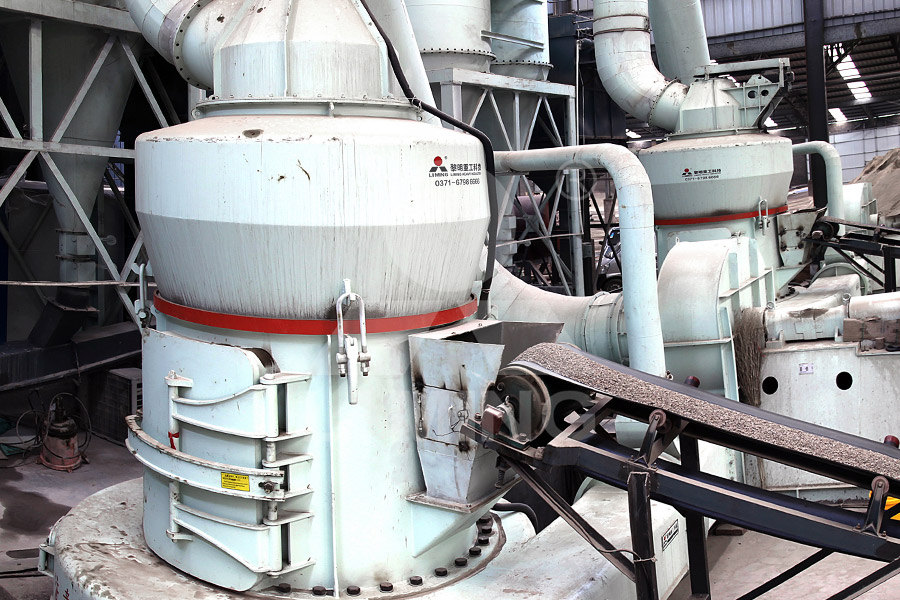

Electromagnetic highfine vertical mill for construction

.jpg)

Construction of the electromagnetic mill with the grinding system,

2016年1月1日 The article presents the construction of an innovative electromagnetic mill, which in comparison to traditional solutions provide a significant reduction of energy consumption 2016年1月1日 The article presents the construction of an innov ative electromagnetic mill, which compared to traditional solutions provide a significant reduction in energy consumption and (PDF) Design of an electromagnetic mill Its ResearchGateThe Metso HIGmill™ is an advanced, energyefficient fine and ultrafine grinding solution that utilizes proven technology With the tall, narrow, vertical body arrangement, grinding media is HIGmill high intensity grinding mill Metso2021年9月23日 It is an industrial mill with highcost performance But if your downstream industries have higher requirements for powder, you can choose CLUM series vertical mills to produce a highend powder The vertical mill has Barite Industrial Ultrafine Grinding Mill SBM

.jpg)

Ultra fine vertical roller millUltra Fine Millultra

CLUM series ultrafine vertical roller millwas produced by Shanghai Clirik Machinery Co, Ltd Relying on 12 years of experience in the production of ultrafine powder and based on German and Taiwan ultrafine vertical mill 2 Electromagnetic mill – design The electromagnetic mill is a device in which the ferromagnetic grinding media are moved by deliberately generated rotating electromagnetic field, as an energy carrier The basic elements of the mill are: inductor of rotating magnetic field and placed in its axis tube, forming a working chamber [1]Design of an electromagnetic mill Its technological and control The process comprises just a scalping cyclone with no circulating load, feed tank and pump, and the mill itself The benefit of high power intensity and vertical installation is a very small footprint The head room over the mill is small and the flanged splitshell construction reduces the space needed for maintenanceHIGmill high intensity grinding mill MetsoAccording to the requirements of construction waste treatment, the process flow of construction waste vertical mill is shown in the above figure: the construction waste particles (with a particle size of ≤ 20 mm) processed through sorting, crushing, iron removal, and impurity removal are transported to the construction waste raw material warehouse using a bucket elevatorCan Construction Waste Be Treated By Vertical Mill? Details of

