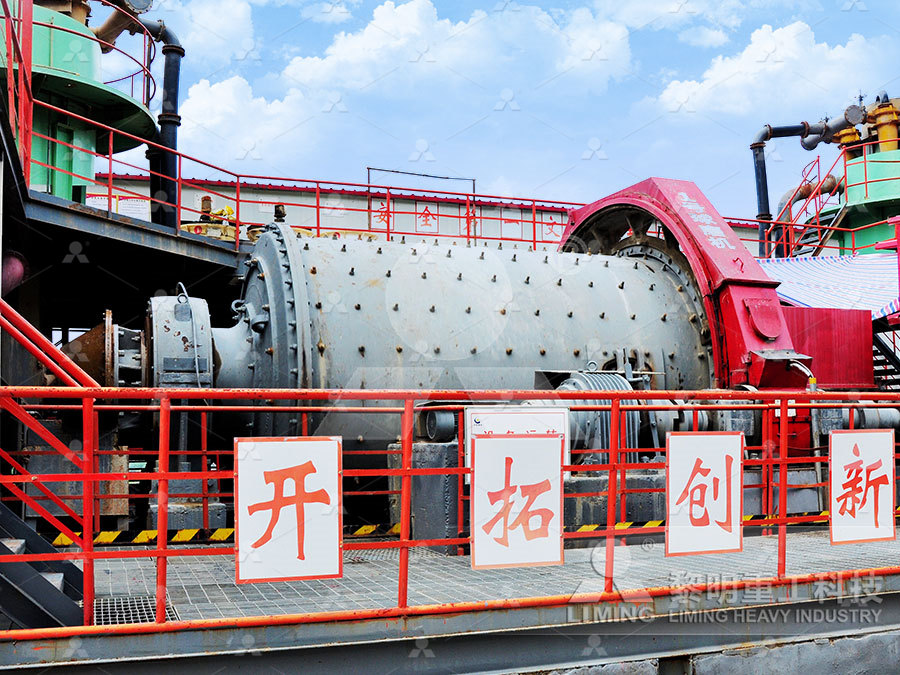

1.83 The output of limestone powder produced by ball mill

.jpg)

Evaluation of the Efficiency of Limestone Powder in Concrete and

2018年2月21日 The results indicate that the efficiency of limestone powder in partially replacing cement can be achieved by particle packing and particle distribution in the concrete and the 2017年9月1日 Limestone powder significantly influences the water stability of MKPC paste The early compressive strength of magnesium phosphate cement reduced under different curing Effect of limestone powder on the water stability of magnesium 2017年6月4日 Introducing these coefficients in the simulator the time required for this size reduction was obtained from the equation (1) With this value and the next scaleup equations (198c) Determination of the Kinetic Parameters of the Limestone The leading stone produced in the US, limestone accounts for 42% of total domestic production It is quarried in nine states with Wisconsin and Indiana producing over 87% of US tonnageLimestone Quarrying and Processing: A LifeCycle Inventory

(PDF) The use of limestone as an extender and its effect on

This report presented the results of seven limestone samples that were investigated for the effects of methylene blue index (MBI) values and total organic carbon (TOC) contents on portland 2021年11月1日 The fraction 4/10 mm was grinded by using the semiindustrial ball mill (65 L with 70 kg of specific balls) to obtain waste brick powder (WBP: fraction 0/01 mm used in this Substitution of limestone filler by waste brick powder in self 2020年5月1日 The main aim of this study is to improve the processing capacity of the largescale ball mill Taking a Φ549 × 883 m ball mill as the research object, the reason for the low Enhancing the capacity of largescale ball mill through process 2016年6月4日 Using limestone powder with a particle distribution of about 8 μm, generates approximately 54 pounds of per CO2 of the CO2 emissions ton produced, whereas a finer The Effects of Limestone Powder Particle Size on the Mechanical

