The temperature of the bearing at the drive end of the reducer is overheated sharply

.jpg)

Understanding Shaft Alignment: Thermal Growth MW

2013年7月12日 Using the above machine example, consider the change in shaft alignment if the outboard end (OE) bearing temperature changed by 20 F and the drive end (DE) bearing temperature changed by 50 F The drive end bearing would grow by 44 mils; however, the 2 天之前 Abstract The results of a comprehensive study of temperature modes of bearing units of drive shaft joints under rated loads Based on experimental studies and modeling of Technical Diagnostics of Bearing Units of a Drive Shaft Based on 2024年5月18日 Taking motor bearings as an example, when the temperature of the rolling bearing exceeds 95°C and the temperature of the sliding bearing exceeds 80°C, the bearing is Causes And Solutions Of Bearing Overheating AUBEARING2021年4月12日 After reinstallation, the maximum motor drive end bearing temperature is 60°C The cooling effect is obvious, and the test operation results show that the highest bearing Solutions to the high temperature of the motor bearing of the

Common factors and solutions for motor bearing overheating

2021年2月25日 When the motor bearing temperature exceeds 95°C and the roller bearing temperature exceeds 80°C, the bearing is overheated The following are some common Majority of them are in relation to reducer protection of overheating and of gears and bearings failures The article contains analysis of heat sources, heat transfer through design structure Heat transfer and lubrication of turboshaft motorreducerIn an alert condition, the bearing temperature may be between 200 and 250 degrees F These elevated temperatures may be due to a heated application, a recently greased bearing, oil How to Manage Hot Bearings in Your Plant Machinery LubricationUsing diagram 1, you can estimate the heat dissipation per degree above ambient temperature, W s, for a bearing with bearing mean diameter d m in a plummer block housing, with the shaft Estimating bearing operating temperature SKF

What Are The Causes of Bearing Overheating? Best

2024年7月17日 Understanding the causes of bearing overheating is crucial for maintaining machinery efficiency and preventing costly failures This guide identifies common factors contributing to bearing overheating and offers 2021年7月1日 When this phenomenon occurs, the front and rear bearing cover should be removed, or a thin paper pad should be added between the bearing cover and the end cover to form enough clearance between the outer bearing The Root Reasons and Solution of High Temperature 2008年9月24日 A plot of the vibration signal of the test bearing during the temperature trending period that occurs 18 h into Test 8 as compared to the signal of the test bearing when not trending, 695 h into Dynamic Bearing Testing Aimed at Identifying the Gear case Temperature : Gear bearing Temperature : Gear bearing Temperature : Gear oil Temperature: Atmosphere Temperature : Pinion bearing Temperature : Pinion bearing Vibration : Pinion bearing Rotation speed and torque : Pinion shaft End of the pinion shaft Small temperature data logger 3 Fig 5 Method of changing the bearing clearanceEffects of bearing clearance and atmospheric temperature on

.jpg)

(PDF) Research on the Bearing Preload of Main Reducer of Rear Drive

2016年1月1日 Research on bearing preload of main reducer of light offroad vehicle [J]Mechanical Engineer, 2007,11:4849 Assembles craft of car rear axle and noise detection and fault diagnoses Jan 年10月12日 However, onsite, they found that the motor bearing drive end was located at the motor cooling air outlet, where the temperature was already 56 degrees In other words, the motor bearing operating in an environment above 50 degrees could not possibly maintain its temperature at 50 degreesGuide to Motor Bearing Temperature Analysis MachineMFG2023年2月15日 1 Carry out temperature tests on the reducer bearing and clear the vent hole 2 correctly install the balance wheel and the intermediate wheel 11 The main bearing temperature is too high, which even causes smoke or parts melting What causes the overhigh temperature of the main bearing The cylinder drive shaft is bent17 Signs of Problems with Ball Mills: Quickly Remove Hidden Troubleswheel, and gearbox housing One end of the gearbox is connected to the bogie frame by an elastic support, and the other end to the wheelset axle; the pinion is located on the drive end of the gearbox, and the gearwheel is fixed to the wheelset axle, as shown in Figure 2 (c) and (d) During operation,Analysis of vibration and temperature on the axle box bearing of

