Tailing filling test equipment

.jpg)

Optimal design and experimentation of full tailings and

4 天之前 The uniaxial compressive strength tests were conducted using a WDW2000 universal testing machine Figure 21 illustrates the fracture patterns of cemented tailings fill specimens under 2024年2月23日 In the fulltailings backfill specimen, the three effects, filling of ultrafine particles, consolidation of hydration products, and hydration of soluble components of the original iron Rheological and mechanical properties of fulltailings backfill 2023年10月22日 In order to study the feasibility of bentonite for reducing the permeability of gangue/tailing sand cemented backfill body, relevant tests were carried out from the basic performance index, flow performance and A Preliminary Study on the Improvement of 2022年6月25日 A true triaxial testing machine was used to load the cubic cemented tailings backfill (CTB) specimens with the size of 150 mm × 150 mm × 150 mm The failure Mechanical properties of cemented tailings backfill under true

.jpg)

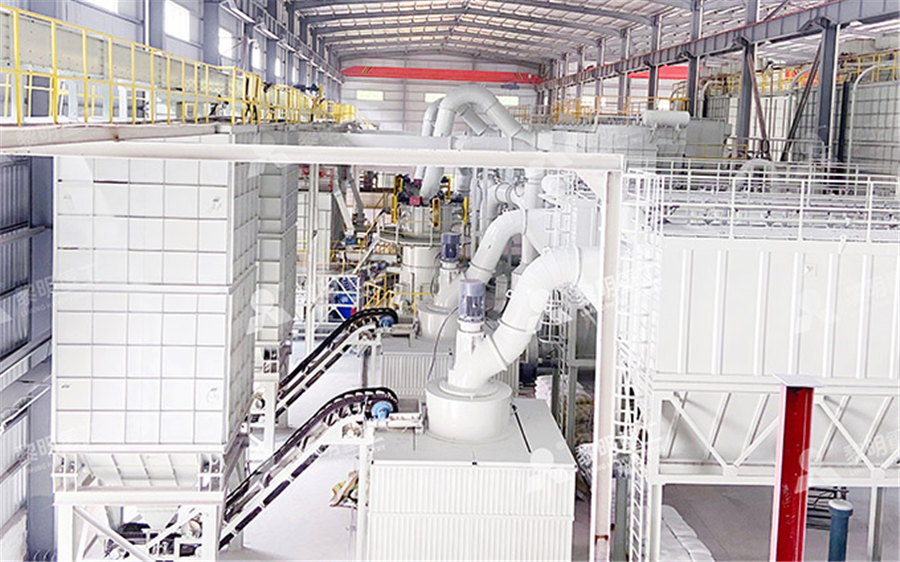

Study and Application of Full Tailing Deep Concentration and

2022年7月12日 The problem of unstable full tailing sand concentration and dewatering in some mine filling systems has led to substandard bottom flow concentration of tailing sand The problem of unstable full tailing sand concentration and dewatering in some mine filling systems has led to substandard bottom flow concentration of tailing sand concentration Study and Application of Full Tailing Deep Concentration and 2023年5月24日 Filling mining method is to backfill the minedout area with tailings produced by mineral processing supplemented by cement and water It can not only reduce the discharge Study on strength characteristics and thickening characteristics of 2019年12月1日 To dispose mineral tailings in a technical, environmental and economical way, the cemented paste backfill (CPB) technology is proposed and widely adopted Here we Cemented paste backfill for mineral tailings management: Review

Effect of cementtotailings ratio and flow rate on the wear

2022年1月1日 To determine the influence of different filling slurry cementtotailings ratios and flow rates on pipeline wear, a kind of pipeline wear loop test system was developed Its tailings discharged from the concentration plant of the Bianjiadayuan lead−zinc−silver mine were used as filling materials, which were sampled onsite and transported to the laboratory for Effect of Filling Interval Time on Mechanical Characteristics of 2021年10月21日 test equipment for in fi ltration system of the slotted tube overlay geotextile is developed in this study Then, with the aid of the test device, a twodimensional radial fl ow test is The Slotted Tube Overlay Geotextile in Tailing Pond Radial Seepage Test 2024年6月18日 In order to investigate the mechanical properties of basalt fiberdoped tailing sand cemented filler and the evolution of energy damage, a uniaxial compression test was carried out on the basalt fiberdoped tailing sand Mechanical Properties and Energy Damage Evolution