Evaluation of the Efficiency of Limestone Powder in Concrete and

The results indicate that the efficiency of limestone powder in partially replacing cement can be achieved by particle packing and particle distribution in the concrete and the benefits of 2015年2月1日 In this study, by varying the proportion of portland cement (OPC), Class Ffly ash (F), and limestone powder (L), SCC mixtures with different strength values were produced, Mechanical properties, durability, and lifecycle assessment of self 2021年11月1日 The fraction 4/10 mm was grinded by using the semiindustrial ball mill (65 L with 70 kg of specific balls) to obtain waste brick powder (WBP: fraction 0/01 mm used in this study, Fig 1 (b)) A commercial limestone filler (more than 981% of calcite) from a Belgian Company was used for the production of selfcompacting reference mortarSubstitution of limestone filler by waste brick powder in self 2020年5月1日 Presently, research on the largescale mill in China and internationally has been focused on process optimization via replacing the conventional grinding process with the combined process of semiautogenousballmillcrushing (SABC), and autogenousballmillcrushing (ABC), the development of largescale the Φ79 m or Φ85 m size ball mill and the Enhancing the capacity of largescale ball mill through process

Performance of sustainable mortar using calcined clay, fly ash

2022年6月1日 Around eight percent of the overall carbon dioxide emissions in the world are generated from cement production activities There are two main sources of cement manufacturing that generate CO 2 emissions The first source is the chemical reaction associated with the production of the cement's main component, clinker, as carbonates (mostly limestone, 4 Milling of Portland Limestone Cements Cement is produced in a seemingly large variety of milling processes from fairly old technology in simple open circuit ball mills to closed circuit ball mill systems X, van Breugel, K (2003) Hydration process of cements blended with limestone powder: Expeimental study and numerical simulation (PDF) The use of limestone as an extender and its effect on 2023年9月19日 This research combines technical, environmental, and economic aspects regarding the utilization of Bege Bahia marble waste (BB) in clinker production Three different ecofriendly clinkers were produced, investigated, and compared with one that is commercially available BB was used to replace 492%, 77%, and 803% of the limestone by total amount of Valorization of Marble Waste Powder as a Replacement for Limestone Ball Mill Grinding Process Handbook Free download as PDF File (pdf), Text File (txt) or read online for free This document provides guidance on ball mill grinding processes It covers topics such as ball mill design including length to diameter ratios, percent loading, critical speed, and internals evaluation Methods for assessing ball charge, wear rates, and liner management are Ball Mill Grinding Process Handbook

Limestone Quarrying and Processing: A LifeCycle Inventory

Limestone is often produced with a natural surface, but finishes can be applied In such cases, often a polished or honed finishing is given to limestone products, but a variety of other finishes are also common Polishing and honing are manually and/or mechanically accomplished through the 2024年2月1日 At low replacement, the limestone powder not only can enhance the hydration of clinker by the socalled filler effect but also reacts with C 3 A in cement, producing hemicarbonate (Hc) and monocarbonate (Mc), contributing to compressive strength [4]Since the permissible limestone contents, which do not decrease compressive strength, depend on the amount of Performance improvement of Portlandlimestone cement by Sustainability 2018, 10 Type of the Paper (Article ResearchGate2007年12月1日 The layout of the plant and a ball mill image are shown in Fig 1, Fig 2 Download: Download fullsize image; Fig 1 Layout of the SOTUMILL/130 plant (Packint, Milano, Italy) used to perform experiments The line is composed of a powder feeder (1), a ball mill (2) a recycling pump (3) and a tank to store the refined chocolate (4)Optimization of processing parameters of a ball mill refiner for

A Bond Work index mill ball charge and closing screen product

2017年8月10日 An alternative mill ball charge is proposed that closely approximates Bond's original total ball mass, number of balls and ball surface area Results of 30 Bond Work index tests of six pure materials (calcite, magnesite, labradorite (feldspar), quartz, andalusite and glass) using closing screen apertures (P 1 ) values of 500, 250, 125, 90 and 63 μm are analysed2020年3月1日 Currently, the hammer mill and roller mill are the most commonly used mills in the pig feed industry Thomas et al (2012; 2018) also investigated the possibility for the use of a multicracker device Mill choices are usually based on ingredient type, energy consumption, grinding capacity as well as the animal speciesSize reduction in feed technology and methods for determining 2015年2月1日 As a result, considering an average clinker factor (kg of clinker per kg of cement) of 078 [4], annual worldwide CO 2 emissions from cement manufacturing add up to almost 23 billion mt, which is nearly 7% of the global emissions from fossil fuel combustion [2]For an average of 918 kg of CO 2 per mt of cement [5], the US cement industry generated about 56 Mechanical properties, durability, and lifecycle assessment of self You need to know bulk density to work with any powder or bulk solid This guide, listing thousands of materials, is meant as a reference tool to assist you in designing your production system Because the bulk density of a substance varies greatly depending on how the material has been handled, the information contained in this reference tool should be used for estimation Bulk Material Density Guide Hapman