.jpg)

Causes And Solutions Of Bearing Overheating AUBEARING

Taking motor bearings as an example, when the temperature of the rolling bearing exceeds 95°C and the temperature of the sliding bearing exceeds 80°C, the bearing is considered to be overheated Based on years of experience in bearing manufacturing and use, Aubearing has summarized the following main causes of bearing heatingInner diameter of the bearing, ( ) 35 35 35 Outer diameter of the bearing, 𝐷 ( ) 40 62 62 Bearing width, 𝐵 ( ) 13 14 14 Dynamic load capacity, C (𝑘𝑁) 15,4 41,5 16,8 a) b) Fig 2 Geometrical values of the vital cycloid speed reducer elements (a); Dimensions of cycloid discsThe influence of the cycloid disc bearing type on the cycloidal 2021年8月25日 The articles shown below are all about the difference between drive end and non drive end bearing, through these related articles, you can get relevant information, notes in use, or latest trends about the difference between drive end and non drive end bearingWe hope these news will give you the help you need And if these difference between drive end and non difference between drive end and non drive end bearingwheel, and gearbox housing One end of the gearbox is connected to the bogie frame by an elastic support, and the other end to the wheelset axle; the pinion is located on the drive end of the gearbox, and the gearwheel is fixed to the wheelset axle, as shown in Figure 2 (c) and (d) During operation,Analysis of vibration and temperature on the axle box bearing of

.jpg)

Design and Testing of a New Type of Planetary

2024年2月4日 This paper presents the design and development of a new type of planetary traction drive bearingtype reducer In this design, the transmission outer ring is replaced with an elastic ring2012年4月11日 Lubricant function in gear reducers In all speed reducers or gear drives, friction is created between internal moving components The primary function of the lubricant is to minimize the friction caused by the sliding and rolling action of the gears and bearings and to dissipate heat by providing a thin layer of oil between moving componentsExtending The Life Of Gear Reducers Efficient Plant2022年10月20日 The considerable heat treatment induced runout value in the end face of the automobile main reducer gear is always dimensionally out of tolerance It directly affects the dimensional accuracy, the grade of carburized and hardened gears, and the postquenching manufacturing costs In this study, three dimensional numerical models were developed to Prediction and Minimization of the Heat TreatmentThe high frequency bearing currents are generated when the bearing voltage surpasses the threshold voltage of the oil film between the rolling elements and the raceway of bearings It can increase the temperature of oil and degrade the performance of the lubricating oil In the end, the pit point appeared in the inner and outer raceway and theThe effect of end windings and the bearing labyrinth seals on

Understanding Shaft Alignment: Thermal Growth MW

2013年7月12日 The drive end bearing would grow by 44 mils; however, the outboard bearing would grow only by 18 mils The result will be a change in both the offset and angular alignment If the motor feet are 20 in apart, the change in the angular alignment will be 013 mil/in [(44 – 18)/20 = 013] open at the top of the coupling2017年12月1日 According to the latest researches, stationary fluid flows with heat exchanges have been considered in gear transmission temperature prediction, along with novel approaches to measure lubricating interface conditions [26], [27]Ronny Beilicke [28] researched the contact of tooth flanks of helical gear pairs using a transient threedimensional thermal Unsteadystate temperature field and sensitivity analysis of gear Temperature Effects On Magnetic Flux Density The motor torque constant (K T) and voltage constant (K E) are directly related to the magnetic flux density (B r) of the permanent magnetsDepending on the physics of the magnet material used, overall flux density will change at a given percentage with an increase in magnet temperatureTemperature Effects on DC Motor Performance Haydon Kerk 2023年10月20日 Motor bearing temperature no higher than seat temperature At this time, if the floatingend bearing bears axial load, it can cause problems such as bearing overheating In such cases, it is necessary to check the motor structure arrangement to ensure the floatingend bearing is appropriateMotor Bearing Heat Generation: A Complete Analysis

