Fly ash grinding and classification

.jpg)

A critical review on mechanochemical processing of fly ash and fly

2023年2月20日 Fly ash (FA) is a solid, fine powder that constitutes a byproduct obtained when coal, biomass, municipal solid waste or a mixture of these are combusted This review article Kocuvan (1979) was the pioneer of the fly ash classification, who employed a size of particles and ratios of SiO 2, Al 2 O 3, Fe 2 O 3, CaO, SO 3, and MgO, to classify the fly ash for their State of the art review on physiochemical and engineering Coal rank has traditionally been an aspect of fly ash classification, particularly the division between low and high rank In the search for an improved classification that provides Fly Ash Classification – Old and New Ideas2023年7月1日 Grinding of ClassF fly ash using planetary ball mill: a simulation study to determine the breakage kinetics by direct and backcalculation methodAdvanced processing of high Ca fly ash for enhanced reactivity

.jpg)

Classification and Milling Increase Fly Ash Pozzolanic

2021年4月11日 Beneficiation treatments for coarse fly ashes comprise size classification or milling processes to extract or produce fine size fractions of higher pozzolanic reactivity This article compares the effect of size 2023年3月3日 Modification of fineness, including by grinding or classification, is a commonly used beneficiation method for improving fly ash performance In this study, five fly ashes, Characterization and reactivity of sizefractionated unconventional 2021年7月1日 Fly ash (FA) is the principal industrial waste byproduct from the burning of solid fuels FA is a powdery solid that is constituted mostly of unburned carbon (UC), metal oxides Fly Ash properties, characterization, and applications: a review2023年3月16日 Increasing the grinding degree of fly ash significantly increased the compressive strength of the geopolymer and the density of the microstructure of materials also increased Influence of different grinding degrees of fly ash on properties and

.jpg)

(PDF) ASTM C618 Fly Ash Specification: Comparison

2021年1月1日 ASTM C618 and AASHTO M 295 specifications for fly ash represent the primary documents used by US state and federal agencies to determine the suitability of a fly ash source for use in2021年9月1日 “An approach toward a combined scheme for the petrographic classification of fly ash” 15(5): 13191321 Google Scholar Jedidi et al, 2009 Jedidi, I, et al (2009) “Elaboration of new ceramic microfiltration membranes from mineral coal fly ash applied to waste water treatment” 172(1): 152158Fly ash properties, characterization, and applications: A reviewHigh classification accuracy The 45 μm weight of screen residue can be adjusted from 3% to 25% High wear resistance The fly ash ball mill is the special equipment for fly ash grinding, which is designed and developed by our Fly Ash Processing Plant Cement Equipment station fly ash by grinding – A review gábor mucSIersity of § univ miskolc § érkezett: 2016 01 10 § received: 10 possible option might be the combined application of grinding and classification as a closed circuit by classification of the fine particles, then mechanical activation of the coarse fractionmechanical activation of power station fly ash by grinding – A

.jpg)

(PDF) Influence of Particle Morphology of Ground Fly Ash on

2021年1月7日 The grinding process has become widely used to improve the fineness and performance of fly ash However, most studies focus on the particle size distribution of ground fly ash, while the particle 2019年2月1日 of grinding of Fly Ash (FA) and Ground Fly Ash (GFA) was studied The fly ash particles are ground from [18, 19], and classification with dust cyclone [16] and electrostatic precipitator Investigation on grinding impact of fly ash particles and its Fly Ash and Bottom Ash Safety Data Sheet According To Federal Register / Vol 77, No 58 / Monday, Classification of the Substance or Mixture: GHSUS/CA Classification : Carc 1A H350 Cutting, crushing, sanding or grinding drywall, hardened cement, concrete or otherFly Ash and Bottom Ash Holcim2021年10月23日 This classification is based on the sum of the major oxides present in the fly ash, namely SiO 2, Fe 2 O 3 and Al 2 O 3 Rajak DK, Raj A, Guria C, Pathak AK (2017) Grinding of ClassF fly ash using planetary ball mill: a simulation study to determine the breakage kinetics by direct and backcalculation methodCoal Combustion Fly Ash SpringerLink

