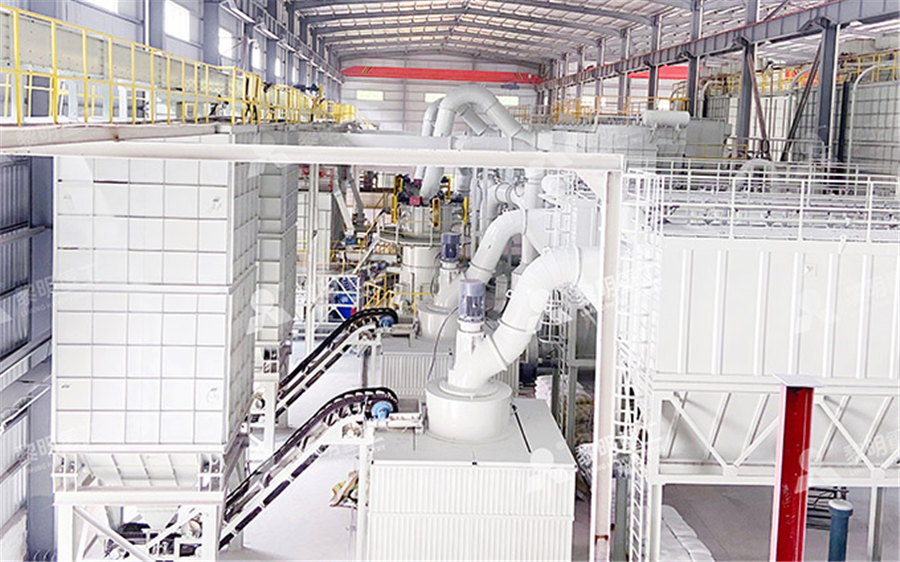

Fly ash ultrafine grinding system and equipment introduction

.jpg)

Ultrafine grinding of fly ash with grinding aids: Impact on particle

2015年3月1日 This paper presents the ultrafine grinding performance of fly ash with grinding aids (GA) and effect of GA on the particle characteristics, pozzolanic reaction degree of 2024年11月1日 Fly ash (FA) is the main combustion byproduct produced after pulverized coal is burned in coalfired furnaces at 1200–1700 °C during coalfired thermal power generation Liquidsolid grinding system: Grinding kinetics of coal fly ash as 2015年3月1日 This paper investigates the influence of mechanical grinding on pozzolanic characteristics of circulating fluidized bed fly ash (CFA) from the dissolution characteristics, Ultrafine grinding of fly ash with grinding aids: Impact on particle 2021年1月1日 This paper reviewed the milling equipment effect on particle size, surface properties, and chemical compositions of activated ash Increasing in the surface area, pozzolana activity and the(PDF) Fly ash morphology and surface modification via

制粉-10.25公众号.jpg)

State of the art review on physiochemical and engineering

The focus of this study is to critically review the physiochemical and engineering properties of the fly ash and its applications in various fields The utilization of fly ash has become a widespread 2015年3月1日 This paper presents the ultrafine grinding performance of fly ash with grinding aids (GA) and effect of GA on the particle characteristics, pozzolanic reaction degree of Ultrafine grinding of fly ash with grinding aids: Impact on particle 2020年8月1日 The study aims to understand the strength improvement and microstructural behavior of ultrafine fly ash particles through synthesis and characterization techniques by analyzing the fly(PDF) Characterisation of ultrafine fly ash as 2024年7月17日 Fly ash is dispersed throughout the grinding chamber under the influence of air currents, making direct measurement of the flow field challenging Consequently, this study resorts to numerical simulations to analyze the Effect of Nozzle Quantity on the Flow Field

