Coal mills are widely used in electricity

Coal Mill an overview ScienceDirect Topics

Coal mills or pulverizers play a very essential part in the coalfired power production system Coal mills grind the coal into fine powder, and the primary air entering the mill dries and drives the coal into the power plant furnace for combustion Mills can be a bottleneck for the power generation GGBFS can be used with an optimum replacement rate of about 50%, but in some applicatioCement Plant2022年3月25日 The work presented in this paper focuses on modeling Mill Parter Shiptype coal mills that are widely used in the coalfired power plants in China The unknown model parameters are(PDF) A Modeling and Optimizing Method for The electricity current intensity of coal mills can be reduced or minimized subject to the coal type parameters and the load of the boiler through optimizing the coal mill operations This paper A Modeling and Optimizing Method for Electricity Current

Development of a Multisegment Coal Mill Model Using an

2007年8月20日 This multisegment mathematical model is derived through analysis of energy transferring, heat exchange, and mass flow balances The work presented in the paper 2017年8月1日 MPStype medium speed coal mills are widely used in the thermal power plants in China They are designed and manufactured by the German company Babcock This kind of Modeling of a medium speed coal mill ScienceDirectCoal quality, that is the properties of coal, has an impact on many parts of a power plant including the coal handling facilities, pulverising mills, boiler, air heater, ESP, ash disposal as well as Expert systems and coal quality in power generation USEAInside the power station, the coal is pulverised to a fine powder in giant grinding mills This is because pulverised coal burns quickly, like gas The pulverised coal is transported to the boiler HOW ELECTRICITY IS PRODUCED AT A COALFIRED POWER

Instrumentation and control in coalfired power plant ICSC

Coalfired plants are the most widely used power plant today They involve the combustion of coal producing high pressure (typically 2400–3500 psig, ~165–240 bar) and high temperature The use of coal as an energy source dates back to second and third century Rome, with archeological evidence suggesting it was mined from outcroppings and used as a heating Coal: Past, Present and Future National Coal Council2020年4月7日 Monitoring and diagnosis of coal mill systems are critical to the security operation of power plants The traditional datadriven fault diagnosis methods often result in low fault recognition rate or even misjudgment due to Modeling of Coal Mill System Used for Fault Simulation 2020年8月14日 The coal mill is one of the important auxiliary engines in the coalfired Energy and Electricity Research Center, Jinan University Signalbased fault diagnosis systems are widely used to(PDF) Application of ModelBased Deep Learning Algorithm in Fault

.jpg)

Strengthening safety in mills and silos Power Engineering International

2014年11月17日 To prevent a coal fire, the mills can be made inert with a steam deluge when an unexpected shutdown occurs, or when there is a high risk of a coal fire Several methods are available to detect the presence of oxidization within the mill or silo: Thermocouples are widely used to detect the heat buildup from oxidation or an earlystage mill fire 2020年8月12日 As the significant ancillary equipment of coalfired power plants, coal mills are the key to ensuring the steady operation of boilers In this study, a fault diagnosis model was proposed on the An investigation of performance characteristics and Coalfired plants are the most widely used power plant today They involve the combustion of coal producing high pressure (typically 2400–3500 psig, ~165–240 bar) and high temperature (>500ºC) steam which is used to drive a turbine at synchronous speed (3000 rpm in countries such as the UK with a 50 Hz supply frequency, 3600 rpm in Instrumentation and control in coalfired power plant ICSC2017年8月1日 MPStype medium speed coal mills are widely used in the thermal power plants in China it was reported that China's lignite reserve exceeds 13% of the country's total proven coal reserves, but the electricity generated by large scale lignitefired boilers accounts for only 3% of the annual domestic electricity output [7]Modeling of a medium speed coal mill ScienceDirect

36.jpg)

Coal Mill in Thermal Power Plant: Enhancing Efficiency and

These mills are typically used in thermal power plants to grind coal to the desired fineness, facilitating efficient combustion and maximizing the generation of electricity Bellian Machinery's coal mills are engineered to meet the specific requirements of thermal power plants, ensuring reliable and efficient operation Key Features and 2024年1月3日 Electricity generated from coal accounted for the largest share in the world total electricity generation (35%), followed by electricity generated from natural gas The most widely used secondary conversion technologies for the conversion of biomass into power or CHP are conventional steam turbines, Biomass for Power Production and Cogeneration SpringerLink2016年10月5日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study performed on a EnergyEfficient Technologies in Cement Grinding IntechOpenTh e burning of coal to generate electricity is a relative newcomer in the long history of this fossil fuel It was in the 1880s when coal was fi rst used to generate electricity for homes and factories By 1961, coal had become the major fuel used to generate electricity in the United Stateshow coal is used to generate electricity KOOKS

.jpg)

