What measures are needed to open a grinding mill

GRINDING MACHINES Carnegie Mellon University

Grinding machines come in various sizes and shapes as listed below Floor Mounted Utility Grinding Machine The typical floormounted utility grinding machine stands waisthigh and is It covers topics such as ball mill design including length to diameter ratios, percent loading, critical speed, and internals evaluation Methods for assessing ball charge, wear rates, and liner management are described Empirical Ball Mill Grinding Process Handbook2021年1月1日 This paper discusses a range of available methods for measuring and calculating mill filling and introduces a new technique for accurately measuring filling that eliminates the An improved method for grinding mill filling measurement and 2021年1月8日 For peak performance and balancing the power available in the SAG mill and ball mill, the transfer size must be measured and controlled The transfer size will be 500 microns A CRITICAL REVIEW OF GRINDING DESIGN PROCEDURES FOR THE

Principles of Sample Preparation by Grinding or Comminution

the measure of homogeneity can be accomplished with a process that creates large size reduction (crushing) where other samples for other processes will require reduction to fine 2018年8月17日 Extreme temperatures, impact velocity, mill load, grinding media, ore types, and applications are some of the factors to be considered while installing new linersGrinding Mills — Types, Working Principle Applications• A torque meter can be equipped to measure the energy input, and by using the total power consumption, one can monitor the grinding process • Cover seals can be provided for ATTRITORS AND BALL MILLS HOW THEY WORK Union Process2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Calculate and Select Ball Mill Ball Size for Optimum

CFB石灰石脱硫剂制备64.jpg)

Principles of Sample Preparation by Grinding or Comminution

The selection of the correct type of mill depends on the material and the factors that will affect size reduction The most important factors that must be considered when selecting a grinding method are: • Hardness or toughness: particularly hard samples will need energy intensive grinding methods such as crushers or cuttersGrinding Mills: Ball Mill Rod Mill Design PartsCommon types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG Grinding Mills 911Metallurgist2023年1月31日 The improper mounting of a grinding wheel is a major cause of grinding wheel breakage Proper steps in mounting a grinding wheel are as follows: Handle and store grinding wheels in a careful manner Handle and store all grinding wheels as if they were made of glass! Select the proper grinding wheel and machine for the jobProper Mounting of a Grinding Wheel Norton Abrasives2023年12月22日 Buying wheat berries can be cheaper than buying the equivalent amount (in weight) of flourEspecially when you buy in bulk So in the long run, milling your own flour could save you a lot of money However, this will be dependent on what you have available in your area though, so it’s worth checking out beforehand #3: Freshly Milling Your Grain Often Gives You Full Guide to Milling your Own Flour at Home (Why, How, Pros

.jpg)

Centerless Grinding: A Complete Guide Ripley Machine

2024年8月22日 Centerless Grinding – How it Works, When It’s Used, and Everything In Between Definition of centerless grinding Centerless grinding is a machining process where cylindrical parts are ground to precise dimensions and 2015年10月15日 The load estimation method has you physically measure distances in the mill Follow the charts below and pull them into this calculator 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Estimate Charge Volume of a Grinding Mill Estimate Charge Volume of a Grinding Mill (Method 1)2020年10月22日 But unfortunately, accidents do happen In 2018, 58 percent of workplace amputations (3,580 cases) involved some type of machinery, according to recent data from the US Bureau of Labor StatisticsParts and materials were involved in 15 percent of the amputations, while tools, instruments and equipment—including powered and unpowered Safety Tips for CNC Machinists: 5 MustKnow Rules for the WorkplaceInformation needed to create a business plan for a grain mill Drafting a grain mill business plan requires research so that you can project sales, investments and cost accurately in your financial forecast, and convince the reader that there is a viable commercial opportunity to be seizedHow to write a business plan for a grain mill?

Autogenous and SemiAutogenous Grinding Mill Testing

2018年4月9日 Pilot plant testing for primary autogenous or semiautogenous grinding gives the following information needed for selection of mills, circuit design, and mill design (1), (2) and (3) Since the ore determines the nature of the product from an autogenous or semiautogenous grinding circuit, the first thing to be determined is the suitability of the product for the next 2021年4月16日 The performance of the processed drum mill reaches its maximum at a relative speed of rotation of the drum 071 ensuring a waterfall mode of grinding of fuel related to the highspeed mode of a Research on the Grinding Energy Density in a Jet MillMill Type Overview Three types of mill design are common The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional AMIT 135: Lesson 7 Ball Mills Circuits – Mining 2017年10月26日 The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a Factors Affecting Ball Mill Grinding Efficiency

