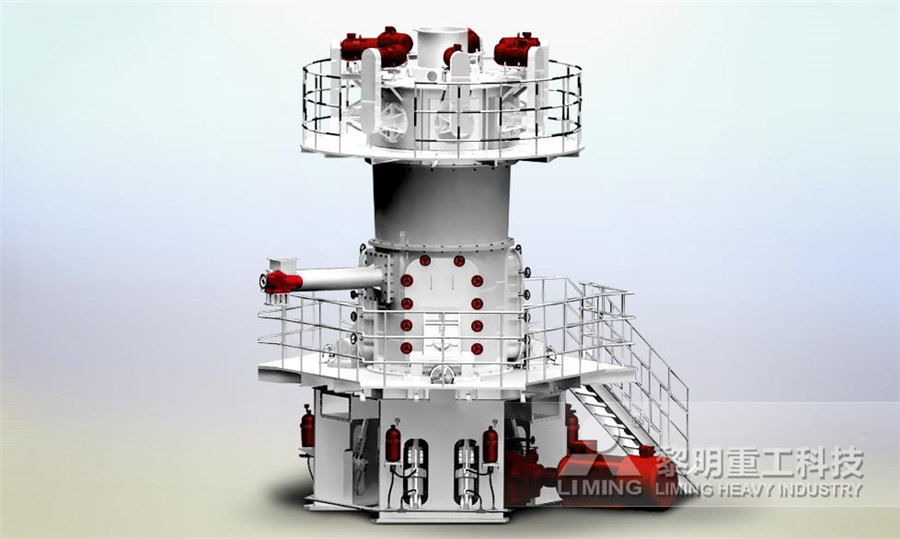

Energysaving vertical mill

.jpg)

Vertimill® Metso

The Vertimill® is globally recognized as an energy efficient grinding mill Through a low total cost of ownership, it brings substantial improvement to the profitability of concentrators During the years, Vertimill® technology has proven to be Vertical stirred milling is a wellrecognized technology for the secondary, regrind and fine grinding applications and are increasingly replacing coarser ball mill applications in secondary and RECENT DEVELOPMENTS IN COARSE GRINDING USING VERTICAL Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Vertical roller mill for raw Application p rocess materialsUBE Vertical Mill, having an advantage that drying, classification and pneumatic transportation can be carried out simultaneously with pulverization, it is better for energy saving than other UBE Vertical Mill UBE Machinery Corporation, Ltd

Review on vertical roller mill in cement industry its performance

2021年1月1日 Vertical roller mill has proved to be a popular choice for finished cement grinding over all other machineries due to advantages like low power consumption, higher capacity, Energy Saving (Less than 30% compared to Ball Mill) Possible to carry out simultaneously with grinding, drying and classifying; Simple equipment configuration; Excellent maintainability; Unique vibration absorbtion technologyUBE Vertical Mill UBE Machinery Corporation, Ltd2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the response surface method Analysis and Optimization of Grinding Performance of 2024年11月12日 With these features, the CLUM series ultrafine vertical grinding mill not only achieves efficient, energysaving, and environmentally friendly production but also significantly CLUM Series Mill: EcoFriendly and EnergySaving, Leading Ultra

.jpg)

Quartz Ultrafine Vertical Mill

Quartz ultrafine vertical mill has the characteristics of stable operation, energysaving, and environmental protection, large output, intelligent and controllable +17 [ protected] language >Shibang Industry Technology Energy Saving Motor Lpm Series Vertical Nano Ceramic Sand Mill with 6L, Find Details and Price about 6L Sand Mill Nanometer Sand Mill from Energy Saving Motor Lpm Series Vertical Nano Ceramic Sand Mill with 6L Dongguan Infor Machinery Technology Co, LtdEnergy Saving Motor Lpm Series Vertical Nano Ceramic Sand Mill 2022年5月9日 By initiating a CL for an industrial cement vertical roller mill Atmaca, A Kanoglu, M Reducing energy consumption of a raw mill in cement industry Energy 42, 261–269 (2012)Modeling of energy consumption factors for an industrial cement Shcronus has launched the CRLM1300 vertical mill which integrates drying and grinding with high efficiency and energy saving CRLM1300 vertical mil can be widely used in cement, metallurgy chemical industry, nonmetallic ore, nonferrous metals ore powder grinding, and electric powerCRLM1300 Vertical MillVertical Roller Mill Raymond MillVertical

.jpg)

