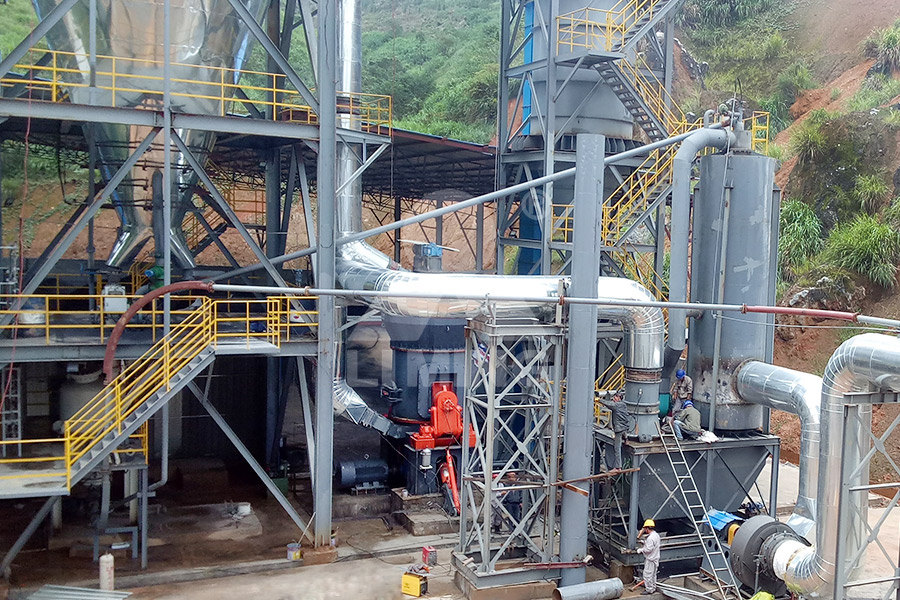

Manganese powder mill

.jpg)

How To Select Equipment For Producing Manganese Powder From

HCMilling (Guilin Hongcheng), as a manufacturer of manganese powder production equipment for manganese flakes, our HLM series manganese vertical roller mill, HC series large manganese Relying on its unique manganese ore data and energy advantages, it has been using Raymond Mill manufactured by Guilin Hongcheng mining equipment manufacturing Co, Ltd to specializing in the production of electrolytic Grinding Manganese PowderTo sum up, there are mainly two kinds of equipment for grinding in electrolytic manganese powder workshop: new Raymond mill and vertical mill, and users can choose according to production News How to choose the electrolytic manganese powder 2021年6月23日 Ball mill is the key equipment for grinding manganese ore after crushing It is widely used in cement, silicate products, new building materials, refractory materials, Manganese Ore Processing Plantmanganese ore production line

.jpg)

Equipment Required To Build A Manganese Ore

2024年11月21日 Once the ore is crushed to the appropriate size, it enters the grinding stage, where the manganese ore is refined into a fine powder using specialized equipment such as ball mills or vertical roller mills To achieve this, Comilog—Compagnie minière de l’Ogooué—operates the world’s largest manganese mine Alongside the Bangombé deposit, Comilog began mining the Okouma deposit in 2023, which will eventually increase the company’s Manganese Eramet2021年8月17日 A manganesemediated reductive dimerization of arylidene malonates by ball milling is reported The process has been optimised and its mechanism explored by CV measurements, radical trapping, and EPRBallMillingEnabled Reactivity of Manganese MetalThis work in three parts presents a summary of the sintered manganese steel properties from 1948 to 2011 involving processing conditions and other characteristics In the first and third part are given results attained by the Manganese in Powder Metallurgy Steels SpringerLink