HighEfficiency Vertical Coal Mill Enhancing Coal Pulverization

The coal vertical mill, also referred to as the vertical roller coal mill, is an advanced equipment developed by our company It combines modern technology with our extensive experience in powder manufacturing This coal pulverizer efficiently integrates coal grinding and drying, providing highperformance and energysaving featuresDownload scientific diagram Construction of electromagnetic mill: (a) electromagnets; (b) the mill with the cover and supply cabinet; (c) working chamber with the grinding media during operationConstruction of electromagnetic mill: (a) electromagnets; (b) the mill The vertical mill is a very compact machine designed to take up less space and offer the user a high level of production capacity with reduced energy consumption The advantages of using the vertical mill in production, as opposed to the horizontal shaft version, are as follows: reduced electricity consumption: when compared to horizontal hammer mills with the same capacity, Vertical hammer mill LamecHGM100A professional ultra fine powder grinder is the new type mining equipment for making micro powders, fine powders, which is widely applied in the industries of metallurgy, mining, chemistry, cement, construction, refractory materials, ceramics, and so on Final product fineness:3002500meshCapacity:0245t/hultra fine powder grinding mill Shanghai Clirik Machinery Co,

Energysaving and Efficient Vertical Roller Mill Fote Machinery

A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal 2016年1月1日 Construction of the electromagnetic mill with the grinding system, A disadvantage of such mill is a high energy consumption and interchangeable parts such as lining and grinding media Comparative analysis of the possibility of obtaining fine grain size in a ball and electromagnetic mill,Construction of the electromagnetic mill with the grinding 2024年3月25日 The GDS2024 type electromagnetic highfrequency vibrating screen has an power of only 12 kW, making it an energysaving product Convenient installation Due to the screen box is stationary, it is convenient to High Frequency Electromagnetic Vibrating ScreenNewtype Pneumatic Ultra Fine Grinding Mill (Jet Mill) Cross Jet Mill; Compact Jet Mill and Separator Combined System Kurimoto Pocket Jet; Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill; Fine Grinding Mill (Centrifugal Roller Vertical Super Fine Grinding Mill (Vertical Roller Mill)

Chalk Micro Powder Mill SBM Ultrafine Powder Technology

2021年9月30日 The chalk micro powder mill is independently developed and produced by SBM It mainly includes 3 types, namely HGM ultrafine grinding mill (1503000 meshes), CLUM vertical mill (1503000 meshes), and wet stirring mill (3256000 meshes) They can grind nonmetallic ores, and the fineness can be adjusted freely according to demandProduct Information, Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill Manufacturing the future Vertical Super Fine Grinding Mill (Vertical Construction Specifications Size Grinding capacity Motor output(kW) (t/h): Conventional Batch Type Highspeed Planetary Mill Kurimoto High G; Horizontal Grinding Mill Overflow Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill High efficiency of pulverization and low power consumption lead to a reduction in electric cost by 4050% compare to ball mill 2 Construction cost reduced Since the drying, grinding and classifying operation are performed simultaneously, the system configuration is simpleUBE Vertical Mill UBE Machinery Corporation, Ltd2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcLimestone Ultrafine Mill Machine SBM Ultrafine Powder

.jpg)

SikaGrind® for vertical roller mills

In a ball mill, the particles are ground by repeated impact forces The material needs usually more than 20 minutes from mill entrance to outlet, uncountable impacts take place on this way Depending on the efficiency of the separator and the Grinding Aid, agglomerates of fine particles are rejected and pass the ball mill again4 [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%]Analysis of a grinding efficiency in the electromagnetic mill for LUMSeries Ultra Fine Vertical Grinding Mill LUMSeries Ultra fine vertical grinding mill is an advanced mill which combining our company’ several years of millproducing experiences, It is designed and researched based on vertical mill technology, absorbing the worldwide ultrafine grinding theoriesLUMSeries Ultra Fine Vertical Grinding MillKefid Machinery2016年12月31日 Request PDF Construction of the electromagnetic mill with the grinding system, classification of crushed minerals and the control system The article presents the construction of an innovative Construction of the electromagnetic mill with the grinding

Vertical mill: The preferred equipment for quicklime production

The quality of the quicklime is largely dependent on the efficiency of the grinding process, which is where the vertical mill comes into play The vertical mill, also known as the vertical roller mill, has emerged as a leading piece of equipment for the production of quicklime due to its advanced technology and operational excellence 22023年12月4日 Advantages of Vertical Boring Mills Vertical boring mills offer several advantages that make them a goto choice for many machining tasks Here are the main advantages of using a vertical boring mill: Handling Large Vertical Boring Mills: A Comprehensive GuideProduct introduction:LUM ultrafine vertical mill is a largescale highfine vertical mill on the basis of LM vertical mill that developed by our company for reference to advanced technology at home and abroad, and suitable for nonmetallic minerals with a largescale ultrafine processingLUM Ultrafine Vertical MillLimestone Powder Ultrafine Vertical Roller Mill Modle : CLUM Series Finished Size: 4003000 mesh Processing Ability: 3 – 45t/h Max Feeding Size: 10 mm M 1 Set Price: $ Range Of Application: Limestone, Calcium Carbonate, Talc, Limestone Powder Ultrafine Vertical Roller Mill

