Industrial grinding of sulfur

Characterization of sulphur particles: prills vs granules

2021年7月5日 Some of the most common industrial uses of sulfur have been to produce sulfuric acid, manufacture inorganic chemicals, construct steel, 2020年7月1日 This method describes a process for recovering sulfur by means of grinding and mixing it with diaryl disulfide at temperatures below the sulfur melting one (115 °C) Then, the Effective extraction of high purity sulfur from industrial residue "dry sulfur fine grinding" (see Figs 6 and 7) is carried out In this fine grinding process, the precrushed raw sulfur is added from the raw material feed unit or from the raw material metering New Sustainable Mechanical Process for Grinding CoarseGrained Crushing a solid block of sulphur into smaller chunks was utilized as the main method of obtaining transportable sulfur pieces Due to considerable dust formations while handling solid sulfur pieces in this form, the industry started Sulphur Forming and Solidification Technologies Kreber

Effects of Multistage Grinding Process and Grinding

2015年12月31日 Grinding process and fineness have been found as significant factors influencing the flotation desulfurization performance of highsulfurous iron ore Moreover, the separation tests ofAbout 70% of the sulfur produced is a byproduct of hydrocarbon processing In oil refineries and gas plants, the sulfur in the feed ends up in the Sulfur Recovery Unit (SRU) as HSulfur forming Granulation process IHS MarkitIPCO’s latest drum granulation technology for the production of premium quality sulfur granules, the SG20, is now commissioned and operating (Figure 1) The technology is located at the site ENDTOEND SULPHUR SOLIDIFICATION SOLUTIONS IPCO2016年8月8日 Grinding wheels were impregnated with a new method of gravitational sulfurization combined with centrifuging The experiments carried out show that the adhesive The effect of sulfurization on the grinding wheel cutting ability in

.jpg)

Assessment of industrial metabolisms of sulfur in a Chinese fine

2012年9月1日 Sulfur outputs include sulfur dioxide emissions, fly ash, bottom ash and flue gas desulfurization residues from coal combustion, SO 2 emissions from the manufacturing 2003年10月11日 Cogrinding nonferrous metal (Cu, Pb, and Zn) oxides with sulfur and iron stimulate solidstate reactions to form nonferrous metal sulfides and iron oxideMechanochemical Sulfidization of Nonferrous Metal Oxides by Grinding 2014年9月17日 Sulfur mining takes place in countries such as Poland, Russia, Ukraine, United States and Turkmenistan Ijen, a quiet but active volcano in East Java, Indonesia contains a one kilometer wide crater lake; a well known site of Sulfur Mining Processing: What to Know2023年11月14日 The functions of industrial sulfur powder are diverse and have different functions in various fields Whether it is rubber manufacturing, explosives, papermaking, food processing, medicine, planting, animal Application fields of different specifications of

.jpg)

(PDF) Research on Explosion Characteristics of Sulfur Dust and

2014年12月31日 PDF As dust explosion is a major risk factor threating the safety of sulfur production, in the industrial proces s because of the high ignition energy and ignition temperatu re, 2021年5月11日 Elemental sulphur combustion is traditionally used to generate SO 2 to produce sulphuric acid that is consumed in chemical industries, but is now also being considered as an energy vector for power generation Despite the fact that sulphur combustion has been practiced for decades, there are limited reaction mechanisms for its combustion chemistry, which is A detailed reaction mechanism for elemental sulphur combustion Although, the quantity of sulfur emitted into atmosphere and sulfur cycle due to human activities is very easy to quantify as compared to natural sources , the majority of manmade sulfur resources are due to fossil fuel (like coal, natural gas and petroleum) burning, smelting of ores (nonferrous metals) and various industrial/burning processes [31,32,33,34]A Critical Review on the Properties and Applications of Sulfur 2023年7月1日 Much more desirable is devulcanization, ie, the selective cleavage of the intermolecular sulfidic bonds, such as carbonsulfur (C–S) and/or sulfursulfur (S–S) bonds, which breaks down the tridimensional network without main chain scissions and degradation of the polymer (Fig 2) [22]Recent advances in the devulcanization technologies of industrially

.jpg)

Mechanochemical sulfidization of zinc oxide by grinding with sulfur

2013年4月1日 Mechanochemical sulfidization of zinc oxide by grinding with sulfur and reductive additives Author links open overlay panel SAITO F Mechanochemical sulfidization of nonferrous metal oxides by grinding with sulfur and iron [J] Industrial Engineering Chemistry Research, 2003, 42(23): 5813 5818 [2] CHENG Yi, GUO Zhaohui, LIU Sulfur dust ignites easily in air Grinding sulfur may produce an explosion hazard Static discharge may ignite sulfur dust Hygiene Measures: Handle in accordance with good industrial hygiene and safety procedures Wash hands and other exposed areas with mild soap and water before eating, drinking, Sulfur Hess CorporationThe Industrial Grinder is a multiblock machine that allows better grinding of items It is a medium tier machine with 40000FE internal energy buffer and 256FE input Also it has internal tank for 16 buckets which store fluid used to grind oreIndustrial Grinder [Tech Reborn]2021年2月13日 Melting also works, but requires grinding afterwards Sulfur can be purchased in fairly pure form on the internet from chemical and industrial companies that are willing to sell to individuals Sulfur can also be obtained by Sulfur Sciencemadness Wiki

