plm1000 type ore mill reducer power

.jpg)

Turbofiner Type PLM Pallmann Industries

The columnar construction of the Turbofiner with clamshell type hinged stator in combination with the cantilevered bearing allows easier exchange of the wear parts and of the complete rotor; 2016年1月1日 Bond’s original work on establishing the energy for size reduction was established in a 244 m (8 foot) internal diameter wet grinding overflow type ball mill Doubt is now Size Reduction and Energy Requirement ScienceDirect2015年6月19日 Use this online calculators for Motor Sizing and Mill sizing as well as mill capacity determinators In extracting from Nordberg Process Machinery Reference Manual I Ball Mill Design/Power Calculation 911Metallurgist2023年4月23日 One of the most used tumbling mills is the ball mill This paper reviews different types of grinding media that have been developed and improved over the years and their (PDF) Grinding Media in Ball MillsA Review ResearchGate

Microsoft Word Mill Operator's Paper FINALdoc

In achieving finer grinds, UFG mills use a finer media size (23 mm) than conventional milling (12100mm) with a much higher installed power per mill unit volume (Table 1) Table 1 Typical Mill 2017年5月1日 Ball mill is an important kind of grinding equipment used to decrease the size of ore particles The power consumption of a ball mill is one of the most important parameters to Effect of lifters and mill speed on particle behaviour, torque, and 2022年12月22日 This is a sizebased crushing test using a conical ball mill to establish an energysize reduction relationship [Shi, 2014] Experiments were conducted with five mono An Energy T 75 Size Reduction Model for Ball Mills Springer2023年1月1日 Scaling up HPGRtower mill comminution circuit should consider size reduction ratio This paper presents the commercial implementation of a novel comminution circuit with Evaluating the performance of an industrialscale high pressure

.jpg)