Synthesis of manganese–zinc ferrite by powder mixing using ferric

2010年11月2日 With the aim of producing finegrained manganese–zinc (Mn–Zn) ferrite at the end of a calcination process at moderate temperatures, this study consisted, at first, of an Manganese ore excavated from the mine is ground into powder by using manganese powder Raymond mill, which is called manganese powder The metallic manganese obtained by electrolysis after the manganese powder is How Can Manganese Powder Be Refined Into 2023年4月10日 Ball mill can grind ore to relatively fine and uniform particle size The manganese ore of 012 mm is sent to the ball mill for grinding, and it can be ground into manganese powder of 01 mm Estimated cost: $5,000 / Set Get 5 Easy but Efficient Steps to Realize Manganese Ore HCM Machinery has whole production line for Raymond Mill, Vertical Roller Mill, Micro Powder Mill Welcome to Guilin HCM Machinery Official WebSite! mkt@hcmilling English Espanol Русский язык 简体中文Grinding Mills, Ultrafine Mills, Powder Processing Equipment

.jpg)

Vibration Mill ALPA Powder Equipment

It can be used for powder mixing, surface coating modification, mechanochemical modification, Grinding media and lining plates can be made of special materials such as high manganese steel, high chromium steel, stainless steel, alumina, zirconia, quartz, Technical parameters of small and medium amplitude MZ series vibration millManganese powder is a freeflowing, brown to black powder with a high melting point (1244 °C) and exceptional resistance to corrosion and abrasion Our highpurity manganese powder (≥999%) is a reliable and valuable material for various industrial and academic applicationsManganese powder, = 999 trace metals SBM micro powder grinding mill is a highly efficient industrial grinding mill, its finished products: 3253000 mesh; it's capacity: 0245t/h +17 [ There are iron, copper, gold, manganese, and other minecrushing production lines in Russia, India, Australia, Brazil, Indonesia, Nigeria, South Africa, Chile, Mexico, and other Micro Powder Grinding MillEuropean Coarse Powder Mill mainly consists of frame, rotor, support iron, and grate bars The frame is divided into two parts: the upper part and the lower part, which are welded by steel plates after being cut Liners made of high manganese steels within the frame can be replaced after being worn out The rotors consist of turn plates, Coarse Powder Grinding Mill SBM Ultrafine Powder Technology

Roller Mill SpringerLink

2023年7月4日 The vertical roller mill has the advantages of low energy consumption, high output, easy maintenance, etc, and has been widely applied in cement, steel and power industry, the preparation of nonmetallic ore ultrafine powder, manganese ore Manganese product including metallurgy manganese, manganese carbonate powder (important material of manganese refining), manganese dioxide powder, HLM VERTICAL MANGANESE MILL TECHNICAL DIAGRAM (MANGANESE INDUSTRY) Model HLM1700MK HLM2200MK HLM2400MK HLM2800MK HLM3400MK Capacity (t/h) 2025 3542 4252 7082 100120Grinding Manganese PowderA process dust explosion in a manganese pulverizing plant is described and probable causes of the incident are discussed Explosibility and ignition characterization data are presented An assessment is made of the feasibility of the use of deflagration suppression as a method of explosion protection in fine metal powder process systemsManganese mill dust explosion NASA/ADSManganese ore excavated from the mine is ground into powder by using manganese powder Raymond mill, which is called manganese powder The metallic manganese obtained by electrolysis after the manganese powder is treated with sulfuric acid and other chemical materials is called “electrolytic manganese”How Can Manganese Powder Be Refined Into Electrolytic Manganese

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as China Lead Powder Mill wholesale Select 2024 high quality Lead Powder Mill products in best price from certified Chinese Co Powder manufacturers, Mining Ore Iron Tin Manganese Lead Zinc Powder Ball Mill Machine US$ 6500 / set 1 set (MOQ) ZHENGZHOU ZHENGJIA HEAVY INDUSTRY CO,LTDLead Powder Mill MadeinChinaPDF On Jul 13, 2021, A Ye Perekos and others published Effect of Ultrasonic Treatment in a Ball Mill of FineDispersed Powder Mixtures of Copper with Manganese and Aluminium on Their Structure Effect of Ultrasonic Treatment in a Ball Mill of FineDispersed Powder MN 103 Manganese powder is used in the chemcal and ceramic industries, as well as in the production of pyrotechnics, grinding wheels, welding rods, ammunition, and in alloy compositions Product Cost In Stock for Immediate Shipping Quantity (LB) Price; 12 LB $ 5079: 310 LB $ 3809: 1125 LB $ 3555 MANGANESE POWDER MANGANESE POWDER Atlantic