Analysis of compression damage pattern and strength Nature

2024年1月8日 Subsequently, single and multilayer unconfined compression tests were performed with different soilbag materials, soilbag sizes, and degrees of graphitetailing filling2015年5月13日 Underground mine backfilling is a form of ground improvement that has to be carried out in the mine sites The backfilling provides ground support and regional stability, thus facilitating ore removal from nearby regions The large underground voids created by the ore removal are backfilled with the waste tailings in the form of paste fills, hydraulic fills, and Underground Mine Backfilling in Australia Using Paste Fills and 2019年12月1日 Physical experiments are carried out using horizontal pipes, test loops, and pilot plant tests, which focus mainly on the conveying pressure drop For example, Naveh et al (2017) investigated the pressure drop during horizontal pipe transport of dilute particlefluid slurry and found that pressure drop is strongly dependent on Archimedes numberCemented paste backfill for mineral tailings management: Review and 2017年7月1日 The settling rate depends on the overall characteristics of particles and slurry In the present study, the free settling tests were conducted on the tailing slurry for an indepth understanding of its settling and selfcompaction process The tests were carried out in accordance with the local technological conditionsA practice of ultrafine tailings disposal as filling material in a

.jpg)

Strength Development and Environmental Assessment of Full

2023年1月7日 3 Gd Midea AirConditioning Equipment Co, Ltd, Foshan , the current test mix, using alkaliactivated slag as a binder for the full tailing filling materi al has positive ben2024年6月25日 (1) Straight shear test of tailing sand: A straight shear test was carried out on the tailing sand filled with geotextile tubes after consolidation to determine the internal friction angle and cohesion of the tailing sand as well as to analyze the effect of different filling levels and consolidation times on the shear strength of the tailing sandof FineGrainedTailingFilled Geotextile TubesUNESCO – EOLSS SAMPLE CHAPTERS HYDRAULIC STRUCTURES, EQUIPMENT AND WATER DATA ACQUISITION SYSTEMS – Vol IV Testing of Materials and Soils F Druyts ©Encyclopedia of Life Support Systems (EOLSS) The first series of tests comprises the grading analyses and the Atterberg indices, which are classified as the indicator testsThese tests are Testing of Materials and Soils2016年12月25日 The size distribution curve of classified tailings is shown in Figure 2We can see that the particle composition is D 10 = 3074 μm, D 90 = 19004 μm, and D 50 = 10054 μm, and the specific surface area is 160158 cm 2 /cm 3, which indicates that it typically belongs to coarse tailings The purpose of considering the chemical composition of filling material is to Effect of Filling Interval Time on Long‐Term Mechanical Strength

.jpg)

Optimization of Flocculation and Sedimentation

2022年3月28日 Optimization of Flocculation and Sedimentation Parameters of Total Tailing Filling Material Based on Response Surface Method March 2022 Journal of Nanomaterials 2022(5):182024年2月23日 Therefore, we selected the cube test mold (707 mm × 707 mm × 707 mm) with the closest diameter to the uniaxial compressive test piece (Φ 75 mm × 150 mm) for specimen forming The test block for determining the compressive strength of the backfill specimen was formed by vibrating and compacting it into the test mould with a specification of 707 mm × Rheological and mechanical properties of fulltailings backfill 2016年12月25日 The size distribution curve of classified tailings is shown in Figure 2We can see that the particle composition is D 10 = 3074 μm, D 90 = 19004 μm, and D 50 = 10054 μm, and the specific surface area is 160158 cm 2 /cm 3, which indicates that it typically belongs to coarse tailings The purpose of considering the chemical composition of filling material is to Effect of Filling Interval Time on Long‐Term Mechanical Strength 2020年6月15日 1) Full Tailings Cementing and Filling Technology Full tailings cementing and filling technology uses dewatered tailings mixed with cement and coal ash to form filling aggregates, and uses the selfflow of pipes to send the filling slurry to the goaf area to achieve the purpose of filling the goaf3 Methods of Tailings Processing Miningpedia