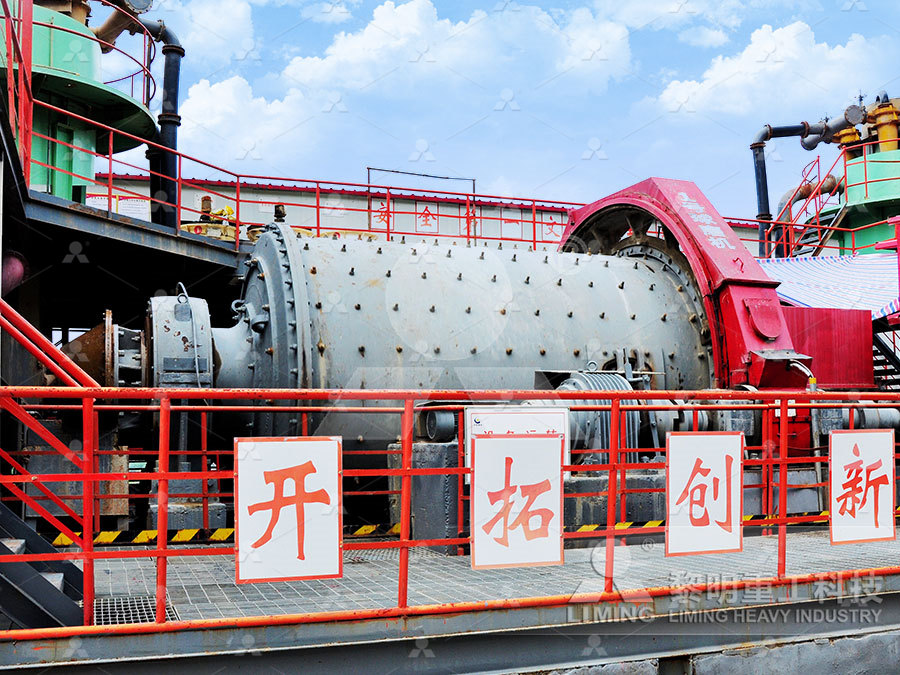

Ore mill, Ore grinding mill All industrial manufacturers

Find your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, Motor power: 75 kW 3,300 kW Machine length: 2,400 mm The overflow type ball mill is a new type of ball mill equipment with simple structure and selfflow discharge of oreIn recent years, the company has undertaken more than 20 provincial and municipal science and technology or technical transformation projects, including five kinds of products such as twostage worm gear reducer, vertical mill reducer, were identified as "hightech products [by provincial science bureau, a new type of vertical mill reducer is awarded [Jiiangsu Excellent new Sugar Mill Reducer China Reducer and Speed ReducerYGM Industrial Raymond Mill Discharge fineness: 80600 mesh Feed size: 35 mm Output: 0435 t/h Materials: Calcite, limestone, wollastonite, gypsum, potassium feldspar, kaolin, bentonite, barite, phosphate rock, manganese ore, YGM Industrial Raymond MillIdeal for brittle, lowhardness materials, such as rare metal ores (eg, tungsten ore, tin ore), gold ore, iron ore, copper ore, quartz, feldspar, coal, glass, construction waste, cement clinker, fertilizer, etc The maximum feed size of MB rod mill is 25 mm The capacity reaches 180 tons/hour, with an output size of 03mmRod Mill Ore MillForui Machinery

.jpg)

Variables Affecting Grinding Mill Power 911Metallurgist

2017年7月3日 The first includes the following: Relation of specific gravity of grinding media to power and type of grind, effect of particle size on power, different pulp densities, different sizes of discharge openings, comparison of batch and continuous opencircuit grind, various speeds and ore charges, rodmill tests at various speeds, various diameters of rods, comparison of large The ball mill is a wellknown ore grinding machine and is widely used in mining, The main parts of a ball mill are motor, reducer, slow drive, power distribution control cabinet, feeding device, main bearing, High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine Ball Mill JXSC Mineral2024年11月26日 Cokes, coal and charcoal (production of briquettes for home heating or industrial purpose (partial coke oven charge, brìquettes treated to obtain form coke, briquettes for gasification); Coal for production of activated carbon; Lignite, peat; ); Steel mill byproducts (Mill scales, Steelgrids, Mill sludges/dust, Blast furnace sludges, EAF dust, Iron pellet fines, DRI Best briquette machine for briquetting salt, DRI, ore, mill scale for 2011年7月18日 1 Vertical Roller Mill Reducer Product Introduction The vertical roller mill reducer is a key transmission part for the vertical mill, which not only transmits the torque but sustains the vertical load It is widely used in industries of construction material, power generating and metallurgy for raw material vertical mill, cement vertical mill, coal vertical mill and slag mill Gearbox/Gear Reducer/Vertical roller mill reducer

EIRICH TowerMill Vertical agitated media mill

the mill grinding chamber, in which the vertical agitator screw is located, TowerMills for grinding over 40 different types of materials 5 units ETM1500 Installed power: 5 x 11 MW Karara Iron Ore Project, Western Australia 4 units: Feed size: F80: 55 microns Product size: P80: 35 microns Throughput: 385 t / hr / TowerMill determination of required deformation resistance and mechanical work for performing the rolling operation; determination of the required power for performingCalculation of the Required Energy for a Stretch Reducing MillApplications: Chemicals (optional feature); Food processing (optional feature); Ore and mineral processing (optional feature); Waste processing or recycling (optional feature); Polymers (optional feature); Scale: Production; Feed: Dry solids; Continuous; Pulverizing of medium hard to soft materials; Type: Pin or universal mills; Operation: Fine milling (100 mesh, +325 mesh Pallmann Industries TurboFiner® Pulzerizer, Type PLM PLM 1250Comprehensive Speed Reducer Types Venturing into the realm of speed reducer types introduces an array of options each suited to specific industrial needs Let’s break them down: Worm Gear Speed Reducers Renowned for their simplicity Reducer Types for Industrial Gearboxes: A

.jpg)

How Many Types of Ball Mill? JXSC Machine

2019年12月26日 1 Central transmission ball mill: The driving power of this type of mill is in the center of the fuselage, and the motor realizes the operation of the ball mill through a reducer During operation, the hollow shaft in the center of Brief introduction of 1 rolling mill reducer, rolling mill reducer, also known as rolling mill gearbox, is used to reduce the input speed and increase the output torque It is mainly used in the rolling mill of steel rolling production lines such as bars, wires, profiles, strips, and platesJinxin transmissionFlying shears seriesVertical mill reducersecondary mill power that permits the range of vari ability samples to be processed according to whether a “SAG Mill limiting” condition, ie, harder ore, or a “Ball Mill limiting” condition, ie, softer ore exists For example, a ratio of 1:15 or up to 1:2 would indicate a trend away from processing harder ore types and an Mill drives: the desire for increased power and the Siemensthe mill grinding chamber, in which the vertical agitator screw is located, TowerMills for grinding over 40 different types of materials 5 units ETM1500 Installed power: 5 x 11 MW Karara Iron Ore Project, Western Australia 4 units: Feed size: F80: 55 microns Product size: P80: 35 microns Throughput: 385 t / hr / TowerMillEIRICH TowerMill Vertical agitated media mill

