Cement vertical mill circulating fan air volume

.jpg)

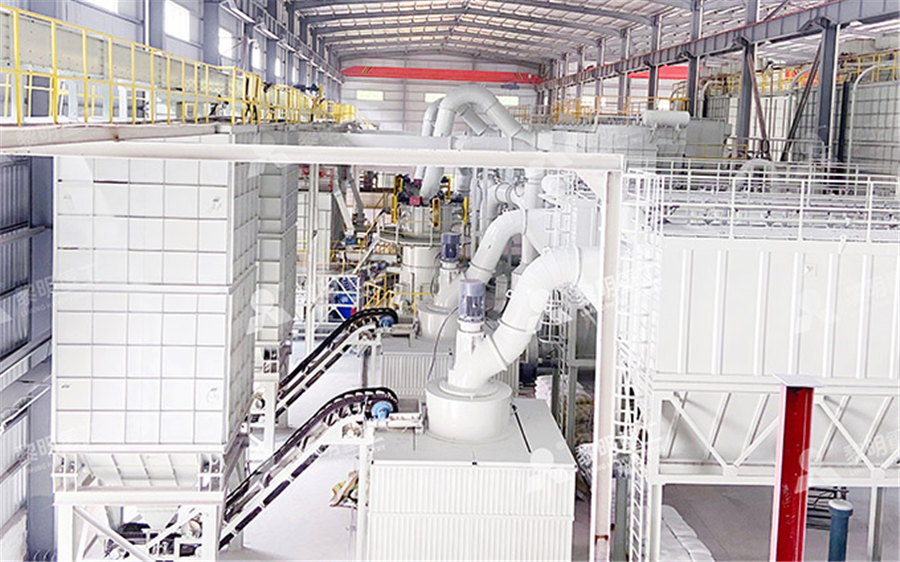

Vertical roller mill for raw Application p rocess materials

Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Vertical roller pregrinding mills (VRPMs) have emerged as an alternative solution to upgrade existing ball mills in the grinding of raw materials and cement They offer an enhanced grinding and AMCL Machinery LtdToday TLTTurbo builds axial and centrifugal flow fans for almost any application The capability of TLTTurbo is evident in the matured product range, which has stood the test under very Fans in Cement Plants BrownleeMorrow Company2023年6月1日 Due to the action of the circulating fan, the hot air entering the mill passes through the annular nozzle around the grinding disc at a speed of 40∼80 m/s to bring the Operation parameters multiobjective optimization method of

.jpg)

Important Operation Tips For Cement Vertical Mill

For example, in order to meet the material drying requirements, it is necessary to provide a larger air volume and a higher air temperature, which will make the wind speed in the mill higher, and the material that should be settled and dropped is The Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the standard reference used by plant operations personnel worldwide Providing a The Cement Plant Operations Handbook International Cement Applying middle shell air volume adjustment technology can solve the contradiction between classifying air volume and grinding air volume, so as to reduce the air volume through the nozzle ring as much as possible while Industrial application of system integration updated Advanced cement additives, specifically designed for VRM, can be a helpful support for the cement industry to broaden the PSD and increase the productivity at the same time Cement SikaGrind® for vertical roller mills

.jpg)

Large cement lines: just one process fan is enough

Venti Oelde’s cement mill fans, kiln fans and filter fans can handle flow volumes of between 1 100 000 and 1 700 000 m³/h at a drive power of four, five or more MW For instance, one raw mill fan downstream of a cyclone compared with Table 3 Power Consumption Of Roller Press Grinding System Overall, we can conclude the three tables: After the longterm operation, although unit raw material grinding power consumption of the cement roller press grinding Comparison Of Vertical Roller Mill And Roller Press MillCyclone Air Separator Features Compared to conventional cement mill separators, our cyclone air separators have the following advantages: Separate the material into three parts: coarse powders (d>150um), mediumcoarse Cement Milll Separator Cyclone Air Separator in been manufacturing its VRPM vertical roller mill system since 1996, which volume of 165,000m3/h A circulating air fan and separator bag VERTICAL ROLLER MILLS Table 4: cement milt performance before and after upgrade Total and AMCL Machinery Ltd

Cement Clinker Grinding Plant ball mills supplier

25195tph clinker grinding plant, best option for start up at low cost Cement clinker grinding unit with ball mill, roll press or VRM 24×7 Consulting SupportCement Vertical Mill; Ultra Fine Grinding Mill The circulating air of the cement cyclone separator is generated by the air blower Circulation Fan: Air Volume (m3/h) 21373: 32427: 39437: 67650: 75200: 91200: : Air Pressure (Pa) 2367: 2302: 2302: 2355: 2325: 2479: 2700: Motor: Y1802: Y200L—2:Cement Separator – Cement Mill Separator Cyclone Air The vertical cement mill not only reduces energy consumption but also ensures the quality of finished cement The air leakage coefficient of the mill is low, the safety is strong, and the O2 content of the fan is less than 8% by using the exhaust gas VRM In Cement Plant Maximize Energy Saving CNBMSINOMA2021年2月25日 Fans employed in cement manufacturing are heavyduty They perform two basic functions ie supply of air or removal of exhaust gases and material handling Variety of process fans that find applications in the cement industry are – raw mill fans, induced draft fans, cooling fans, raw mill exhaust fans, coal mill fans, and cooler exhaust fansIndustrial Fan solutions for Cement industry applications

