Where is the technology for producing α gypsum powder

Process for producing alpha gypsum powder by liquid phase

2007年10月24日 A technology of gypsum powder and liquid phase method, which is applied in the field of α gypsum powder production, which can solve problems such as unstable product performance, uneven heating, temperature adjustment, etc, and achieve stable product The production method comprises the following steps: (1) mixing phosphogypsum with a dry basis mass content larger than or equal to 95% with water to prepare slurry; (2) adding a crystal Production method of alphagypsum powder with high strengthThe process comprises the following specific steps of: placing a chemical gypsum as a raw material in a mixing machine, and spraying a mixed aqueous solution of a crystal modifier of Process for producing highstrength alphagypsum from chemical The invention discloses a manufacturing technique of alphaplaster powder through liquidphased method in the alphaplaster powder preparing technical domain, which comprises the following CNA Process for producing alpha gypsum powder by

.jpg)

Innovative synthesis of highstrength αhemihydrate gypsum:

2024年10月15日 Specifically, the growth of αHH can be divided into 3 steps, 1) the dissolution of dihydrate gypsum (DH), 2) the formation of HH nuclei, and 3) the crystallization of αHH For 2024年1月17日 The synthesis of αcalcium sulfate hemihydrate (αCSH) from flue gas desulfurization (FGD) gypsum is a good way to realize the comprehensive utilization of FGD Preparation of αHigh Strength Gypsum from Flue Gas 2021年11月1日 Flue gas desulfurized gypsum mainly comes from thermal power plants, smelters, and largeenterprise boilers, and contains industrial byproducts produced through a Production and resource utilization of flue gas desulfurized 2024年10月14日 This study explored the production of a medium–low strength αhemihydrate gypsum (αHH) from phosphogypsum using an autoclaved method The influence of slurry Preparation of Medium–Low Strength Hemihydrate Gypsum from

Utilization of phosphogypsum to synthesize αhemihydrate

2023年3月3日 In this study, αhemihydrate gypsum (αHH) was synthesized from PG in H 3 PO 4 –H 2 O solution (wetprocess phosphoric acid solution and phosphoric acid solution) under In the production of construction gypsum from phosphogypsum, the same machines are currently used in which calcium sulfate hemihydrate is produced from natural gypsum stone V V Open Access proceedings Journal of Physics: Conference seriesThe Company possesses 4 gypsum mines and 14 production enterprises in Sanmenxia of Henan Province, Sanmenxia Yongtai Gypsum Technology Co, Ltd is located in Xiaodongmen, Huixing Town, Hubin District, α Gypsum Powder β Gypsum Powder Gypsum Mortar SUBSIDIARY Distribution Of DomesticHenan Yongtai Gypsum (Group) Co, Ltd gypsum、powder The technical process of liquid phase method production αtype high strength gypsum is advanced, control is accurate, and the obtained αtype gypsum intensity of its production is high, and the coefficient of expansion is little, and made model can copy details exactlyChinese patent literature CN A (application number: 87) disclose a kind of continous Production method of alphagypsum powder with high strength

Production and use of byproduct gypsum in the ScienceDirect

1996年1月1日 Therefore, the production of gypsum binders and materials is the most effective method of desulphogypsum utilization Their applicability in gypsum technology results in high purity and consequently, stability of chemical and physical properties attributed to When Gypsum ( CaSO 4,2H 2O) is ground to a powder and heated at 150° to 165° C, threequarters of its combined water is removed producing hemihydrate plaster ( CaSO 4,1/2H 2O), commonly known as the ‘Plaster of Paris’ When this powder is mixed with water the resulting paste sets hard as the water recombines to produce Gypsum againFactsheet on: What is Gypsum?Producing alpha gypsum powder by liquid phase method, be to become fineness to be the terra alba that certain granules distributes raw material gypsum crushing grinding, in mixing tank, blend together certain density gypsum slip with water then, and heat temperature raising, gypsum slip after being mixed enters through shurry pump to be changeed in the brilliant device, under the Process for producing highstrength alphagypsum from chemical gypsum The method of producing gypsum binders is aimed at achieving the technical result of providing opportunities for producing αmodifications of calcium sulfate hemihydrate and multiphase gypsum binders, obtained on its basis, at atmospheric pressure The technical result is achieved due to the fact that the new method, involving dehydration of gypsum raw material lumps, Method for producing a gypsum binder Google Patents