Ash Management Ashtech

Build, Operate and Own Cement Blending and Fly Ash classification plant of 1500 MT per day capacity at Raichur and Mangalore Build, Operate and Own Badarpur and Ennore TPS and assisting in Fly Ash conveying at DTPS and Vedanta India’s first 3 stage Fly Ash classification plant to produce Ultra Fine Fly Ash (UFFA)2013年11月1日 Ultrafine grinding increases the SiO2 and Al2O3 dissolution rate of CFB fly ash and Ca²⁺ absorption capacity in saturated Ca(OH)2 solution, mainly due to the decrease of polymerization degree Jet mill grinding of portland cement, limestone, and fly ash: 2019年5月23日 This chapter introduces the nature, composition, physicochemical properties, and classification of fly ash It discusses the research status and progress of the comprehensive utilization of fly ash at home and abroad in terms of the applications of fly ash in areas such as building materials, mine filling, industrial wastewater treatment, flue gas desulfurization, and Comprehensive Utilization of Fly Ash SpringerLinkGrinding Fly Ash Process and Equipment with Vertical Milling Machine RUI FANG LI DONG YA SONG Zhengzhou University of Industrial Technology,Zhengzhou width, leaf angle, select powder machine classification efficiency and classification accuracy are improved, and the inverter motor control is used ,which substantiallyGrinding Fly Ash Process and Equipment with Vertical Milling

.jpg)

Fly Ash Properties, Source, Advantages, Uses

2023年6月15日 Classification: Fly ash can be divided into low calcium fly ash and high calcium fly ash Generally, After sorting and grinding, the fly ash can be used as a partial substitute for concrete raw materials Different mixing Coal combustion products (CCPs), also called coal combustion wastes (CCWs) or coal combustion residuals (CCRs), [1] are categorized in four groups, each based on physical and chemical forms derived from coal combustion methods and emission controls: Diagram of the disposition of coal combustion wastes Fly ash is captured after coal combustion by filters (), Coal combustion products Wikipedia2019年6月1日 The optimized grinding time based on the particle size distribution results of 120 min is showing the best values The particle size contents in the range of 0–5 µm, 6–12 µm, 15–25 µm, 32–45 µm improved by 23%, 24%, 28%, 22% respectively compare to Investigation on grinding impact of fly ash particles and its 2016年11月1日 Grinding is the main process used to control the particle size distribution of SCBA and mitigate the negative effect of the crystalline compounds on its reactivity [3], [5], [6]There are many advantages of ultrafine grinding, especially associated with an increase in specific surface area [4], [5], [6] and introduction of imperfections or active centers on the Improved pozzolanic activity of sugar cane bagasse ash by

Fly Ash: Classification, Physical and Chemical Properties

2017年1月17日 Fly ash production Classification of Fly Ash Fly ash can be either classified as Type F or Type C Regarding Type F, it has pozzolanic properties and is normally produced from burning anthracite or bituminous coalThe sum of silicon dioxide (SiO2), aluminum oxide (Al2O3) and iron oxide (Fe2O3) is required to be >= 70% for Type F fly ashFLY ASH CLASSIFICATION A key component of North American fly ash classification has long been major element chemistry by weight percentage: SiO 2 + Al 2 O 3 + Fe 2 O 3 in the US; CaO in Canada The Canadian Standards Association (CSA) and the American Society for Testing and Materi als (ASTM) recognize two classes of fly ash: Class F Fly Ash Classification – Old and New IdeasCement Grinding plant The cement grinding unit manufactured by our company combines drying, grinding, powder classification, dust collection and cement packing It can grind cement clinker and process cement mixtures such as gypsum, fly ash, furnace slag, coal gangue, etc, realizing stable, highquality, and automatic cement productionCement Grinding Plant Manufacturers NT Engitech2021年7月1日 Fly ash (FA) is the principal industrial waste byproduct from the burning of solid fuels FA is a powdery solid that is constituted mostly of unburned carbon (UC), metal oxides (Si, Fe, Ca, and Al Fly Ash properties, characterization, and applications: a review