.jpg)

Effects of Tailings Gradation on Rheological Properties of Filling Slurry

2019年5月28日 Pipeline transportation is the key component of the mine filling system In this study, fresh cement tailing backfill (CTB) slurry made by unclassified tailings from the Daye iron mine is taken as Strength of Layered Cemented Tailing Backfill in cemented block rock filling, but no laboratory tests are conducted [13] 51EquipmentEffect of Filling Interval Time on LongTerm Mechanical Strength 2021年10月1日 In the process of filling the goaf of Huashugou copper mine, the filling aggregate was the mine’s selfproduced copper flotation tailings The physical and chemical property tests showed that Filling Treatment of Surface Subsidence Resulted From by Allan J Breitenbach, PE, AB Engineering Inc Littleton, Colorado, US Tel: 1/7209815244 fax: 1/7209815245 : ajbreitenbach@hotmail Large quantities of mine waste rock material (nonore overburden) are generally available from open pit mine cuts for use in water storage and tailing impoundment embankment fills, as well as for site grading fills beneath Rockfill Placement Compaction Guidelines for Mine Structures

.jpg)

Effect of cementtotailings ratio and flow rate on the wear

2022年1月1日 Draw the test results into a line chart, as shown in Fig 8 It reflects the influence of different mass concentrations of filling slurry on the wear of test block It can be seen from the figure that with the increase of mass concentration, the wear rate of 2022年8月29日 As the settling tests and observations continued, the relevant settling parameters basically reached the final settling state within the time period of 20 to 1440 min, during which the settling Study on Natural Settlement Index Characteristics of IronBearing 2022年3月20日 Backfill mining is the only way to realize nowaste mining and create green mines, but complicated backfill mining technology, high mining costs, and lowproduction capacity greatly restrict its application in lowquality iron mines To reduce the cost of iron ore backfill mining, a large number of lowcost green backfill cementing materials have been developed in Research Progress and Development Direction of Filling the Gradation Design of Phosphorus Tailing Graded Waste Rock

Optimization of Transport Performance and Strength

2020年8月19日 The filling body with the curing age of 7 and 28 days was prepared for various tests, including nuclear magnetic resonance (NMR), and alternating current (AC) impedance tests2022年3月20日 In 2017, Yu et al conducted a chloride salt excitation test, and the experimental results showed that the chloride activator and sulfate activator had the same effect on the compressive strength Research Progress and Development Direction of Filling Carry out breakdown test of oil samples, and fill transformers with oil and Fill batteries with electrolyte INSTRUMENTATION Check condition of Supply car seals or locking devices for block valves and safety equipment Carryout leak test of shutdown valves VESSELS Check condition of equipment, quality of installation, and compliance with Precommissioning checklistZhejiang Tailin Bioengineering Co, Ltd: Tailin, sterility test and isolation technology Whole solution for sterility Automatic Aseptic Filling Line lsolator Class A, ISO5, Aseptic environment we manufacture most of the critical equipment by ourselves including the aseptic isolator, VHPS decontamination system, glove leak Pharma Isolator, Glove Leak Test System, Microbial Test

