Under what circumstances are vertical grinding ore grinding machines used

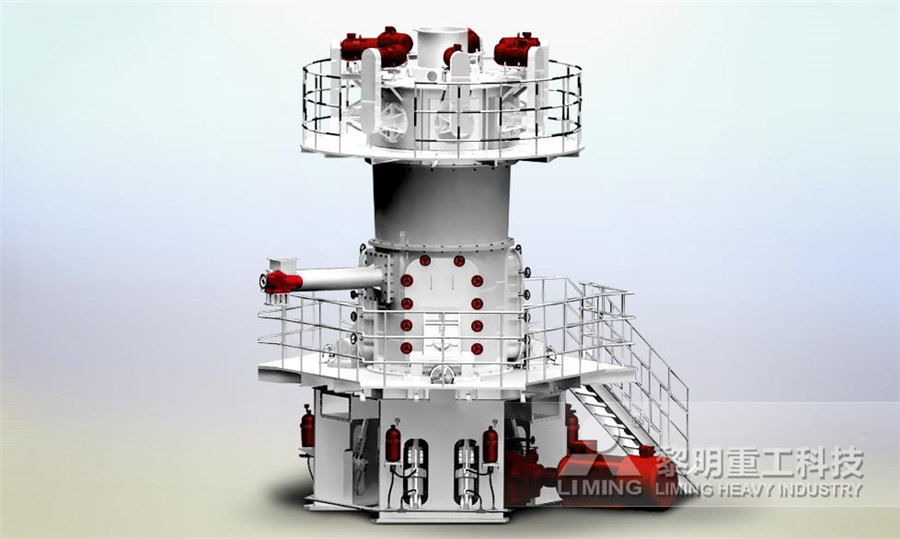

Vertical Roller Mills used for the comminution of mineral ores

Vertical roller mills are traditionally airswept mills A VRM applies a compressive force using fixed rollers pressing downwards on a rotating grinding table The material to be ground is fed into the centre of the grinding table via a feed chute2019年4月16日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE Vertical stirred milling is a wellrecognized technology for the secondary, regrind and fine grinding applications and are increasingly replacing coarser ball mill applications in secondary and RECENT DEVELOPMENTS IN COARSE GRINDING USING VERTICAL 2012年9月1日 Mills (VRM) installations and summarises the main benefits of the dry compressive Loesche grinding technologies in Airflow and OverflowMode Some of these Latest Installations And Developments Of Loesche Vertical Roller

.jpg)

Operational parameters affecting the vertical roller mill

2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants 2023年7月20日 Moist grinding, a special grinding method, is used to prepare pellets for smelting According to the grinding medium features, ore grinding is mainly classified into ball grinding Ore Grinding SpringerLink2015年3月15日 Verticalrollermills (VRM) are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principle Results of extensive test Research of iron ore grinding in a verticalrollermill2021年1月16日 Cylindrical and internal grinding machines are used for grinding cylindrical diameters and bores (internal diameter) Centreless grinding machines come under the cylindrical grinding machine category Tool and cutter grinding Surface Grinder Types of Grinders How They Work

How does a grinding machine work and what are the

2018年2月17日 Functioning of the grinding machine The grinding machine is a machine tool used to carry out finishing operations, often the grinding machine is characterized by a great structural rigidity As the name suggests, the grinding 2023年4月23日 Harder ores have a larger grinding re sistance than soft ores ther efore, hard ores have lower breakage rates than soft ores Wear resistance depends on the stre ngth of the ore being ground [6 7 ](PDF) Grinding Media in Ball MillsA Review2021年11月8日 Illite ore industrial grinding mill machines include ultrafine grinding mills, vertical roller mills, highpressure mills, wet stirring mills, coarse mills, and so on It can be applied to different illite grinding operation requirements and meet Illite Ore Industrial Grinding Mill Machine SBM Ultrafine 2015年4月9日 Grinding mills are size reductions machines that often follow crushers in the processes where finer products are desired after crushing Different grinding machines are usually named as mills, for example rod mills, ball mills, and attrition mills Because of the name, verb milling is also been used as a synonym for grindingGrinding Mills and Their Types IspatGuru

Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant

2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]Under no circumstances we will share your email address with third parties Please also note our privacy policy Sub Sub Category Ids 1153 « 1; 2 » Used Surface grinding machines vertical (26) Machineseeker now with more than 200,000 used machines: Used Surface grinding machines vertical for sale (26)2021年11月23日 This is a small grinder operated with electric power It can be easily carried anywhere Grinding can be done by holding it in hand It is used for cleaning heavy welding jobs On one end of the motor shaft, a grinding wheel is fitted and on the other end, a handle or switch for operating the machine is fixed according to our convenience14 Types of Grinding Machines [Working, Diagram PDF] The 2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Copper ore grinding in a mobile vertical roller mill pilot plant

Machining 101: What is Grinding? Modern Machine Shop

2021年7月3日 It is not suitable for conventional grinding machines, but for those which are compatible with it, it offers high productivity and cost effectiveness Creep feed grinding is a plunge operation with high horsepower requirements, and which also requires a heavy flow of cutting fluid close to the nip to remove chips and cool the work2022年12月13日 After the mining of lithium ore, the bulk material is first crushed by electromagnetic dressing equipment; Then under the action of belt conveyor, it is evenly sent to the grinding machine for deep grinding treatment; After grinding, lithium ore powder should be reasonably screened by spiral classifierHow to mine lithium ore, mineral processing, crushing, grinding2022年2月28日 Generally, grinding process efficiency can mainly be improved by either improving the grinding behavior of the material being ground or enhancing the grinding machines Recently, the use of additives socalled grinding aids, which is applied in a small amount of 001–025 wt% related to the mass of product, has reduced these problems and been Grinding SpringerLink2016年5月10日 In the handling of wet, sticky ores such as encountered in tropical areas having distinct dry and rainy seasons, the crushing plant is a section of the mill which must be planned very carefully Unless this is done, crushing becomes a constant source of trouble resulting in lost production and high milling cost In some areas rainfall is high for prolonged periodsCrushing and Grinding Wet Sticky Ore 911Metallurgist

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

2019年4月16日 Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like limestone, clinker, phosphate, manganese, magnesite, feldspar and titanium2021年1月1日 for controlled vertical spindle surface grinding multiaxis Comput er Numerical Control (CNC) machine are provided and addressed in depth in this stud y During the grinding pr ocess, a method in CONTROL OF VERTICAL SPINDLE SURFACE GRINDING FROM A 2023年3月6日 Vertical roller mills (VRM) are commonly used in the processing of iron ore for dry grinding for several reasons: vertical roller mill Energy Efficiency: VRMs are known for their energy efficiencyWhy is vertical roller millbased dry grinding used in iron ore 2021年5月5日 Colum is like a vertical pillar of the machine in this section the abrasive wheel, wheel head, and wheel guard are kept The column is also made up of cast iron The Grinding Machine is used for finishing the cylindrical and flat surfaces In other words, we can say it is used for grinding various materialsGrinding Machine: Definition, Parts, Working Principle, Operation

Ore Grinding Machines: Ball Mill, Rod Mil Grinding Media

Ore grinding machines can be divided into many types according to different classification methods, each with significant characteristics The following is a general introduction to the types of oregrinding machines and their characteristics According to the different media of the mill, the grinding machines are divided into: If the medium is steel balls, it is called a ball mill;2023年7月20日 (2) Various working parameters of grinding mill, including fraction of critical speed for grinding mill, filling rate for grinding mill, grinding concentration, grinding cycle load, etc (3) And grinding material properties, including ore grindability, feeding particle size, etc Huge energy and steel consumption in ore grinding process greatly affect the subsequent separation Ore Grinding SpringerLinkCondition: excellent (used), Year of construction: 2011, Functionality: fully functional, Vertical Surface Grinding Machine OMN SPR 600 Article Number: 1410052 Manufacturer: OMN Year of Manufacture: ca 2011 Condition: Excellent overall condition Delivery: Under no circumstances we will share your email address with third partiesUsed Vertical Grinding for sale (10,880) MachineseekerConditions under which grinding wheels are used vary considerably, and a wheel that is satisfactory on one machine may be too hard or soft for the same operation on another machine The following basic factors are considered when How to Use a Surface Grinder Machine: American

Research of iron ore grinding in a verticalrollermill

Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGate2018年6月18日 Pretreatment of ores to improve energy efficacy of grinding has been explored for decades However, many of these techniques are still at developmental stages and a review has been presented in Ore Pretreatment Methods for Grinding: Journey and ProspectsEffect of media type on ore grinding performance There are many factors that will affect the ore grinding performance in ball mills The type of media, the size and shape of the particles, and the speed at which they are ground are just a few of the factors that can have a significant impactFactors affecting ores grinding performance in ball millsNew and Used Grinding Machines Grinding Machines are used to grind surfaces of metal materials Grinding Machines consist of a work table and a vertical column which is where the abrasive wheel, wheel guard, and wheel head are placed The abrasive wheel is coated with abrasion or a friction material which allows the metal material to easily be grinded from the New and Used Grinding Machines Equipt