(PDF) The influence of the cycloid disc bearing type on

2021年6月4日 Conference: MATEC Web of Conferences 343, 01004 (2021) / 10th International Conference on Manufacturing Science and Education – MSE 2021; At: Sibiu, Romania2021年7月26日 On the basis of the computational fluid dynamics (CFD) method, this study calculates the surface convective heat transfer coefficients of the sun gear, planetary gear, ring gear, and bearing before and after the opening of the planetary gear of a fandriven gearbox A numerical fitting method is used to establish the calculation model of the convective heat Parameter design method for the heat transfer performance of a NDE = Nondrive end DE = Drive end 1 Rolling bearings in electric machines Design requirements NDE DE Design requirements Operating conditions Manufacturing Maintenance Bearing selection and calculated life 10 1 Rolling bearings in electric machines Design requirements Speed6230 Rolling bearings in electric motors and generators SKF2021年7月23日 The slewing drive is overheated or there is noise in the bearing part (1) Insufficient lubricating oil When the lubrication oil level is insufficient or the reducer cannot reach a reasonable height due to oil leakage, it may cause high temperature or noise in the bearing part of the reducer; (2) The bearing cap or seal part is mon faults of slewing drive LDB

Lightweight design of the planetary gear reducer of reduction drive

2022年9月1日 To optimize the 3stages planetary gear reducer (PGR) in the EarthPressureBalance Shield Machine (EPBSM), it is necessary to firstly define the EPBSM environment2021年2月25日 When the motor bearing temperature exceeds 95°C and the roller bearing temperature exceeds 80°C, the bearing is overheated The following are some common factors and solutions for motor bearing overheating 1 The rolling bearing is installed incorrectly, and the fit tolerance is too tight or too mon factors and solutions for motor bearing overheatingIn detail, the three firstaction solutions for bearing currents are: 1 Incorporating an insulated bearing at the nondriven end An effective solution for motors with an IEC frame size of 280 and upwards is to substitute the bearing at the nondriven end with an insulated bearing that prevents current flowing through this pointHow to deal with persistent bearing currents ABB Group2022年1月13日 Hotcore heavy reduction rolling is an innovative technology for continuous casting billet at the end of solidification The deformation characteristics of GCr15 bearing billet were investigated over the temperature range of 1000–1300 °C with the strain rate of 0001–10 s−1 by the Gleeble 3800 thermomechanical simulator Firstly, the true stress–strain data are Modeling flow stress and grain size of GCr15 bearing steel at high

Temperature rise curve of railway bearing B: (a) the

Download scientific diagram Temperature rise curve of railway bearing B: (a) the circumferential direction of outer ring; (b) outer ring axial; (c) the circumferential direction of inner 2024年7月17日 Understanding the causes of bearing overheating is crucial for maintaining machinery efficiency and preventing costly failures This guide identifies common factors contributing to bearing overheating and offers What Are The Causes of Bearing Overheating? Best 2021年7月1日 When this phenomenon occurs, the front and rear bearing cover should be removed, or a thin paper pad should be added between the bearing cover and the end cover to form enough clearance between the outer bearing The Root Reasons and Solution of High Temperature 2008年9月24日 A plot of the vibration signal of the test bearing during the temperature trending period that occurs 18 h into Test 8 as compared to the signal of the test bearing when not trending, 695 h into Dynamic Bearing Testing Aimed at Identifying the

.jpg)

