Why does hightemperature calcined gypsum slow to set in cement

R)8OC`6F[ZIB.jpg)

Preparation of highperformance building gypsum by calcining

2021年11月1日 First, the setting time of the samples slowly increases with the increase of calcination temperature When the FGD gypsum is calcined at 160 °C, the final setting time is significantly reduced, and the initial setting time decreases as the sample is calcined at 180 °C2023年2月27日 Gypsum calcined at 400 °C (Fig 4 c) contained ∼ 90 wt% anhydrite and exhibited a featherlike morphology likely due to further mineral contraction, which can be Influence of calcination temperature on hydration behavior, The effect of adding gypsum on setting time can be seen in Figure 3 SNI 1570642004 requires that the initial setting time for PCC is ≥ 90 minutes, and the final setting time ≤ 375Effect of gypsum on the setting time ResearchGate2024年6月15日 However, the recycling of gypsum products resulting in the production of calcium sulfatebased binder (gypsum plaster, CaSO 4 05H 2 O; or anhydrite, CaSO 4) leads to the New insight into the phase changes of gypsum

.jpg)

Influence of the Calcination Temperature of Synthetic

2020年10月28日 The pastes with the content of gypsum that was obtained at higher calcination temperatures probably contained increased amounts of crystallization seeds, which accelerated the settingDepending on the calcination byproduct(s), the behavior of set gypsum (after rehydration) can fluctuate For example, it has been observed that set αhemihydrate can obtain a four times Influence of the calcination process in traditional gypsum with 2022年9月1日 Gypsum has been known to regulate cement setting since more than 100 years, whereas the understanding of the physiochemical mechanism remains incomplete Here, we New insights into the effect of gypsum on hydration and elasticity 2020年3月19日 One of the most appreciated properties of gypsum is its fire resistance, caused by the chemically bonded water in the crystals When hardened gypsum is exposed to high Changes in structure and composition of gypsum paste at

