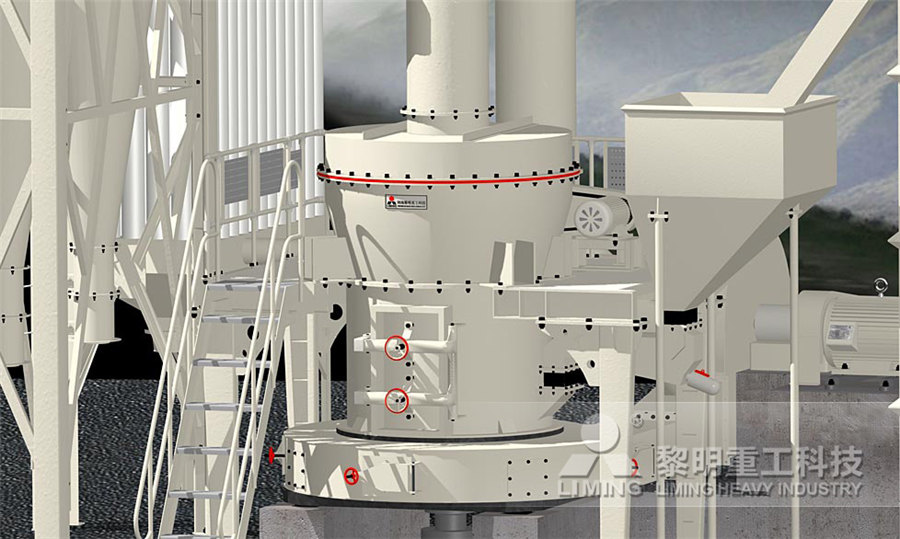

Coke heavy calcium crusher

.jpg)

CASE STUDY Coker pump design Sulzer

heavy crude, these units provide significant revenue for the business by maximizing the amount of saleable products from the original volume of crude oil Throughout the delayed coker plant, pumps of various designs are used to transport high temperature, corrosive fluids through the To prevent the larger particles from choking the eye of the impeller, pumps can be equipped with coke crushers, which reduce the size of the particles and allow them to pass through the impeller Predominantly, coker charge pumps are Coker pump design SulzerThe Calcined Coke Crusher offered by Weifang Jinghua Powder Engineering Equipment Co, Ltd is a highperformance equipment designed specifically for the crushing of calcined petroleum China Calcined Coke Crusher Manufacturer, Supplier JINGHUAPetroleum coke calcining is a three step process, including drying, devolatization and densification The coke calcining process is a timetemperature function, conducted in an oxygen deficient atmosphere Important control variables are Petroleum Coke Calcining Systems Metso

Mechanical Engineering – Jülch GmbH

Thanks to our many years of experience in the petrochemical sector, we are the world's leading manufacturer of Petroleum Coke Crushers We thus produce the heart of the CCSS for refineries all over the world We offer you the best The direct quench type is the most widely used method of cooling in the coke calcining industry Metso’s air seals (marketed as Goodeal and Superdeal seals) with their overlapping steel plates provide an air seal that significantly reduces Coke Calcining Systems Metso Automation PDF 2021年8月25日 To prevent the larger particles from choking the eye of the impeller, pumps can be equipped with coke crushers, which reduce the size of the particles and allow them to pass through the impeller Predominantly, coker Coker Pump Design Engineer LiveProblems crushed The second key technology was a solution to the problem of pump performance impairment by large solid particles For applications like these, Sulzer has CASE STUDY Twelve pumps for Chinese refinery

.jpg)

Sulzer Pumps for the Hydrocarbon Processing Industry Muhur

As a global leader in pump design and manufacture, Sulzer Pumps is recognized for delivering the excellent product quality and performance reliability required for a wide range of 2022年10月31日 The petroleum coke crushers developed with Bosch Rexroth enable refinery operators to meet their environmental requirements more easily, making an active contribution Cokecrusher case study Engineer Live2024年6月2日 When choosing the right equipment for petroleum coke crushing, several factors should be considered: Feed Size: The size of the pet coke feed material will influence the type and size of the crusher required Capacity Petroleum Coke Crusher: Choosing the Right EquipmentZhengzhou Hengxing Heavy Equipment Co, Ltd: We're known as one of the most professional stone crusher, grinding ball mill, rotary drying equipment, calcination equipment, coal briquetting equipment manufacturers and suppliers in China China Stone Crusher, Grinding Ball Mill, Rotary Drying

