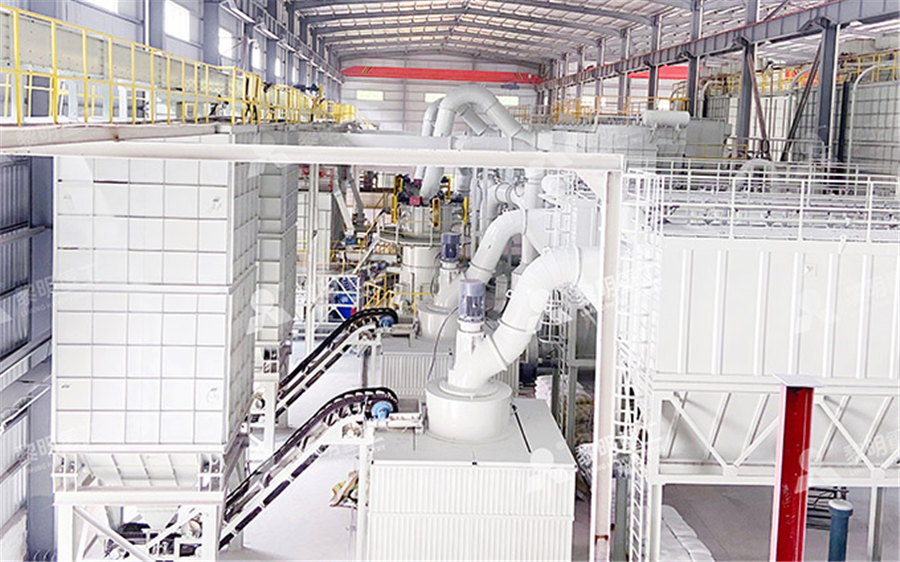

Ore grinding machine with a large output of 30 tons per hour

Dasen: all in one ore mining machinery, equipment, solution

2024年10月25日 Dasen Mining is a professional ore mining machinery, equipment manufacturer, supplier and mining solution provider for gold ore, copper ore, tungsten ore, tin After the goldbearing ore undergoes crushing and grinding operations, the Solutions30 Ton Per Hour Ore Grinding Plant From China/Raymond Mill Price/Raymond Mill Manufacturer, Find Details and Price about Mining Machine Grinding Mill from 30 Ton Per Hour Ore Grinding 30 Ton Per Hour Ore Grinding Plant From China/Raymond Mill Our Enduron® HPGR portfolio ranges from pilot machines to large format production machines including the world’s largest operational roller surface, capable of processing over 118,000 Our Dynamic HPGR Technology for Mineral Grinding Weir

30 ton per hour ore grinding plant from china/raymond mill price

30 Ton Per Hour Ore Grinding Plant From China/raymond Mill Price/raymond Mill Manufacturer , Find Complete Details about 30 Ton Per Hour Ore Grinding Plant From China/raymond Mill Sandmine provides comprehensive onestop solutions in multiple fields such as sand and aggregate making, metal ore crushing, solid waste disposal, industrial powder processing, and SANDMINE CRUSHING, GRINDING SCREENING TECHNOLOGYEvery mining operation has a unique grinding process Metso has experience of over 8,000 grinding mills globally Reliable, energyefficient technology and solutions across wet, dry, Grinding MetsoWe have designed 300+ ore crushing and grinding projects for users in more than 40 countries and regions around the world Sand production line with an output of 800 tons per hour Ore Crushing, Sand Making, Grinding Machinery Bellian Mining

.jpg)

How to configure a 500tonperhour gravel production line?

2024年3月5日 In addition to the crusher, a complete stone production line with an output of 500 tons per hour also requires some auxiliary equipment such as: vibrating feeder, vibrating screen, belt conveyor, etc According to different user needs, dust Output: 6 t/h 350 t/h Motor power: 75 kW 3,300 kW Machine length: 2,400 mm 7,200 mm years, with the continuous consumption of highgrade ores, the characteristics of poor, fine and miscellaneous minerals have become prominent, and the sorting and processing of lowgrade and refractory oresOre mill, Ore grinding mill All industrial manufacturersUp to 300 tons per hour (varies with material composition and moisture content,feed system capacity and selected components) Maximum screenable output ranges from minus 8 mesh producing 100 tons per hour to minus 14 mesh producing 30 tons per hourIndustry ApplicationsGrinding for heavy clay applicaBall Mill Design Power CalculationThe basic en/168/grinding mill tons per hourmd at main lbsid/en2024年7月17日 They handle feed sizes up to 800 mm and output capacities from 30 to 2,000 t/h They are affordable, suitable for budgetconscious users However, the blow bars and impact plates wear out quickly when crushing hard rocks The machine struggles with wet or muddy materials, making blockages hard to clear 3Types of Crushers: Choosing the Right One for Each Stage

