What brand of kaolin processing equipment is good

.jpg)

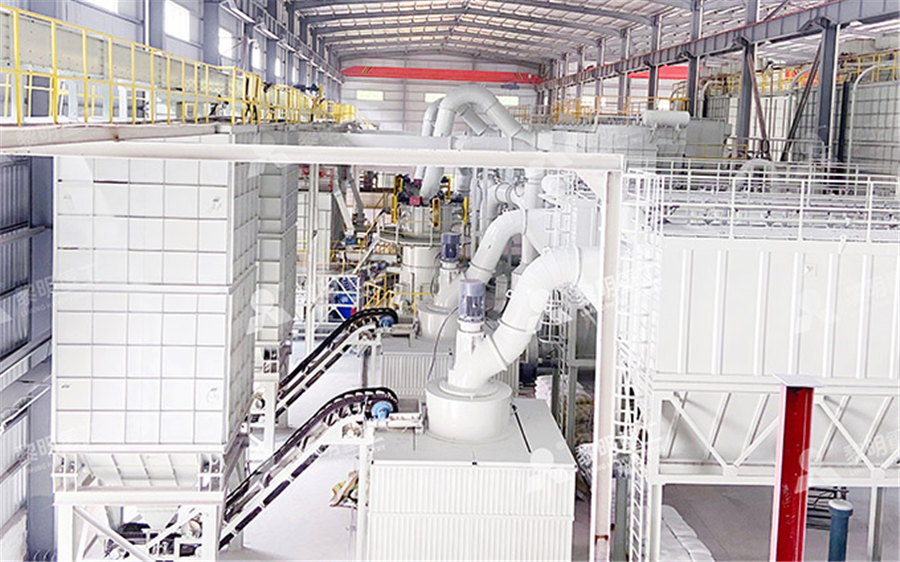

Kaolin Processing Plant MachinerySBM Industrial Technology Group

2023年1月3日 The choice of kaolin processing plant machinery means a lot to the production efficiency of the whole production line As a professional manufacturer, SBM has good reputation in China and abroad If you want to know more about the kaolin processing plant machinery, 2022年8月10日 Kaolin Clay Milling Process Choose the main machine according to the output and powder fineness requirements: below 325 mesh, you can choose a Raymond mill; 1502500 mesh can choose an ultrafine grinding Kaolin grinding production line and equipment selectionKaolin processing equipment The crushing process can be constructed by Jaw Crusher, Vibrating Feeder, Vibrating Screen, and Belt Conveyor Jaw Crusher could be changed through Cone Kaolin crushing and grinding process equipment, kaolin ball millKaolin processing equipment helps grind kaolin to a suitable particle size This controls low and high shear viscosities of adhesives Kaolin products are widely used in cosmetology because of their fine size particles, which makes them Kaolin making equipment Making

Advanced kaolin grinding production line equipment: Elevating

The advanced kaolin grinding production line equipment represents a significant leap forward in the processing of this valuable mineral By offering a combination of high efficiency, precision, 2019年8月23日 Kaolin is widely used in ceramics, paper, rubber, plastics and refractory industries due to its excellent processabilities such as plasticity, cohesiveness, sinterability and fire resistance There are three main types of Kaolinite Processing Equipment, Process Flow, CasesHosokawa Micron offers excellent processing solutions for drying and mixing kaolin, for example for the production of fillers, pigments, ceramic products, concrete additives or pharmaceutical PROCESS SYSTEMS FOR KAOLIN POWDER Hosokawa Micron BVKaolin (china clay, kaolinite) processing and beneficiation can obtain highpurity products, increase the quality and utilization of minerals, and meet some high valueadded market applications Maximize kaolin grade and recovery rate; Kaolin Processing plant JXSC Machinery