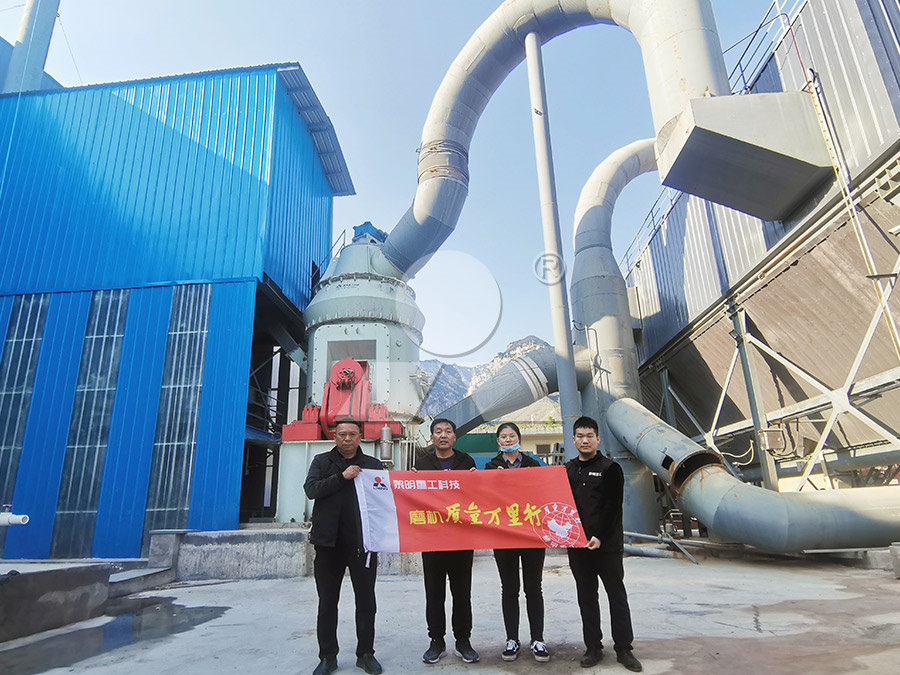

Grinding and calcining of gypsum with Pfeiffer grinding plants

Thanks to the relatively high temperature level in the gypsum calcining mill, the gypsum is simultaneously calcined The inlet temperature at the hot gas duct of this mill is usually about finish is continuously exposed to high temperatures It commences at the surface exposed to the fire and proceeds gradually through the gypsum layer ie the thickness of the gypsum plaster covering the core of the plasterboard The covering of the calcined gypsum formed on the exposed faces adheres tenaciously to theon: Fire and the Construction Products Directive Why are Gypsum Gypsum can be used as a raw material, mineralizer, retarder and activator in cement plants Among the components, SO 2 is used to balance the sulfuralkali ratio in the calcining of clinker and improve the calcining operation and the service life of refractory materials Roles of gypsum: 1 As a raw material, it can be used in the production of CSA cement, slaggypsum cement, What are the Roles of Gypsum in Cement Production2015年10月15日 Gypsum quantitative determination in cements may be done from their thermogravimetric analysis (TG) data, which uses the mass of the water released from its gypsum dehydration during cement analysis, to determinate its content stoichiometrically Depending on the operational conditions used to mill the gypsum with clinker, its partial dehydration may Gypsum content determination in Portland cements by

Effect of high temperatures on gypsumbased composites

2018年4月20日 Safety in case of fire is one of the basic requirements for structures [1] and therefore it is important to obtain detailed knowledge of the fire behaviour of every building material that is specified in the construction design One of the materials which can be considered to be fireresistant is gypsum, which is often used for fire protection of other materialsPhosphorgypsumbased concrete with sawdust aggregate Gypsum concrete is a building material used as a floor underlayment used in woodframe and concrete construction for fire ratings, sound reduction, radiant heating, and floor leveling [1] It is a mixture of gypsum plaster, Portland cement, and sand [1]Gypsum concrete is sometimes called gypcrete by construction Gypsum concrete Wikipedia2020年7月1日 Limestone calcined clay cement (LC3) – consisting of Portland cement (OPC) clinker, calcined clay, limestone powder and gypsum – has been considered a promising solution to current challenges Development of limestone calcined clay cement (LC3) concrete Heating of Gypsum: When the water of crystallization is removed from Gypsum (CaSO 4 2 H 2 O), a Hemihydrate Gypsum or Calcined Gypsum (CaSO 4 1 2 H 2 O) is produced CaSO 4 2 H 2 O (s) → ∆ CaSO 4 1 2 H 2 O (aq) + 3 2 H 2 O (l) Gypsum Calcinated Gypsum; Uses of calcinated gypsum: Used in making casts and patterns for molds and statuesWhat is Calcination Gypsum? BYJU'S

Effect of high temperatures on gypsumbased composites

Request PDF On Apr 20, 2018, Magdaléna Doleželová and others published Effect of high temperatures on gypsumbased composites Find, read and cite all the research you need on ResearchGateFigure 332 Relationship between liquid phase and temperature as a function of A/F ratio A 100% LSF value expresses the theoretical limit to the amount of lime (CaO) that can be added to a mix until all of the calcium would be combined into clinker compounds, with no C2S remainingEverything you need to know about Kiln System Operations in Cement Meanwhile, the standard free energy of the reaction = 0 when the temperature is set at 1121 K, or 848 °C Calcination of Gypsum Gypsum or calcium sulfate dihydrate (CaSo 4 2H 2 O) is a mineral of calcium that is mined in various parts of the worldCalcination Definition, Examples, Process, Calcination of Gypsum 2013年10月21日 A dip water temperature of 50 °C, a twentyfourply cast thickness, use of a plastic pillow, overwrapping of a curing plaster cast with synthetic, and use of a splint folded on itself were associated with temperatures causing burns 11Plaster of Paris: Past, present and future Journal of Clinical

.jpg)

Cement SpringerLink

2021年3月3日 Cement is produced by a hightemperature (about 1500 °C) reaction in a rotary kiln of carefully proportioned and blended ratios of lime (CaO), silica (SiO 2), alumina (Al 2 O 3), and iron oxide (Fe 2 O 3)The production of cement is a chemical process requiring an accurate blend of the previously cited four key organic oxides and the limitation of several undesirable Calcination of photocatalyst at high temperature in various atmospheres results in violent vibration of surface atoms and easy diffusion and overflow of surface lattice O By calcined BMO in the air, the maximum VB band of BMO increases from 166 eV to 136 eV, and the minimum CB edge movement of 026 eV appears at − 114 eV (Fig 11 aCalcination an overview ScienceDirect Topics2016年1月1日 Gypsum remains one of the most common mineral binders Gypsumbased products are known as being environmentally friendly materials The main component of the products is calcium sulphate, which exists in hydrous and nonhydrous compounds: dihydrate (CaSO 4 2H 2 O), hemihydrate (CaSO 4 05H 2 O) and anhydrate (CaSO 4)Compared to Sustainability of gypsum products as a construction materialGypsum is added to control the “setting of cement” If not added, the cement will set immediately after mixing of water leaving no time for concrete placing what is the role of gypsum if we are add250% gypsum for grinding cement and same clinker we add 40% gypsum for grinding cement what is the effect in compressive strength ReplyWhat is the purpose of adding gypsum in cement?