Effects of bearing clearance and atmospheric temperature on

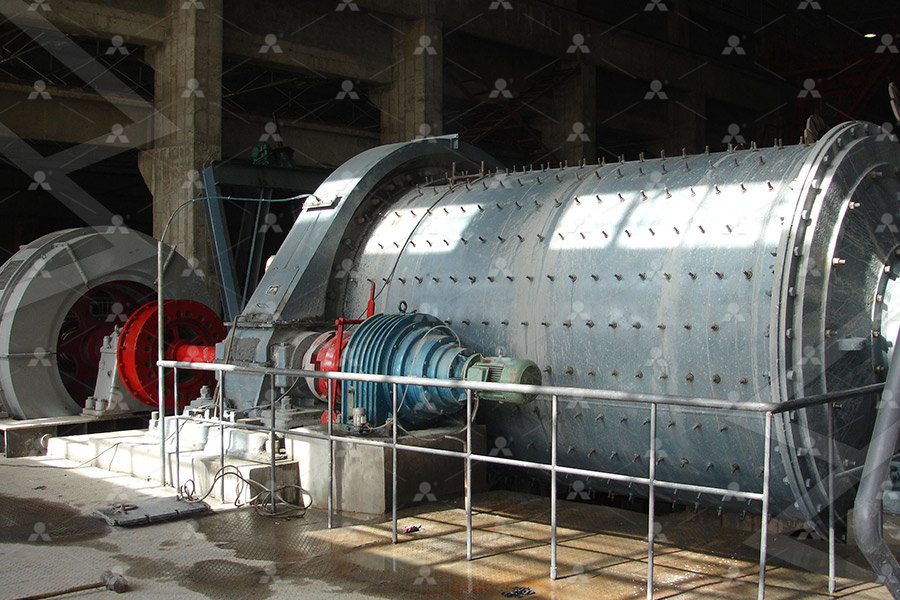

Gear case Temperature : Gear bearing Temperature : Gear bearing Temperature : Gear oil Temperature: Atmosphere Temperature : Pinion bearing Temperature : Pinion bearing Vibration : Pinion bearing Rotation speed and torque : Pinion shaft End of the pinion shaft Small temperature data logger 3 Fig 5 Method of changing the bearing clearance2016年1月1日 Research on bearing preload of main reducer of light offroad vehicle [J]Mechanical Engineer, 2007,11:4849 Assembles craft of car rear axle and noise detection and fault diagnoses Jan 2005(PDF) Research on the Bearing Preload of Main Reducer of Rear Drive 2023年10月12日 However, onsite, they found that the motor bearing drive end was located at the motor cooling air outlet, where the temperature was already 56 degrees In other words, the motor bearing operating in an environment above 50 degrees could not possibly maintain its temperature at 50 degreesGuide to Motor Bearing Temperature Analysis MachineMFG2023年2月15日 1 Carry out temperature tests on the reducer bearing and clear the vent hole 2 correctly install the balance wheel and the intermediate wheel 11 The main bearing temperature is too high, which even causes smoke or parts melting What causes the overhigh temperature of the main bearing The cylinder drive shaft is bent17 Signs of Problems with Ball Mills: Quickly Remove Hidden Troubles

Analysis of vibration and temperature on the axle box bearing of

wheel, and gearbox housing One end of the gearbox is connected to the bogie frame by an elastic support, and the other end to the wheelset axle; the pinion is located on the drive end of the gearbox, and the gearwheel is fixed to the wheelset axle, as shown in Figure 2 (c) and (d) During operation,Taking motor bearings as an example, when the temperature of the rolling bearing exceeds 95°C and the temperature of the sliding bearing exceeds 80°C, the bearing is considered to be overheated Based on years of experience in bearing manufacturing and use, Aubearing has summarized the following main causes of bearing heatingCauses And Solutions Of Bearing Overheating AUBEARINGInner diameter of the bearing, ( ) 35 35 35 Outer diameter of the bearing, 𝐷 ( ) 40 62 62 Bearing width, 𝐵 ( ) 13 14 14 Dynamic load capacity, C (𝑘𝑁) 15,4 41,5 16,8 a) b) Fig 2 Geometrical values of the vital cycloid speed reducer elements (a); Dimensions of cycloid discsThe influence of the cycloid disc bearing type on the cycloidal