Kaolinite clay block grinding equipment

Kaolinite Process Equipment

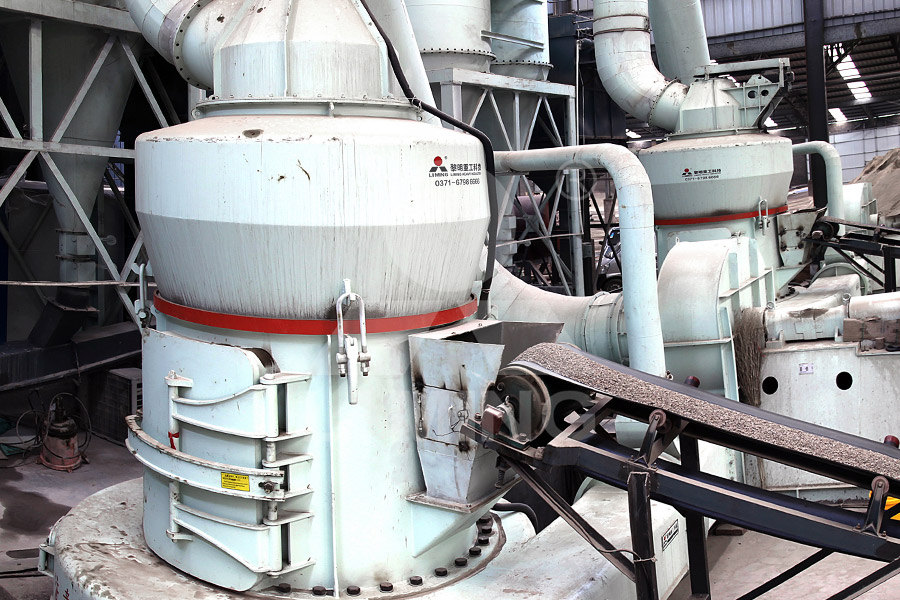

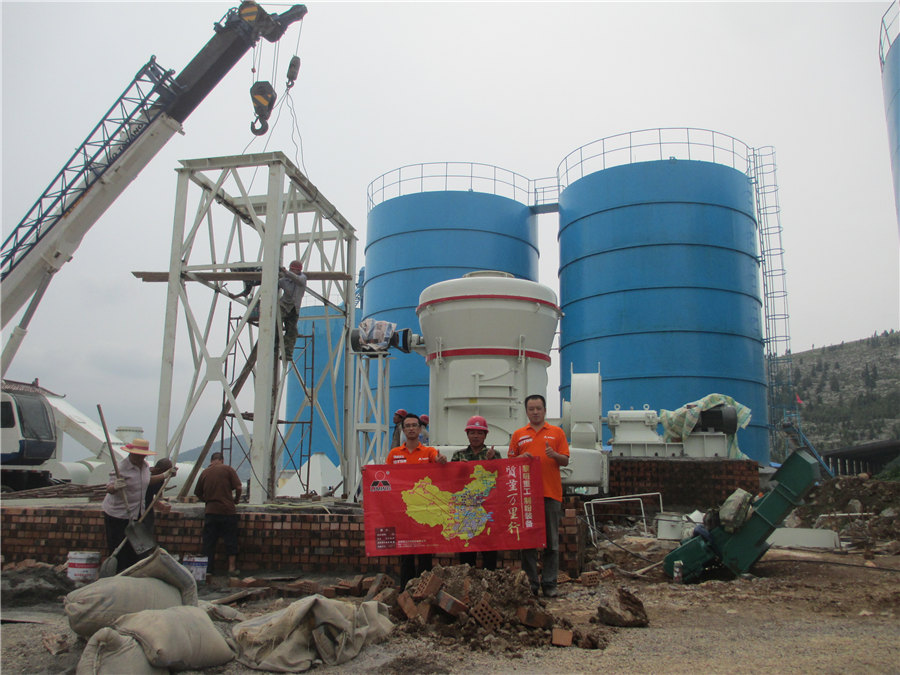

2024年10月24日 The processing of kaolinite requires a series of equipment and procedures to extract the pure mineral from raw kaolin ore and prepare it for commercial use This article The kaolin grinding production line is a comprehensive system designed to process raw kaolin into a fine powder that meets the specific requirements of different industrial applications This Advanced kaolin grinding production line equipment: Elevating 2022年3月31日 Kaolin clay processing equipment and process flow Kaolin grinding powder needs to process kaolinite of different particle size into 801000 mesh There are various types Kaolin grinding powder processing industrial equipmentNoncoalbearing kaolin (soft clay and sandy clay), mainly used in paper coatings and ceramic industry 1, Raymond Mill: Raymond Mill is low investment costs, high capacity, low energy Kaolin Grinding Mill Powder Making Machine

.jpg)