Grinding Mills and Their Types – IspatGuru

2015年4月9日 Small machines can have a throughput of only a few tens of kg per hour whereas larger machines are capable of handling up to 40 or 50 tons per hour and occasionally more Feed size varies according to the machine The machines are often fitted with screens for closed circuit grinding Product size can be controlled by changing screens2016年1月11日 Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing The Experts: SandVik Mining + Metso and Quarry Academy = all agree The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eighthour crushing day are Crusher Operating Costs: How to Optimize and Reduce2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum Grindingby 3050% Features Small footprint, modular design, fast installation and movement The production cost per ton of fine powder is greatly reduced, which makes some lean iron ores economical Dry grinding process is short, avoid over grinding, no magnetic agglomeration ore grade is high 5 6 8 7 9 New process and new ideas, large output per hour,introduction of new type iron ore grinding and dry separation

How Ball Mill Ore Feed Size Affects Tonnage Capacity

2017年7月26日 The grinding mill output will vary considerably with the Work Index If the feed size was 13,000 micrometers for the same grind production size, theoretical output from Fig (21) would change from about 90,000 tons per day on the 13 Work Index down to 65,000 tons per day on the 16 Work IndexThese grinding rolls exhibited higher capacity and lower energy consumption than was expected A single Polycom24/17 treated over 3 thousand tons of goldbearing copper ore per hour Cerro Verde mine HPGHR grinds 120 thousand t/ day as against 108 thousand t specified by the equipment standard This can be explained by the underratedHIGH PRESSURE GRINDING ROLLS—A PROMISING AND COST 2024年4月17日 Maximum milling output of up to 615 tons per hour Diverse options are available, including dry and wet ball mills (with comparisons), as well as grid and overflow ball mills (with comparisons) Options for grinding ball Quick Pick: Compare 4 Top Barite Grinding Mills for 2023年12月5日 Transformative Grinding Solutions: 20 Tons Per Hour Grinding Mill Redefines Productivity In the bustling mining landscape of worldwide, a groundbreaking project is reshaping ore processing with grinding mill 20 tone per hour

Increase Your Material Output: A Guide to Tons per Hour in

Tons per hour of a machine is an ever changing number that is influenced by many different factors in the production pipeline Larger jaw box sizes, such as 20 X 30, will lead to improved tons per hour output and contribute to a thriving operationRecently, the deep processing project of kaolin with an annual output of 100,000 tons of Inner Mongolia Shengyue New Material Technology Co, Ltd was successfully put into operation in Zhungeer Industrial Park, Zhungeer Economic Development Zone, Ordos, Inner Mongolia The project mainly uses solid waste coal gangue as raw material, and finally produces products News How To Configure The Calcined Kaolin Grinding Mill 2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process Control2016年3月5日 Mill No 1 has done 5100 units of reduction with an output of 2½ tons per hp or 5100 x 2½ = 12,750 units of reduction work, while mill No 2 has done 3737 units of reduction with an output of three tons per horsepower or 11,211 units of reduction This shows an excess efficiency of mill No 1 over mill No 2 of 127 per centCrushing Energy Work of Crushing Machines 911Metallurgist

Ball Mill Of 510t/h For The Gold Ore In Zimbabwe

2019年6月21日 In November 2018, an Australian customer invested in a ball mill with a capacity of 510 tons per hour He decided to purchase a ball mill from FTM Machinery Ltd Recommended from his friend, FTM company’s manager made a plan for him after knowing his needs and production environment and chose the Ф1830×4500 ball mill2009年1月1日 Also, equipment like ball mill is used at the final stages of grinding Among the comminution and grinding equipment, HPGR is increasingly utilized as tertiary crusher or primary mill because of Processing of Magnetite Iron Ores–Comparing Grinding OptionsSAG mills play an important role in copper ore mining by efficiently breaking down large chunks of material into manageable sizes while also using less energy than traditional methods The Grinding Laws and Machines Grinding is an essential process in the mining industry, and it involves breaking down large pieces of ore into smaller fragmentsUnderstanding the SAG Mill in Copper Ore Mining Process2016年2月18日 The numerator is calculating the volume of one swing of a jaw, times the density of material in the chamber, times the number of cycles per minute This should give you the mass of material crushed per minute The Estimate Jaw Crusher Capacity 911Metallurgist

Ultrafine vertical roller mill SBM Ultrafine Powder

While passing across the track in the grinding plate, large blocks of materials are crushed and grinded directly 1000 square meters of exhibition hall, covering 200+ mining equipment SBM’s ore grinding equipment sells well all over the 2013年9月18日 Auxiliary Machine; Spare Parts; Ore Plant; Grinding Plant; News; 500010000 tons / day largescale sand and gravel aggregate Output is 20800 tons per hour of stone stone production line, stone production line, sand the quality of the recycled aggregate, Output of 100020000 tons of aggregate sand and gravel 2022年6月27日 A complete production of 400 tons per hour of river pebble includes feeding system, primary crushing system, secondary crushing system, sand making system, screening system, and washing system Raw material feeding system pebble and gravel materials are generally of different sizes The feeder has two modes: feeding and vibration TheCapacity 400 tons per hour pebble crushing equipment CM 2016年6月20日 AZ Guide to Screening Ore, Rock Aggregate A simple definition of a “screen” is a machine with surface(s) used to classify materials by size Screening is defined as “The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or rejection by a screening surface”Ore, Rock Aggregate Screening (Complete Guide)