2FD{P}PC]854]XQ.jpg)

Electric Drives for Large Ore Grinding Mills 911Metallurgist

2019年4月19日 This application is particularly worthy of care because some 40% of the 75 megawatts of power used by a large copper ore concentrator, or some 60% of the 200 megawatts supplied to a large iron ore concentrator, are for grinding Mill Power Transmission ArrangementsTransmission Stage: two stages, power double split structure; three stages, parallel gears+ power double split structure Rated Power: 800 – 8,000 kW Applications Applied to industries such as cement processing, coal and mines etc, the gearboxes are used for tube mill to grind materials such as ore, coal sheets or cement clinker01 NGC GearsReason: This is a common problem mining ball mills face, resulting in low productivity and low ore processing efficiency One reason may be the improper design of the grinding chamber, which affects the flow of materials and reduces grinding efficiency Additionally, worn or damaged liners can hinder the grinding process by reducing the effective impact between the ball and the Inventory Of Common Faults And Solutions Of Mining Ball MillMain reducer for MLX200 cement pregrinding vertical mill used for Zhejiang Jinshou Cement Co, Ltd, supporting CKP vertical mill of Kawasaki Main reducer for MLX90 coal vertical mill used for India LANCO 2×660MW coalfired power plant project, supporting HP series vertical mills by Shanghai Heavy Machinery CoMLX Vertical Mill Gearbox China TAILONG DECELERATOR

From Ore to Iron with Smelting and Direct Iron

2017年10月17日 Smelting Reduction Figure 2: The smelt reduction vessel (SRV) is the core technology component of the Hismelt process Source: RioTinto While years of ironmaking technology innovations have optimized blast 2015年10月19日 The Bottom Table lists many of the common size rod mills giving speed, loading and power data The rod mill motor power is in horsepower at the mill pinionshaft For different length rod mills power varies directly as rod length For difference between new and worn liners increase power draw by 6%, and adjust for bulk density per Table ARod Mill Design Power Draw 911Metallurgist2018年1月25日 The aim of this project is design a gearbox for senior pellet mill machine is R D (Research Development) type project This machine is use to produce pellets which are animal feedDesign A Speed Reduction Gear Box in Senior Pellet Raymond mill series gear reducer CIC HMC can design and product various types of ZZ series gear reducer, and ZJ series gear reducer which professionally for the mills of building industry The ZZ series, including singlestage,twostage,triple and single grade derived,the twostage derived planetary gear reducer The reducers are widely used in mining, metallurgy, petrol Raymond Mill 1400 Rpm Input 280 Rpm Output Gear Reducer

(PDF) i) Direct Reduced Iron: Production ResearchGate

2016年3月30日 In book: Encyclopedia of Iron, Steel, and Their Alloys (pppp 10821108) Chapter: i) Direct Reduced Iron: Production; Publisher: CRC Press, Taylor and Francis Group, New YorkConsult BEIJING POWER EQUIPMENT GROUP CO LTD's entire BPEG ZGM Coal Mill catalogue on DirectIndustry Page: 1/4 Exhibit with us {{>currencyLabel}} Back {{>currenciesTemplate All BEIJING POWER EQUIPMENT GROUP CO LTD catalogs and technical brochures BPEG Aircore Reactors 24 Pages BPEG Line Trap 16 Pages BPEG BPEG ZGM Coal Mill BEIJING POWER EQUIPMENT GROUP CO Large Mill Power 34' 36' 38' 40' 42+ M W 20% balls Upgraded Freeport mill Upgraded Pelambres mill First 42' mill D25×EGL •Three commonly used mill motor types: –Gearless drives •largest size, up to 28 MW •highest efficiency particular project and ore Step 4: Select Speed •The rated speed of a motor is nominatedChoosing the Right Motors for your Mills Overflow type: discharge ore through the hollow shaft Grid type: discharge ore through grid plate Peripheral type: discharge ore around the cylinder Classification by transmission mode: Central drive ball mill: the power end of this kind of mill is in the center of the machine body, and the motor realizes the operation of the ball mill Ball mill liner Wear Parts For Industry Qiming Casting