.jpg)

Early hydration and mechanical performance of composited

The high carbon dioxide emissions in OP and OA are attributed to the high temperatures, approximately 1450 °C, including during the cement production process, along with a series of hydration that decompose raw materials, leading to substantial carbon dioxide releaseA dip water temperature of 50 °C, a twentyfourply cast thickness, use of a plastic pillow, overwrapping of a curing plaster cast with synthetic, and use of a splint folded on itself were associated with temperatures causing burns 11Plaster of Paris: Past, present and future PMC PubMed Central 2023年11月15日 Studies have shown that although LC3 cement contains a high amount of alumina, its chloride binding capacity is not very high compared to high alumina cement [62] The conversion of monocarboaluminate and stratlingite to Friedel's salt is reported to result in greater chemical binding rather than physical binding of chlorides [ 63 , 63 ]Properties, compatibility, environmental benefits and future 2022年7月18日 Calcined gypsum is produced when dihydrate gypsum is fired at the temperature of 800 to 1100°C At this time, a little calcium sulphate is decomposed to generate new phase CaO, which gives calcined gypsum certain hydrating ability The condensation speed of calcined gypsum is slowThe Power of Gypsum Indian Cement Review

.jpg)

Limestone calcined clay cement and concrete: A stateoftheart

2021年11月1日 Limestone calcined clay cement (LC 3) is one such recently developed ternary blended cement in which the alumina from the calcined clay and the carbonate from the limestone also react with each other, along with the traditional pozzolanic reaction of calcined clay and the filler effect of limestone, creating a synergy between the three primary components (clinker, 2023年3月22日 At these high temperatures, chemical reactions occur that form the cement clinker Upon exiting the kiln, the cement clinker is cooled to approximately 80ºC Gypsum is then added to the composition and the Solex Cement production and cooling2022年3月26日 Gypsum can be used as a raw material, mineralizer, retarder and activator in cement plants Among the components, SO2 is used to balance the sulfuralkali ratio in the calcining of clinker andWhat are the Roles of Gypsum in Cement ProductionThe most widely used compositions contain 52 to 62 percent calcined gypsum, 25 to 18 percent highwetbulk cellulosic fiber, and sufficient foaming agent to achieve good workability A slowset plaster sample was excluded from the Why Does Plaster Get Hot? drywalleugene

Influence of calcination temperature on hydration behavior,

2023年2月27日 FESEM images of gypsum: a) uncalcined gypsum showing delamination along primary {0 1 0} cleavage planes; b) gypsum calcined at 200 °C containing > 80 wt% bassanite (note the extensive cracking associated with shrinkage along specific [hkl] directions due to H 2 O loss); c) gypsum calcined at 400 °C containing ∼ 90 wt% anhydrite (note the featherlike Calcination temperature can be set at approximately 135180℃ and can be tuned to minimize residual gypsum and soluble anhydrite production and maximize hemihydrate production The kettle stirring rate can be adjusted by a variable DC motor controller and all calcination exhaust is drawn through a cyclone and baghouse dust collection systemGypsum CalcinationDEFINITIONS cement = hydraulic binder forming a paste with water, which sets and hardens due to hydration reactions;5 composed of ground clinker, ∼5 wt % calcium sulfate and small concentrations of other additives; creates the strength, durability and soundness of concrete and mortar gray Portland cement (Portland cement) = ordinary Portland cements of grayish color Cement Formation—A Success Story in a Black Box: High Temperature 2023年7月10日 High temperature calcination and mechanical ball milling are the most effective methods for increasing the volcanic ash activity of electrolytic manganese residues (EMR) and pretreating hazardous substances (NH 3N and Mn 2+)In this study, the effects of different calcination temperatures (200, 400, 600, 800, and 1000 °C) and different EMR dosages (10, Selfstabilisation of hightemperature calcined electrolytic

