HOME→Calcium carbonate sports high fine vertical mill as two calcium hydroxide mills do synchronization

Calcium carbonate sports high fine vertical mill as two calcium hydroxide mills do synchronization

.jpg)

CALCIUM CARBONATE (GCC) Hosokawa Alpine

The Hosokawa Alpine wet mill ANRCL produces these highgrade qualities costeffectively down to a fineness of d99 = 2 µm MASTERBATCH For the production of masterbatches by The vertical agitated media mill ANR is employed for the energyefficient ultrafine grinding of highly concentrated limestone slurries (GCC) The most typical application is the manufacture Calcium Carbonate (GCC) Hosokawa AlpineHCM's HLMX series ultrafine vertical mill has the characteristics of high efficiency, stability, intelligence and environmental protection It is favored by customers and has a high share in HLMX1700 ultrafine vertical mill helps create an ultrafine powder It is often used to produce powders as fine as 10 microns The vertical mill has a large output and a small footprint Compared with the ball mill, although the powder produced by the vertical mill is not as good as the powder produced How to Choose a Calcium Carbonate Grinding Mill

Calcium Carbonate Powder Plant HLMX Superfine

Calcium carbonate mill HLMX calcium carbonate powder vertical mill has equipped superfine vertical mill mainframe to produce calcium carbonate powder, with high calcium carbonate content index (>98%), heavy metal (calculated as 2024年9月14日 They grind calcium carbonate (CaCO3) into fine powder for various uses Skip to content metallurgy, and chemicals It is often used to produce powder as fine as 10 microns Vertical mill has large output and small How to choose a suitable calcium carbonate grinding And there are many kinds of calcium carbonate grinders available, such as ball mill, roller mill, vertical mill, wet grinding mill and so on Since different grinding mills have different capacity and diameters, Daswell can help you to choose the best suitable one for Customize Suitable Calcium Carbonate Plant DASWELL2009年11月1日 Characterization of Calcium Carbonate, Calcium Oxide, and Calcium Hydroxide as Starting Point to the Improvement of Lime for Their Use in Construction November 2009 Journal of Materials in Civil Characterization of Calcium Carbonate, Calcium Oxide, and Calcium

The advantages of ultrafine vertical mill in the processing and

2023年3月21日 Application of ultrafine vertical mill in the processing and production of ultrafine heavy calcium Highend calcium carbonate production line with an annual output of 300,000 tons in Anhui, The CLUM series of ultrafine vertical mills developed and produced by SBM micropowder technology are very popular in the global marketCalcium carbonate powders of different finenesses have different application ranges Common calcium carbonate powders include 200 mesh, 400 mesh, 600 mesh, 800 mesh, 1200 mesh, 15003000 mesh, etc The CLUM series of ultrafine vertical mills developed and produced by CLIRIK can meet the production needs of various calcium carbonate powders Calcium Carbonate Ultrafine Vertical Grinding Roller MillGreater finenesses up to d 97 = 16μm, especially at high outputs, are most efficiently produced by vertical wet mill systems such as the ANRCL and either used directly as a slurry in the paint or paper industry or by means of an Atritor Cell Mill in a single process step dried, optionally coated and top cut cleaned by means of an integrated air classifierCalcium Carbonate (GCC) Hosokawa Micron MalaysiaHLMX ultrafine vertical mill is a highend ultrafine grinding mill equipment developed by the HCM research and development team on the basis of coarse powder vertical mills and a series of optimization and upgrades for ultrafine powder grinding and screening Advantages and characteristics of HLMX series ultrafine vertical mill 1[Conference News] HCM’s Vertical Mill Injects Green And Low

Characterization of Calcium Carbonate, Calcium Oxide, and Calcium

2009年10月15日 In this paper a complete characterization of lime cycle transitions is described CaCO 3 was collected from a Mexican mine and was processed to obtain Ca (OH) 2 through CaO When the calcium hydroxide interacted with the CO 2 in the air forming CaCO 3, the lime cycle was completedCrystal structure and spectroscopy characterization was carried out to 2023年9月19日 HGM ultrafine powder grinding mill processing advantages HGM ultrafine powder grinding mill is mainly suitable for ultrafine powder processing of nonflammable and brittle materials with medium and low Calcium carbonate milling process SBM Ultrafine Heavy calcium carbonate (heavy calcium) is obtained by directly pulverizing natural limestone, calcite, etc by a mechanical method (Raymond mill or the like) Light calcium carbonate (light calcium) is obtained by calcining limestone at calcium carbonate grinding mill, calcium carbonate In order to deepen the cooperation opportunities between calcium product production units and equipment suppliers On September 1216, 2021, the 2021 China (Rizhao) Calcium Industry Chain Expo will be held in Shandong, ChinaCLIRIK Ultrafine Grinding Mills Shine At 2021 Calcium Carbonate

