Energysaving measures for industrial grinding machine manufacturers

.jpg)

Energy efficiency of stateoftheart grinding processes

2018年1月1日 Specific energy consumption was determined as a function of material removal rate and compared to results of milling and turning processes The key influence factors on 2013年1月1日 The paper presents an overview of energy efficiency approaches, focusing in both production and machine tool level and how these two can be integrated together Energy Efficient Manufacturing from Machine Tools to 2023年2月2日 These studies aim to find machining parameters that can reduce energy on the one hand (37% of researchers), including SEC, SCE, net cutting energy (NSCE), active Optimization techniques for energy efficiency in machining 2021年8月31日 In this paper, we shall examine the review of energy consumption by machine tools and energy minimisation strategies in the manufacturing process The aim is to review the existing stateoftheart A review of energy consumption and minimisation

.jpg)

Energy consumption model and energy efficiency

2017年6月15日 The case study shows that the proposed energy consumption model can provide fundamental support for energy consumption forecasting, energy efficiency analysis and energysaving optimisation during the machine 2013年8月25日 There are effective ways to reduce energy consumption of machine tools such as reducing required energy, shutting down the power to standby equipment, and shortening Energyefficient manufacturing on machine tools by machining 2024年3月11日 The carbon footprint associated with energyintensive grinding operations underscores the need for sustainable alternatives and more energyefficient practices in the Application of sustainable techniques in grinding process for 2020年7月1日 This keynote paper provides an overview of current machine and processrelated measures to improve the energy efficiency of metal cutting machine tools Based on an analysis of the(PDF) Energy efficient machine tools ResearchGate

.jpg)

Energy Prediction Models and Distributed Analysis of

2023年8月14日 Duflou et al introduced energyefficient decisionmaking technologies for energy saving from a unit process focus: multimachine, factory, multifacility, and supply chain levels The energy evaluation results and 2020年10月1日 VOMAT systems on the other hand adapt to the production process If, for example, the grinding machine runs at a slower speed, only the required amount of coolant is filtered If a VOMAT central system provides Creating Optimal Conditions with ResourceSaving 2024年11月19日 Shenyang Machine Tool, established in 1993 with roots tracing back to 1933, stands as a pillar in China’s machine tool industry Listed on the Shenzhen Stock Exchange (stock code: ), the company emerged from The 10 Best Grinding Machine Manufacturers Brands2013年3月1日 Processes like grinding, transport of materials and crushing utilize machine drives and account for the majority of electricity consumption, as is evident in the result of the Manufacturing Energy Consumption Survey (MECS) in 1998 presented in Fig 3Process heating, by which clinker is made in large kilns, accounts for about 90% of the natural gas consumption An overview of energy savings measures for cement industries

Energy efficiency of manufacturing systems: A review of energy

2019年12月10日 Energy efficiency represents an important measure for mitigating the environmental impacts of manufacturing processes, and it is the first step towards the implementation of sustainable production (IPCC, 2018)Additionally, from the companies’ points of view, energy efficiency is becoming an important theme in production management due to 2022年1月18日 We discuss energy saving tips for manufacturers in this post This will ensure that motor energy for a particular process or machine is used optimally From this, you may see energy savings anywhere According to the US Department of Energy, repairing leaks in an industrial steam distribution system will lead to 5–10 Energy saving tips for manufacturers Business Energy QuotesBelow, we’ve compiled our top energysaving tips for manufacturing plants into two main strategies: reducing energy consumption and optimizing energy usage Strategy #1: Reduce energy consumption Decreasing the amount of lost energy in your electrical systems is key to cutting energy consumption8 Proven EnergySaving Tips for Manufacturing PlantsThe grinding mill has a small length to diameter ratio, poor wear resistance, long grinding time, and low work efficiency The working efficiency of the cement separator is low so that the micro powder with particle size between 3 and 32μm can’t be separated Energy Saving Measures of Cement Grinding Plant Select energysaving cement millMaking Your Cement Grinding Plant Energy Saving Cement Grinding

