles are composed of a mixture of various particles Therefore, the quality of fly ash mainly depends on the composition of various particles, and the quality is affected by the change in composition []Scanning electronic microscope (SEM) observation shows that fly ash includes spherical particles, slag particles, Comprehensive Utilization of Fly Ash SpringerLink2021年9月1日 Coal fly ash is primarily produced in power plants as a byproduct of coal combustion “Environmentalbenign utilisation of fly ash as lowcost adsorbents” 136(3): 482501 Google Scholar Wong, 1995 Wong, J J E T (1995) “The production of artificial soil mix from coal fly ash and sewage sludge” 16(8): 741751 Fly ash properties, characterization, and applications: A reviewFly ash bricks absorb less quantity of water which is under IS requirement Fly ashclay bricks give nil efflorescence The values of these characteristics for fly ash bricks are excellent and have exceeded those pertaining to clay bricks Moreover, fly ash bricks have been produced with a naturally occurring reddish colour similar to that ofENGINEERING PROPERTIES OF CLAY BRICKS WITH USE OF FLY ASH

.jpg)

(PDF) Exploring the Viability of Fly Ash Bricks as an

2023年3月1日 Fly ash brick is impervious to efflorescen ce b eing free of solub le salts About 10 million tonnes of fly ash are produced yearly as waste from coal fired thermal power plants in Turkey2024年10月23日 Fly ash (FyA), a byproduct from FyA finds applications in the construction industry, including road and brick construction, forest road building, and the cement industry When added to concrete, it enhances splitting tensile strength, compressive strength, and workability, while also reducing the environmental impact of cement Comprehensive Review of Fly Ash: Environmental Impact and new technology for building brick making, with which fly ash content in brick may reach 50–80 %, and practice and theory supports are provided for the development and production of highcontent fly ash brick, which fly ash content is more than 50 % The wall body products mainly include: bricks, building sheets and building blocks, andNew technology and application of brick making with coal fly ash2014年6月25日 Mixing various properties of fly ash in clay material (550% by weight, in ratio of dry fly ash to wet clay, at a step of 5% each) this will from 16 bricks of each proportion have been manufacturedENGINEERING PROPERTIES OF CLAY BRICKS WITH USE OF FLY ASH

.jpg)

Analysis of the characteristics and environmental benefits of rice

2024年3月28日 Materials Ordinary Portland Cement (OPC) which complies with American Standard ASTM C 150 TypeI mark was used as the primary binder for the fabrication of concrete mixes []The chemical formulations of OPC as well as RHA are detailed in Table 1The RHA was derived from the husk or hull of rice seed, which is the seed’s protective outer coveringFigure 1 shows fly ash produced in a typical pulverizedcoalfired utility boiler and collected by an electrostatic precipitator There are two commonly used methods for removing the fine powdery fly ash from the fly ash hopper of the precipitator – a wet method or a dry method [12–15]In the wet method, water is used to flush the fly ash out of the hoppers and the ash slurry is pumped Fly Ash SpringerLinkFly ash has several benefits that make it an attractive alternative to traditional materials The following are some of the benefits of fly ash Environmental Benefits Fly ash is an environmentally friendly alternative to traditional materials It reduces the amount of waste sent to landfills and reduces the need for raw materials Cost SavingsHow do You Process Fly Ash?PDF On Aug 1, 2024, Somaya Ben Abbou and others published Enhancing Compressive Strength and Sustainability – HighPerformance Concrete with Fly Ash and Brick Waste Powder Find, read and (PDF) Enhancing Compressive Strength and Sustainability – High

.jpg)

Estimation of the addition of fly ash and its environmental

2024年3月13日 The cement industry is one of those that consumes the most energy, due to the high temperatures required to produce this material, and it is also one of the most that generates high CO2 emissions In this work, the addition of sugarcane ash, bituminous coal and hazardous residues in cement pastes were evaluated For this, cement pastes were produced in 2020年4月28日 The rapid economic development in China places a large demand for energy, and as a result, thermal power plants in China are producing an enormous amount of coal fly ash (CFA) which causes severe environmental pollution This paper briefly describes the current production and utilization status of CFA in China and identifies the challenges confronting Utilization of coal fly ash in China: a minireview on challenges 2022年1月1日 This paper investigates the properties of rice husk ash (RHA) produced by using a ferrocement furnace The effect of grinding on the particle size and the surface area was first investigated (PDF) Synthesis and Characterization of fly ash brick2021年7月9日 Coal fly ash and granulated ground blast furnace slag (GGBS) are more widely used as supplementary cementitious materials in cement production This study investigates the influence of highvolume ordinary Portland cement (OPC) replacement with fly ash and/or GGBS on the flow, compressive strength and environmental impacts of the resulting binary and Sustainable ternary cement blends with highvolume ground