Innovative synthesis of highstrength αhemihydrate gypsum:

2024年10月15日 Highstrength gypsum is the recognized designation for αhemihydrate gypsum, often referred to as αHH (CaSO 4 05H 2 O), which is a cementitious material with low water requirement and high strength [8]The strength of αHH is generally between 25 and 50 N/mm 2, which is three times that of ordinary building plaster, and has superior working 2023年12月1日 Additionally, 3D powder printing technology (3DP) is gaining a lot of attention in the fields of building and decoration because of its excellent consistency and straightforwardness (Feng et al, 2019; Xu et al, 2023; Park et al, 2021; Ingaglio et al, 2019; Guo et al, 2022)Furthermore, gypsum has been a fundamental component in the 3DP process and Flowability prediction of recycled αhemihydrate gypsum for 3D powder 2022年1月7日 Phosphogypsum (PG) is a massive industrial solid waste In this paper, PG was purified by flotation method, and αhemihydrate gypsum (αHH) was prepared by the autoclaving method The morphology The study on the effect of flotation purification on the performance 2011年1月1日 Gypsum is the most common sulfate mineral on earth and is commonly associated with halite, anhydrite, sulfur, calcite and dolomite in recent coastal (sabkha or salina) and/or continental (playa Gypsum: Properties, production and applications Request PDF

.jpg)

1116 Gypsum Manufacturing US EPA

wallboard, gypsum must be partially dehydrated or calcined to produce calcium sulfate hemihydrate (CaSO4 ½H 2O), commonly called stucco A flow diagram for a typical gypsum process producing both crude and finished gypsum products is shown in Figure 11161 In this process gypsum is crushed, dried, ground, and calcined2021年11月1日 The main synthetic materials are αhemihydrate gypsum dihydrate, calcium carbonate, adsorption materials and composite material (Table 4) The preparation of αhemihydrate gypsum (αHH) is an effective way to realize the highvalue utilization of FGD gypsum The formation mechanism and crystal structure of αHH are shown in Fig 4Production and resource utilization of flue gas desulfurized gypsum Major Gypsum Producing Countries United States: The United States is one of the leading producers of gypsum, with significant production occurring in states such as Texas, Iowa, California, Michigan, and Oklahoma Gypsum is used in Gypsum: Properties, Uses, Formation, Types – Geology In2021年7月1日 Flue gas desulfurized gypsum (FGD gypsum), mainly originates from thermal power plants, smelters, and largescale enterprise boilers This article reviews the production in China and the latest Production and resource utilization of flue gas desulfurized gypsum

.jpg)

Formation of αHemihydrate Inside of a Gypsum Crystal during

2022年12月8日 Formation of αHemihydrate Inside of a Gypsum Crystal during the Dehydration Process Christian Pritzel 1, 2, *, Mohammadamin Emami 1,3 , Sandra Afflerbach 4 , Manuela Killian 22023年5月15日 Figure 1: a: Gypsum crystals produced from sodium sulphate and calcium chloride; b: Natural gypsum cut along black lines; c: Gypsum crystals from a, with directions from Figure 2 marked with arrows, on side from Figure 3 marked with yellow, on cleavage plane with red; d: Crystal from a) along caxis marked in blackUnderstanding gypsum in 3 diagramsThe work investigates the physical, mechanical, and technological properties of mixtures to manufacture cores in a foundry The filler is technical salt, the binder is an aqueous solution of The physical properties of different gypsum powdersIn conclusion, gypsum powder production technology offers numerous benefits for businesses looking to produce highquality gypsum powder With advanced equipment and expertise, gypsum powder production lines are able to meet the strictest quality standards and deliver a consistent and uniform product Countries like Luxembourg, Gypsum powder production technology

.jpg)