Synthesis of manganese–zinc ferrite by powder mixing using

2010年11月2日 With the aim of producing finegrained manganese–zinc (Mn–Zn) ferrite at the end of a calcination process at moderate temperatures, this study consisted, at first, of an “electrochemically designed” powder mixing by wetball milling a mixture of manganese (MnO2), zinc (ZnO), and iron (Fe2O3 granules produced by an acid recovery unit of a Brazilian The 012mm manganese powder sieved by the vibrating screen is evenly sent to the ball mill for grinding, The manganese powder that meets the beneficiation requirements is sent to the magnetic separator for strong magnetic separation and magnetic separation to remove sundries; Tags: Manganese Ore crusher, Manganese ore crushing equipment processing technologyAs a manufacturer of sulfur grinding mill machines, HCMilling(Guilin Hongcheng) recommends that you choose a manganese ore vertical mill for the preparation of manganese ore powder desulfurizer Preparation of HLM Vertical Desulfurization Agent grinding mill machine Product Advantages of Manganese Ore Powder Desulfurization Agent 1Which Type Of Desulfurization Agent Grinding Mill Machine 2022年8月25日 The unqualified manganese powder is sent to the ball mill for grinding Stage 3: mineral processing The manganese powder meeting the ore dressing requirements is sent to the magnetic separator for strong magnetic separation to remove impurities, and the obtained manganese powder is sent to the dryer for drying to obtain manganese refined powderManganese ore processing production line

News How to choose the electrolytic manganese powder grinding mill

HCM's HC1700 vertical pendulum Raymond mill, HLM series manganese carbonate vertical mill and other equipment have a high reputation in manganese ore enterprises all over the world market share, the following two types of electrolytic manganese powder grinding mill equipment will be introduced to you2011年3月1日 With the aim of producing finegrained manganese–zinc (Mn–Zn) ferrite at the end of a calcination process at moderate temperatures, this study consisted, at first, of an “electrochemically designed” powder mixing by wetball milling a mixture of manganese (MnO2), zinc (ZnO), and iron (Fe2O3 granules produced by an acid recovery unit of a Brazilian Synthesis of manganese–zinc ferrite by powder mixing using Solutions of BRANDT MANGANESE SULFATE POWDER may be prepared for dilute sprays according to nutritional need and the following 2935 South Koke Mill Road Springfield, Illinois 62711 USA www brandt co 800 300 6559 Information regarding the Brandt Manganese Sulfate Powder1991年1月20日 Elemental aluminum and manganese powder mixtures have been mechanically alloyed in a Spex mill It has been shown that supersaturated solid solutions of aluminum containing as much as 185 at% Mn can be produced in the asmilled condition Room temperature aging produced a metastable fcc phase with a = 04772 nmMetastable phases in mechanically alloyed Al Mn powder mixtures

Manganese Ore Processing – ATAIRAC ENGINEERED PRODUCTS

2021年8月4日 The finial powders send to dryer to get high grade manganese powder Equipment Configuration: 1 The crushing machine for manganese ore: jaw crusher, hydraulic cone crusher 2 The grinding machine for manganese ore: ball mill, spiral classifier 3 The magnetic separation machine: magnetic separatorFerro silicon manganese grinding mill/powder grinding mill: —— five models: HGM80, HGM90, HGM100, HGM100A, and HGM125 ——finished production fineness: 300meshes~3000meshes, 547 micron ——the capacity (ton/hour) ranges from 04T/H to 12T/H Application of ferro silicon manganese grinding mill/powder grinding mill:Ferro silicon manganese powder grinding millManganese Ore Supplier, Manganese Powder, Manganese S Manufacturers/ Suppliers Hunan Daji Manganese Industry Co , Ltd Sign In Join Free For CAS No Manganese Powder Mno2 for Steel Mill P 015% Min FOB Price: US $300500 / Ton Min Order: 1 Ton Manganese Ore Manufacturer, Manganese Powder, Manganese 2020年10月1日 Request PDF Innovative methodology for cotreatment of mill scale scrap and manganese ore via oxidization roastingmagnetic separation for preparation of ferrite materials Mill scale scrap Innovative methodology for cotreatment of mill scale scrap and