An AdvancedCoke Handling Process Refining Community

Global Heavy CrudeProc [miob/d] Source: Oil Gas Journal 2010 More Stringent Regulations forHeavy Fuel Oils Global SulphurLimit [%w/w] Coke Drum Crusher Sump Sump ToClean WaterTank Coke Drum Crusher Sluiceway Hydrobin Coke Water Clarification System Coke Fines Chute • Open System • NoInlineCrusher2021年9月13日 These crushers are made of steel, and some are able to crush multiple cans at once The price often depends on the tool’s storage capacity Some require wall mounting, but many are large and heavy enough to stand on the floor Tips Attach a wallmounted can crusher to the studs This gives it extra stability Never use a can crusher on steel 5 Best Can Crushers Dec 2024 BestReviewsPetroleum coke can be divided into needle coke, projectile coke or spherical coke, sponge coke,Making Petroleum coke powder firstly should confirm which kind of petroleum coke The combustion temperature of petroleum coke powder in a glass melting furnace can reach or approach the flame temperature of heavy oil combustion at 16501730 degreesPetroleum coke grinding mill, Petroleum coke mill, Petroleum coke Pyd1750 New Type Spring Cone Crusher for Iron Ore/ Hydrated Lime/ Heavy Calcium/ Hard Stone/ Gypsum/ Coke/ Pet Coke/ Fly Ash/ Yanliu/ Clay Ceremsite Sand US$10,0000050,00000 / Piece 1 Piece (MOQ)Pyd1750 New Type Spring Cone Crusher for Iron Ore/ Hydrated Lime/ Heavy

Calcium Carbonate Heavy Request for Quotation ChemBK

2022年11月12日 the crushing method first crushes white stone (natural limestone) in the jaw crusher to make which is prepared by calcination, digestion and CO2 carbonation: limestone crushed to 50150mm is mixed with coke (3050mm) in a ratio The raw material for wet grinding calcium by grinding method is heavy calcium carbonate or calcite Don’t throw away those old soda cans, here are 24 DIY can crusher ideas that will help you turn those crushed cans into greatlooking new things Are you aware of how useful a homemade can crusher is? A can crusher is a tool that can mount or dismount the 24 Homemade DIY Can Crusher Ideas To Scrap Empty CansKREAT Heavy Industry Technology Co,Ltdis a professional company which has a set of mobile conveying crushing and screening equipment both in research development,manufacturing,sales,leasing and servicesKREAT products are widely used in mining,engineering construction,earth and stone works,road construction,urban infrastructure YUNNAN KREAT HEAVY INDUSTRY SCIENCE TECHNOLOGY The need for environmentally compatible and at the same time economical solutions for processing the heavy residues of the refinery industry is increasing: Not least, more and more countries are tightening environmental and occupational health and safety requirements in the operation of refineries because the use of bunker oil in shipping is coming under increasing Mechanical Engineering – Jülch GmbH

.jpg)

Calcium Carbonate Powder Processing

Introduction Calcium carbonate, commonly known as limestone, stone powder, marble, etc It is an inorganic compound, the main component is calcite, which is basically insoluble in water and soluble in hydrochloric acid It often exists in coke ovens must be crushed, usually to a top size of about 314inch Very small sizes must be screened from the crushed coke, leaving an acceptable size of about 3/4" ~1/8" Problems encountered in crushing chemical coke to the desired size range include excessive wear on crusher rolls, the production of coke dust, and a conCOKE CRUSHING CHARACTERISTICS University of Illinois China Calcium Carbonate Crusher wholesale Select 2024 high quality Calcium Carbonate Crusher products in best price from certified Chinese Crusher Machinery manufacturers, Crusher Equipment suppliers, wholesalers and factory on MadeinChinaCalcium Carbonate Crusher MadeinChinaDouble teeth roller crusher for crushing calcium carbide in Malaysia, coal/limestone/ calcium carbide/pet coke Motor Type AC Motor Brand Name TIANHE Input Size 800 mm Output Size 200 mm Roller type two rollers The Machines classification Mining Machinery Name Double teeth roller crusher for crushing calcium carbide in Malaysia