Modeling of closedcircuit ball milling of cement clinker via a PBM

2023年9月1日 Closedcircuit ball mills have been operated for cement milling for decades [[7], [8], [9]]Fig 1 shows the process flow of a closedcircuit, twocompartment cement ball mill The closedcircuit operation helped to reduce overmilling of particles [10], resulting in lower specific power consumption [11] in comparison with opencircuit operation, where the ball mill is 2016年6月4日 specific gravity of cement and limestone powder Type I OPC has a specific gravity of 315, while that of limestone powder is 270 Replacing the cement with limestone powder will affect the density, and since the density affects the compressive strength of concrete, it will result in lower strength (Neville, 2011) 314 Air ContentThe Effects of Limestone Powder Particle Size on the Mechanical 2018年7月1日 The output of stage one is then fed into a ball grinding mill with a cone cavity to produce fine powders with a maximum size of 45 μm, which can be categorized as RP Fig 1 (a) describes the preparation method of RP through the secondary processing of CD wasteMechanical properties of concrete mixed with recycled powder produced 2019年6月1日 A pictorial view of the cement and limestone powder is presented in Fig 3 Lime stone powder (LSP) with specific gravity of 248 was used as fillers The percentage composition of LSP was kept constant at 5% of the weight of concrete The chemical composition of the cement and limestone powder is presented in Table 3Application of response surface methodology: Predicting and

A process mineralogy approach to study the efficiency of

2020年12月3日 Analysis of particle size distribution for open and closedcircuit ball mills feed and product showed that d 90 value of feed and product of opencircuit mill is 4383 and 4233 microns 2020年2月1日 The mill operating conditions were as follows: mill diameter D: 254 cm; ball diameter d: 254 cm; mill speed ω, expressed as fraction of the critical speed: 06; ball load J, expressed as fraction of the mill volume occupied by balls at rest: 05; particle load U, expressed as fraction of the void volume of the static ball charge occupied by particles: 10 (actual Energy absorption and specific breakage rate of particles under 2023年10月1日 Before calcination, the samples underwent a series of crushing and milling processes First, a Denver black jaw crusher was used for primary crushing Samples with sizes 2 mm were first passed through a rod mill before undergoing ball millingPrioritization of lowgrade kaolinite and mixed clays for 2018年1月1日 Effect of CaCo 3 , calcitic agricultural limestone (aglime), dolomitic aglime, pelleted lime, and an untreated control on soil pH for different incubation periods (averages across three soils)Influence of Source and Particle Size on Agricultural

.jpg)

(198c) Determination of the Kinetic Parameters of the Limestone

2017年6月4日 This work describe the process of the design of a discontinuous industrial tumbling ball mill, starting with the determination of the kinetic parameters of a breakage, the specific rate of breakage S i and the primary daughter fragment distribution b i,j, in a laboratory tumbling ball mill for limestone The relevance of this work in Powder Technology teaching is 2022年3月1日 Therefore, in this experimental study, laboratorytype ball mills and cylpebs were preferred A stainlesssteel laboratory batchtype ball mill with internal dimensions of 200 × 200 mm and a volume of 6283 cm 3 was used in the grinding Analysis of grinding aid performance effects on dry fine milling of 2022年6月1日 The most commonly used strategy to prevent ASR expansion in concrete is to use appropriate amounts of supplementary cementitious materials (SCMs) by replacing cement [4]SCMs help prevent the expansion due to ASR by consuming calcium hydroxide and lowering the pore solution alkalinity (and thus pH) due to both dilution (replacement of cement) and The efficacy of portlandlimestone cements with supplementary 2023年7月1日 An eggshell contains 94% of calcium carbonate (CaCO 3), 1% of calcium phosphate (Ca 3 (PO 4) 2), 1% magnesium carbonate (MgCO 3) and 4% organic matter [9], [10] which replace limestone [11]Blended cement has numerous advantages for the environment, economy, and technology [11]The chemical composition of eggshell powder (ESP) is similar Sustainable cement replacement using waste eggshells: A review