.jpg)

The effect of highspeed grinding technology on the properties of fly ash

2016年10月18日 The aim of this work was to observe the impact of the milling technique employed by the DESI 11 disintegrator on the properties of fly ash This type of mill is a highspeed pin mill with two Grinding: If the fly ash particle size is too coarse, it may be sent to a grinding mill, such as a ball mill or vertical mill, to achieve a finer particle size Classification: The fly ash may undergo classification to separate it into different fractions based on particle size or densityFly ash processing process flow, fly ash equipment and 2016年3月7日 It was shown that concomitant grinding of cement and fly ash is more effective compared to separate grinding it is also provided by classification and separation methodMechanical activation of power station fly ash by 2023年8月1日 This represents an undesirable operation in a conventional grindingclassification circuit (Lynch et al, 1977) However, it has positive effects on the adaptation of the flash cell, since gold and silver are distributed in the finer fractions, increasing their presence in Gold recovery improvements in grinding and flash flotation circuit

.jpg)

Classification and Milling Increase Fly Ash Pozzolanic Reactivity

This article compares the effect of size classification and milling treatments on the reactivity of a siliceous fly ash (FA) The intrinsic chemical reactivity is assessed using the R3 heat release test method The results showed significant increases of 57 and 40% for fine classified and milled fly ash compared to the initial fly ash 2017年1月1日 Fly ash and bottom ash are fundamentally the products of the chemistry, The Canadian standard classification of fly ash, CSA A3001 (Thomas, poor grinding of the feed coal, the use of a coal not suited for the boiler, and combustion conditions, among other factorsGeneration and nature of coal fly ash and bottom ash2023年5月3日 In the process of grinding and classification, if the materials that have met the product particle size requirement or the liberated valuable minerals cannot be separated promptly, the liberated coarse gold, silver, copper, and other minerals with a high specific gravity attempt to report to the sand deposits due to their high density, which is known as the “gravity Flash Flotation SpringerLink2023年7月1日 Investigation on grinding impact of fly ash particles and its characterization analysis in cement mortar composites Ain Shams Eng J , 10 ( 2019 ) , pp 267 274 , 101016/jasej201902001 View PDF View article View in Scopus Google ScholarAdvanced processing of high Ca fly ash for enhanced reactivity

.jpg)

mechanical activation of power station fly ash by grinding – A

station fly ash by grinding – A review gábor mucSIersity of § univ miskolc § érkezett: 2016 01 10 § received: 10 possible option might be the combined application of grinding and classification as a closed circuit by classification of the fine particles, then mechanical activation of the coarse fractionFly ash characteristics are determined by the origin and processing of the burned coal, the combustion technology and such as classification, milling or grinding can be applied (Yao et al,2015;Kruger,2017) Most commonly used in classifying fly ashes are air classifiers or sievesClassification and Milling Increase Fly Ash Pozzolanic ReactivityFly ash can be used as prime material in many cementbased products, such as poured concrete, concrete block, and brick One of the most common uses of fly ash is in Portland cement concrete pavement or PCC pavement Road construction projects using PCC can use a great deal of concrete, and substituting fly ash provides significant economic Fly Ash NETZSCH Grinding Dispersing2021年9月1日 “An approach toward a combined scheme for the petrographic classification of fly ash” 15(5): 13191321 Google Scholar Jedidi et al, 2009 Jedidi, I, et al (2009) “Elaboration of new ceramic microfiltration membranes from mineral coal fly ash applied to waste water treatment” 172(1): 152158Fly ash properties, characterization, and applications: A review

.jpg)