An overview of energy savings measures for cement industries

2013年3月1日 Request PDF An overview of energy savings measures for cement industries Due the advances in the industrial processes, in which the cement industry is a major contributor, energy consumption 2023年2月2日 Metal working process is one of the main activities in mechanical manufacturing industry; it is considered as a major consumer of energy and natural resources In material removal process, the selection of cutting parameters and cooling or cutting liquid is necessary to save energy and achieve energy efficiency as well as sustainability During the last two Optimization techniques for energy efficiency in machining In today’s industrial environment, energy efficiency become a pivotal factor for manufacturing facilities aiming to Map out all the major energyconsuming systems in your facility, such as HVAC, lighting, machinery, and compressed which serves as a reference point for measuring the impact of future energysaving measures and 9 Efficient Energy Tips for Manufacturing Facilities BECIS2022年1月1日 Significant effort has been devoted in recent literature to cre ate datadriven models for industrial energy savings A recent survey on industrial datadriven energy savings can be found in [5] The survey presents an interesting analysis on the current situation on the topic and provide guidelinesEnergy monitoring of manufacturing plants: a real case application

(PDF) Methods of EnergySaving Measures

PDF On Jan 1, 2021, Shalini Aggarwal and others published Methods of EnergySaving Measures Find, read and cite all the research you need on ResearchGate x BUREAU OF ENERGY EFFICIENCY Table 11 Different categories of industries covered under the EC Guidelines 1 Table 41 Components of standards 6 Table 42 Details of equipment under CategoryA industries 6 Table 61 Air ratios for boilers 11 Table 62 Air ratio for industrial furnaces 12 Table 81 Flue gas temperature of boilers 19 Table 82 Waste heat recovery for ENERGY CONSERVATION GUIDELINES Bureau of Energy Efficiency2014年12月31日 Energy efficiency has developed into an important objective for industrial enterprises However, there is still a need for systematic approaches to reduce energy consumption in factories(PDF) An Approach for Reducing Energy Consumption in Factories Both energy efficiency and energy conservation are important to saving energy While different plants can save energy through oneoff conservation and efficiency efforts, we recommend developing an energy management system The DOE’s approach to energy management is aligned with the ISO 50001:2018 Energy Management StandardSaving Energy: A QuickStart Guide for Small to Medium Manufacturers

.jpg)

WALTER INFO 1/2023 ENERGY SAVING

valves optimize the coolant supply in an energysaving manner 3 LED machine light We use energysaving LED machine lights in all machines The machine status light also uses LED technology In addition to the energy saving during operation with practically no heating of the light, the LED technology guarantees a long service life of the valves optimize the coolant supply in an energysaving manner 3 LED machine light We use energysaving LED machine lights in all machines The machine status light also uses LED technology In addition to the energy saving during operation with practically no heating of the light, the LED technology guarantees a long service life of the WALTER INFO 1/2023 ENERGY SAVING2024年8月25日 Table 1 summarizes the papers that provide quantitative data, with the majority following the approach of utilizing ANNs for learning to build models These models then offer predictive data for facilitating energysaving control and management in factories The aspects of energy management include providing optimized startstop times, scheduling control, and Universal artificial intelligence workflow for factory energy saving 2020年1月19日 Why Energy Saving Is Important For Any Business Energy saving is essential for many reasons, chief among them: Energy saving is excellent for your bottom line Understanding how and where the power that you use is spent helps you to reign in production costs and remain competitive As one of the most significant expenses, this can make or Energy Saving Tips for Manufacturers, Industries, And Business

.jpg)

