How much is a coal slag grinding machine

Wholesale Slag Grinding Machine MadeinChina

Enhance your Mining Mill setup with our premium Wholesale Slag Grinding MachineWholesale purchases of mining mills provide cost savings due to bulk ordering, streamlined procurement processes, and potentially discounted pricesVertical coal mill, also known as vertical roller coal mill or vertical coal grinding mill, is a mechanical equipment for crushing and grinding coal into coal power Mainly used for grinding coal grinding machine CHAENGChina Slag Grinding Machine wholesale Select 2024 high quality Slag Grinding Machine products in best price from certified Chinese Machine Machinery manufacturers, Machine China Slag Grinding Machine, Slag Grinding Machine Madein Find the right mine mill from Alibaba Explore our mining equipment to find the ideal wholesale slag grinding machine model and mills for any mining challengeSimple Ore Extraction: Choose A Wholesale slag grinding machine

Coal Testing Equipment Gilson Co

Capacity is up to six 8oz (237ml) sample jars and also meets ASTM D2013 test standard Our lab coke coal testing equipment include crushers, grinders, splitters mixers are used for The LM vertical grinding machine, also known as a vertical mill, is a type of equipment commonly used for preparing slag, powdered coal, and silicate cement This machine is known for its Equipment for preparing slag/powdered coal silicate cement LM GREATWALL MACHINERY CORPORATION Slag Grinding Plant CHAENG can undertake EPC turnkey services for slag / steel slag / nickel slag / manganese slag powder production line slag grinding plant+CHAENG Xinxiang Great Wall Machinery Co, GGBS or slag and specialized additives are stored using highly efficient material handling equipment like stacker, recalimer, apron, feeder, bucket elevator, conveyors, weightier and Slag Grinding Plant Manufacturers NT Engitech

.jpg)

Price Guide: Grinding Machines MachineTools

Historical Prices The prices listed in this guide are asking prices and do not reflect the price in which the item was sold for or the item's retail value Click here to see machines that are FOR of granulated blastfurnace slag and pozzolans presents extra challenges to the grinding process A careful assessment of grinding options available is key to efficient grinding operations n by Frank Benavides and Russell Reimer, PEC Consulting Group LLC, USA GRINDING 1 SEPTEMBER 2022 INTERNATIONAL CEMENT REVIEW T he increasing pressure to useGRINDING Grinding options for slag and pozzolan PEC 2019年10月11日 AGICO Cement is a cement grinding plant manufacturer, we'd like to helps you learn more about cement grinding plant and cement grinding machines Skip to content +86 s How Much Do You Know About Cement Grinding 2008年3月3日 Grinding slag for cement replacement requires only about 25% of the energy needed to manufacture normal Portland cement The machine, with a boom length of 23m, will produce a stockpile height up to 12m allowing a large quantity of material to be stored with the minimum of machine movementsEfficient and reliable handling of GBFS and GGBFS at grinding

.jpg)