Kaolin Grinding Mill Powder Making Machine

Noncoalbearing kaolin (soft clay and sandy clay), mainly used in paper coatings and ceramic industry 1, Raymond Mill: Raymond Mill is low investment costs, high capacity, low energy 2021年11月17日 Dry grinding is mostly used for ultrafine grinding of hard kaolin or kaolin, especially for directly processing kaolin into ultrafine powder that can meet user requirements At present, the product fineness that can be Ultrafine grinding of kaolin ALPA Powder EquipmentAbout Kaolin Clay Kaolin, also known as kaolinite or ceramic clay, is a mineral primarily extracted from kaolinite oreIt is named after the hill in China (Kaoling) from which it was mined for centuries Kaolin contains primarily aluminum Kaolin (Kaolinite) Processing JXSC Mineralkaolin is fed into rotary driers and then into airfloating equipment The latter usually consists of a pulverizing unit and an air separator The fine particles are transported to collecting chambers and the coarse particles are fed back into the pulverizer Dry processing yields a INDUSTRIAL APPLICATIONS OF KAOLIN Springer

.jpg)

1125 Clay Processing US EPA

bentonite processing, SCC 305045 for fuller’s earth processing, and SCC 305046 for common clay and shale processing Clays are categorized into six groups by the U S Bureau Of Mines The categories are kaolin, ball clay, fire clay, bentonite, fuller’s earth, and common clay and shale Kaolin, or china clay,2019年8月23日 The wet process includes three stages of ore preparation, ore beneficiation processing and product processing The beneficiation stage may include hydraulic grading, flotation, selective flocculation, magnetic separation, chemical treatment (bleaching), etc to remove different impurities The prepared slurry pulp is first desanded by the rake type Kaolinite Processing Equipment, Process Flow, Cases JXSC 2024年11月21日 This is a complete kaolin processing plant, including a feeder, belt conveyor, spiral washer, attrition scrubber, trommel screen, wheel washer, dewatering screen, hydrocyclone, thickener, and filter press Flowchart Explanation Of Kaolinite clay processing plant Use a forklift or excavator to feed the raw materials to the hopper, through an Kaolinite Clay Beneficiation Process: Kaolin Processing2023年9月28日 6 Laboratory flotation machine: (silica sand) The XFD flotation machine has wide applications in mines and laboratory flotation machines for flotation experiments Production practice has shown that this flotation machine has a reasonable structure, stable operation, reliable operation, and performance that meets the advanced level of foreign flotation machinesLab Kaolin Separating Purification Equipment And Process

Kaolin making equipment Making

It can treat diarrhea, mouth sore, ulcers, and also helps in tablets productionControlling the level of viscosity is a problem in the adhesive industry, but including kaolin during production with an enclosed mixing system for adhesives can help you with thatKaolin processing equipment helps grind kaolin to a suitable particle size2020年4月14日 A new largescale suspension calcination process and key equipment suitable for dehydration and calcination of kaolin clay are introduced The pretreatment process can be designed to meet various raw materials with different moisture contents, and the burning system has high heat transfer efficiency with a fivestage cyclone preheater, a suspension calciner Research and Design of Suspension Calcining Technology and Equipment Phrase one: raw material crushing Kaolin blocks will be crushed to 15mm50mm fineness by crusher Phrase two: grinding Crushed Kaolin material will be sent to the storage hopper by the elevator and then the feeder will send the material to the main mill for grinding Phrase three: powder classifying Ground material will be classified, coarse powder will fall back to the main Kaolin Grinding Mill Powder Making MachineOne of the process stages of kaolin clay processing to alumina is solidliquid separation process after HCl leaching with subsequent washing of silica residue Our laboratory studies have shown that of existing equipment most efficiently for this task pressure filterStudy of Filtration and Washing of Residue After HCL Leaching of Kaolin

.jpg)

Kaolin Imerys

Kaolin is a rock from which the clay mineral kaolinite is derived This one has been used for millennia as the principal ingredient in porcelain tableware Today Imerys kaolins bring critical properties to a host of end applications ranging 2021年8月27日 Kaolin is the deposit of naturally occurring minerals containing hydrated aluminum silicates Widely known as white clay or china clay, these minerals have desirable properties crucial for industrial and commercial All Steps in Kaolin Production Mining and The plant equipment consists mainly of: Mining equipment, crusher, roller with classifier, attritioning cells, hydrocyclones, thickener, bleaching equipment, filter press, dryerpulverizer, bagging If kaolin is heated to 800ºC, an intermediate product is formed called MetakaolinKaolinProcessing, Technology, Applications, Equipment Up to now, most of Vietnam's Kaolin is exported as raw materials, which both do not have high economic value and are a waste of national resources With the existing advantage of a modern GermanCzech technology line invested in 2009, right after the covid19 epidemic was controlled, QBBK renovated and upgraded equipment for kaolin deep processingProdukt Kaolin Quang Binh Bohemia