Large Vertical Mill Reducer Maintenance

2023年6月25日 The large reducer supporting the vertical mill should be included in this column Once an accident occurs, the site maintenance is difficult, the technical content is high, and the maintenance cycle is long, which has a great impact on the normal production and operation of This series Bevel planet gearbox is mainly used for vertical mill of cement production line and vertical mediumspeed mill of coal production line, as well as for other industries JLP series gearbox adopts threestage ( bevelparallel shaftplanetary gearing) driving typePlanetary Gearbox for Vertical Mill Gearbox and ReducerFind your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, Motor power: 75 kW 3,300 kW Machine length: 2,400 mm The overflow type ball mill is a new type of ball mill equipment with simple structure and selfflow discharge of oreOre mill, Ore grinding mill All industrial manufacturersIn recent years, the company has undertaken more than 20 provincial and municipal science and technology or technical transformation projects, including five kinds of products such as twostage worm gear reducer, vertical mill reducer, were identified as "hightech products [by provincial science bureau, a new type of vertical mill reducer is awarded [Jiiangsu Excellent new Sugar Mill Reducer China Reducer and Speed Reducer

YGM Industrial Raymond Mill

YGM Industrial Raymond Mill Discharge fineness: 80600 mesh Feed size: 35 mm Output: 0435 t/h Materials: Calcite, limestone, wollastonite, gypsum, potassium feldspar, kaolin, bentonite, barite, phosphate rock, manganese ore, Ideal for brittle, lowhardness materials, such as rare metal ores (eg, tungsten ore, tin ore), gold ore, iron ore, copper ore, quartz, feldspar, coal, glass, construction waste, cement clinker, fertilizer, etc The maximum feed size of MB rod mill is 25 mm The capacity reaches 180 tons/hour, with an output size of 03mmRod Mill Ore MillForui Machinery2017年7月3日 The first includes the following: Relation of specific gravity of grinding media to power and type of grind, effect of particle size on power, different pulp densities, different sizes of discharge openings, comparison of batch and continuous opencircuit grind, various speeds and ore charges, rodmill tests at various speeds, various diameters of rods, comparison of large Variables Affecting Grinding Mill Power 911MetallurgistThe ball mill is a wellknown ore grinding machine and is widely used in mining, The main parts of a ball mill are motor, reducer, slow drive, power distribution control cabinet, feeding device, main bearing, High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine Ball Mill JXSC Mineral

Best briquette machine for briquetting salt, DRI, ore, mill scale for

2024年11月26日 Cokes, coal and charcoal (production of briquettes for home heating or industrial purpose (partial coke oven charge, brìquettes treated to obtain form coke, briquettes for gasification); Coal for production of activated carbon; Lignite, peat; ); Steel mill byproducts (Mill scales, Steelgrids, Mill sludges/dust, Blast furnace sludges, EAF dust, Iron pellet fines, DRI 2011年7月18日 1 Vertical Roller Mill Reducer Product Introduction The vertical roller mill reducer is a key transmission part for the vertical mill, which not only transmits the torque but sustains the vertical load It is widely used in industries of construction material, power generating and metallurgy for raw material vertical mill, cement vertical mill, coal vertical mill and slag mill Gearbox/Gear Reducer/Vertical roller mill reducerthe mill grinding chamber, in which the vertical agitator screw is located, TowerMills for grinding over 40 different types of materials 5 units ETM1500 Installed power: 5 x 11 MW Karara Iron Ore Project, Western Australia 4 units: Feed size: F80: 55 microns Product size: P80: 35 microns Throughput: 385 t / hr / TowerMillEIRICH TowerMill Vertical agitated media mill determination of required deformation resistance and mechanical work for performing the rolling operation; determination of the required power for performingCalculation of the Required Energy for a Stretch Reducing Mill