Influence of the ultrafine fly ash dosages on the mechanical

2023年1月28日 To reduce the filling cost of highwater backfilling material (HWBM) in mining backfill and improve the recycling utilization of the industrial waste such as the coal fly ash Fly Ash Ultrafine Ball Mill Grinding and Classifying Production Line, Inner bypass (double casing) ash handling system Horizontal Distance:150~2500m Output(tph) :15~185t/h Price: Negotiated Port: shanghai Supporting equipment of conveying system Belt conveyor parts Large and medium sized finishing partsFly Ash Ultrafine Ball Mill Grinding and Classifying Production LineThe fly ash processing plant produced by AGICO includes a ball mill grinding system, conveying system, dust collecting system, ash classifying system and ash storing system It helps our customers realize reasonable solid waste Fly Ash Processing Plant Cement Equipment the power plant fly ash every year which make turning waste into treasureThe author studied the vertical milling machine grinding ash process, which improves the grinding efficiency, to meet the requirements of the project fly ash handling equipment Ash grinding in the country started relatively late [3], which is still relatively superficial Grinding Fly Ash Process and Equipment with Vertical Milling

Liquidsolid grinding system: Grinding kinetics of coal fly ash as

2024年11月1日 The results show that wet grinding superfine can significantly affect the strength development of fly ash ultrafine supplementary cementing material The relationships between strength activity index, uniformity coefficient, and fractal dimension are shown in Fig 10 (c) and (d), which are analyzed using the linear regression method2020年11月20日 The shrinkingcore model is originally proposed by Tomosawa [15] and later modified by Park et al [16], Maruyama [17] and Narmuluk et al [18]In this paper, Narmuluk’s modified version [18] is adopted Compared with other modified models, Narmluk considers the effects of the transport and deposition process of the hydration products (mainly CSH) on the Research on properties evolution of ultrafine fly ash and 2020年12月10日 Fly ash (FA), a byproduct of coal combustion, along with other pozzolans, is now widely adopted for use as a cement component in concrete by all the major standards, with up to 55% FA content in pozzolanic cement CEM IV 197–1:2011 [13], for exampleFA is also recognized as an ecofriendly material as its usage helps to lower the carbon footprint of the Effect of ultrafine fly ash on concrete performance and durability2019年6月1日 The optimized grinding time based on the particle size distribution results of 120 min is showing the best values The particle size contents in the range of 0–5 µm, 6–12 µm, 15–25 µm, 32–45 µm improved by 23%, 24%, 28%, 22% respectively compare to Investigation on grinding impact of fly ash particles and its

.jpg)

Effect of Fly Ash with Different Particle Size Distributions on the

2020年9月15日 Fly ash has become an important component of concrete as a supplementary cementitious material Fly ash, as an admixture in concrete, has a great impact on the improvement of concrete properties and utilization of resources In this work, fly ashes with different particle size distributions (S Tsivilis, Andersen, normal and F distributions) were 2019年2月1日 Department of Civil Engineering, Faculty of Engineering and Technology, SRM Institute of Science and Technology, Kattankulathur , Tamil Nadu, IndiaInvestigation on grinding impact of fly ash particles and its 2015年9月15日 A system dynamics model is presented by simulating five different cement lifecycle scenarios in order to quantify the net CO 2 reductions when using upgrading processes of fly ash Ultrafine grinding for the mechanical activation of FA is the UP modelled using published and direct data from the equipment manufacturerEffective carbon emission reductions from using upgraded fly ash 2024年5月25日 This study investigated the influences of ultrafine fly ash (UFA) and ultrafine slag powder (USL) on the compressive strengths, autogenous shrinkage, phase assemblage, and microstructure of magnesium potassium Influence of Ultrafine Fly Ash and Slag Powder on

.jpg)

A study on the effective utilization of ultrafine fly ash and silica

4 天之前 To improve the reactivity of fly ash, a novel ultrafine fly ash (UFFA) was produced by mechanically separating the ultrafine fractions of Class F fly ash to make fly ash highly reactive At a low replacement level of 5 %–15 % by cement weight, it shows improvement in the strength of the concrete and decreases permeability compared to regular fly ash concretes2020年7月1日 In this study, to promote the chloride binding capacity of coal fired fly ash (RFA) in cementitious materials, wet grinding was employed and ultrafine fly ash (UFA) with D50 = 21 μm was prepared Preparation of ultrafine fly ash by wet grinding and its utilization 2016年3月7日 Mechanical activation can result in improvement of bulk and surface reactivity of the material Depending on the conditions of activation process, the overall chemistry of the solid material may Mechanical activation of power station fly ash by grinding2021年8月1日 (a) Fly ash ultra fi ne grinding equipment fl ow diagram, (b) Illustration of the preparation of coreshell structured LWA 206 Y Yang et al / Journal of the Taiwan Institute of Chemical (PDF) Highly effective chromium immobilization by an ultrafine fly ash