The Ultimate Guide to Using a Grain Mill Discover Real Food in

2024年4月1日 The ground flour is typically collected in a container placed beneath the mill End of Milling: After grinding, remaining grains should be cleared from the mill to avoid heat buildup and potential damage Maintaining Consistent Grinding Quality Users should check and calibrate the mill's grinding settings regularly to ensure uniform particle 2022年4月29日 Grind curves map the essential performance measures of a grinding mill to the mill load and rotational speed The curves vary with the changes in the feed ore characteristic but show generic Extremum seeking control for optimization of an openloop grinding mill If you want to start a maize milling business or a posho mill business in Kenya, South Africa, Zambia, etc a well 4、Choose the Right Corn Grinding Equipment You need to register your business with the relevant authorities in your country before it 7 Tips for Starting a Maize Milling Business Plan vosonThe required power consumption of a grinding mill based on the calculations shown above can be estimated thanks to this free Excel calculator : Calculation Tool Grinding Mill Power Calculation Warning : this calculator is provided to illustrate the concepts mentioned in this webpage, it is not intended for detail design Grinding power : step by step calculation PowderProcess

How to Start a Stump Grinding Business in 13 Steps

2023年4月22日 In addition to stump grinding and stump removal, you could offer tree trimming, tree removal, or other forms of tree care How much should you charge for stump grinding? Stump grinding prices are based on the size of the stump and range from $100 to $500 Check prices in your area to make sure you’re competitive2022年1月23日 Open Circuit Rod Mill followed by Closed Circuit Ball Mill In this case the grinding circuit comprises an open circuit rod mill followed by a closedcircuit ball mill The ball mill is most often closed over a classifier like a hydro cyclone (Fig 311) or DSM style screen with a fine cut of 1–15 mmPhysical Bauxite Processing: Crushing and Grinding of BauxiteDIFFERENT MILLS REQUIRE DIFFERENT AMOUNTS OF MEDIA •BASED UPON WORKING VOLUME OR TOTAL VOLUME •Mills such as the Immersion Mill have a fixed amount determined by size of the basket •Steel Ball Mill 333% •Open Head Sand Mill 3545% •Ceramic Pebble Ball Mill 50% •Dry Grind Batch Attritor 4560% •Wet Grind Batch Attritor 3845% •Continuous How to Choose the Correct GRINDING MEDIA PCI Mag2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process Control

.jpg)

A guide to SAG Mill management

2024年5月17日 A SAG (SemiAutogenous Grinding) mill is a giant rotating cylinder filled with grinding media and the ore being reduced As the mill rotates, the grinding media lifts and the impact crushes the feed material SAG mill control refers to the practice of managing the mill load, which is the amount of material inside the mill at any given time2021年1月1日 Mill filling has a dominant effect on grinding mill performance (Apelt, Asprey and Thornhill, 2001), and therefore, its accurate measurement is vital for modelling grinding mill performanceMeasuring filling is also necessary to estimate the composition of the load for mill modelling: rock and slurry for AG mills; rock, balls and slurry for SAG mills; or balls and slurry An improved method for grinding mill filling measurement and 2022年3月14日 The proposed extremum seeking controller could reduce the need for a plant operator to manually select the optimal operating conditions that maximize the performance measures of a grinding mill Since the controller is agnostic to the process model, the grinding mill can be optimised without the need for a detailed process modelExtremum seeking control for optimization of an openloop grinding mill 2016年7月8日 The Work Index values listed in Table I and II apply directly to a wet grinding overflow type rod mill 75 feet in diameter in open circuit; and to a wet grinding overflow type ball mill 75 feet in diameter in closed circuit with a rake classifier at 250% circulating load, and with 80% or more of the feed passing 4 meshEquipment Sizing: Crusher or Grinding Mill 911Metallurgist

Closed Circuit Grinding VS Open Circuit Grinding

2016年10月12日 Open Circuit Grinding Open circuit grinding consists of one or more grinding mills, either parallel or in series, that discharges a final ground product without classification equipment and no return of coarse discharge back to the mill Some very simplistic examples of open circuit grinding are see below and are made of a Rod mill, Ball Mill 2024年5月9日 In older mill systems, the mill inlet is often closed off, so it is not possible to measure the velocity directly In these cases, you need to look for other clues One simple test is to compare the mill outlet Blaine fineness with that of the mill filter dustMeasuring ball mill ventilation Chryso North Americaoff the finger The grinding head is pivoted 5 degrees as in the above image This makes only the outer edge of the grinding wheel contacting the flute of the end mill The center height of the grinding head is set to the same height as the center of the spindle axis of the end mill holder The wheel rotation will be clockwiseEnd mill grinding The HobbyMachinist2022年11月26日 The wheat you will be grinding: There are two main types of wheat, hard wheat, and soft wheat Hard wheat is typically used to make bread, while soft wheat is used to make pastry and cakes Depending on the wheat you will be grinding, you will need to choose a flour mill machine designed for that specific type of wheatFlour Mill Business Plan in India: Cost, Profits Idea2MakeMoney