Effects of Mechanical Activation on Physical and Chemical

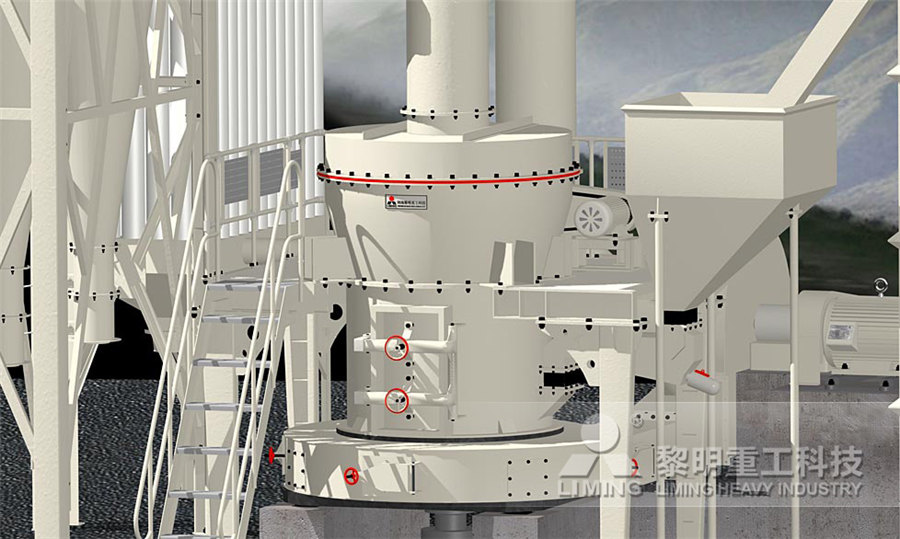

Coatings 2021, 11, 902 3 of 16 Table 1 Composition of Coalgasification Slag and Cement Composition SiO2 Al2O3 CaO Fe2O3 MgO Na2O K2O P2O5 SO3 Other LOI CGS 4875 2005 1069 967 284 165 211 Equipment for preparing slag/powdered coal silicate cement LM vertical grinding machine The LM vertical grinding machine, also known as a vertical mill, is a type of equipment commonly used for preparing slag, powdered coal, and silicate cement This machine is known for its efficiency, reliability, and costeffectiveness in the grinding Equipment for preparing slag/powdered coal silicate cement LM 2020年1月30日 In a newer way to get rid of the “slag”, Timesavers has introduced its Hammerhead Slag GrinderThe innovative approach to grinding metal involves tiny pins that rotate in the opposite direction of the metal being fed into the machine, which allows for the pins to hit and remove any excess metal that does not belong to the main partWhat is Slag Grinding? — Carlson Fabrication Solutions2022年2月26日 Blast furnace slag can be processed into the following materials by various processes In China, blast furnace slag is usually processed into water slag, slag gravel, expanded slag and slag beadsWater slag is the process of putting the hotmelt blast furnace slag into water for rapid cooling, which mainly includes slag pool water quenching or furnace front What is Blast Furnace Slag and How to Process It?

The Carbon Cost of Slag Production in the Blast Furnace: A

2016年2月5日 The quality of raw materials (iron ore, coal, and coke) has a clear impact on the carbon emissions of the hot metal production in steel making So far, very little work has been done to measure and quantify this impact Yet for benchmarking, technology choice and general carbon optimization are important elements The total slag production of a blast furnace gives 2021年11月23日 This is a small grinder operated with electric power It can be easily carried anywhere Grinding can be done by holding it in hand It is used for cleaning heavy welding jobs On one end of the motor shaft, a grinding wheel is fitted and on the other end, a handle or switch for operating the machine is fixed according to our convenience14 Types of Grinding Machines [Working, Diagram PDF] The Light grinding noises after the exchange of the coals are normal they must first "grind in" The grinding noises should not be heard after 3 4 machine loads Tips Tricks With many machines, you can easily change the coals yourself however, a check of the engine for any other errors can often only be carried out by a specialistWashing machine change coals when, how and why?and granulated blast furnace slag The MPS technology, however, is also applied in numerous installations simultaneously size for hard coal grinding at a steelworks with a throughput of 60tph at 175 per cent R0090mm In Ukraine, the erection of an MPS 200COAL GRINDING IMPS: more than meets the eye Gebr Pfeiffer

Black Beauty Blasting Media Coal Slag Midvale Industries

This coal slag leads the industry for quality and performance for abrasive blasting It removes paint, rust, and comes in a variety of sizes to reach various mil profiles and SSPCSP finishes Black Beauty is an economical abrasive that works as a good alternative to silica and river sand2020年5月14日 Before you send inquiry Please provide us with project information as much as possible: For a complete project: the material availability, the required output capacity, the process technology, your budgetary and How Much Does It Cost To Start A Cement Plant?2019年9月27日 AGICO offers cement making machines including cement mill, rotary kiln, cement crusher, cyclone preheater, cement dryer, clinker cooler etc any need? Skip to content +86 Cement Euipment Overview Cement Making Machines Cement 2021年5月5日 Because the abrasives are placed on the surface to do the finishing process with much more accuracy The grinding machine is widely used to finish the workpiece Do you know why? Because the work removal rate is low between 025 to 05 mmGrinding Machine: Definition, Parts, Working Principle, Operation