What is the use of kaolin after grinding PDF Free Download

2021年4月26日 Kaolin is a type of clay mineral that is processed through grinding to produce fine particles between 801000 mesh This processing improves its brightness, whiteness, and particle size distribution, allowing it to be used in a wide range of applications including ceramics, refractory materials, papermaking, rubber products, petrochemical processes, and materials High quality 380v Mineral Processing Equipment Kaolin Clay Processing Plant from China, Brand Name: ZT: Certification: ISO9001:008: Model Number: magnetic separator, flotation separator, ore washer and drying machinery Our products are of very good quality and have a good sale at home and abroad for almost 50 countries380v Mineral Processing Equipment Kaolin Clay Processing PlantKaolin is used in paper production, in paints, rubber, plastic, ceramic, chemical, pharmaceutical and cosmetic industries HUMAN EXPOSURE: Kaolin is a natural component in soil and found in ambient air Kaolin mining and refining involve considerable exposure and significant exposure is expected in paper, rubber and plastics productionKaolin Al2H4O9Si2 CID PubChem2023年8月1日 Kaolin's size and dimensional aspects make it a good filler for coatings and other materials [5] Its small particles help to improve the wettability, smoothness, and durability of these materials Kaolin chemical structure and element composition give it An overview of kaolin and its potential application in

“Ball Clay”Processing, Properties, Uses Formula

Hi, This is awesome information on ball clay I am actually doing a school assignment using ball clay where i am trying to make jars the thing is that i mixed the clay and water last Tuesday and the clay is still not manageable really sticky and i can’t shape anything is this normal with ball clay or is there some trick that you can show me to help the water evaporate quicker?2024年7月10日 What is Kaolin? Kaolin, also known by other names such as China clay, white clay, and kaolinite, is a naturally occurring clay mineral It’s popular in the world of cosmetics for its gentle nature and impressive benefits Kaolin is primarily composed of the mineral kaolinite and is typically found in nature as a fine, soft white powderKaolin: What Is It, Cosmetic Uses, Benefits Side EffectsAll the samples were obtained from the production route of a kaolin processing plant in Minerals 2020, 10, 403 4 of 11 Devon (southwest England) after blast coolingproduction of calcined kaolin ResearchGateprocesses and optimize our equipment and resources We are committed to creating the greatest value possible for you As the kaolin clay experts, we operate at the intersection of nature and technology KaMin offers a wide variety of clays that have been specially designed to improve the physical performance propertiesKaolin Clay for Rubber and Plastics

Kaolin grinding production line and equipment

2022年8月10日 Before kaolin can be used reasonably, it needs to be ground into powder to reflect its value Kaolin grinding production line and equipment selection aggregates The hardness is 20~35, the specific gravity is 1991年9月1日 This review outlines the geology and occurrence of kaolins in the world and the state of the art in processing highquality kaolins The physical and chemical characteristics of kaolin are also reviewed with respect to their use for specific applications in paper, ceramics and refractories, plastics, rubber, adhesives and paint industriesKaolin: processing, properties and applications ScienceDirectIndustrial Equipment Infrastructure Stratarock is a brand of products from Indcon Inc The Stratarock line is made up of materials for the setting of industrial equipment and systems designed to protect and repair their These products are applicable to a wide range of industries including Cement, gypsum, kaolin, aggregates Home Stratarock IndustrialProcess equipment is used in several applications like water treatment, steam power generation, It helps in good quality product/output and also aids the operators with smooth and hasslefree functioning CoorsTek, Emerson, Fisher, Xylem, and Culligan are few brands which manufacture process equipment of various designs, sizes, Understanding Process Equipment Types of Process Equipment