The relevance of ultrafine fly ash properties and mechanical

2018年10月20日 The grinding process followed a procedure as, 1) confirming the tight close of the grinding chamber, starting the grinder and adjusting its rotation speed to 30 Hz, and 2) loading raw fly ashes slowly into the rotating grinding chamber from the hopper and grinding fly ash under mechanical force generated by the highspeed rotating grinding wheel, and 3) after grinding, 2020年7月15日 1 Introduction The incorporation of supplementary cementitious materials (SCMs) could improve the fresh and hardened performance of cementitious materials (Coppola et al, 2018a, Coppola et al, 2018b, Fernández et al, 2018, Hossain et al, 2018, Huang et al, 2018, Juenger and Siddique, 2015, Li et al, 2019, Li et al, 2020, Martirena and Monzó, 2018, Preparation of ultrafine fly ash by wet grinding and its utilization Brief Introduction HGM Ultra fine grinding mill (also called micro powder mill, superfine powder grinding mill, ultra fine powder grinder) is designed by SBM RD department on the basis of multiple innovations and testing It has been proved by thousands of customers that our ultra fine powder grinder has outstanding features, stable quality, easy operation, and maintenanceUltra Fine Grinding Mill SBM Ultrafine Powder TechnologyFly Ash Processing Process There are different equipment configurations and processes for grinding fly ash On the market, ultra fine ball mill grinding, Raymond mill grinding, and vertical roller mill grinding all exist SINOMA prioritizes production efficiency and the quality of finished fineness and has developed the TRM series VRM for fly ash grinding and the TRMF series for Fly Ash Processing Plant Superfine Final Product CNBMSINOMA

REVIEW ON ULTRAFINE FLY ASH CONCRETE

I INTRODUCTION Ultrafine fly ash not only increase slump and spread, but also reduce the slump loss [Li Yijin et al, 2004]4 grinding aid fly ash Compressive strength initially reduces Maximum compressive strength found 4656 MPa at 15 % RFA, 4983 MPa atMultiple fine grinding options are available for testing in our Process Development Center Our processing design engineers will help you examine, design, test, and quantify implementing the right grinding or micronizing system – either as an integral component of a larger processing system or to produce a final productFine Grinding Machines and Micronizing Equipment Bepex2023年9月15日 The original Class FI fly ash (OFA) with a d 50 of 1593 μm was used along with three UFAs produced from OFA, namely, UFA1 was prepared by separation and UFA2 via grinding (Fig 1), and UFA3 by grinding followed by separation which was set as a comparison between two preparation methods 425# ordinary PC conforming to GB1752007 and ISO Comparative study on the performance of ultrafine fly ash 2024年5月7日 Multicriteria optimization results for flyash as an additive on metakaolinbased geopolymer composites show that the optimal composition of the geopolymer matrix within the selected variation Multicriteria optimization of the composition, thermodynamic and

.jpg)

Ultrafine GGBS and Fly Ash as Cement Replacement for

2024年9月30日 For this study, the fly ash percentage was maintained at 20% for all trials, with the ultrafine GGBS percentage varying from 15% to 30% Keywords: Sustainable Concrete; Ultrafine GGBS; Fly ash 2020年12月10日 Ultrafine grinding of fly ash with grinding aids: Impact on particle characteristics of ultrafine fly ash and properties of blended cement containing ultrafine fly ash Construction and Building Materials, Volume 78, 2015, pp 250259Effect of ultrafine fly ash on concrete performance and durabilityRESEARCH ARTICLE Influence of different grinding degrees of fly ash on properties and reaction degrees of geopolymers Qingwei Sun1, Siyuan Zhao ID 1*, Xuzhe Zhao , Yu Song2, Xinyu Ban1, Ni Zhang1 1 College of Civil Engineering, Liaoning Technical University, Fuxin, China, 2 College of Civil Engineering, Guangxi Key Laboratory of Mechanics and Geotechnical Engineering, Influence of different grinding degrees of fly ash on properties 2022年2月9日 Ultrafine fly ash is used, with a top size of 10 μm and an average particle size of 2 to 4 μm (Karthik et al 2003) Ultrafine fly ash is obtained as a byproduct from burning pulverized coal in electric power generating plants (Long et al 2002) Ultrafine fly ash is usually processed from the class F fly ash source (Steve et al 2013)Effect of curing regimes on microstructural and strength