A Survey and Analysis on Electricity Consumption of Raw Material Mill

2021年1月22日 In the whole process of cement production, the electricity consumption of a raw material mill accounts for about 24% of the total Based on the statistics of the electricity consumption of the raw Closed circuit system mainly composed of the cement vertical mill Roller press and ball mill pregrinding system When the fan air volume is determined, Air volume (m3/min) Capacity (t/h) Feed rate (t/h) Rotor speed (r/min) Motor power (KW) N250: 250: 1113:Cement Mill Separator High Efficiency Cement SeparatorIn cement industry raw mill exhaust fans handle 22 ton of exhaust gases for the production of 1 ton of clinker Raw mill exhaust fans are operated with very adverse situations because the fan handles mainly gases such as CO2, N2, The 6 Main Process Fans in Cement factoryVol3 No1 Desember 2021 Tinjauan Pustaka Fan merupakan alat yang berfungsi untuk megalirkan air flow dalam mill air flow system Hampir kebanyakan pabrik menggunakan fan untuk proses industri EFISIENSI MILL FAN PADA CEMENT MILL DI PABRIK BATURAJA II

.jpg)

Circulating fan for cement mill of variable frequency

However, when the circulating fan used at present is used, the air volume of the circulating fan is difficult to adjust according to the actual usage amount of the raw materials, so that great waste of resources and energy is easily caused, and therefore, a variablefrequency circulating fan for a cement mill is required to solve the problems2023年6月1日 This study aims to improve the output and production efficiency of a large vertical mill by optimizing its operational parameters This paper takes a large vertical mill in LGM as the object, a numerical calculation method of particle–fluid coupling system in large vertical mill based on CFDDPM theory, and a multiobjective optimization method of operating parameters of Operation parameters multiobjective optimization method of 2021年6月10日 1 Introduction In the cement industry, grinding is one of the most consuming energy stages in the production units Around 65% of the total used electrical energy in a cement plant has to be utilized to grind raw materials, coal, and clinker [1,2]Through the process, many variables can affect the efficiency and productivity of this dry grinding procedure, such as the Ventilation Prediction for an Industrial Cement Raw Ball Mill by Comprehensive Report on Fans in Cement Factories Raw mill fans are used to supply air for raw material drying and grinding, ensuring the right airflow through the mill Example Brands and Models Alstom Power: 2G5014; TMEIC: VF Series; Venti Oelde: RMA Series; Capacity and Estimated PricesMost Important Fans in Cement Industry

Industrial application of system integration updated technology

TCDRI CFD simulation results show that the mill resistance decreases by 214% when the middle shell air volume accounts for 15% of the mill air volume and the mill resistance decreases by 312% when the middle shell air volume accounts for 20% of the mill air volume under the same working conditionsIn this study, separator rejects of a closed circuit cement tube milling were dry ground in a 10l pilot scale vertical stirred mill Tests were done as open and closed circuitOpen and closed circuit dry grinding of cement mill rejects in a It might in some cases be subsequently found that the volume of separating air is insufficient, so that a freshair flap has to be installed in the air duct between the circulating air fan and the separator If this done, care must be taken that the fan capacity is adequate with regard to air volume and pressureProcess Training Ball Mill INFINITY FOR CEMENT EQUIPMENTThe margin on raw mill fans is typically lower: 10% on volume and 20% on pressure The raw mill fan is of large capacity and its specifications are determined by the mill characteristics The cement mill and coal mill are similar to the raw mill requirements Main filter fan The main filter fan (which evacuates the raw mill and kiln gases) is Narayana Jayaraman and Francisco Benavides, PEC Consulting,

China Quality cement vertical mill seal fan SIMO

Cement vertical mill seal fan, is exclusively used in cement vertical mill system protection It output high pressure, the front of the filter filtering effect is good, to ensure the sealing requirements of cement vertical mill295% in both the chambers Both the chambers of the cement mill were charged with 80% of the designed charge, which works out to 86 t in Ist chamber and 172 t in the IInd chamber The mill is utilised for production of OPC 33 grade, OPC 53 grade and PPC The blaines for the cements of different grades are being maintained as given below:PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL Information on the importance of false air in the kiln and raw mill process in cement plants False air calculation and measurement Comparison between different sealing solutions to reduce false air in kilns The importance of equipment maintenance to reduce false air Manuel Castro November 2019 Rev May 2022 1FALSE AIR IN THE CEMENT MANUFACTURING PROCESSThe differential pressure of the vertical roller mill is generally controlled at 5000~7000Pa to ensure the proper air volume The change of the pressure difference within the mill is mainly affected by the feed amount when other conditions are constantHow to Improve Grinding Efficiency of Vertical Roller Mill