The Role of Clay Dryers in Industrial Clay Processing

The following breaks down how drying is used in processing some of the most common industrial clays Kaolin Kaolin, also commonly referred to as China clay, is one of the most important clay minerals, with uses spanning a range of different industries and applications Kaolin clay is commonly used in: Paper making; Tableware and china; MedicineThe processing equipment for kaolin includes: crushing equipment, crushing equipment, screening equipment, and grinding equipment Equipment, etc Related Articles How to remove iron from kaolin Whiteness is the main parameter affecting kaolin process performance, the higher the whiteness, the higher the purity, the higher its use valueKaolin common wet beneficiation process and equipment2008年8月1日 Mullite is a versatile material used in traditional and advanced ceramic, due to low thermal expansion, high thermal shock and creep resistance The production of waste from ore industry is a problem that is increasing nowadays The kaolin processing industry produces residue rich in Al2O3 and SiO2 These oxides are good precursors to produce mullite The aim Use of Kaolin Processing Waste for the Production of Mullite Soft kaolin is usually produced by water washing method The process of washing kaolin production mainly includes the following steps: Mix Mortar: mix kaolin ore with a certain proportion of water to form a slurry; Mashing: In the mixer or masher, kaolin is dispersed and separated from sandy minerals and plant fibers by adding water and dispersant, in order to prepare a slurry of Kaolin Processing Plant Water Washed Kaolin Process MC

Kaolin (Kaolinite) Processing JXSC Mineral

About Kaolin Clay Kaolin, also known as kaolinite or ceramic clay, is a mineral primarily extracted from kaolinite oreIt is named after the hill in China (Kaoling) from which it was mined for centuries Kaolin contains primarily aluminum kaolin is fed into rotary driers and then into airfloating equipment The latter usually consists of a pulverizing unit and an air separator The fine particles are transported to collecting chambers and the coarse particles are fed back into the pulverizer Dry processing yields a INDUSTRIAL APPLICATIONS OF KAOLIN Springerbentonite processing, SCC 305045 for fuller’s earth processing, and SCC 305046 for common clay and shale processing Clays are categorized into six groups by the U S Bureau Of Mines The categories are kaolin, ball clay, fire clay, bentonite, fuller’s earth, and common clay and shale Kaolin, or china clay,1125 Clay Processing US EPA2019年8月23日 The wet process includes three stages of ore preparation, ore beneficiation processing and product processing The beneficiation stage may include hydraulic grading, flotation, selective flocculation, magnetic separation, chemical treatment (bleaching), etc to remove different impurities The prepared slurry pulp is first desanded by the rake type Kaolinite Processing Equipment, Process Flow, Cases JXSC

.jpg)

Kaolinite Clay Beneficiation Process: Kaolin Processing

2024年11月21日 This is a complete kaolin processing plant, including a feeder, belt conveyor, spiral washer, attrition scrubber, trommel screen, wheel washer, dewatering screen, hydrocyclone, thickener, and filter press Flowchart Explanation Of Kaolinite clay processing plant Use a forklift or excavator to feed the raw materials to the hopper, through an 2023年9月28日 6 Laboratory flotation machine: (silica sand) The XFD flotation machine has wide applications in mines and laboratory flotation machines for flotation experiments Production practice has shown that this flotation machine has a reasonable structure, stable operation, reliable operation, and performance that meets the advanced level of foreign flotation machinesLab Kaolin Separating Purification Equipment And ProcessIt can treat diarrhea, mouth sore, ulcers, and also helps in tablets productionControlling the level of viscosity is a problem in the adhesive industry, but including kaolin during production with an enclosed mixing system for adhesives can help you with thatKaolin processing equipment helps grind kaolin to a suitable particle sizeKaolin making equipment Making2020年4月14日 A new largescale suspension calcination process and key equipment suitable for dehydration and calcination of kaolin clay are introduced The pretreatment process can be designed to meet various raw materials with different moisture contents, and the burning system has high heat transfer efficiency with a fivestage cyclone preheater, a suspension calciner Research and Design of Suspension Calcining Technology and Equipment

-2.jpg)

Kaolin Grinding Mill Powder Making Machine

Phrase one: raw material crushing Kaolin blocks will be crushed to 15mm50mm fineness by crusher Phrase two: grinding Crushed Kaolin material will be sent to the storage hopper by the elevator and then the feeder will send the material to the main mill for grinding Phrase three: powder classifying Ground material will be classified, coarse powder will fall back to the main One of the process stages of kaolin clay processing to alumina is solidliquid separation process after HCl leaching with subsequent washing of silica residue Our laboratory studies have shown that of existing equipment most efficiently for this task pressure filterStudy of Filtration and Washing of Residue After HCL Leaching of Kaolin