Preparation of αcalcium sulfate hemihydrate from industrial by

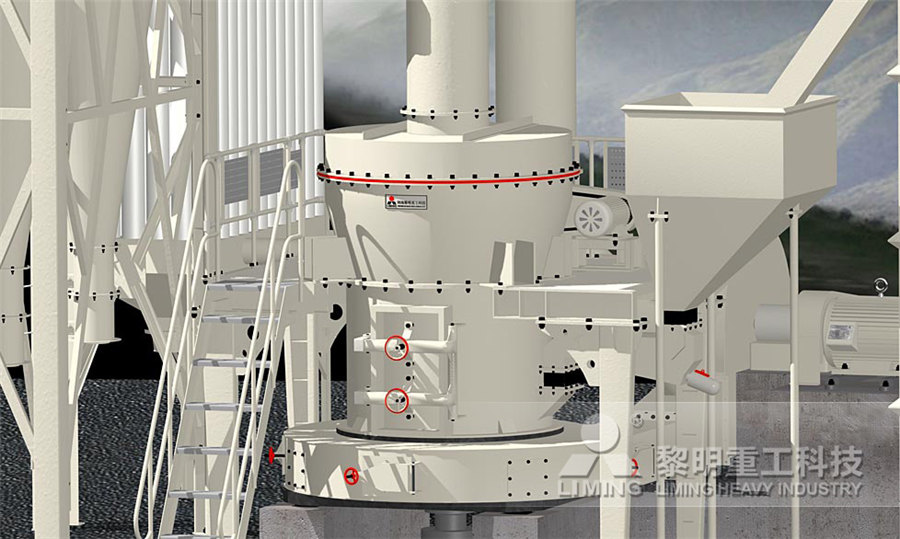

2020年11月23日 The synthesis of hemihydrate gypsum (αHH) crystals with a low aspect ratio is of great significance to practical production for the effective utilization of flue gas desulfurization (FGD) gypsum2023年1月31日 Preparation of αhemihydrate gypsum crystal is an approach for utilization of phosphogypsum (PG), but the soluble phosphorus impurities in PG have a crucial influence on the performance of αhemihydrate gypsum In this article, different forms of soluble phosphorus (H3PO4, H2PO4− and HPO42−) on the setting time and mechanical properties of α Effect of Soluble Phosphorus on the Mechanical Properties of α 2023年11月2日 They use advanced technology to provide highspeed grinding and classification, which results in the production of ultrafine gypsum powder Particle Size Range: Ultrafine mills can produce gypsum powder with a very narrow and precise particle size distribution, typically in the submicron to micron rangeHow To Set Up a Gypsum Powder Production Line From Scratch2023年8月22日 Flue Gas Desulphurized Gypsum (FGDG) is a byproduct generated by the thermal power industry to remove sulfur dioxide (SO 2) from flue gas emissionsThis paper provides a comprehensive review of flue gas desulphurized (FGD) gypsum production, property, and applications in the construction industryA comprehensive review of flue gas desulphurized gypsum: Production

Gessi Roccastrada, Italian gypsum plaster

WE ARE THE GYPSUM IN ITALY Gessi Roccastrada is an Italian gypsum plaster manufacturer specialized in the production of gypsum panels for interior walls, gypsum powder and gypsum products for the building industry The 2024年5月14日 Gypsum powder production line is a process that involves the processing of gypsum (CaSO₄2H₂O) into a fine powder form, suitable for use in various construction and manufacturing applications This article provides an overview of the production line, its components, and its significance in the industry Raw Material Extraction and PreparationWhat is Gypsum Powder Production Line?2019年11月8日 The origin of gasporosity in goldbased alloys produced via lostwax casting in CaSO4bonded investment has been identified using a combination of microanalytical and thermal techniques(PDF) Study on the Thermal Expansion Performance of Gypsum in Key words: flue gas desulfurization gypsum; αhemihydrate gypsum; calcinationhydration treatment; dissolution; surface characteristics Cite this article as: GUAN Qingjun, SUN Wei, GUAN Changping, YU Weijian, ZHU Xiangnan, Sultan Ahmed Khoso, WANG Ping, PENG Wenqing Promotion of conversion activity of FGD gypsum into αhemihydrate gypsumPromotion of conversion activity of flue gas desulfurization gypsum