Ultrafine GCC ( Ultrafine calcium carbonate) APEX TW

Ultrafine calcium carbonate is a natural nontoxic filler widely used in industries like rubber, plastics, papermaking, ink, and coatings Its production involves both dry and wet methods, derived from mechanically grinding and crushing natural limestone, offering various specifications of calcium carbonate to meet diverse application needs This product boasts fine particle 2022年8月30日 There are many models of 1250 mesh calcium carbonate powder ultrafine vertical mills, and the models cover the output from 3 to 40 tonsThe calcium carbonate powder produced covers 45um to 2um, which can be used in PVE, PE, paint, coating grade products, paper making Primer, paper topcoat and other fields1250 mesh calcium carbonate powder ultrafine vertical mill2023年9月28日 Calcium Carbonate Vertical Mill A calcium carbonate vertical mill, also known as a vertical roller mill, is a specialized equipment used for grinding and processing calcium carbonate It is characterized by its vertical arrangement and the use of multiple grinding rollers to exert grinding force on the material Here are some key features and Exploring Different Grinding Mills for Calcium Carbonate 2024年6月7日 EPIC Powder's ring roller mill is ideal for producing ultrafine calcium carbonate powder with low investment and high efficiency Skip to content Home; Vertical Air Classifier; Ultrafine Air Classifier; Surface Modification Menu Toggle One of the advantages of the ring roller mill is its high grinding efficiencyRoller Mill Calcium Carbonate Production Line

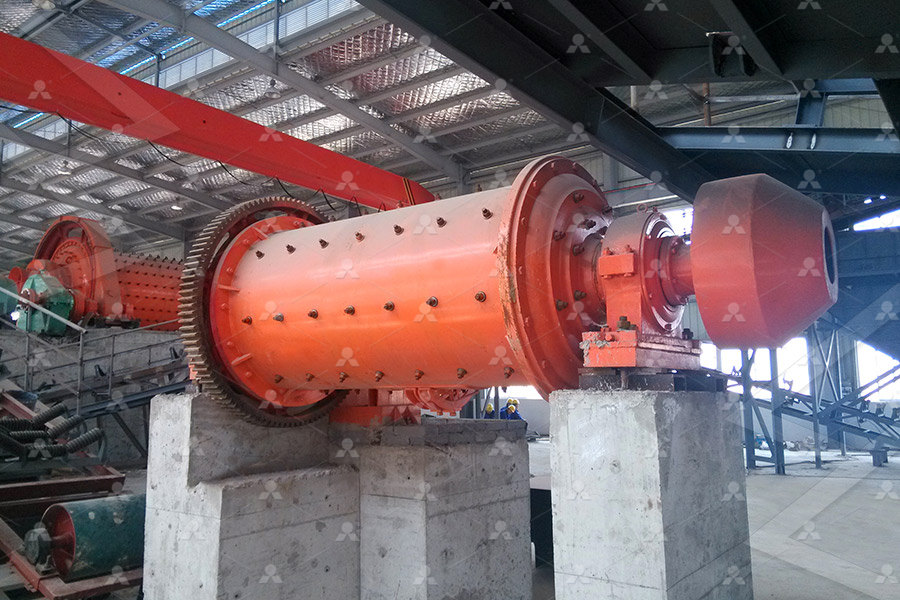

The carbonation kinetics of calcium hydroxide nanoparticles: A

2019年7月1日 The reaction of Ca(OH) 2 with CO 2 to form CaCO 3 (carbonation process) is of high interest for construction materials, environmental applications and art preservation Here, the “Boundary Nucleation and Growth” model (BNGM) was adopted for the first time to consider the effect of the surface area of Ca(OH) 2 nanoparticles on the carbonation kinetics2007年7月24日 Calcium carbonate is used in large amounts in the pulp and paper industry as a paper filler When it is manufactured, the calcium carbonate waste is purged from the process Here we demonstrate that, due to the elevated calcium concentration of 1685 g kg−1 dry weight (dw), alkaline pH of 126 and neutralizing (liming) effect value of 424% expressed as Ca Calcium carbonate waste from an integrated pulp and paper mill Roller mill (vertical roller mill/roller mill) is one of the main largescale equipment for fine grinding and ultrafine grinding of heavy calcium carbonate It is characterized by a large crushing ratio The most suitable product particle size News Calcium powder processing machinery and We are a calcium carbonate ball mill plant factory with over 30 years of work experience in this industry, and are at the leading domestic level in the grinding and grading technology of ball mills We can screen and evaluate the raw Calcium Carbonate Ball Mill Plant DASWELL

.jpg)

