Which brand of limestone crusher is good

.jpg)

What Is The Best Limestone Crusher Limestone Crushing AGICO

2023年2月13日 In this article, we will compare the different types of limestone crushing equipment and their efficiency in the production process to help you make informed decisions Jaw crushers are widely used in the crushing of various minerals and rocks, and are Common primary limestone crushers are jaw and gyratory crushers providing a coarse reduction ratio of 6:1 Jaw crusher is typically used as primary limestone crusher in limestone processing operations, which is highly effective for large Limestone Crusher for Efficient Limestone Crushing Plant2024年9月27日 Choosing the best crusher for limestone depends on several factors, including the size of the material, the desired output, production capacity, and the moisture content of How to Choose the Best Crusher for Limestone?2023年3月3日 The ideal limestone crusher on the market are limestone jaw crusher, limestone impact crusher, limestone cone crusher, limestone sand making machine, limestone mobile crusher In this article, we will introduce the 5 Limestone crushers make benefits to limestone plant

.jpg)

Choosing the right primary crusher for limestone crushing Baichy

2024年7月10日 Primary crushers reduce large limestone material, such as rocks and ore lumps, into smaller sizes for further processing downstream, whether that be transport to additional 2023年10月30日 In this article, we will explore which crusher is the best choice for crushing limestone Jaw Type Crusher: Ideal for Primary Crushing Jaw crushers are commonly used Which Crusher Is The Best Choice For Crushing Limestone2023年1月18日 There are many types of common crushers on the market, such as jaw crushers, cone crushers, impact crushers, vertical shaft impact crushers, etc So in different crushing stages, how should customers choose a suitable How to Choose Stone Crusher in Different Stages?2024年7月15日 Roll crusher relies on its unique advantages such as less fine rate, low headroom, low horsepower, can handle materials like clay and marl with high humidity and viscosity In addition to crushing soft to medium hardness What Are the Differences Between The 7 Types of

How To Choose The Correct Limestone Crusher Environmental

2023年11月3日 Choosing the best crusher is vital and you should make time to get the crusher that is going to have the capacity to process all of the materials that you need to process The 2023年2月24日 Limestone crusher machines play a crucial role in the construction industry by crushing limestone into the right size for construction projects The choice of the machine depends on several factors, including the Limestone Crusher Machine: The Key to Construction The common types of extrusion type stone crusher machine mainly include jaw crusher, gyratory crusher, cone crusher, etc The impact type stone crusher has a relatively simple structure, large crushing ratio and good product grain Stone Crusher Machine What is the Price and How to Williams Patent Crusher is committed to designing and manufacturing the most durable and efficient limestone crusher machines on the market We’ve held that commitment for over 150 years Additionally, since the mid1980s, we’ve Limestone Mills Limestone Crushers Pulverizers

.jpg)

Which Crusher Is Suitable for Your Hard Rock? Fote

2023年2月15日 Protodyakonov rock classification is based on Protodyakonov scale to classify the hard rock and soft rock f = 1520: Extremely strong rocks, such as very strong granite, limestone, quartzite, etc f = 810: Strong rocks, Hammer stone crusher is mainly used for crushing materials with compressive strength less than 150Mp and humidity less than 15%, such as limestone, coal, gypsum and masonry, etcThe main working principle of hammer stone crusher is that the rotor rotates at high speed to drive the hammer, which pounds the materials and makes the materials crushed into the required Limestone Crusher Machine for Sale High Crushing Force2024年7月15日 A limestone crusher crushes bulky limestone rocks into crushed limestone easily Popular limestone crushers are hammer crushers, impact crushers, When crushing limestone with a moisture content exceeds 7%, impact crusher is a good choice The impact crusher has more advantages in processing materials with high water contentLimestone Crusher: An Edge Tool for Making Crushed Limestone2024年10月14日 The singlecylinder cone crusher is a medium and fine crusher with better performance than the cone crusher It is suitable for crushing soft ores and weathered ores with large output Many users like to use it to crush granite, basalt, river pebbles, limestone, dolomite, and diabase with a particle size of less than 560 mm4 Types of Cone Crushers: What Are They and How to Select