coal grinding machine CHAENG

Characteristics 1 High efficiency and large output GRMC series coal vertical grinding mill has higher working efficiency Compared with the same type of old vertical mill, the output increases by 2050%, and can greatly reduce the operation power consumption of the coal mill;Jijiug More than 216 Grinding Machines for sale Price starting from USh 55,000 in Uganda choose and buy today! Make betterGrinding Machines in Uganda for sale Price on Jijiug"Concrete mixed with coal slag has good water retention, plasticity, less bleeding, which means only highquality product can bring me more money This Raymond grinding line did bring me considerable profit" 300 kiloton/annually coal slag grinding plant Yes! I'm interested 3 Quartz stone grinding plant in PakistanHighefficient Raymond Mill Fote MachineryIntroduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring millVertical Grinding Mill (Coal Pulverizer) Explained saVRee

Great Charcoal Powder Mixer For Grinding In Coal Line

2024年7月9日 Charcoal powder mixer (also known as wheel mill, charcoal mixer machine, charcoal powder grinding machine) is used for mixing and pressurizing charcoal powder, necessary in the coal processing plant It can handle charcoal powder with a capacity of 0310t/h You can choose suitable output to meet your charcoal making line demands2020年4月3日 Slag grinding mill is popular used in steel slag, slag, coal mines, thermal power plants, Calcium Carbonate Ultrafine Grinding Machine, Fineness 800 Mesh D97 Sep 16, 2020How Much Is the Vertical Slag Grinding Mill2021年7月1日 Pan et al [31] used a thermogravimetric analyser to study the gas release laws of fine slag and raw coal during pyrolysis The fine slag from coal–water slurry gasification and the fine slag from pulverized coal gasification followed different pyrolysis rules due to different functional group structures after undergoing different reactionsReview of the characteristics and graded utilisation of coal Price Guide: Grinding Machines Historical Prices The prices listed in this guide are asking prices and do not reflect the price in which the item was sold for or the item's retail valuePrice Guide: Grinding Machines MachineTools

How to Process Coal into Pulverized Coal in 5 Steps?

2024年1月11日 With a vertical roller mill (VRM) VRMs consist of a rotating table or bowl and rollers 1 To grind the coal, feed raw or initially crushed coal into the mill which is then ground between the rotating components; 2 Finally, hot air removes moisture, carries the pulverized coal out, and a classifier segregates the particles; Here is all you need to know about the VRM:Slag Grinding GE Machinery is a supplier for timesaving machine solutions for radiussing and metal finishing across the UK and Ireland GE Machinery – Deburring and Metal Finishing Machinery 0333 242 0424 Slag Grinding GE Machinery Applications for metal finishing2024年1月27日 How Much Power Does a Grinding Machine Require? Power requirements for different types of grinding machines vary: Manual Bench Grinders: Typically require between 250 – 750 watts Surface Grinders: Range from 2,000 to 5,000 watts, depending on sizeWhat is a Grinding Machine: Definition, Types, Components2024年4月1日 Coal gasification technology has led to a significant increase in CGS discharge and consequently, the disposal of gasified solid waste gasification slag has become a major concern [10]It is reported that, more than 70 million tons of CGS is produced every year in China [11]Only a very small part of the slag is used, while the vast majority of CGS is simply Modification and resource utilization of coal gasification slag

.jpg)