Attrition Mills Technology and Experience Roytec Global

KLM VERTICAL MILL KLM vertical mill is universally recognized as the equipment of energysaving and high efficiency The vertical mill has a reducer drive system, Replaceable WearResistent Spiral Agitator and an online monitoring control system It usually uses high chromium steel balls as grinding pared with the ball mill system, the energy consumption of the vertical mill system can be reduced by 30% to 40% The vertical grinding mill does not have the metal impact sound of the steel balls colliding with each other and the liner in the ball mill, so the noise is low, which is 2025dB lower than that of the ball millIndustrial Vertical Grinding Mill2024年11月12日 The CLUM Series Ultrafine Vertical Mill sets a new standard in ultrafine powder production by combining advanced ecofriendly and energysaving technology with precision engineering CLUM Series Ultrafine Vertical Grinding Mill Key Advantages: CLUM Series Ultrafine Vertical Mill 1 UltraLow Operating Cost WearResistant Alloy Material: The CLUM Series Mill: EcoFriendly and EnergySaving, Leading Ultra Energy Savings and Improved Recovery with Small Grinding Media Michel Brissette, MScA, Grinding Process 3531655 FAX: 5143531768 Email: mbrissette@waenam Key Words: Energy Savings, Small Media, Fine Grinding, Ball Mill, Vertical Stirred Mill st January 20 to 22, 2009 Ottawa, Ontario, Canada 41 Annual Meeting of the Canadian Energy Savings and Improved Recovery with Small Grinding Media

ENERGY SAVINGS AND TECHNOLOGY COMPARISON USING

In ball mills, energy savings vary from 10 per cent to 40 per cent compared to 25 mm media A regrind ball mill with a mix of small grinding media can be as energy effi cient as an Isa Mill charged with 25 and 35 mm beads In vertical stirred Material circulation inside the mill FSmidth Cement flsmidthcement 3 ATOX coal mill Proven technology Today the airswept vertical roller mill is the standard solution for coal grinding installations And thanks to our continuous refinement of the ATOX coal mill over the years, today’s leading airswept vertical roller mill is the ATOX COAL MILL(22) 26112019 (43) 02072020 (57) An energysaving optimization method of a cement raw material vertical mill system Safe, convenient and reasonable auxiliary decisionmaking is smartly provided by a machine learning method without changing any structure and principle of a production equipment, adding additional measuring spots and affecting normal productionEnergysaving optimization method of cement raw material vertical mill Information on UBE Machinery's UBE Vertical Mill HOME PRODUCTS UBE Vertical Mill UBE Vertical Mill; UBE Vertical Mill UBE Vertical Mill As for limestone, cement we can respond to the high quality and energy saving of UBE Vertical Mill UBE Machinery Corporation, Ltd

Vertical roller mill for raw Application p rocess materials

Fig2 Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimationThe ultrafine vertical mill is currently the superlarge ultrafine grinding equipment in Asia, which has been successfully applied in the market and has mature technology It can replace imported equipment and is an ideal equipment for largescale production of ultrafine powder with high efficiency, high yield, environmental protection and energy savingTable Roller Mill Vertical MillVertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill, vertical coal mill, and ultrafine vertical millvertical roller mill, vertical coal mill, vertical slag mill, superfine Energy saving Multiround powder selection variable frequency speed regulation intelligent control Automatic control of the whole process What is the difference between Raymond mill and vertical mill? Vertical mills and Raymond mills are similar to "standing work", and they are quite different from horizontal ball millsvertical roller mill clirikultrafine vertical mill, Raymond vertical

.jpg)

LUM series superfine vertical roller grinding mill

High grinding efficiency:High grinding efficiency and low energy consumption, saving 40% 50% power consumption compared to ball millSpecial structure design of grinding roller and grinding table, large diameter of grinding roller, large grinding area, hydraulic automatic pressure deviceThe advantages of the vertical roller mill include high grinding efficiency and low energy consumption For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution due to its relatively low installation cost, ease of operation and maintenance, energy savings, and good product qualityVertical roller mill DARKOHLM vertical grinding mill and vertical roller mill is a highefficiency energysaving advanced pulverizing equipment integrating drying, pulverizing, grading and conveying, which has been researched and developed by Guilin Hongcheng Company for more than 20 years Hongcheng HLM vertical grinding mill has the advantages of high grinding efficiency, low power HLM Vertical Grinding Mill Vertical Roller MillVERTIMILL® is Metso’s gravityinduced, vertical stirred mill Its vertical configuration allows for large throughputs while maintaining a small footprint in your circuit The VERTIMILL® can bring up to 40% savings in energy consumption in some cases, and helps in reaching excellent recovery rates by producing a sharper particle distributionMetso Vertimills

.jpg)

Vertical Mill Jiangsu Sailong Energy Saving Technology

The main products include: Rotary Dryer,Dust Collector,Powder Separator, Ball Mill,Vertical Mill,etc Robin: +86 13705101208 Cliff: +86 13805102308 English2023年7月4日 The column mill is a vertical mill using high speed, medium pressure, and continuous, repeated grinding It consists of the belt pulley, the gearbox high efficiency, energy saving, and convenient maintenance It is widely applied in the crushing and grinding of metal and nonmetallic ores The product particle size can be less Roller Mill SpringerLinkVertical milling machines are a popular choice for machinists due to their versatility, rigidity, and spacesaving design Here are some of the key benefits they offer: Versatility: Vertical mills can perform a wide range of operations, Maximize Efficiency: Horizontal Mill vs Vertical MillThe vertical roller mill integrates crushing, drying, grinding, and conveying +17 [ protected] environmental protection and energysaving, high classification efficiency, a wide range of finished products, high degree of automation, high reliability, convenient maintenance, low operating costs, high quality, Dolomite Ultrafine Vertical Roller Mill