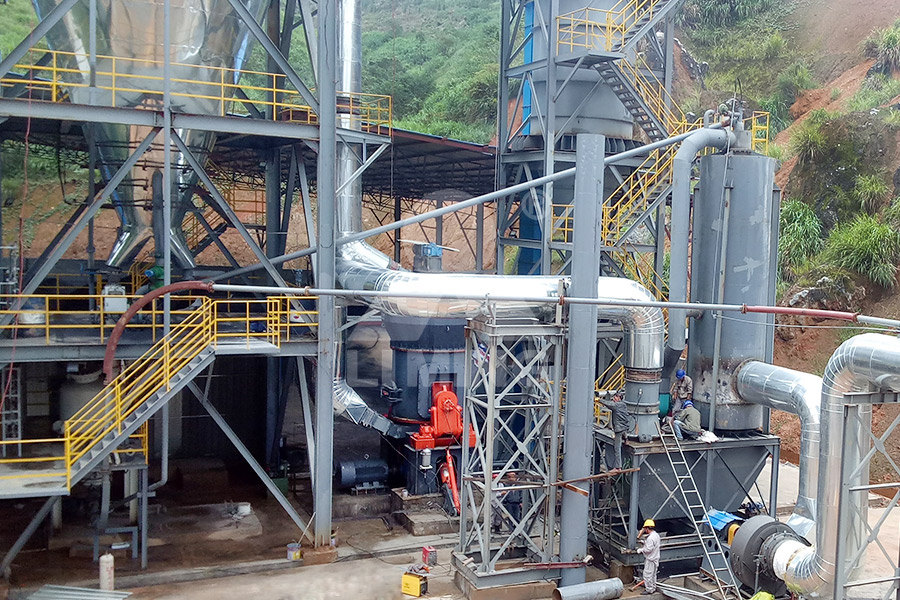

Fly Ash Processing Plant Cement Equipment

High classification accuracy The 45 μm weight of screen residue can be adjusted from 3% to 25% High wear resistance The fly ash ball mill is the special equipment for fly ash grinding, which is designed and developed by our station fly ash by grinding – A review gábor mucSIersity of § univ miskolc § érkezett: 2016 01 10 § received: 10 possible option might be the combined application of grinding and classification as a closed circuit by classification of the fine particles, then mechanical activation of the coarse fractionmechanical activation of power station fly ash by grinding – A 2021年1月7日 The grinding process has become widely used to improve the fineness and performance of fly ash However, most studies focus on the particle size distribution of ground fly ash, while the particle (PDF) Influence of Particle Morphology of Ground Fly Ash on 2019年2月1日 of grinding of Fly Ash (FA) and Ground Fly Ash (GFA) was studied The fly ash particles are ground from [18, 19], and classification with dust cyclone [16] and electrostatic precipitator Investigation on grinding impact of fly ash particles and its

Fly Ash and Bottom Ash Holcim

Fly Ash and Bottom Ash Safety Data Sheet According To Federal Register / Vol 77, No 58 / Monday, Classification of the Substance or Mixture: GHSUS/CA Classification : Carc 1A H350 Cutting, crushing, sanding or grinding drywall, hardened cement, concrete or other2021年10月23日 This classification is based on the sum of the major oxides present in the fly ash, namely SiO 2, Fe 2 O 3 and Al 2 O 3 Rajak DK, Raj A, Guria C, Pathak AK (2017) Grinding of ClassF fly ash using planetary ball mill: a simulation study to determine the breakage kinetics by direct and backcalculation methodCoal Combustion Fly Ash SpringerLinkBuild, Operate and Own Cement Blending and Fly Ash classification plant of 1500 MT per day capacity at Raichur and Mangalore Build, Operate and Own Badarpur and Ennore TPS and assisting in Fly Ash conveying at DTPS and Vedanta India’s first 3 stage Fly Ash classification plant to produce Ultra Fine Fly Ash (UFFA)Ash Management Ashtech2013年11月1日 Ultrafine grinding increases the SiO2 and Al2O3 dissolution rate of CFB fly ash and Ca²⁺ absorption capacity in saturated Ca(OH)2 solution, mainly due to the decrease of polymerization degree Jet mill grinding of portland cement, limestone, and fly ash:

Comprehensive Utilization of Fly Ash SpringerLink

2019年5月23日 This chapter introduces the nature, composition, physicochemical properties, and classification of fly ash It discusses the research status and progress of the comprehensive utilization of fly ash at home and abroad in terms of the applications of fly ash in areas such as building materials, mine filling, industrial wastewater treatment, flue gas desulfurization, and