.jpg)

Coarse Powder Hammer Mill

Coarse Powder Mill,Coarse Powder Grinding Mill,Hammer mill +29 which are welded by steel plates after being cut Liners made of high manganese steels within the frame can be replaced after being worn out The rotors consist of turnplates, pin shafts, and hammers which are grouped regularly in the main shaftPowder Metallurgy Progress, Vol9 (2009), No 2 98 manganese and carbon ferromanganese grades manufactured industrially for other requirements seem to be effective manganese carriers for use in powder metallurgy [2,13] The objective of the present work is to characterize and analyze complexly theELECTROLYTIC MANGANESE AND FERROMANGANESE POWDER Manganese powder is a freeflowing, brown to black powder with a high melting point (1244 °C) and exceptional resistance to corrosion and abrasion Our highpurity manganese powder (≥999%) is a reliable and valuable material for various industrial and academic applicationsManganese powder, = 999 trace metals Manganese ore excavated from the mine is ground into powder by using manganese powder Raymond mill, which is called manganese powder The metallic manganese obtained by electrolysis after the manganese powder is How Can Manganese Powder Be Refined Into

5 Easy but Efficient Steps to Realize Manganese Ore

2023年4月10日 Ball mill can grind ore to relatively fine and uniform particle size The manganese ore of 012 mm is sent to the ball mill for grinding, and it can be ground into manganese powder of 01 mm Estimated cost: $5,000 / Set Get HCM Machinery has whole production line for Raymond Mill, Vertical Roller Mill, Micro Powder Mill Welcome to Guilin HCM Machinery Official WebSite! mkt@hcmilling English Espanol Русский язык 简体中文Grinding Mills, Ultrafine Mills, Powder Processing EquipmentIt can be used for powder mixing, surface coating modification, mechanochemical modification, Grinding media and lining plates can be made of special materials such as high manganese steel, high chromium steel, stainless steel, alumina, zirconia, quartz, Technical parameters of small and medium amplitude MZ series vibration millVibration Mill ALPA Powder EquipmentManganese powder is a freeflowing, brown to black powder with a high melting point (1244 °C) and exceptional resistance to corrosion and abrasion Our highpurity manganese powder (≥999%) is a reliable and valuable material for various industrial and academic applicationsManganese powder, = 999 trace metals

.jpg)

Micro Powder Grinding Mill

SBM micro powder grinding mill is a highly efficient industrial grinding mill, its finished products: 3253000 mesh; it's capacity: 0245t/h +17 [ There are iron, copper, gold, manganese, and other minecrushing production lines in Russia, India, Australia, Brazil, Indonesia, Nigeria, South Africa, Chile, Mexico, and other European Coarse Powder Mill mainly consists of frame, rotor, support iron, and grate bars The frame is divided into two parts: the upper part and the lower part, which are welded by steel plates after being cut Liners made of high manganese steels within the frame can be replaced after being worn out The rotors consist of turn plates, Coarse Powder Grinding Mill SBM Ultrafine Powder Technology2023年7月4日 The vertical roller mill has the advantages of low energy consumption, high output, easy maintenance, etc, and has been widely applied in cement, steel and power industry, the preparation of nonmetallic ore ultrafine powder, manganese ore Roller Mill SpringerLinkManganese product including metallurgy manganese, manganese carbonate powder (important material of manganese refining), manganese dioxide powder, HLM VERTICAL MANGANESE MILL TECHNICAL DIAGRAM (MANGANESE INDUSTRY) Model HLM1700MK HLM2200MK HLM2400MK HLM2800MK HLM3400MK Capacity (t/h) 2025 3542 4252 7082 100120Grinding Manganese Powder

Manganese mill dust explosion NASA/ADS

A process dust explosion in a manganese pulverizing plant is described and probable causes of the incident are discussed Explosibility and ignition characterization data are presented An assessment is made of the feasibility of the use of deflagration suppression as a method of explosion protection in fine metal powder process systems