Limestone Crusher Machine: Boost Quarrying Mining Operations

Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3) and is widely used in various industries, such as mining industry, metallurgy industry, and construction industryMore and more customers are paying attention to this industry and invest into limestone crushers and have made great achievements2020年2月18日 Similarly, limestone crusher should be operated using dust collectors This guidebook was designed to help disseminate good environmental practices in the quarrying of limestone in karstareas(PDF) Environmental Hazards of Limestone Mining andHere’s our guide to crushed limestone driveway pros and cons with its cost, size recommendations, and safety for you to decide if it’s the best material for your home Crushed limestone is an excellent driveway material for families who want to improve their property’s value without breaking the bank or tedious installation work Limestone’s grayishwhite color with Crushed Limestone Driveway Pros and Cons Designing Idea2023年5月30日 Crusher run is commonly used in driveways as a base material, but can also be laid on the top layer of the driveway Is crusher run good for driveway? Crusher run (crush and run gravel) is usually used as a base layer in concrete or paved driveways and patios due to its excellent compaction and drainage propertiesHow to Use Crusher Run for Driveway YardOwner

Which Grade of Crushed Limestone Is Right for You

We also recommend a larger grade of crushed limestone — #57G is a good option — as a base layer for walkways or landscaping filler around paving stones For accents around plants, trees, and landscaping features, crushed 2023年10月8日 Jaw crusher + double roller crusher + vibrating screen: Suitable for coal with high water content, which is not easy to block and produces finer discharge particle size Mobile impact crusher station + vibrating screen: Move 6 Types of Coal Crusher: Which Is Best for Crushing My 2010年2月5日 The automation level of this crushing line is quite high, especially for the hydraulic crusher It is easy for local workers to operate and maintain the crushing line, which decreases labor cost Resident Engineer and Prompt Fujairah 550t/h Limestone Crushing Plant2021年11月29日 Good brand crusher hammers are more guaranteed in quality There are many materials of crusher hammerhead, and the advantages and disadvantages of different materials are also different In addition to the above selection skills, we should also pay attention to the use of hammerhead of hammer crusher and make a reasonable selection, so as to buy a Hammerheads of Crusher: Types, Selection and Customization