A Review on the Optimization of the Mechanical Properties of

2022年9月27日 The samples were grinded in a ball mill using ceramic balls as Competitive Research Grant Round 2, Science and Technology Human Resource Development Project (STHRDP)Project Output 03 (Grant No Makul, N Use of increasing amounts of bagasse ash waste to produce selfcompacting concrete by adding limestone powder waste 2006年12月1日 A third data set was used as an independent case to validate the Lupin grinding circuit model built based on the other two data sets The particle size distributions of the tube ball mill discharge and hydrocyclone underflow and overflow streams have been given in Table 1, Table 2, respectivelyThe particle size distribution curves of the abovementioned streams can Spreadsheetbased simulation of closed ball milling circuits2022年6月26日 Coal gangue is a kind of hard rock produced during coal mining and, it commonly comprises limestone, claystone, and to a lesser extent, shale and volcanic rocks It has low carbon content and generally accounts for about 10% of coal output and 25% of China’s industrial waste discharge [ 4 , 5 ]Using Chinese Coal Gangue as an Ecological Aggregate and ItsModel NO: 1200*2400 Type: Ball Mill Motor Type: AC Motor Motor Power: 22KW Rotationl Speed: 2325r/min Application: ConstructionLimestone Ball Mill China Used Ball Mill for Sale and Ball Mills

.jpg)

Substitution of limestone filler by waste brick powder in self

2021年11月1日 The fraction 4/10 mm was grinded by using the semiindustrial ball mill (65 L with 70 kg of specific balls) to obtain waste brick powder (WBP: fraction 0/01 mm used in this study, Fig 1 (b)) A commercial limestone filler (more than 981% of calcite) from a Belgian Company was used for the production of selfcompacting reference mortar2020年5月1日 Presently, research on the largescale mill in China and internationally has been focused on process optimization via replacing the conventional grinding process with the combined process of semiautogenousballmillcrushing (SABC), and autogenousballmillcrushing (ABC), the development of largescale the Φ79 m or Φ85 m size ball mill and the Enhancing the capacity of largescale ball mill through process 2022年6月1日 Around eight percent of the overall carbon dioxide emissions in the world are generated from cement production activities There are two main sources of cement manufacturing that generate CO 2 emissions The first source is the chemical reaction associated with the production of the cement's main component, clinker, as carbonates (mostly limestone, Performance of sustainable mortar using calcined clay, fly ash 4 Milling of Portland Limestone Cements Cement is produced in a seemingly large variety of milling processes from fairly old technology in simple open circuit ball mills to closed circuit ball mill systems X, van Breugel, K (2003) Hydration process of cements blended with limestone powder: Expeimental study and numerical simulation (PDF) The use of limestone as an extender and its effect on

Valorization of Marble Waste Powder as a Replacement for Limestone

2023年9月19日 This research combines technical, environmental, and economic aspects regarding the utilization of Bege Bahia marble waste (BB) in clinker production Three different ecofriendly clinkers were produced, investigated, and compared with one that is commercially available BB was used to replace 492%, 77%, and 803% of the limestone by total amount of Ball Mill Grinding Process Handbook Free download as PDF File (pdf), Text File (txt) or read online for free This document provides guidance on ball mill grinding processes It covers topics such as ball mill design including length to diameter ratios, percent loading, critical speed, and internals evaluation Methods for assessing ball charge, wear rates, and liner management are Ball Mill Grinding Process HandbookLimestone is often produced with a natural surface, but finishes can be applied In such cases, often a polished or honed finishing is given to limestone products, but a variety of other finishes are also common Polishing and honing are manually and/or mechanically accomplished through the Limestone Quarrying and Processing: A LifeCycle Inventory2024年2月1日 At low replacement, the limestone powder not only can enhance the hydration of clinker by the socalled filler effect but also reacts with C 3 A in cement, producing hemicarbonate (Hc) and monocarbonate (Mc), contributing to compressive strength [4]Since the permissible limestone contents, which do not decrease compressive strength, depend on the amount of Performance improvement of Portlandlimestone cement by

Type of the Paper (Article ResearchGate

Sustainability 2018, 10 2007年12月1日 The layout of the plant and a ball mill image are shown in Fig 1, Fig 2 Download: Download fullsize image; Fig 1 Layout of the SOTUMILL/130 plant (Packint, Milano, Italy) used to perform experiments The line is composed of a powder feeder (1), a ball mill (2) a recycling pump (3) and a tank to store the refined chocolate (4)Optimization of processing parameters of a ball mill refiner for