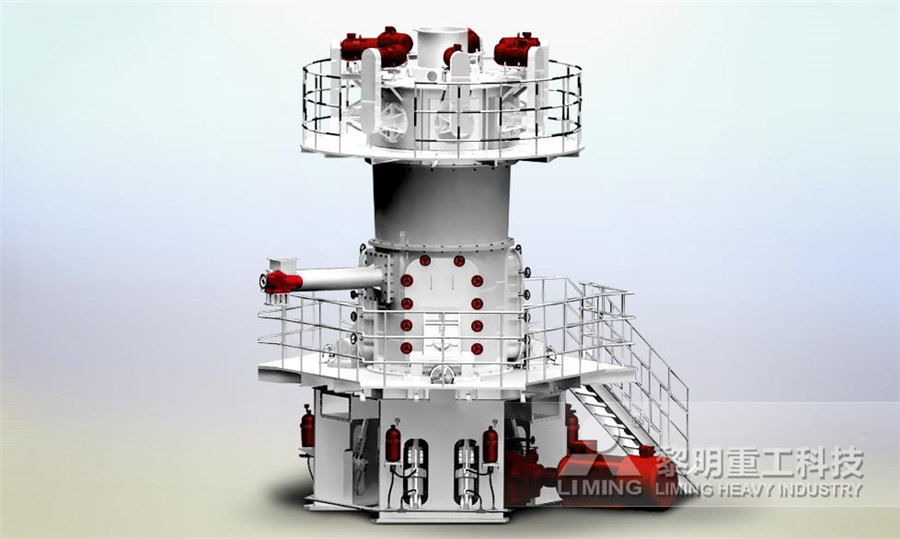

What is Limestone Grinding Mill SBM Mill Crusher

2023年5月15日 Particle sizes needed for various industries’ finished goods vary We should be able to achieve the necessary particle size distribution using the grinding mill we select Energy Efficiency A grinding mill’s energy use represents a considerable running expense, thus choosing one that is energy efficient is crucial This might save 2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Calculate and Select Ball Mill Ball Size for Optimum The selection of the correct type of mill depends on the material and the factors that will affect size reduction The most important factors that must be considered when selecting a grinding method are: • Hardness or toughness: particularly hard samples will need energy intensive grinding methods such as crushers or cuttersPrinciples of Sample Preparation by Grinding or ComminutionGrinding Mills: Ball Mill Rod Mill Design PartsCommon types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG Grinding Mills 911Metallurgist

.jpg)

Proper Mounting of a Grinding Wheel Norton Abrasives

2023年1月31日 The improper mounting of a grinding wheel is a major cause of grinding wheel breakage Proper steps in mounting a grinding wheel are as follows: Handle and store grinding wheels in a careful manner Handle and store all grinding wheels as if they were made of glass! Select the proper grinding wheel and machine for the job2023年12月22日 Buying wheat berries can be cheaper than buying the equivalent amount (in weight) of flourEspecially when you buy in bulk So in the long run, milling your own flour could save you a lot of money However, this will be dependent on what you have available in your area though, so it’s worth checking out beforehand #3: Freshly Milling Your Grain Often Gives You Full Guide to Milling your Own Flour at Home (Why, How, Pros 2024年8月22日 Centerless Grinding – How it Works, When It’s Used, and Everything In Between Definition of centerless grinding Centerless grinding is a machining process where cylindrical parts are ground to precise dimensions and Centerless Grinding: A Complete Guide Ripley Machine2015年10月15日 The load estimation method has you physically measure distances in the mill Follow the charts below and pull them into this calculator 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Estimate Charge Volume of a Grinding Mill Estimate Charge Volume of a Grinding Mill (Method 1)

.jpg)

Safety Tips for CNC Machinists: 5 MustKnow Rules for the Workplace

2020年10月22日 But unfortunately, accidents do happen In 2018, 58 percent of workplace amputations (3,580 cases) involved some type of machinery, according to recent data from the US Bureau of Labor StatisticsParts and materials were involved in 15 percent of the amputations, while tools, instruments and equipment—including powered and unpowered Information needed to create a business plan for a grain mill Drafting a grain mill business plan requires research so that you can project sales, investments and cost accurately in your financial forecast, and convince the reader that there is a viable commercial opportunity to be seizedHow to write a business plan for a grain mill?2018年4月9日 Pilot plant testing for primary autogenous or semiautogenous grinding gives the following information needed for selection of mills, circuit design, and mill design (1), (2) and (3) Since the ore determines the nature of the product from an autogenous or semiautogenous grinding circuit, the first thing to be determined is the suitability of the product for the next Autogenous and SemiAutogenous Grinding Mill Testing