The structure of MPS mediumspeed coal mill system

At present, this type of mill has been widely used in coalfired power plants of China, electricity production breakdowns can be significantly reduced First, HOW ELECTRICITY IS PRODUCED AT A COALFIRED POWER STATION An overview of power generation at a modern coalfired power station INTRODUCTION the coal is pulverised to a fine powder in giant grinding mills This is because pulverised coal burns quickly, like gas The pulverised coal is transported to the boiler furnace with air where it burnsHOW ELECTRICITY IS PRODUCED AT A COALFIRED POWER 2023年3月17日 Coal mining boomed during the British Industrial Revolution as it provided fuel for steam engines of all kinds in factories, transport, and agricultureDraining flooded mines to extract more coal was the reason the Coal Mining in the British Industrial Revolution2020年4月7日 Monitoring and diagnosis of coal mill systems are critical to the security operation of power plants The traditional datadriven fault diagnosis methods often result in low fault recognition rate or even misjudgment due to Modeling of Coal Mill System Used for Fault

Development of a Multisegment Coal Mill Model Using an

2007年10月1日 Wei et al [11] proposed a multisegment coal mill model that covers six milling processes (startup, standard milling, shutdown, idle and transit periods) with parameters identified in each processfrom combustion of the coal is used to raise high pressure superheated steam that drives a steam turbine generator Steam turbine plants have been in use for over a hundred years, and have reached supercritical conditions with percentage efficiencies in the upper 40s, LHV (lower heating value) basis, at favourable locations Coalfired power plantsUnderstanding coalfired power plant cycles ICSCtrillion kilowatthours of electricity used coal as its source of energy Natural gas, in addition to being burned to heat water for steam, can also be burned to produce hot combustion gases that pass directly through a turbine, spinning the blades of the turbine to generate electricity Gas turbines are commonly used when electricity utilityELECTRICITY A Secondary Energy Source Lehigh University2012年11月17日 2 1Introduction Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form Pulverized coal achieved its first commercial success in the cement industry At Wisconsin Electric Power Company, the use of pulverized coal was also shown to be a viable fuel for Coal mill pulverizer in thermal power plants PPT SlideShare

(PDF) MPS mills for coal grinding ResearchGate

2014年1月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on 2020年4月7日 present, this type of mill has been widely used in coalfired power plants of China, and its structure is shown in Figure 1 The mediumspeed coal mill system is mainly composed of ra w coal bunker,Modeling of Coal Mill System Used for Fault SimulationFIRE RISKS IN MILLS AND SILOS The greatest risk of spontaneous heating and subsequent fire occurs when the mill is shut down under load, as this leaves a large amount of pulverised fuel inside a hot mill The large surface area of the pulverised coal and the high temperature inside the mill lead to rapid oxidation of the coalCOAL HANDLING SAFETY Land Instruments Internationalanalysis of coal mills operation, coal particles size distribution and they impact on boiler operation can be performed using developed models 1 Introduction Combustion and cocombustion process modeling using CFD tools (Computational Fluid Dynamics) is a known area of research and widely used by the academic andNumerical investigation using two different CFD codes of

Power through the ages Nature

2017年11月29日 In London, Thomas Edison opens the first coalfired power station, providing electricity for lighting, followed a few months later by Pearl Street power plant in New York City, which has the 2016年1月1日 The demand for higher efficiency power inverters was growing rapidly In the Hbridge topology, all the power switches usually operate at high frequency, and the higher the switching frequency the Electricity, an Essential Necessity in Our Life2023年9月1日 The Levelized Cost of Electricity (LCOE) is a generally accepted financial indicator of different power plants, where the LCOE is taken as electricity price, in constant currency, at which energy electricity produced should be sold over the generation life of the power plant to cover investment as well as OM expenses, and return of capital for the investors The levelized cost of energy and modifications for use in electricity 2023年10月19日 Hydroelectric energy, also called hydroelectric power or hydroelectricity, is a form of energy that harnesses the power of water in motion—such as water flowing over a waterfall—to generate electricity People have used this force for millennia Over 2,000 years ago, people in Greece used flowing water to turn the wheel of their mill to ground wheat into flourHydroelectric Energy Education

How electricity is generated US Energy Information

2023年10月31日 Steam turbines are used to generate most of the world’s electricity, and they accounted for about 42% of US electricity generation in 2022 Most steam turbines have a boiler where fuel is burned to produce hot water and steam in a heat exchanger, and the steam powers a turbine that drives a generator2015年8月1日 Mill problems originate mainly due to poor controls or faults occurring within the milling system As discussed by GQ Fan and NW Rees [3], the control of mills remains very simple in most of the power plants due to the fact that the mill system is highly nonlinear with strong coupling among the variables and it is very difficult to measure some important Review of control and fault diagnosis methods applied to coal mills 2023年12月19日 Historically, coal was mainly used for heating and cooking, but during the Industrial Revolution, its use expanded dramatically Coal was used to fuel steam engines, driving the expansion of railways and industrial machinery To this day coal continues to be used in industrial processes; it is primarily used in electricity generation, steel Coal: Composition, Uses, Figures and Debates2015年8月1日 Coal mill modeling for monitoring and control (extended abstract) H Palizban et al Practical optimal predictive control of power plant coal mills; P Niemczyk et al Improved coal grinding and fuel flow control in thermal power plants; P Pradeebha et al Modeling and control of coal mill; SG Cao et al Fuzzy logic control of vertical Review of control and fault diagnosis methods applied to coal mills