Energy Saving: A Quick Start Guide for Small and Medium Manufacturers

More than onethird of the energy consumed in the United States (more than $200 billion a year) is used to power our manufacturing plants and industrial factories Saving energy can lead to cost savings and strengthen the company’s manufacturing competitiveness2011年3月19日 Due to environmental legislation and increasing customer demand, the development and deployment of energyrelated improvement measures for machine tools has intensifiedEnergy Efficiency Measures for the Design and Operation of Machine 2015年8月1日 Request PDF Towards greener machine tools – A review on energy saving strategies and technologies The imbalance between energy supply and demand is expected to keep increasing, with the Towards greener machine tools – A review on energy saving Browse through 316 Manufacturer producer in the grinding machines industry on Makenas Grain Milling Technology is a turnkey flour, semolina, maize, and steel silo plants milling machines manufacturer from Turkey We are a dynamic and expanding company with energy, transportation and industrial user industries Our range of Manufacturer producer grinding machines Europages

.jpg)

Energy conservation and consumption reduction in grinding

2023年11月1日 Grinding operation is the last preparation stage before beneficiation In this stage, the material undergoes the combined action of impact and grinding, so that the ore particle size is diminished and the qualified materials is provided for succeeding beneficiation operations [1, 2]Generally, the quality of the grinding product is also an important factor to determine the 2015年2月20日 Manufacturers can monitor a machine’s energy use themselves, either through systems embedded in a machine’s control system or by using external tools Beckhoff Automation’s EtherCAT I/O system and TwinCAT PCbased control software integrate power monitoring into the same system used for machine control, motion control and moreA Guide to EnergyEfficient Machine Decisions Automation Worldvalves optimize the coolant supply in an energysaving manner 3 LED machine light We use energysaving LED machine lights in all machines The machine status light also uses LED technology In addition to the energy saving during operation with practically no heating of the light, the LED technology guarantees a long service life of the WALTER INFO 1/2023 ENERGY SAVING2024年11月23日 MAZAK is a wellknown manufacturer of machine tools worldwide, established in 1919 The company specializes in a wide range of CNCrelated products, including lathes, lathemill cutting centers, vertical and horizontal machining centers, CNC laser systems, FMS flexible production systems, CAD/CAM systems, CNC devices, and production support softwareTop 10 CNC Machine Manufacturers (Source: CCID Consulting)

.jpg)

Saving Energy: A QuickStart Guide for Small to Medium Manufacturers

Both energy efficiency and energy conservation are important to saving energy While different plants can save energy through oneoff conservation and efficiency efforts, we recommend developing an energy management system The DOE’s approach to energy management is aligned with the ISO 50001:2018 Energy Management Standardvalves optimize the coolant supply in an energysaving manner 3 LED machine light We use energysaving LED machine lights in all machines The machine status light also uses LED technology In addition to the energy saving during operation with practically no heating of the light, the LED technology guarantees a long service life of the WALTER INFO 1/2023 ENERGY SAVING2023年10月2日 Instead, the use of renewable energy in manufacturing can help reduce a factory’s carbon footprint and can increase a manufacturer’s energy resilience Energy resilience is the degree to which an organisation can maintain operations through energy shocks Manufacturers can increase their energy resilience by diversifying their sources of Energy Efficiency in Manufacturing: A Complete Guide Mavarick2020年10月1日 VOMAT systems on the other hand adapt to the production process If, for example, the grinding machine runs at a slower speed, only the required amount of coolant is filtered If a VOMAT central system provides Creating Optimal Conditions with ResourceSaving