EIRICH TowerMill Vertical agitated media mill

n Reduced energy consumption, from 25% to 50% savings compared with conventional mills n Longer life of grinding media and wear items n High operating availability, n The energy distribution within the vertical mill is constant for any given height and radius n These characteristics, 2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the response surface method (RSM) was employed with the VRM experiments to systematically investigate the influence of operating parameters on the energy Analysis and Optimization of Grinding Performance of Vertical 2015年3月10日 The Institute of Mineral Processing at the Montanuniversitaet Leoben in cooperation with the company CEMTEC has developed a pilot scale, 200 mm table diameter, vertical roller mill for energy controlled laboratory tests The mill provides the technical options to vary process parameters like airflow, mass flow, grinding force and classifier speed in a wide An energy based comparison of vertical roller mills and Boost recovery and energy savings with our vertical fine grinding mills Robust performance in a compact footprint Equipment Parts Services Sustainability Investors Company Equipment In a vertical fine grinding mill, material is fed from the Vertical mills for fine grinding – FLS

.jpg)

LUM Ultrafine Vertical Grinding Mill

LUM Ultrafine Vertical Grinding Mill can effectively control the product size, chemical composition and iron content, and ensure the purity and whiteness of finished materials Energysaving Economical2015年8月12日 1 high efficiency and energy saving vertical roller mill Non metallic mineral powder processing industry industrial scale and fine product level has become the measure of a national non metallic mineral industry development level of an important sign of, and high efficiency and energy saving of vertical roller mill and processing technology is key to the High efficiency and energy saving vertical roller millQuartz ultrafine vertical mill has the characteristics of stable operation, energysaving, and environmental protection, large output, intelligent and controllable +17 [ protected] language >Shibang Industry Technology Quartz Ultrafine Vertical MillEnergy Saving Motor Lpm Series Vertical Nano Ceramic Sand Mill with 6L, Find Details and Price about 6L Sand Mill Nanometer Sand Mill from Energy Saving Motor Lpm Series Vertical Nano Ceramic Sand Mill with 6L Dongguan Infor Machinery Technology Co, LtdEnergy Saving Motor Lpm Series Vertical Nano Ceramic Sand Mill

Modeling of energy consumption factors for an industrial cement

2022年5月9日 By initiating a CL for an industrial cement vertical roller mill Atmaca, A Kanoglu, M Reducing energy consumption of a raw mill in cement industry Energy 42, 261–269 (2012)Shcronus has launched the CRLM1300 vertical mill which integrates drying and grinding with high efficiency and energy saving CRLM1300 vertical mil can be widely used in cement, metallurgy chemical industry, nonmetallic ore, nonferrous metals ore powder grinding, and electric powerCRLM1300 Vertical MillVertical Roller Mill Raymond MillVertical KLM VERTICAL MILL KLM vertical mill is universally recognized as the equipment of energysaving and high efficiency The vertical mill has a reducer drive system, Replaceable WearResistent Spiral Agitator and an online monitoring control system It usually uses high chromium steel balls as grinding mediaAttrition Mills Technology and Experience Roytec GlobalCompared with the ball mill system, the energy consumption of the vertical mill system can be reduced by 30% to 40% The vertical grinding mill does not have the metal impact sound of the steel balls colliding with each other and the liner in the ball mill, so the noise is low, which is 2025dB lower than that of the ball millIndustrial Vertical Grinding Mill

.jpg)

CLUM Series Mill: EcoFriendly and EnergySaving, Leading Ultra

2024年11月12日 The CLUM Series Ultrafine Vertical Mill sets a new standard in ultrafine powder production by combining advanced ecofriendly and energysaving technology with precision engineering CLUM Series Ultrafine Vertical Grinding Mill Key Advantages: CLUM Series Ultrafine Vertical Mill 1 UltraLow Operating Cost WearResistant Alloy Material: The Energy Savings and Improved Recovery with Small Grinding Media Michel Brissette, MScA, Grinding Process 3531655 FAX: 5143531768 Email: mbrissette@waenam Key Words: Energy Savings, Small Media, Fine Grinding, Ball Mill, Vertical Stirred Mill st January 20 to 22, 2009 Ottawa, Ontario, Canada 41 Annual Meeting of the Canadian Energy Savings and Improved Recovery with Small Grinding MediaIn ball mills, energy savings vary from 10 per cent to 40 per cent compared to 25 mm media A regrind ball mill with a mix of small grinding media can be as energy effi cient as an Isa Mill charged with 25 and 35 mm beads In vertical stirred ENERGY SAVINGS AND TECHNOLOGY COMPARISON USING Material circulation inside the mill FSmidth Cement flsmidthcement 3 ATOX coal mill Proven technology Today the airswept vertical roller mill is the standard solution for coal grinding installations And thanks to our continuous refinement of the ATOX coal mill over the years, today’s leading airswept vertical roller mill is the ATOX COAL MILL