Vertical Grinding: An Overview Indiana Precision Grinding

2020年3月25日 What is Vertical Grinding? Vertical grinding takes everything we know about standard grinding and turns it on its side Literally Instead of the workpiece being held on one side of the machine and the grinding wheel moving along the Xaxis (horizontally) to grind the part, the piece is secured to the bottom and the wheel moves vertically along the Zaxis on top 2022年12月8日 A CNC grinding machine uses a rotating grinding wheel to remove small amounts of material from a workpiece They are, first and foremost, finishing machines In the case of round work, a machinist often removes significant amounts of material using a lathe before transferring the part to a cylindrical grinding machine for the finishing C Grinding Machine Buyers Guide: Types, Price, Uses, Features2019年10月8日 31 Selfgrinding, semiautogenous grinding machine Since the use of selfgrinding and semiselfgrinding technology in the 1950s, it has grown into a mature, reliable and continuously applied technology In the selfgrinding process, the ore larger than 100 mm in the mill acts as a grinding mediumCrushing and Grinding Process JXSC Machine2022年8月31日 Dear Colleagues, The grinding process, as a primary stage of ore/raw material processing, is a necessary operation in beneficiation plants It not only provides the appropriate particle size for subsequent separation operations but also enables the liberation of valuable minerals from the gangueGrinding Modeling and Energy Efficiency in Ore/Raw Material

.jpg)

Grinding Machines SpringerLink

2019年1月1日 Grinding machines with oil as coolant require a fire protection 9 Grinding machines are preferably equipped with a contact recognition sensor on acoustic emission (AE) basis, to detect, when the grinding wheel touches the workpiece With this very precise relative material, removal can be achieved 102021年1月16日 Cylindrical and internal grinding machines are used for grinding cylindrical diameters and bores (internal diameter) Centreless grinding machines come under the cylindrical grinding machine category Tool and cutter grinding Surface Grinder Types of Grinders How They Work 2018年2月17日 Functioning of the grinding machine The grinding machine is a machine tool used to carry out finishing operations, often the grinding machine is characterized by a great structural rigidity As the name suggests, the grinding How does a grinding machine work and what are the 2023年4月23日 Harder ores have a larger grinding re sistance than soft ores ther efore, hard ores have lower breakage rates than soft ores Wear resistance depends on the stre ngth of the ore being ground [6 7 ](PDF) Grinding Media in Ball MillsA Review

Illite Ore Industrial Grinding Mill Machine SBM Ultrafine

2021年11月8日 Illite ore industrial grinding mill machines include ultrafine grinding mills, vertical roller mills, highpressure mills, wet stirring mills, coarse mills, and so on It can be applied to different illite grinding operation requirements and meet 2015年4月9日 Grinding mills are size reductions machines that often follow crushers in the processes where finer products are desired after crushing Different grinding machines are usually named as mills, for example rod mills, ball mills, and attrition mills Because of the name, verb milling is also been used as a synonym for grindingGrinding Mills and Their Types IspatGuru2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot PlantUnder no circumstances we will share your email address with third parties Please also note our privacy policy Sub Sub Category Ids 1153 « 1; 2 » Used Surface grinding machines vertical (26) Machineseeker now with more than 200,000 used machines: Used Surface grinding machines vertical for sale (26)

.jpg)

14 Types of Grinding Machines [Working, Diagram PDF] The

2021年11月23日 This is a small grinder operated with electric power It can be easily carried anywhere Grinding can be done by holding it in hand It is used for cleaning heavy welding jobs On one end of the motor shaft, a grinding wheel is fitted and on the other end, a handle or switch for operating the machine is fixed according to our convenience2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Copper ore grinding in a mobile vertical roller mill pilot plant2021年7月3日 It is not suitable for conventional grinding machines, but for those which are compatible with it, it offers high productivity and cost effectiveness Creep feed grinding is a plunge operation with high horsepower requirements, and which also requires a heavy flow of cutting fluid close to the nip to remove chips and cool the workMachining 101: What is Grinding? Modern Machine Shop