Effects of several retarders on setting time and strength of

2020年4月20日 With the improvement of living standards, people's requirements for living environment are getting higher and higher To this end, many scholars have done a lot of research, including “sterilization and humidity control [1], temperature adjustment [2], insulation [3] ” etc However, only improving the comfort of the environment is not enough for sustainable 2021年8月4日 This content was downloaded from IP address 204217148254 on 21/03/2023 at 15:37LIME CALCINED CLAY CEMENT (LC3): A Review ResearchGate2020年9月22日 Calcined clay has become the supplementary cementitious materials with the greatest potential to reduce the clinker/cement In this research, the mechanical strengths and sulphate resistance of blended cements with a high content of calcined clay as a pozzolanic addition were evaluated to demonstrate that these cements could be designed as CEM Portland Cements with High Content of Calcined Clay: finish is continuously exposed to high temperatures It commences at the surface exposed to the fire and proceeds gradually through the gypsum layer ie the thickness of the gypsum plaster covering the core of the plasterboard The covering of the calcined gypsum formed on the exposed faces adheres tenaciously to theon: Fire and the Construction Products Directive Why are Gypsum

.jpg)

What are the Roles of Gypsum in Cement Production

Gypsum can be used as a raw material, mineralizer, retarder and activator in cement plants Among the components, SO 2 is used to balance the sulfuralkali ratio in the calcining of clinker and improve the calcining operation and the service life of refractory materials Roles of gypsum: 1 As a raw material, it can be used in the production of CSA cement, slaggypsum cement, 2015年10月15日 Gypsum quantitative determination in cements may be done from their thermogravimetric analysis (TG) data, which uses the mass of the water released from its gypsum dehydration during cement analysis, to determinate its content stoichiometrically Depending on the operational conditions used to mill the gypsum with clinker, its partial dehydration may Gypsum content determination in Portland cements by2018年4月20日 Safety in case of fire is one of the basic requirements for structures [1] and therefore it is important to obtain detailed knowledge of the fire behaviour of every building material that is specified in the construction design One of the materials which can be considered to be fireresistant is gypsum, which is often used for fire protection of other materialsEffect of high temperatures on gypsumbased compositesPhosphorgypsumbased concrete with sawdust aggregate Gypsum concrete is a building material used as a floor underlayment used in woodframe and concrete construction for fire ratings, sound reduction, radiant heating, and floor leveling [1] It is a mixture of gypsum plaster, Portland cement, and sand [1]Gypsum concrete is sometimes called gypcrete by construction Gypsum concrete Wikipedia

Development of limestone calcined clay cement (LC3) concrete

2020年7月1日 Limestone calcined clay cement (LC3) – consisting of Portland cement (OPC) clinker, calcined clay, limestone powder and gypsum – has been considered a promising solution to current challenges Heating of Gypsum: When the water of crystallization is removed from Gypsum (CaSO 4 2 H 2 O), a Hemihydrate Gypsum or Calcined Gypsum (CaSO 4 1 2 H 2 O) is produced CaSO 4 2 H 2 O (s) → ∆ CaSO 4 1 2 H 2 O (aq) + 3 2 H 2 O (l) Gypsum Calcinated Gypsum; Uses of calcinated gypsum: Used in making casts and patterns for molds and statuesWhat is Calcination Gypsum? BYJU'SRequest PDF On Apr 20, 2018, Magdaléna Doleželová and others published Effect of high temperatures on gypsumbased composites Find, read and cite all the research you need on ResearchGateEffect of high temperatures on gypsumbased compositesFigure 332 Relationship between liquid phase and temperature as a function of A/F ratio A 100% LSF value expresses the theoretical limit to the amount of lime (CaO) that can be added to a mix until all of the calcium would be combined into clinker compounds, with no C2S remainingEverything you need to know about Kiln System Operations in Cement

.jpg)

Calcination Definition, Examples, Process, Calcination of Gypsum

Meanwhile, the standard free energy of the reaction = 0 when the temperature is set at 1121 K, or 848 °C Calcination of Gypsum Gypsum or calcium sulfate dihydrate (CaSo 4 2H 2 O) is a mineral of calcium that is mined in various parts of the world