.jpg)

Top 10 Best Mineral Processing Equipment Fote Machinery

Achieve highgrade concentrates through effective grinding, screening, ore beneficiation, and The capacity reaches180 tons/hour, with an output size of 20–100 mesh pyrite, platinum ore, zircon, rutile, monazite, tungsten ore, tin ore, tantalum ore, and other minerals with large density differences Feed size: 0 02–03 mm 1 Prepare cement raw materials: The primary raw materials are limestone and clay, along with fly ash, iron ore, and coal 2 Grinding: The raw materials are ground into fine powder (1–25 mm) using crushers and mills Typical ratios: 67–75% limestone, 1015% clay, 05–15% iron ore, and 85–11% coal 3Overview of Cement Making Machine (with Price and Capacity)2015年10月15日 Learn how to calculate the grinding capacity of your ball mill with 911 Metallurgist This guide provides essential formulas, insights, and tips to optimize your milling process and enhance production efficiencyCalculate Ball Mill Grinding Capacity 911Metallurgist2019年4月16日 The development of a largescale IsaMill™ unit—10,000 L with 3 MW of Within the scope of the study ore grinding performance of the a minimum production of 2200 tons of cement per (PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

.jpg)

Stone quarry crusher machine 400 ton per hour

2013年3月19日 Capacity 350 tons per hour crushing machine stone crusher with production capacity of 500 tons per hour 350TPH400 ton per hour Stone harga produk quarry equipment list for mining 30 ton per hour rock crushing plant2024年3月5日 In addition to the crusher, a complete stone production line with an output of 500 tons per hour also requires some auxiliary equipment such as: vibrating feeder, vibrating screen, belt conveyor, etc According to different user needs, dust How to configure a 500tonperhour gravel production line?Output: 6 t/h 350 t/h Motor power: 75 kW 3,300 kW Machine length: 2,400 mm 7,200 mm years, with the continuous consumption of highgrade ores, the characteristics of poor, fine and miscellaneous minerals have become prominent, and the sorting and processing of lowgrade and refractory oresOre mill, Ore grinding mill All industrial manufacturersUp to 300 tons per hour (varies with material composition and moisture content,feed system capacity and selected components) Maximum screenable output ranges from minus 8 mesh producing 100 tons per hour to minus 14 mesh producing 30 tons per hourIndustry ApplicationsGrinding for heavy clay applicaBall Mill Design Power CalculationThe basic en/168/grinding mill tons per hourmd at main lbsid/en

.jpg)

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 They handle feed sizes up to 800 mm and output capacities from 30 to 2,000 t/h They are affordable, suitable for budgetconscious users However, the blow bars and impact plates wear out quickly when crushing hard rocks The machine struggles with wet or muddy materials, making blockages hard to clear 32015年4月9日 Small machines can have a throughput of only a few tens of kg per hour whereas larger machines are capable of handling up to 40 or 50 tons per hour and occasionally more Feed size varies according to the machine The machines are often fitted with screens for closed circuit grinding Product size can be controlled by changing screensGrinding Mills and Their Types – IspatGuru2016年1月11日 Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing The Experts: SandVik Mining + Metso and Quarry Academy = all agree The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eighthour crushing day are Crusher Operating Costs: How to Optimize and Reduce2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum Grinding

introduction of new type iron ore grinding and dry separation

by 3050% Features Small footprint, modular design, fast installation and movement The production cost per ton of fine powder is greatly reduced, which makes some lean iron ores economical Dry grinding process is short, avoid over grinding, no magnetic agglomeration ore grade is high 5 6 8 7 9 New process and new ideas, large output per hour,2017年7月26日 The grinding mill output will vary considerably with the Work Index If the feed size was 13,000 micrometers for the same grind production size, theoretical output from Fig (21) would change from about 90,000 tons per day on the 13 Work Index down to 65,000 tons per day on the 16 Work IndexHow Ball Mill Ore Feed Size Affects Tonnage CapacityThese grinding rolls exhibited higher capacity and lower energy consumption than was expected A single Polycom24/17 treated over 3 thousand tons of goldbearing copper ore per hour Cerro Verde mine HPGHR grinds 120 thousand t/ day as against 108 thousand t specified by the equipment standard This can be explained by the underratedHIGH PRESSURE GRINDING ROLLS—A PROMISING AND COST