Autoclave‐Free Formation of α‐Hemihydrate Gypsum

2005年3月8日 Download Citation Autoclave‐Free Formation of α‐Hemihydrate Gypsum Flue gas gypsum may be converted to αhemihydrate by suspending the starting material in inorganic salt solutions of 2020年8月26日 DOI: 101021/acsiecr0c03305 Corpus ID: ; Unraveling a Sustainable Process for the Production of HighStrength αGypsum Using Soda Residues and H2SO4 @article{Wang2020UnravelingAS, title={Unraveling a Sustainable Process for the Production of HighStrength $\alpha$Gypsum Using Soda Residues and H2SO4}, Unraveling a Sustainable Process for the Production of HighStrength α 2021年11月1日 Flue gas desulfurized gypsum (FGD gypsum), mainly originates from thermal power plants, smelters, and largescale enterprise boilersThis article reviews the production in China and the latest beneficial utilizations of FGD gypsum China is a large coalconsuming country and has always had serious SO 2 emissions Therefore, the Chinese government has Production and resource utilization of flue gas desulfurized gypsum Powder process technology: Gypsum is monoclinic system, with a high degree of cleavage, easily split into thin slices When gypsum is heated to 100 ~ 200 ° C, it loses some crystal wate, and hemihydrate gypsum appears αhemihydrate gypsum crystal is good and solid; βhemihydrate gypsum is flaky and cracked, with small crystal and high specific surface area than the α Gypsum Powder Process Technology, Gypsum Grinding Mill

Henan Yongtai Gypsum (Group) Co, Ltd gypsum、powder

The Company possesses 4 gypsum mines and 14 production enterprises in Sanmenxia of Henan Province, Sanmenxia Yongtai Gypsum Technology Co, Ltd is located in Xiaodongmen, Huixing Town, Hubin District, α Gypsum Powder β Gypsum Powder Gypsum Mortar SUBSIDIARY Distribution Of DomesticThe technical process of liquid phase method production αtype high strength gypsum is advanced, control is accurate, and the obtained αtype gypsum intensity of its production is high, and the coefficient of expansion is little, and made model can copy details exactlyChinese patent literature CN A (application number: 87) disclose a kind of continous Production method of alphagypsum powder with high strength1996年1月1日 Therefore, the production of gypsum binders and materials is the most effective method of desulphogypsum utilization Their applicability in gypsum technology results in high purity and consequently, stability of chemical and physical properties attributed to Production and use of byproduct gypsum in the ScienceDirectWhen Gypsum ( CaSO 4,2H 2O) is ground to a powder and heated at 150° to 165° C, threequarters of its combined water is removed producing hemihydrate plaster ( CaSO 4,1/2H 2O), commonly known as the ‘Plaster of Paris’ When this powder is mixed with water the resulting paste sets hard as the water recombines to produce Gypsum againFactsheet on: What is Gypsum?

Process for producing highstrength alphagypsum from chemical gypsum

Producing alpha gypsum powder by liquid phase method, be to become fineness to be the terra alba that certain granules distributes raw material gypsum crushing grinding, in mixing tank, blend together certain density gypsum slip with water then, and heat temperature raising, gypsum slip after being mixed enters through shurry pump to be changeed in the brilliant device, under the The method of producing gypsum binders is aimed at achieving the technical result of providing opportunities for producing αmodifications of calcium sulfate hemihydrate and multiphase gypsum binders, obtained on its basis, at atmospheric pressure The technical result is achieved due to the fact that the new method, involving dehydration of gypsum raw material lumps, Method for producing a gypsum binder Google Patents2024年10月15日 Highstrength gypsum is the recognized designation for αhemihydrate gypsum, often referred to as αHH (CaSO 4 05H 2 O), which is a cementitious material with low water requirement and high strength [8]The strength of αHH is generally between 25 and 50 N/mm 2, which is three times that of ordinary building plaster, and has superior working Innovative synthesis of highstrength αhemihydrate gypsum: 2023年12月1日 Additionally, 3D powder printing technology (3DP) is gaining a lot of attention in the fields of building and decoration because of its excellent consistency and straightforwardness (Feng et al, 2019; Xu et al, 2023; Park et al, 2021; Ingaglio et al, 2019; Guo et al, 2022)Furthermore, gypsum has been a fundamental component in the 3DP process and Flowability prediction of recycled αhemihydrate gypsum for 3D powder

The study on the effect of flotation purification on the performance

2022年1月7日 Phosphogypsum (PG) is a massive industrial solid waste In this paper, PG was purified by flotation method, and αhemihydrate gypsum (αHH) was prepared by the autoclaving method The morphology 2011年1月1日 Gypsum is the most common sulfate mineral on earth and is commonly associated with halite, anhydrite, sulfur, calcite and dolomite in recent coastal (sabkha or salina) and/or continental (playa Gypsum: Properties, production and applications Request PDF