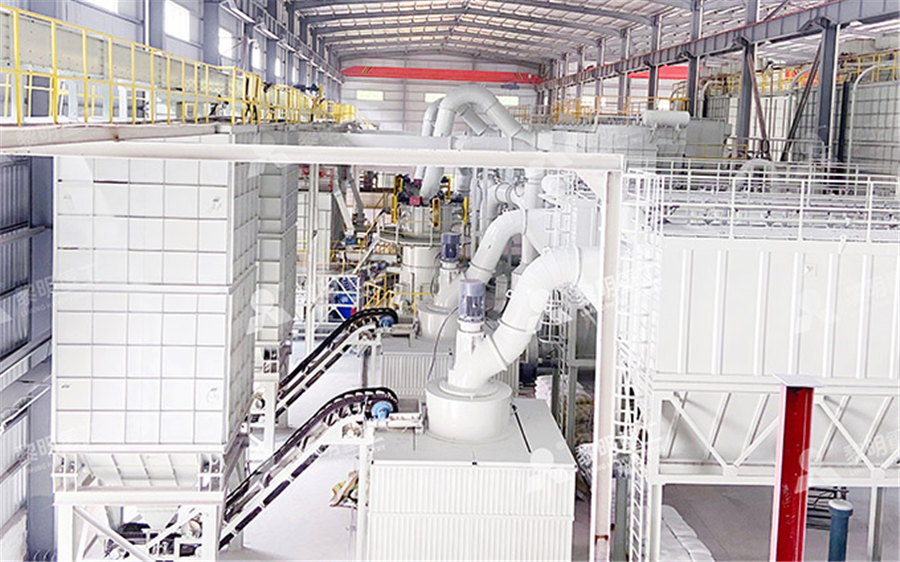

Coal mill can be widely used in electricity generation

July 4, 2011 PRLog Coal mill, which is also known as coal grinding mill or coal milling machine, is used to pulverize and dry coal before it is blown into the power plant furnace in the coalfired power plantsAs the “black blood of industry”, coal is usually grinded into micro size powder, which usually to be filled into the fire power plant, to generate power2020年8月14日 The coal mill is one of the important auxiliary engines in the coalfired Energy and Electricity Research Center, Jinan University Signalbased fault diagnosis systems are widely used to(PDF) Application of ModelBased Deep Learning Algorithm in Fault 2014年11月17日 To prevent a coal fire, the mills can be made inert with a steam deluge when an unexpected shutdown occurs, or when there is a high risk of a coal fire Several methods are available to detect the presence of oxidization within the mill or silo: Thermocouples are widely used to detect the heat buildup from oxidation or an earlystage mill fire Strengthening safety in mills and silos Power Engineering International2020年8月12日 As the significant ancillary equipment of coalfired power plants, coal mills are the key to ensuring the steady operation of boilers In this study, a fault diagnosis model was proposed on the An investigation of performance characteristics and

.jpg)

Instrumentation and control in coalfired power plant ICSC

Coalfired plants are the most widely used power plant today They involve the combustion of coal producing high pressure (typically 2400–3500 psig, ~165–240 bar) and high temperature (>500ºC) steam which is used to drive a turbine at synchronous speed (3000 rpm in countries such as the UK with a 50 Hz supply frequency, 3600 rpm in 2017年8月1日 MPStype medium speed coal mills are widely used in the thermal power plants in China it was reported that China's lignite reserve exceeds 13% of the country's total proven coal reserves, but the electricity generated by large scale lignitefired boilers accounts for only 3% of the annual domestic electricity output [7]Modeling of a medium speed coal mill ScienceDirectThese mills are typically used in thermal power plants to grind coal to the desired fineness, facilitating efficient combustion and maximizing the generation of electricity Bellian Machinery's coal mills are engineered to meet the specific requirements of thermal power plants, ensuring reliable and efficient operation Key Features and Coal Mill in Thermal Power Plant: Enhancing Efficiency and 2024年1月3日 Electricity generated from coal accounted for the largest share in the world total electricity generation (35%), followed by electricity generated from natural gas The most widely used secondary conversion technologies for the conversion of biomass into power or CHP are conventional steam turbines, Biomass for Power Production and Cogeneration SpringerLink

EnergyEfficient Technologies in Cement Grinding IntechOpen

2016年10月5日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study performed on a Th e burning of coal to generate electricity is a relative newcomer in the long history of this fossil fuel It was in the 1880s when coal was fi rst used to generate electricity for homes and factories By 1961, coal had become the major fuel used to generate electricity in the United Stateshow coal is used to generate electricity KOOKSAt present, this type of mill has been widely used in coalfired power plants of China, electricity production breakdowns can be significantly reduced First, The structure of MPS mediumspeed coal mill system