What Type Of Coal Gangue Grinding Mill Machine Is Suitable For Grinding

What kind of machine is suitable for grinding coal gangue into powder? This is a widely concerned issue for customers who want to recycle and reuse coal gangue Coal gangue is one of the common industrial solid waste, with a large storage capacity, which urgently needs to expand the scope of reuse Grinding coal gangue into powder has become a powerful wayCoal grinding operation is monitored for following parameters to ensure objectivity and economy of operation Product fineness (Residues) on 90micron and 200micron sieves Feed moisture, % and Product moisture, % Production rate, tonnes/hour Specific power Coal Grinding Cement Plant OptimizationIn PC combustion, the coal is dried and is ground to a specified fineness, with a maximum particle size of 250–300 μm, depending on the reactivity of the coal Coal preparation, which involves feeding, drying, and grinding of the coal, and the pneumatic transport of the pulverized coal to the burners, is fully integrated with the boilerPulverised Coal Combustion an overview ScienceDirect Topicsof granulated blastfurnace slag and pozzolans presents extra challenges to the grinding process A careful assessment of grinding options available is key to efficient grinding operations n by Frank Benavides and Russell Reimer, PEC Consulting Group LLC, USA GRINDING 1 SEPTEMBER 2022 INTERNATIONAL CEMENT REVIEW T he increasing pressure to useGRINDING Grinding options for slag and pozzolan PEC

.jpg)

How Much Do You Know About Cement Grinding

2019年10月11日 AGICO Cement is a cement grinding plant manufacturer, we'd like to helps you learn more about cement grinding plant and cement grinding machines Skip to content +86 s 2008年3月3日 Grinding slag for cement replacement requires only about 25% of the energy needed to manufacture normal Portland cement The machine, with a boom length of 23m, will produce a stockpile height up to 12m allowing a large quantity of material to be stored with the minimum of machine movementsEfficient and reliable handling of GBFS and GGBFS at grinding Coatings 2021, 11, 902 3 of 16 Table 1 Composition of Coalgasification Slag and Cement Composition SiO2 Al2O3 CaO Fe2O3 MgO Na2O K2O P2O5 SO3 Other LOI CGS 4875 2005 1069 967 284 165 211 Effects of Mechanical Activation on Physical and Chemical Equipment for preparing slag/powdered coal silicate cement LM vertical grinding machine The LM vertical grinding machine, also known as a vertical mill, is a type of equipment commonly used for preparing slag, powdered coal, and silicate cement This machine is known for its efficiency, reliability, and costeffectiveness in the grinding Equipment for preparing slag/powdered coal silicate cement LM

.jpg)

What is Slag Grinding? — Carlson Fabrication Solutions

2020年1月30日 In a newer way to get rid of the “slag”, Timesavers has introduced its Hammerhead Slag GrinderThe innovative approach to grinding metal involves tiny pins that rotate in the opposite direction of the metal being fed into the machine, which allows for the pins to hit and remove any excess metal that does not belong to the main part2022年2月26日 Blast furnace slag can be processed into the following materials by various processes In China, blast furnace slag is usually processed into water slag, slag gravel, expanded slag and slag beadsWater slag is the process of putting the hotmelt blast furnace slag into water for rapid cooling, which mainly includes slag pool water quenching or furnace front What is Blast Furnace Slag and How to Process It?2016年2月5日 The quality of raw materials (iron ore, coal, and coke) has a clear impact on the carbon emissions of the hot metal production in steel making So far, very little work has been done to measure and quantify this impact Yet for benchmarking, technology choice and general carbon optimization are important elements The total slag production of a blast furnace gives The Carbon Cost of Slag Production in the Blast Furnace: A2021年11月23日 This is a small grinder operated with electric power It can be easily carried anywhere Grinding can be done by holding it in hand It is used for cleaning heavy welding jobs On one end of the motor shaft, a grinding wheel is fitted and on the other end, a handle or switch for operating the machine is fixed according to our convenience14 Types of Grinding Machines [Working, Diagram PDF] The

-2.jpg)

Washing machine change coals when, how and why?

Light grinding noises after the exchange of the coals are normal they must first "grind in" The grinding noises should not be heard after 3 4 machine loads Tips Tricks With many machines, you can easily change the coals yourself however, a check of the engine for any other errors can often only be carried out by a specialist