.jpg)

HGM80 ultra fine mill, HGM80 ultra fine grinder

HGM80 ultra fine mill, Performance and features of HGM80 ultra fine mill, HGM80 ultra fine grinder: 1 High efficiency about 25 times as long as that of vertical shaft impact crusher and turbomill Especially when handling calcium carbonate and 2021年1月29日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing consumes around Increase productivity of vertical roller mill using seven QC tools2024年9月28日 High Grinding Efficiency: The vertical mill design enables high throughput and fine grinding of materials, resulting in a uniform and consistent product Low Energy Consumption : With an optimized grinding process and reduced power usage, Baichy’s vertical mills help lower energy costs, contributing to more sustainable operationsWhere to Source HighQuality Vertical Mills for Cement PlantsThe ultrafine vertical mill is currently the superlarge ultrafine grinding equipment in Asia, which has been successfully applied in the market and has mature technology It can replace imported equipment and is an ideal equipment for largescale production of ultrafine powder with high efficiency, high yield, environmental protection and energy savingTable Roller Mill Vertical Mill

Picture: Loesche GmbH, Germany CEMENT SikaGrind® FOR VERTICAL ROLLER MILL

FOR VERTICAL ROLLER MILLS The cement industry has contributed a significant share to the progress of the concrete technology: ́ Good and long lasting workability ́ Adaption to different ambient temperatures (summer/winter) ́ Pumpability, long distance and/or high elevation, no separation ́ Fast strength development, high early strength2021年9月23日 It is an industrial mill with highcost performance But if your downstream industries have higher requirements for powder, you can choose CLUM series vertical mills to produce a highend powder The vertical mill has Barite Industrial Ultrafine Grinding Mill SBM CLUM series ultrafine vertical roller millwas produced by Shanghai Clirik Machinery Co, Ltd Relying on 12 years of experience in the production of ultrafine powder and based on German and Taiwan ultrafine vertical mill Ultra fine vertical roller millUltra Fine Millultra 2 Electromagnetic mill – design The electromagnetic mill is a device in which the ferromagnetic grinding media are moved by deliberately generated rotating electromagnetic field, as an energy carrier The basic elements of the mill are: inductor of rotating magnetic field and placed in its axis tube, forming a working chamber [1]Design of an electromagnetic mill Its technological and control

HIGmill high intensity grinding mill Metso

The process comprises just a scalping cyclone with no circulating load, feed tank and pump, and the mill itself The benefit of high power intensity and vertical installation is a very small footprint The head room over the mill is small and the flanged splitshell construction reduces the space needed for maintenanceAccording to the requirements of construction waste treatment, the process flow of construction waste vertical mill is shown in the above figure: the construction waste particles (with a particle size of ≤ 20 mm) processed through sorting, crushing, iron removal, and impurity removal are transported to the construction waste raw material warehouse using a bucket elevatorCan Construction Waste Be Treated By Vertical Mill? Details of The coal vertical mill, also referred to as the vertical roller coal mill, is an advanced equipment developed by our company It combines modern technology with our extensive experience in powder manufacturing This coal pulverizer efficiently integrates coal grinding and drying, providing highperformance and energysaving featuresHighEfficiency Vertical Coal Mill Enhancing Coal PulverizationDownload scientific diagram Construction of electromagnetic mill: (a) electromagnets; (b) the mill with the cover and supply cabinet; (c) working chamber with the grinding media during operationConstruction of electromagnetic mill: (a) electromagnets; (b) the mill

Vertical hammer mill Lamec

The vertical mill is a very compact machine designed to take up less space and offer the user a high level of production capacity with reduced energy consumption The advantages of using the vertical mill in production, as opposed to the horizontal shaft version, are as follows: reduced electricity consumption: when compared to horizontal hammer mills with the same capacity, HGM100A professional ultra fine powder grinder is the new type mining equipment for making micro powders, fine powders, which is widely applied in the industries of metallurgy, mining, chemistry, cement, construction, refractory materials, ceramics, and so on Final product fineness:3002500meshCapacity:0245t/hultra fine powder grinding mill Shanghai Clirik Machinery Co, A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal Energysaving and Efficient Vertical Roller Mill Fote Machinery