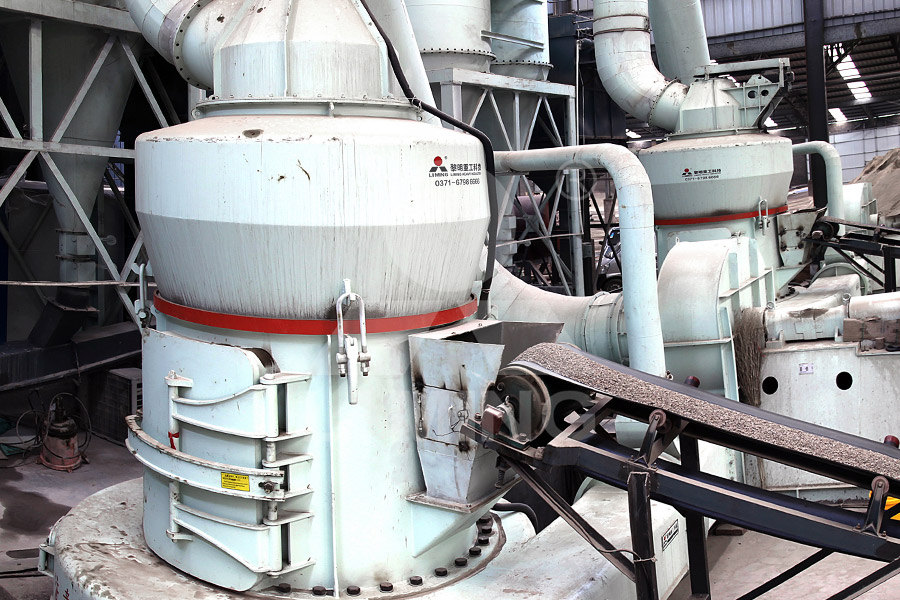

The 10 Best Grinding Machine Manufacturers Brands

2024年11月19日 Shenyang Machine Tool, established in 1993 with roots tracing back to 1933, stands as a pillar in China’s machine tool industry Listed on the Shenzhen Stock Exchange (stock code: ), the company emerged from 2013年3月1日 Processes like grinding, transport of materials and crushing utilize machine drives and account for the majority of electricity consumption, as is evident in the result of the Manufacturing Energy Consumption Survey (MECS) in 1998 presented in Fig 3Process heating, by which clinker is made in large kilns, accounts for about 90% of the natural gas consumption An overview of energy savings measures for cement industries2019年12月10日 Energy efficiency represents an important measure for mitigating the environmental impacts of manufacturing processes, and it is the first step towards the implementation of sustainable production (IPCC, 2018)Additionally, from the companies’ points of view, energy efficiency is becoming an important theme in production management due to Energy efficiency of manufacturing systems: A review of energy 2022年1月18日 We discuss energy saving tips for manufacturers in this post This will ensure that motor energy for a particular process or machine is used optimally From this, you may see energy savings anywhere According to the US Department of Energy, repairing leaks in an industrial steam distribution system will lead to 5–10 Energy saving tips for manufacturers Business Energy Quotes

8 Proven EnergySaving Tips for Manufacturing Plants

Below, we’ve compiled our top energysaving tips for manufacturing plants into two main strategies: reducing energy consumption and optimizing energy usage Strategy #1: Reduce energy consumption Decreasing the amount of lost energy in your electrical systems is key to cutting energy consumptionThe grinding mill has a small length to diameter ratio, poor wear resistance, long grinding time, and low work efficiency The working efficiency of the cement separator is low so that the micro powder with particle size between 3 and 32μm can’t be separated Energy Saving Measures of Cement Grinding Plant Select energysaving cement millMaking Your Cement Grinding Plant Energy Saving Cement Grinding 2013年3月1日 Request PDF An overview of energy savings measures for cement industries Due the advances in the industrial processes, in which the cement industry is a major contributor, energy consumption An overview of energy savings measures for cement industries2023年2月2日 Metal working process is one of the main activities in mechanical manufacturing industry; it is considered as a major consumer of energy and natural resources In material removal process, the selection of cutting parameters and cooling or cutting liquid is necessary to save energy and achieve energy efficiency as well as sustainability During the last two Optimization techniques for energy efficiency in machining

9 Efficient Energy Tips for Manufacturing Facilities BECIS

In today’s industrial environment, energy efficiency become a pivotal factor for manufacturing facilities aiming to Map out all the major energyconsuming systems in your facility, such as HVAC, lighting, machinery, and compressed which serves as a reference point for measuring the impact of future energysaving measures and