Kaolin production equipment: Screening and stone grinding process

Grinding is the process of reducing kaolin lumps to a fine powder The following equipment is used for stone grinding: Ball Mills: These mills use steel balls to crush and grind the kaolin According to their industrial value, clay deposits are commonly grouped into four general classes Industrial kaolins, which encompass pure kaolin, refractory clays, and bauxitic kaolin, among Clay calcination technology: stateoftheart review by the RILEM Kaolin (china clay, kaolinite) processing and beneficiation can obtain highpurity products, increase the quality and utilization of minerals, and meet some high valueadded market applications Maximize kaolin grade and recovery rate; Kaolin Processing Plant, China Clay Washing ProcessBased on the comprehensive investigation and analysis of the application status and the existing problems of suspension calcination technology in these industries, we creatively developed a Research and Design of Suspension Calcining Technology and

Kaolin Clay: Understanding Its Processing and Grinding

What are the special characteristics, applications, and grinding processes of kaolin? All applications of kaolin must be processed into a fine powder before it can be added to other materials to achieve full fusion The kaolinite is sent to 2024年7月1日 Prototropy in Kaolinite during Percussive Grinding Volume 18 Issue 6 Our systems are now restored following recent technical disruption, and we’re working hard to catch up on publishing We apologise for the inconvenience causedPrototropy in Kaolinite during Percussive Grinding Clays and Clay 2024年7月1日 Bates, T F and Hinckley, D N (1959) Mineralogy and petrology of the kaolin clays of the Piedmont and Coastal plane regions of Southeastern United States: NSF Research Grant, G 3735, Annual Progress Report, June 1, 1958July 1, 1959 Prototropy in Kaolinite during Percussive Grinding Volume 18 Issue 6 Skip to main Prototropy in Kaolinite during Percussive Grinding Clays and Clay 2022年3月31日 Kaolin clay processing equipment and process flow Kaolin grinding powder needs to process kaolinite of different particle size into 801000 mesh There are various types of grinding equipment that can be used, such as jaw crusher, Raymond mill, ultrafine grinding mill and other equipment are commonly usedKaolin grinding powder processing industrial equipment

Phase Transformation of Kaolinite Clay Springer

researchers, clay mineralogists and teaching professors, ceramic technocrats, and various end users of clay products throughout the world with keen interest This book is planned to serve as a text for both undergraduate and graduate students Researchers of clay mineralogist and students of material science at university are vii2024年10月29日 This study focuses on using kaolinite, a clay mineral, as an additive due to its potential to improve the performance of highdensity cement by modifying key propertiesEnhancing the properties of highdensity oil well cement with PDF On Jan 1, 2015, Blanca Bauluz Lázaro published HALLOYSITE AND KAOLINITE: TWO CLAY MINERALS WITH GEOLOGICAL AND TECHNOLOGICAL IMPORTANCE Find, read and cite all the research you need on HALLOYSITE AND KAOLINITE: TWO CLAY MINERALS WITH The use of supplementary cementitious materials as a partial replacement for Portland cement is the most effective way to reduce the carbon footprint of the concrete industry Raw clays containing kaolinite (kaolin) are promising substitute materials In the field, raw clays are often mixed with calcite and this is thought to affect their behaviour after calcination This study The impact of calcite impurities in clays containing kaolinite on

Prototropy in Kaolinite during Percussive Grinding Clays and Clay

When kaolinite undergoes percussive grinding, pronounced changes take place in its ir absorption spectrum even in the earliest stages of the grinding when the lattice is not yet destroyed In this report, attention is directed to the change in the stretching bands of the hydroxyl ions A remarkably rapid effect on the band of the intralayer hydroxyl ions has been observed 2019年1月1日 Kaolinite, with the chemical formula of Al 2 [Si 2 O 5](OH) 4, is a naturally occurring inorganic silicate clay mineral with a layer structure consisting of siloxane and gibbsitelike layersThe siloxane layer is composed of SiO 4 tetrahedra linked in a hexagonal array The bases of the tetrahedra are approximately coplanar and the apical oxygen atoms are linked to Kaolinite Nanomaterials: Preparation, Properties and Functional and provided clay is located close to the plant Should the clay be located 200km from the plant profitability is much less (IRR 2224 per cent) though still acceptable In the case of a grinding station, profitability remains high (IRR >50 per cent) even when clay is located far from the plant In the case of a greenfieldMANUFACTURING EXCELLENCE LC: a promising alternative2019年3月18日 This paper details the main factors influencing the performance of limestone calcined clay cements (LC3) The kaolinite content plays a major role in the rheological properties as well as strength development Even in the presence of secondary phases, kaolinite can be accurately quantified by thermogravimetric analysis The performance of LC3 is slightly Impacting factors and properties of limestone calcined clay

.jpg)

Mechanochemical activation of natural clay minerals:

2019年5月8日 Mechanochemical activation can be defined as a process able to induce structural disorder through intensive grinding In certain conditions, it may increase the chemical reactivity of the processed material The process is 2004年7月1日 Electroosmotic and hydraulic flow rates through kaolinite and bentonite clays July 2004; 32 EQUIPMENT since it blocks and forms a barrier within the pore space to the liquid flow(PDF) Electroosmotic and hydraulic flow rates through kaolinite 2022年6月1日 Influence of processing parameters variation on the development of geopolymeric ceramic blocks with calcined kaolinite clay The equipment used was SSX550 Shimadzu SEDX microscope 3 Results and discussions Feasibility study on fabrication of geopolymer bricks by wasted grinding wheel at room temperature J Renew Mater Influence of processing parameters variation on the development Materials 2018, 11, 1860 4 of 13 Table 2 Studied process parameters Water/Powder Balls/Powder Speed (rpm) Grinding Duration (min) Sample ID3 500 20 DG3R 5 DG5R 25 DG25RActivation of a Raw Clay by Mechanochemical Process—Effects of

.jpg)

Kaolinite Process Equipment

2024年10月24日 Kaolinite, a clay mineral rich in aluminum silicate, is a key industrial material used in the production of ceramics, paper, rubber, paints, and many other products The processing of kaolinite requires a series of equipment and procedures to extract the pure mineral from raw kaolin ore and prepare it for commercial use2015年2月1日 Milled Kaolinite clay is obtained by using studies also confirmed that particle size distribution changed mostly in the first hour of grinding and depends on the grinding equipment Structural and thermal behavior of proclay kaolinite using high energy 2018年6月14日 Sandstone oil reservoirs consist of different clay minerals such as kaolinite, illite, and chlorite These clay minerals highly affect the formation damage during enhanced oil recovery (EOR) and well stimulation operations in these reservoirs No attention was paid to investigate the effect of these clay minerals on the formation damage during different reservoir processes In Clay minerals damage quantification in sandstone rocks using 2000年7月1日 Kaolinite clay is one of important ceramic materials In this paper, the kaolinite clay was ground by dry grinding and wet grinding The powder samples ground for different time were measured by [Spectra on the influence of grinding to kaolinite structure]

.jpg)

Prototropy in Kaolinite during Percussive Grinding

When kaolinite undergoes percussive grinding, pronounced changes take place in its ir absorption spectrum even in the earliest stages of the grinding when the lattice is not yet destroyed In this report, attention is directed to the change in the stretching bands of the hydroxyl ions A remarkably rapid effect on the band of the intralayer hydroxyl ions has been observed allow them to act as a grinding media for the kaolinite particles, thus accelerating the grinding process, (Makó et al 2001;Rescicetal2011; Hamzaoui et al 2015) Results obtained by Sánchez et al (1999) showed that mechanical milling of the kaolinite can generate a significant amount of Al surface in a tetrahedral coordinationMechanochemical activation of natural clay minerals: an Springer2024年9月21日 This study investigated the physicochemical effects of kaolinite (CK) and montmorillonite (CM) calcined clays on the sulfate balance, early hydration, and artificial pore solution of limestone calcined clay cement (LC3) The effects of fineness, clay dissolution, and ionadsorption capacity were evaluated by isothermal calorimetry, compressive strength, ICP Effects of kaolinite and montmorillonite calcined clays on the 2018年7月9日 Effect of grinding and water vapour on the particle size of kaolinite and pyrophyllite Volume 36 Issue 1 Last updated 27/06/24: Online ordering is currently unavailable due to technical issues We apologise for any delays responding to Effect of grinding and water vapour on the particle size of kaolinite

Engineered Kaolinite as a Sustainable Advanced Material 12

Kaolinite a catalyst in Mechanochemical conversion of Cellulose to sugar Source: S M Hick et al: Green Chem2010, 12, 468 Solubilization of dry cellulose to sugar in Spex mill Kaolinite reused Kaolinite dry milled with lignocellulosics Þ Sugars; lignin; kaolinite reused Sugars to Ethanol (biofuel) Lignin to nonoilbased polymers Wt% Sugars2004年12月20日 Grinding did not seem to influence the formation of siliconaluminum spinel from kaolinite The present results may explain why ground kaolinite samples prepared via different routes—eg, with differences in grinding—behave differently during hightemperature transformations, as reported in the related literatureEffects of Dry Grinding on the Structural Changes of Kaolinite 1999年11月1日 The effect of grinding on coal gangue, however, had not been investigated systematically Present understanding regarding the effects of grinding on coal gangue is still restricted to that on kaolinite Furthermore, the differences in the inherent mechanisms between grinding and thermal activation on coal gangue have not been investigated so farTwo dimensions comminution of kaolinite clay particles2018年7月9日 Grinding caused particles to fragment and resulted in the formation of stable large spheroidal aggregates of fine particles These two processes were not clearly separated by a specific grinding time, but occurred in parallel shortly after grinding was started, although aggregate formation persisted at longer grinding timesEffects of dry grinding on two kaolins of different degrees of