Environmental impact of concrete containing high volume fly ash

2024年4月5日 The fly ash utilisation in concrete will reduce GHG emissions by 13–15% (Flower and Sanjayan, 2007) Similarly, 50% GGBS in concrete reduced GHG emissions by 14–37% (Miller, 2018) The combination of fly ash and GGBS reduced GHG emissions by 47% compared to concrete made with OPC (Park et al, 2012)2023年11月6日 By mixing concrete and fly ash, one can build longerlasting structures, reducing the need for frequent maintenance or replacement, which in turn conserves materials and energy Apart from using fly ash as an aggregate, fly ash is also used in brick or block format to lessen the infrastructural impact on the environmentThe Environmental Benefits of Fly Ash in Construction IBMD2020年4月5日 This work investigates the feasibility of comechanochemical treatment of oilcontaminated drill cuttings (OCDC), circulation fluidized bed combustion (CFBC) fly ash, and quicklime to prepare nonsintered lightweight aggregates (NSLWAs) The NSLWAs with high cylinder compressive strength and low water absorption could be obtained under the condition Preparation of nonsintered lightweight aggregates through co 2020年3月1日 Waste foundry sand (WFS) is a byproduct of both ferrous (iron and steel) and nonferrous (copper, aluminum, and brass metal) castings production, and WFS is used for molding and casting operations with highquality silica sand (Siddique et al, 2010; Siddique and Noumowe, 2008)In 2015, approximately 100,000 tons of WFS were disposed of in Thai The potential of industrial waste: using foundry sand with fly ash

(PDF) Fly Ash Brick: An Environmental Pollutant Converts into

2023年10月12日 Fly ash is one of the common residues produced from combustion of coal In past, fly ash was unconditionally released into the atmosphere Recent concerns about environmental pollution led to 2022年7月7日 To date, heavyweight concretes have been produced from various heavy aggregates as radiation insulation materials, and their gamma ray absorption levels have been investigated Many of the studies have used heavy aggregates instead of cement or coarse aggregates from composite material components The present study prepared lightweight Investigation of gamma ray absorption levels of composites produced 2012年1月1日 Fly ash is a waste material of coal firing thermal plants and its accumulation near power plants causes severe pollution problems Therefore, its utilization as a raw material for brick making A Brief Overview of Fly Ash Brick Production ResearchGateThe fly ash processing plant produced by AGICO includes a ball mill grinding system, The fly ash ball mill is the special equipment for fly ash grinding, be made into different types of concrete blocks through batching, mixing, Fly Ash Processing Plant Cement Equipment

.jpg)

fly ash handling equipment

Value in Waste: Fly Ash Reuse and Recovery Opportunities Fly ash has proven to offer a wide range of benefits when used as a LWA, to the extent that it has become a key material in the construction industry; the use of fly ash as a LWA can provide economic benefits such as reduced structural, shipping, and handling costs, as well as environmental benefits that come along 2022年12月1日 Methods of sampling fly ash: 2021: Japan: JIS A 6201: Fly ash for use in concrete: 2015: United Kingdom: BS EN 4501: Fly ash for concrete Definition, specifications and conformity criteria: 2012: BS EN 4502: Fly ash for concrete Conformity evaluation: 2005: PD CEN/TR 15840: Evaluation of conformity of fly ash for concrete Guidelines for Fly ash for sustainable construction: A review of fly ash concrete 2020年5月23日 Global fly ash generation is about 800 million tons, and India produced 21704 million tons from 2018 to 2019 [9] The utilization of fly ash in India for 2018 to 2019 is 16840 million tons [10] Fly Ash: Production and Utilization in India An Overview2009年1月1日 Environmental Properties of Fly Ash Bricks January 2009; Authors: were manufactured using pilot size equipment strong fly ash brick can be produced at compaction pressure of 3,000 psi, Environmental Properties of Fly Ash Bricks Request PDF

Chapter 1 Fly Ash An Engineering Material Fly Ash Facts for

2017年6月27日 Coarse ash particles, referred to as bottom ash or slag, fall to the bottom of the combustion chamber, while the lighter fine ash particles, termed fly ash, remain suspended in the flue gas Prior to exhausting the flue gas, fly ash is removed by particulate emission control devices, such as electrostatic precipitators or filter fabric baghouses (see Figure 11)2015年4月1日 China has ranked first in the coal fly ash emission in the world The multipurpose use of the fly ash from power plant waste is always an important topic for the Chinese environmental protection New technology and application of brick making with coal fly ash2023年6月29日 The recovery of municipal solid waste incineration (MSWI) fly ash is currently considered to be the most viable solution for its management However, in developing resource recovery technologies, it is crucial to consider the overall environmental impact This study employed a lifecycle assessment (LCA) to compare environmentally friendly red bricks LifeCycle Assessment of Municipal Solid Waste Incineration Fly Ash 2019年5月23日 524 Composition of Fly Ash Particles The fly ash particles are composed of a mixture of various particles Therefore, the quality of fly ash mainly depends on the composition of various particles, and the quality is affected by the change in composition []Scanning electronic microscope (SEM) observation shows that fly ash includes spherical particles, slag particles, Comprehensive Utilization of Fly Ash SpringerLink

.jpg)

Fly ash properties, characterization, and applications: A review

2021年9月1日 Coal fly ash is primarily produced in power plants as a byproduct of coal combustion “Environmentalbenign utilisation of fly ash as lowcost adsorbents” 136(3): 482501 Google Scholar Wong, 1995 Wong, J J E T (1995) “The production of artificial soil mix from coal fly ash and sewage sludge” 16(8): 741751