.jpg)

Effective carbon emission reductions from using upgraded fly ash

2015年9月15日 A system dynamics model is presented by simulating five different cement lifecycle scenarios in order to quantify the net CO 2 reductions when using upgrading processes of fly ash Ultrafine grinding for the mechanical activation of FA is the UP modelled using published and direct data from the equipment manufacturer A material flow analysis (MFA) was carried 2024年7月1日 Mechanical grinding can greatly relieve the agglomeration of glass particles in fly ash and improve the effective activity of fly ash The physical processing and sieving of ultrafine fly ash are presented in Fig 1The production process of ultrafine fly ash involves several key systems to ensure the fine quality and consistency of the productUsing ultrafine fly ash to achieve lowcarbon, high strength and Fly Ash Ultrafine Ball Mill Grinding and Classifying Production Line, Inner bypass (double casing) ash handling system Horizontal Distance:150~2500m Output(tph) :15~185t/h Price: Negotiated Port: shanghai Supporting equipment of conveying system Belt conveyor parts Large and medium sized finishing partsFly Ash Ultrafine Ball Mill Grinding and Classifying Production LineThe fly ash processing plant produced by AGICO includes a ball mill grinding system, conveying system, dust collecting system, ash classifying system and ash storing system It helps our customers realize reasonable solid waste Fly Ash Processing Plant Cement Equipment

.jpg)

Grinding Fly Ash Process and Equipment with Vertical Milling

the power plant fly ash every year which make turning waste into treasureThe author studied the vertical milling machine grinding ash process, which improves the grinding efficiency, to meet the requirements of the project fly ash handling equipment Ash grinding in the country started relatively late [3], which is still relatively superficial 2024年11月1日 The results show that wet grinding superfine can significantly affect the strength development of fly ash ultrafine supplementary cementing material The relationships between strength activity index, uniformity coefficient, and fractal dimension are shown in Fig 10 (c) and (d), which are analyzed using the linear regression methodLiquidsolid grinding system: Grinding kinetics of coal fly ash as 2020年11月20日 The shrinkingcore model is originally proposed by Tomosawa [15] and later modified by Park et al [16], Maruyama [17] and Narmuluk et al [18]In this paper, Narmuluk’s modified version [18] is adopted Compared with other modified models, Narmluk considers the effects of the transport and deposition process of the hydration products (mainly CSH) on the Research on properties evolution of ultrafine fly ash and 2020年12月10日 Fly ash (FA), a byproduct of coal combustion, along with other pozzolans, is now widely adopted for use as a cement component in concrete by all the major standards, with up to 55% FA content in pozzolanic cement CEM IV 197–1:2011 [13], for exampleFA is also recognized as an ecofriendly material as its usage helps to lower the carbon footprint of the Effect of ultrafine fly ash on concrete performance and durability

Investigation on grinding impact of fly ash particles and its

2019年6月1日 The optimized grinding time based on the particle size distribution results of 120 min is showing the best values The particle size contents in the range of 0–5 µm, 6–12 µm, 15–25 µm, 32–45 µm improved by 23%, 24%, 28%, 22% respectively compare to 2020年9月15日 Fly ash has become an important component of concrete as a supplementary cementitious material Fly ash, as an admixture in concrete, has a great impact on the improvement of concrete properties and utilization of resources In this work, fly ashes with different particle size distributions (S Tsivilis, Andersen, normal and F distributions) were Effect of Fly Ash with Different Particle Size Distributions on the 2019年2月1日 Department of Civil Engineering, Faculty of Engineering and Technology, SRM Institute of Science and Technology, Kattankulathur , Tamil Nadu, IndiaInvestigation on grinding impact of fly ash particles and its