114 Calcium Carbide Manufacturing US EPA

coke and lime; coke dryer coke; tap fume vent coke and lime; furnace room vent coke and lime; crusher calcium carbide; charging conveyor coke and lime NA = not applicable ND = no data Neg = negligible SCC = Source Classification Code b Filterable PM is that collected on or before the filter of an EPA Method 5 (or equivalent Calcium Carbonate Ball Mill,Buy Quality Calcium Carbonate ISO9001: 2000 2 reliable operation 3 easy to repair 4 grind the CPC, quartz, glass, gold, bauxite Calcium carbonate powder grinding mill Ball mill 1 Cpcgrindingballmill Crusher Mills, Cone Crusher, Jaw Crushers150 thousand t/a burnt coke grinding line in Zhejiang, China garbage crushing station is mainly composed of feeder + jaw crusher + impact crusher / cone crusher + sand making machine + vibrating screen and other equipment or the grinding of heavy calcium carbonate and lime grinding, we can meet your multifaceted needsIndex Mobile Crushers, mobile crusher plantOil sands, oil shale and extra heavy crudes present signifi cant opportunities and challenges to the petroleum industry Developing these resources demands a specialized coke crusher design and a double suction fi rst stage impeller for low NPSH applications Pressure 100 bar / 1 450 psi Temperature 450 °C / 840 °FSulzer Pumps for the Hydrocarbon Processing Industry Muhur

.jpg)

Delayed Coking Operational Optimization Refining Community

– One nuclear point (density) mid point between normal coke bed height and TTL (alarm for water fill during quench) – Continuous level to cover coke bed height 2 hrs before switch to mid point between normal coke bed height and TTL – Bottom nuclear point (density) detector at 25% fill (coke volume) 30 Optimization During Coking Cycle2021年8月25日 Scott Graham reveals how to optimise processing performance and reliability in refineries Delayed coker units (DCUs) occupy the lower reaches of the oil refining strategy, upgrading the residue from other parts of the plant Especially important in the processing of heavy crude, these units provide considerable revenue for the business by maximising the Coker Pump Design Engineer Live1、 Improve processing performance In general rubber product formulas, it is often necessary to add several portions of heavy calcium; In light colored fillers, heavy calcium has good dispersibility and can be mixed with rubber in any ratio, or other additives can be mixed together, making mixing convenientNews The role of heavy calcium in the rubber industry and its 2023年12月11日 Heavy calcium carbonate and light calcium carbonate are two distinct forms of calcium carbonate with different physical and chemical properties Heavy calcium carbonate offers higher density, excellent The Difference Between Heavy Calcium Carbonate

.jpg)

Coker pump design Sulzer

Once the coke has been steamed and cooled, high pressure water jets are used to loosen the coke and wash it out of the bottom of the drum Jet cutting pumps are high pressure units, around 4’300 psi (300 bar) with a flow rate typically We supply green petroleum coke double roll coal crusher, mobile coal crusher, coke coal crusher] High FC Pitch Coke: 1High carbon, cs cone crusher for coke – process crusher cs cone crusher for coke 1 Views lignite, magnesia, chromium oxide green, gold ore, clay, kaolin, coke and so on main structures of used CS series Green Coke Crusher Crusher Mills, Cone Crusher, Jaw CrushersCoal coke crushers india,Coal coke crusher and mill india In fact, there are several types of coal crushers Coal Jaw crusher is the most common crusher in coal crusher plant and used as primary coal crusherTypes Of Coal Crushers Crusher Mills, Cone Crusher, Jaw CrushersPCZ Heavy Hammer Crusher PCZ series of hammer crusher is mainly used in building materials industry, the construction of roads and railways, buildings, and other applications of stones Especially it is suitable for crushing medium hard limestone, and the compressive strength is lower than 250MPa in crushing hard, brittle materials, such as limestone, dolomite, coal and Hammer Crushers FTM Mining Machine

.jpg)