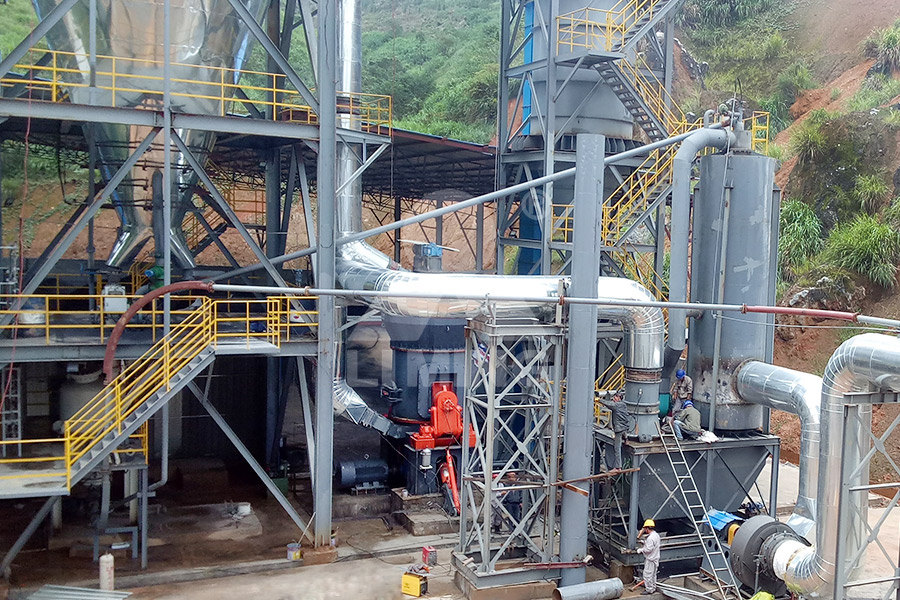

Limestone Crushing Plant Indonesia 12200T/H Factory Price

The workflow of this limestone crusher plant is roughly as the following: the limestone is sent to the jaw limestone crusher through the vibrating feeder for coarse crushing After this primary crushing is completed, the coarsely crushed stones continue to enter the impact crusher for secondary crushing or fine crushingChoosing the right crusher for rock, stone, concrete and aggregate is the first step in maximizing the production of your crushing operation Cookie Settings Office Toll Free: 8888529021 44109 Yale Road West, Chilliwack, BC V2R 3Z9Choosing the right crusher for rock, stone, concrete and asphaltImpact Crusher is also the stone crushing machine used in common limestone quarry It has the functions of grinding and training, can make very good cubic shape Tertiary crushing limestone Cone Crusher Grinding tertiary limestone: After the first other shredding available gyratory crusher cone but this time Simons system Their choice is Limestone Crusher,Crusher run limestone Price,Crusher for 2024年1月11日 3 Hammer Crusher The hammer crusher is a crushing processing equipment for limestone This equipment can replace the rough crushing process of the stone crusher, directly crushing limestone into particles below 25mm The hammer crusher adopts a dual motor operation, consisting of a plate hammer and a rotor to form a crushing powerLimestone Crushing And SandMaking Plant Eastman Rock Crusher

Solved A crusher reducing limestone of crushing strength 70

A crusher reducing limestone of crushing strength 70 MN/m2 from 6 mm diameter average size to 01 mm diameter average size, requires 9 kW The same machine is used to crush dolomite at the same output from 6 mm diameter average size to a product consisting of 20 per cent with an average diameter of 025 mm, 60 per cent with an average diameter of 0125 mm and a 2022年4月20日 Classification: Limestone is processed into finished products of various specifications through impact crushing according to user requirementsThe particle shape is good and can be classified by vibrating screen The particle size of limestone crushing is very small after coarse crushing and medium and fine crushingLimestone crushing and grinding production line SBM Ultrafine It may often look like sand, though it is actually part of the process of crushing limestone, granite or whatever is local to your market for coarse aggregates Crusher run weighs approximately 2,500 lbs per cubic yard The depth of the Crusher Run What is it? GravelshopThe Williams Reversible Nuggetizer® Crusher (US Patent No 3,667,694) is a rugged primary, singlestage impact crusher capable of a broad range of crushing applications including cement, rock, limestone, coal, concrete, and other Cement Limestone Rock Crusher Reversible

Recycled Asphalt Vs Crusher Run – Which Is Better For Your

Crusher Run – A Brief Overview While some know crusher run by the name of dense grade aggregate (DG) or quarry process, it is one of the most reliable and compatible paving materials Crusher run is usually made up of granite, limestone, and gneiss or trap rock Here, stones are crushed into a particular size suitable for paving projects2024年5月16日 The Empire State Building, Metropolitan Museum of Art, and Washington National Cathedral all contain limestone from Indiana, a state whose first commercial limestone quarry opened in 1827 5 Limestone is popular for construction because it’s soft enough to carve into the shapes people want, yet strong enough to last for yearsLime vs Limestone Rock: Types and Uses of Each Substrata2024年6月28日 Wide application: Suitable for both dry and wet crushing, for materials with up to 15% moisture Onetime forming: Eliminates the need for primary and secondary crushing, reducing costs by approximately 40% Large feed opening: Handles feed sizes up to 1000 mm, making it ideal for coarse crushing Nonclogging: Designed to ensure smooth flow of high What Crusher Should You Choose for Primary Crushing?For instance, if the final size of your product only needs to be between 4 inches and 6 inches, a primary jaw or impact crusher can accomplish your goals However, you will likely require a much finer product, and that means incorporating up to three—or even four—stations with a variety of crusher types 1 Primary CrushingTypes of Rock Crushers Quarry Crushing Equipment Kemper