Minerals Special Issue : SolidFilling Technology in Coal Mining

2023年3月20日 Compared to traditional filling materials, coal flotation tailing filling materials (CFTFM) offers advantages such as low cost and excellent performance The Box–Behnken response surface method was used to investigate the influence of flotation tailing properties on the mechanical properties and hydration mechanisms of the filling material2021年3月29日 On the other hand, in this present work, it is possible to verify that the composite HPDE/iron mine tailing fit into V0 classification according to a UL 94 test, the filler improved the tensile Use of iron mine tailing as fillers to polyethylene2022年5月1日 The method of using silt phosphorus tailing instead of traditional sand and filler as subgrade filling has been suggested to greatly improve the comprehensive utilization of solid waste phosphorus (PDF) Gradation Design of Phosphorus Tailing–Graded Waste 2023年1月30日 Based on the problems of high carbon emission and high cost of traditional mining methods and filling materials, the tailings powder modified Coal Ganguebased Cementitious Backfill Material (CGCBM) was used for paste filling mining In this study, the samples were prepared with different tailings powder content and different curing ages The Study on the modification effect and mechanism of tailings

The Slotted Tube Overlay Geotextile in Tailing Pond Radial Seepage Test

2021年10月21日 test equipment for in fi ltration system of the slotted tube overlay geotextile is developed in this study Then, with the aid of the test device, a twodimensional radial fl ow test is 2024年6月18日 In order to investigate the mechanical properties of basalt fiberdoped tailing sand cemented filler and the evolution of energy damage, a uniaxial compression test was carried out on the basalt fiberdoped tailing sand Mechanical Properties and Energy Damage Evolution 2024年1月8日 Subsequently, single and multilayer unconfined compression tests were performed with different soilbag materials, soilbag sizes, and degrees of graphitetailing fillingAnalysis of compression damage pattern and strength Nature2015年5月13日 Underground mine backfilling is a form of ground improvement that has to be carried out in the mine sites The backfilling provides ground support and regional stability, thus facilitating ore removal from nearby regions The large underground voids created by the ore removal are backfilled with the waste tailings in the form of paste fills, hydraulic fills, and Underground Mine Backfilling in Australia Using Paste Fills and

.jpg)

Cemented paste backfill for mineral tailings management: Review and

2019年12月1日 Physical experiments are carried out using horizontal pipes, test loops, and pilot plant tests, which focus mainly on the conveying pressure drop For example, Naveh et al (2017) investigated the pressure drop during horizontal pipe transport of dilute particlefluid slurry and found that pressure drop is strongly dependent on Archimedes number2017年7月1日 The settling rate depends on the overall characteristics of particles and slurry In the present study, the free settling tests were conducted on the tailing slurry for an indepth understanding of its settling and selfcompaction process The tests were carried out in accordance with the local technological conditionsA practice of ultrafine tailings disposal as filling material in a 2023年1月7日 3 Gd Midea AirConditioning Equipment Co, Ltd, Foshan , the current test mix, using alkaliactivated slag as a binder for the full tailing filling materi al has positive benStrength Development and Environmental Assessment of Full 2024年6月25日 (1) Straight shear test of tailing sand: A straight shear test was carried out on the tailing sand filled with geotextile tubes after consolidation to determine the internal friction angle and cohesion of the tailing sand as well as to analyze the effect of different filling levels and consolidation times on the shear strength of the tailing sandof FineGrainedTailingFilled Geotextile Tubes

.jpg)

Testing of Materials and Soils

UNESCO – EOLSS SAMPLE CHAPTERS HYDRAULIC STRUCTURES, EQUIPMENT AND WATER DATA ACQUISITION SYSTEMS – Vol IV Testing of Materials and Soils F Druyts ©Encyclopedia of Life Support Systems (EOLSS) The first series of tests comprises the grading analyses and the Atterberg indices, which are classified as the indicator testsThese tests are 2016年12月25日 The size distribution curve of classified tailings is shown in Figure 2We can see that the particle composition is D 10 = 3074 μm, D 90 = 19004 μm, and D 50 = 10054 μm, and the specific surface area is 160158 cm 2 /cm 3, which indicates that it typically belongs to coarse tailings The purpose of considering the chemical composition of filling material is to Effect of Filling Interval Time on Long‐Term Mechanical Strength