Amazoncouk: Can And Bottle Crusher

Electric Can Crusher For recycling 12 oz and 16 oz aluminium metal cans crusher Heavy duty crusher for recycling aluminium soda, soda beer, coke cans and plastic water bottles 35 out of 5 stars 32024年7月10日 What is coke fine Coke fine refers to the smallsized particles or fine granules of coke, a carbonrich material derived from coal or petroleum These fine particles are typically produced as a byproduct during the crushing, screening, and handling of larger coke pieces Coke fine sources types of them At present, coke fines primarily come from the following two Coke briquette making and the binders MAXTONBuy OSSIAN Premium Wall Mounted 2 in 1 Can Crusher and Bottle Opener – Heavy Duty Large 16oz 500ml Aluminium Drinking Tin Can Kitchen Recycle Tool with Soft Grip Foam Handle and Bottle Opener at Amazon UK Crusher from OSSIAN effortlessly crushes aluminium cans up to 16oz / 500ml, making it perfect for drinking cans such as Coke or Pepsi, OSSIAN Premium Wall Mounted 2 in 1 Can Crusher and Bottle 2024年5月11日 Constructed with highlevel thick steel metal, the Pardecor 16 oz Metal Can Crusher/Smasher is a heavyduty wallmounted crusher designed for easy recycling of aluminum cans The upgraded grip handle enhances durability with a 20% increase in iron thickness, making it a reliable tool for compacting cans and reducing storage space in recycling Best Can Crushers: Crush Your Recycling Efforts with Ease!

.jpg)

Petroleum Coke Crusher: Choosing the Right Equipment

2024年6月2日 When choosing the right equipment for petroleum coke crushing, several factors should be considered: Feed Size: The size of the pet coke feed material will influence the type and size of the crusher required Capacity Zhengzhou Hengxing Heavy Equipment Co, Ltd: We're known as one of the most professional stone crusher, grinding ball mill, rotary drying equipment, calcination equipment, coal briquetting equipment manufacturers and suppliers in China China Stone Crusher, Grinding Ball Mill, Rotary Drying Global Heavy CrudeProc [miob/d] Source: Oil Gas Journal 2010 More Stringent Regulations forHeavy Fuel Oils Global SulphurLimit [%w/w] Coke Drum Crusher Sump Sump ToClean WaterTank Coke Drum Crusher Sluiceway Hydrobin Coke Water Clarification System Coke Fines Chute • Open System • NoInlineCrusherAn AdvancedCoke Handling Process Refining Community2021年9月13日 These crushers are made of steel, and some are able to crush multiple cans at once The price often depends on the tool’s storage capacity Some require wall mounting, but many are large and heavy enough to stand on the floor Tips Attach a wallmounted can crusher to the studs This gives it extra stability Never use a can crusher on steel 5 Best Can Crushers Dec 2024 BestReviews

Petroleum coke grinding mill, Petroleum coke mill, Petroleum coke

Petroleum coke can be divided into needle coke, projectile coke or spherical coke, sponge coke,Making Petroleum coke powder firstly should confirm which kind of petroleum coke The combustion temperature of petroleum coke powder in a glass melting furnace can reach or approach the flame temperature of heavy oil combustion at 16501730 degreesPyd1750 New Type Spring Cone Crusher for Iron Ore/ Hydrated Lime/ Heavy Calcium/ Hard Stone/ Gypsum/ Coke/ Pet Coke/ Fly Ash/ Yanliu/ Clay Ceremsite Sand US$10,0000050,00000 / Piece 1 Piece (MOQ)Pyd1750 New Type Spring Cone Crusher for Iron Ore/ Hydrated Lime/ Heavy 2022年11月12日 the crushing method first crushes white stone (natural limestone) in the jaw crusher to make which is prepared by calcination, digestion and CO2 carbonation: limestone crushed to 50150mm is mixed with coke (3050mm) in a ratio The raw material for wet grinding calcium by grinding method is heavy calcium carbonate or calcite Calcium Carbonate Heavy Request for Quotation ChemBKDon’t throw away those old soda cans, here are 24 DIY can crusher ideas that will help you turn those crushed cans into greatlooking new things Are you aware of how useful a homemade can crusher is? A can crusher is a tool that can mount or dismount the 24 Homemade DIY Can Crusher Ideas To Scrap Empty Cans

YUNNAN KREAT HEAVY INDUSTRY SCIENCE TECHNOLOGY

KREAT Heavy Industry Technology Co,Ltdis a professional company which has a set of mobile conveying crushing and screening equipment both in research development,manufacturing,sales,leasing and servicesKREAT products are widely used in mining,engineering construction,earth and stone works,road construction,urban infrastructure The need for environmentally compatible and at the same time economical solutions for processing the heavy residues of the refinery industry is increasing: Not least, more and more countries are tightening environmental and occupational health and safety requirements in the operation of refineries because the use of bunker oil in shipping is coming under increasing Mechanical Engineering – Jülch GmbH