Vertical Shaft Lime Kiln for Cement Plant

Active lime vertical kiln equipment supporting Calcination of limestone Qualified limestone goes to the top of the preheater through the belt conveyor, and the material is introduced into the body of the preheater from the silo at the top of the preheater through the discharge chute, and at the same time, the hightemperature flue gas from the rotary kiln preheats the material to 600°C 2021年6月10日 In cement mills, ventilation is a critical key for maintaining temperature and material transportation However, relationships between operational variables and ventilation factors for an industrial cement ball mill were not addressed until today This investigation is going to fill this gap based on a newly developed concept named “conscious laboratory (CL)” For Ventilation Prediction for an Industrial Cement Raw Ball Mill 2017年4月1日 In the airswept mode, the verticalrollermill and a high efficiency dynamic classifier are suited above each other as a single unit (Fig 1) Material is fed to the grinding chamber and transported by table rotation to the grinding gap between the fixed grinding rollers and the mill tableOperational parameters affecting the vertical roller mill Figure 612 Vertical roller mill for raw material preparation (Photo Courtesy of TXI) Emission Control Measures Dust collecting devices in the raw mill and raw mix storage areas include mechanical cyclones, fabric filters, and, rarely, electrostatic precipitators (ESPs)Everything you need to know about Air Emissions and Control

Analisa Kinerja Alat Vertical Cement Mill di Pabrik II PT Semen

2022年1月10日 Alat cement mill dibantu oleh mill fan yang berfungsi untuk mengenerate air flow dalam mill air flow sistem sehingga proses penggilingan, pengurangan moisture, pemisahan, dan transport material Mill motor speed Classifier speed Material temperature Mill air flow Mill fan speed Material moisture Mill differential pressure Water injection Mixture composition Product transport volume Grinding aid injection Composition of raw material Temperature after the mill Hot gas Grinding roller wear Mill vibrations Fresh air Figure2PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL Table 3 Power Consumption Of Roller Press Grinding System Overall, we can conclude the three tables: After the longterm operation, although unit raw material grinding power consumption of the cement roller press grinding Comparison Of Vertical Roller Mill And Roller Press MillCyclone Air Separator Features Compared to conventional cement mill separators, our cyclone air separators have the following advantages: Separate the material into three parts: coarse powders (d>150um), mediumcoarse Cement Milll Separator Cyclone Air Separator in

.jpg)

and AMCL Machinery Ltd

been manufacturing its VRPM vertical roller mill system since 1996, which volume of 165,000m3/h A circulating air fan and separator bag VERTICAL ROLLER MILLS Table 4: cement milt performance before and after upgrade Total 25195tph clinker grinding plant, best option for start up at low cost Cement clinker grinding unit with ball mill, roll press or VRM 24×7 Consulting SupportCement Clinker Grinding Plant ball mills supplierCement Vertical Mill; Ultra Fine Grinding Mill The circulating air of the cement cyclone separator is generated by the air blower Circulation Fan: Air Volume (m3/h) 21373: 32427: 39437: 67650: 75200: 91200: : Air Pressure (Pa) 2367: 2302: 2302: 2355: 2325: 2479: 2700: Motor: Y1802: Y200L—2:Cement Separator – Cement Mill Separator Cyclone Air The vertical cement mill not only reduces energy consumption but also ensures the quality of finished cement The air leakage coefficient of the mill is low, the safety is strong, and the O2 content of the fan is less than 8% by using the exhaust gas VRM In Cement Plant Maximize Energy Saving CNBMSINOMA

.jpg)

Industrial Fan solutions for Cement industry applications

2021年2月25日 Fans employed in cement manufacturing are heavyduty They perform two basic functions ie supply of air or removal of exhaust gases and material handling Variety of process fans that find applications in the cement industry are – raw mill fans, induced draft fans, cooling fans, raw mill exhaust fans, coal mill fans, and cooler exhaust fans2021年1月22日 In the whole process of cement production, the electricity consumption of a raw material mill accounts for about 24% of the total Based on the statistics of the electricity consumption of the raw A Survey and Analysis on Electricity Consumption of Raw Material Mill Closed circuit system mainly composed of the cement vertical mill Roller press and ball mill pregrinding system When the fan air volume is determined, Air volume (m3/min) Capacity (t/h) Feed rate (t/h) Rotor speed (r/min) Motor power (KW) N250: 250: 1113:Cement Mill Separator High Efficiency Cement Separator