.jpg)

Research on Synthesis of Kaolinite Clay and Humidity JSTAGE

problems, this review focuses on the recent development of kaolinite clay synthesis and the use of kaolinite as a humidity conditioning material (1) Kaolinite clay synthesis has been investigated During investiga tions, a sphericalshaped kaolinite, which is 2023年2月22日 Kaolinite is a 1:1 type layered phyllosilicate/clay mineral with a crystal structure consisting of SiO 4 tetrahedral sheets and AlO 2 (OH) 4 octahedral sheets in a periodic array along the caxis [1]The world mine production and reserves of kaolin (a fine clay rich in kaolinite) was about 45 million metric tons in 2021, with the largest producers being India, China, High and lowdefect kaolinite for brick making: Comparisons of 2017年12月9日 There are also alternative sources of materials which can be used in place of pure calcined kaolinite clay These include: Lower purity kaolin clays containing moderate to high amounts of quartz can be used as pozzolans (Castillo et al 2010) Paper sludge—this is often a mixture of kaolin with cellulose, sometimes also containing calcite, which can be calcined to Metakaolin SpringerLink2024年7月1日 Prototropy in Kaolinite during Percussive Grinding Volume 18 Issue 6 Our systems are now restored following recent technical disruption, and we’re working hard to catch up on publishing We apologise for the inconvenience causedPrototropy in Kaolinite during Percussive Grinding Clays and Clay

.jpg)

Prototropy in Kaolinite during Percussive Grinding Clays and Clay

2024年7月1日 Bates, T F and Hinckley, D N (1959) Mineralogy and petrology of the kaolin clays of the Piedmont and Coastal plane regions of Southeastern United States: NSF Research Grant, G 3735, Annual Progress Report, June 1, 1958July 1, 1959 Prototropy in Kaolinite during Percussive Grinding Volume 18 Issue 6 Skip to main 2022年3月31日 Kaolin clay processing equipment and process flow Kaolin grinding powder needs to process kaolinite of different particle size into 801000 mesh There are various types of grinding equipment that can be used, such as jaw crusher, Raymond mill, ultrafine grinding mill and other equipment are commonly usedKaolin grinding powder processing industrial equipmentresearchers, clay mineralogists and teaching professors, ceramic technocrats, and various end users of clay products throughout the world with keen interest This book is planned to serve as a text for both undergraduate and graduate students Researchers of clay mineralogist and students of material science at university are viiPhase Transformation of Kaolinite Clay Springer2024年10月29日 This study focuses on using kaolinite, a clay mineral, as an additive due to its potential to improve the performance of highdensity cement by modifying key propertiesEnhancing the properties of highdensity oil well cement with

HALLOYSITE AND KAOLINITE: TWO CLAY MINERALS WITH

PDF On Jan 1, 2015, Blanca Bauluz Lázaro published HALLOYSITE AND KAOLINITE: TWO CLAY MINERALS WITH GEOLOGICAL AND TECHNOLOGICAL IMPORTANCE Find, read and cite all the research you need on The use of supplementary cementitious materials as a partial replacement for Portland cement is the most effective way to reduce the carbon footprint of the concrete industry Raw clays containing kaolinite (kaolin) are promising substitute materials In the field, raw clays are often mixed with calcite and this is thought to affect their behaviour after calcination This study The impact of calcite impurities in clays containing kaolinite on When kaolinite undergoes percussive grinding, pronounced changes take place in its ir absorption spectrum even in the earliest stages of the grinding when the lattice is not yet destroyed In this report, attention is directed to the change in the stretching bands of the hydroxyl ions A remarkably rapid effect on the band of the intralayer hydroxyl ions has been observed Prototropy in Kaolinite during Percussive Grinding Clays and Clay 2019年1月1日 Kaolinite, with the chemical formula of Al 2 [Si 2 O 5](OH) 4, is a naturally occurring inorganic silicate clay mineral with a layer structure consisting of siloxane and gibbsitelike layersThe siloxane layer is composed of SiO 4 tetrahedra linked in a hexagonal array The bases of the tetrahedra are approximately coplanar and the apical oxygen atoms are linked to Kaolinite Nanomaterials: Preparation, Properties and Functional

.jpg)

MANUFACTURING EXCELLENCE LC: a promising alternative

and provided clay is located close to the plant Should the clay be located 200km from the plant profitability is much less (IRR 2224 per cent) though still acceptable In the case of a grinding station, profitability remains high (IRR >50 per cent) even when clay is located far from the plant In the case of a greenfield