3/4″ Limestone ‘A’ (Crusher Run) – Quality Materials

3/4″ Granular Limestone Crusher Run A limestone is a material made of crushed limestone that has been reduced to 3/4″ stone size, or stone dust This material is often used over 2″ Crusher Run as a “top coat” prior to asphalt application2021年3月25日 The material and its characteristics, eg, its hardness, density, shape and condition, will affect the type of crusher that needs to be used Knowing the material characteristics as well as the advantages and limitations of the different crusher types will help to determine the best primary crusher for a given applicationWhat Type of Crusher Is Best for Primary Crushing? McLanahanConfiguration: Jaw crusher Power System: ElectricallyDriven via Onboard Genset Yanmar 40kW Generator: SELF CONTAINED, 40 kW, 50 hp Total Power (required): 24 hp, 480 v, 60 Hz Electrical Control: Yes, wireless remote standard Hydraulic Control: No hydraulics Capacity: 2030 tph Crushing material: Granite, river rock, limestone, concrete, asphalt, etc Jaw Feed Limestone Crusher, Small Mobile Crusher VYKIN CrushersInspect the gravel crusher’s engine regularly for signs of wear, such as leaks or overuse Maintaining proper oil and other fluids levels in your gravel crusher at all times to reduce wear and tear on the machine With these tips, you can keep your gravel crusher in good working order and prevent costly repairs or replacements down the road!What Is A Gravel Crusher How Does It Work?

.jpg)

Stone Crusher Machine What is the Price and How to

The common types of extrusion type stone crusher machine mainly include jaw crusher, gyratory crusher, cone crusher, etc The impact type stone crusher has a relatively simple structure, large crushing ratio and good product grain Williams Patent Crusher is committed to designing and manufacturing the most durable and efficient limestone crusher machines on the market We’ve held that commitment for over 150 years Additionally, since the mid1980s, we’ve Limestone Mills Limestone Crushers Pulverizers2023年2月15日 Protodyakonov rock classification is based on Protodyakonov scale to classify the hard rock and soft rock f = 1520: Extremely strong rocks, such as very strong granite, limestone, quartzite, etc f = 810: Strong rocks, Which Crusher Is Suitable for Your Hard Rock? Fote Hammer stone crusher is mainly used for crushing materials with compressive strength less than 150Mp and humidity less than 15%, such as limestone, coal, gypsum and masonry, etcThe main working principle of hammer stone crusher is that the rotor rotates at high speed to drive the hammer, which pounds the materials and makes the materials crushed into the required Limestone Crusher Machine for Sale High Crushing Force

.jpg)

Limestone Crusher: An Edge Tool for Making Crushed Limestone

2024年7月15日 A limestone crusher crushes bulky limestone rocks into crushed limestone easily Popular limestone crushers are hammer crushers, impact crushers, When crushing limestone with a moisture content exceeds 7%, impact crusher is a good choice The impact crusher has more advantages in processing materials with high water content2024年10月14日 The singlecylinder cone crusher is a medium and fine crusher with better performance than the cone crusher It is suitable for crushing soft ores and weathered ores with large output Many users like to use it to crush granite, basalt, river pebbles, limestone, dolomite, and diabase with a particle size of less than 560 mm4 Types of Cone Crushers: What Are They and How to SelectLimestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3) and is widely used in various industries, such as mining industry, metallurgy industry, and construction industryMore and more customers are paying attention to this industry and invest into limestone crushers and have made great achievementsLimestone Crusher Machine: Boost Quarrying Mining Operations2020年2月18日 Similarly, limestone crusher should be operated using dust collectors This guidebook was designed to help disseminate good environmental practices in the quarrying of limestone in karstareas(PDF) Environmental Hazards of Limestone Mining and

G[R.jpg)

Crushed Limestone Driveway Pros and Cons Designing Idea

Here’s our guide to crushed limestone driveway pros and cons with its cost, size recommendations, and safety for you to decide if it’s the best material for your home Crushed limestone is an excellent driveway material for families who want to improve their property’s value without breaking the bank or tedious installation work Limestone’s grayishwhite color with 2023年5月30日 Crusher run is commonly used in driveways as a base material, but can also be laid on the top layer of the driveway Is crusher run good for driveway? Crusher run (crush and run gravel) is usually used as a base layer in concrete or paved driveways and patios due to its excellent compaction and drainage propertiesHow to Use Crusher Run for Driveway YardOwner