Calcium Carbonate: Uses, Dosage, and Potential Side

2023年11月14日 Calcium carbonate supplements are an effective way to increase your calcium intake if your diet isn’t sufficient, or you have a condition that leads to lower calcium levels Learn about At 2021 Calcium Carbonate Industry Conference,CLIRIK highlighted two ultrafine Raymond mills that are widely acclaimed in the field the 2021 National Calcium Carbonate Industry HighValue Development Exchange Conference was The CLIRIK CLUM ultrafine vertical Raymond mill is developed by introducing advanced foreign technology under Ultra Fine Raymond Mill Is The Future Of Calcium Carbonate 1The Distinction between Light and Heavy Calcium Carbonate The primary distinction between heavy calcium and light calcium lies in their packing density Heavy calcium exhibits a higher packing density, typically ranging from 08 to 13g/cm3, while light calcium possesses a lower packing density, usually falling within the range of 05 to 07g/cm3Classification and Differentiation of Calcium CarbonateThe main production technologies of light calcium carbonate at home Carbonation method Calcining the raw materials such as limestone to generate lime (ingredient for calcium oxide); then adding water to digest lime to generate lime milk (ingredient for calcium hydroxide) and then passing into the carbon dioxide carbide lime milk for calcium carbonate precipitation; lastly, the Grinding mill for Calcium carbonate

.jpg)

vertical roller mill clirikultrafine vertical mill, Raymond vertical

The company's products mainly include ultrafine grinding mills, highpressure suspension roller pulverizers These mills are particularly useful in industries requiring extremely fine powders, such as in hightech ceramics, advanced composites, and certain chemical HGM80 calcium carbonate vertical powder mill in Vietnam chrome 2016年2月21日 One challenge of the concept presented in Figure 1 is that the produced calcium carbonate is precipitated in a solution of ammonia and ammonium chloride, which raises concern that chloride may be embedded in the product and hinders its commercial use However, the maximum chloride content that can be allowed in a PCC product is not clear as there does not Performance of Separation Processes for Precipitated Calcium Carbonate calcium hydroxide (Ca(OH) 2), a soft white powder that is widely used as a raw material in the chemical industryIt forms when calcium oxide is mixed with waterThe compound has two hydroxide ions (OH −) for each ion of calcium (Ca 2+)The chemical is ionic, with aqueous and electrolytic dissociations both producing calcium ions and hydroxide ionsCalcium hydroxide Definition, Formula, Uses, Properties, Facts 2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the mill Grinding: Use a bucket elevator to send the crushed small pieces of calcium carbonate to the silo, then use a vibrating feeder to send them Guide to Calcium Carbonate Grinding: Mills, Tips, and Uses

How to Choose a Calcium Carbonate Grinding Mill

It is often used to produce powders as fine as 10 microns The vertical mill has a large output and a small footprint Compared with the ball mill, although the powder produced by the vertical mill is not as good as the powder produced Calcium carbonate mill HLMX calcium carbonate powder vertical mill has equipped superfine vertical mill mainframe to produce calcium carbonate powder, with high calcium carbonate content index (>98%), heavy metal (calculated as Calcium Carbonate Powder Plant HLMX Superfine 2024年9月14日 They grind calcium carbonate (CaCO3) into fine powder for various uses Skip to content metallurgy, and chemicals It is often used to produce powder as fine as 10 microns Vertical mill has large output and small How to choose a suitable calcium carbonate grinding And there are many kinds of calcium carbonate grinders available, such as ball mill, roller mill, vertical mill, wet grinding mill and so on Since different grinding mills have different capacity and diameters, Daswell can help you to choose the best suitable one for Customize Suitable Calcium Carbonate Plant DASWELL

Characterization of Calcium Carbonate, Calcium Oxide, and Calcium

2009年11月1日 Characterization of Calcium Carbonate, Calcium Oxide, and Calcium Hydroxide as Starting Point to the Improvement of Lime for Their Use in Construction November 2009 Journal of Materials in Civil 2023年3月21日 Application of ultrafine vertical mill in the processing and production of ultrafine heavy calcium Highend calcium carbonate production line with an annual output of 300,000 tons in Anhui, The CLUM series of ultrafine vertical mills developed and produced by SBM micropowder technology are very popular in the global marketThe advantages of ultrafine vertical mill in the processing and Calcium carbonate powders of different finenesses have different application ranges Common calcium carbonate powders include 200 mesh, 400 mesh, 600 mesh, 800 mesh, 1200 mesh, 15003000 mesh, etc The CLUM series of ultrafine vertical mills developed and produced by CLIRIK can meet the production needs of various calcium carbonate powders Calcium Carbonate Ultrafine Vertical Grinding Roller MillGreater finenesses up to d 97 = 16μm, especially at high outputs, are most efficiently produced by vertical wet mill systems such as the ANRCL and either used directly as a slurry in the paint or paper industry or by means of an Atritor Cell Mill in a single process step dried, optionally coated and top cut cleaned by means of an integrated air classifierCalcium Carbonate (GCC) Hosokawa Micron Malaysia

[Conference News] HCM’s Vertical Mill Injects Green And Low

HLMX ultrafine vertical mill is a highend ultrafine grinding mill equipment developed by the HCM research and development team on the basis of coarse powder vertical mills and a series of optimization and upgrades for ultrafine powder grinding and screening Advantages and characteristics of HLMX series ultrafine vertical mill 1