Industrial Grinder ARK: Survival Evolved Wiki

The Industrial Grinder in ARK: Survival Evolved is a crafting machine used to grind up crafted items into a quarter of their crafting ingredients The Grinder can grind up many crafted items, such as tools, weapons, armor, structures, and 2023年7月29日 A high sulfur content is one of the challenges in the processing of refractory bauxites in China The high carbon content of bauxite makes it more difficult to deal with Desulfurization and decarbonization are the critical issues Flotation Decarbonization and Desulfurization of a 2021年1月1日 discuss the sulfur melter as industrial product grinding machines and drilling machines P r asetyo et al / Structural I n tegrity P r ocedia 00 (2019) 000–00 0 3 Table 1(PDF) Investigation of Sulfur Melter Heating Coil as an Industrial 2012年11月1日 Mechanical grinding of lead oxide and lead dioxide with sulfur was conducted Mechanochemical reaction between lead oxide (lead dioxide) and sulfur happened The formation of lead sulfide accompanied by lead sulfate was confirmed after grinding Sulfidization reaction for lead dioxide was much easier than lead oxide The reaction could be applied to treat lead Mechanochemical sulfidization of lead oxides by grinding with sulfur

Effects of Mill Speed and Air Classifier Speed on Performance of an

2021年6月29日 The results show that the floatability of CuO is improved after grinding with sulfur, by the formation of surface layer with properties similar to CuS due to the CuS bondingAMSOIL Industrial cutting and grinding fluids assist with metal machining by lubricating and cooling the work area They increase wheel life during grinding operations and optimize metal cutting performance to protect machine tools, minimizing maintenance and providing peace of mind to overcome your manufacturing challengesCutting Grinding Fluid AMSOIL Industrial2024年4月9日 refined sulfur powder was prepared from industrial sulfur in the presence of carbon disulfide by recrystallization, vacuum distillation, grinding and sieving Foodgrade sulfur is prepared by heating industrial sulfur, adding arsenic removing agent and heavy metal removing agent, refining, grinding and sievingsulfur precipitated ChemBK2023年9月7日 At present, high sulfur bauxite is gradually being used in the production of alumina industry to address the shortage of bauxite resources in China However, sulfurcontaining minerals in bauxite can cause iron pollution in the digestion system, corrode steel facilities, increase caustic consumption, and affect the quality of alumina products From the Characterization of High Sulfur Bauxite and Its Phase

.jpg)

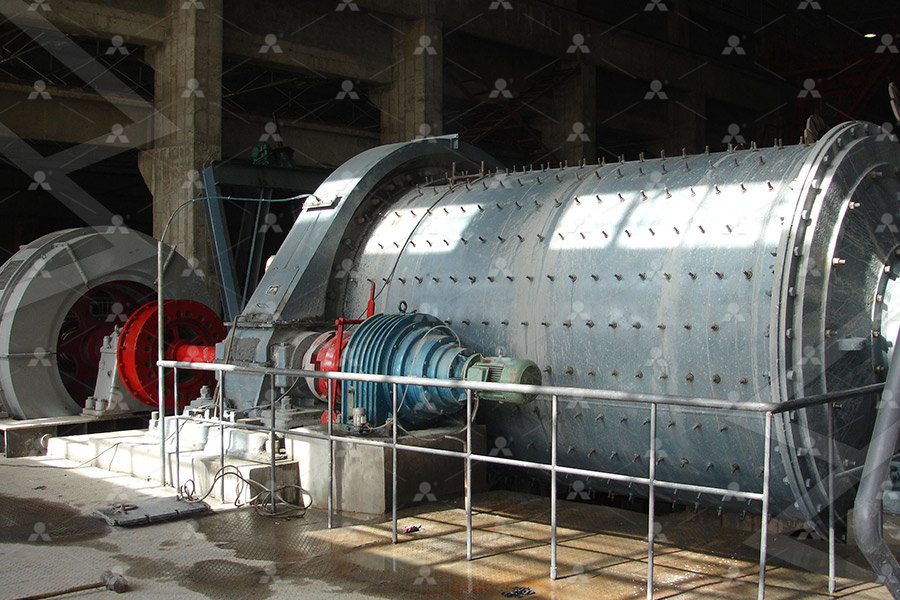

Sulfur Grinding SystemMill Powder Tech Solutions

Food Industrial, Chemical Mills / Grinders / Pulverizers; Food Industrial, Chemical MillsMixers / Blenders; Mini / Laboratory Grinder; Sifter; Turnkey System; Sulfur Grinding System PM Series Features Treatment:Grinder Material Properties:NonOily Fineness:20mesh ~ 150mesh Capacity:50kg ~ 500kg2021年8月17日 Grinding is a basic physical process, and the grinding tools #8220;mortar and pestle#8221; have been in use since times immemorial It has been practiced in almost all spheres of human life from kitchen to laboratories as well as in large industrial processesMechanochemistry: Synthesis that Uses Force SpringerLink2022年7月12日 In the production process of industrial sulfur powder, static electricity is generated due to the friction of ball milling equipment, the friction of sulfur powder parts and equipment problems When the concentration of Analysis of Electrostatic Characteristics of Industrial 2023年6月14日 This research aims to recover sulfur from sulfur residues of the chemical method for purifying mine sulfur in the AlMishraq mine by studying and using thermal and airthermal treatment with a temperature range of 130190 oC and an increase of 10 degrees for each treatment After being prepared in the sulfur residues (foam) by grinding it to 200 mesh and Recovery of Sulfur from the Residues of the Chemical Method for

.jpg)

Energy Sources, Part A: Recovery, Utilization, and Environmental

2023年4月23日 The maximum% of desulfurization rate reached 2469% under optimum conditions of wetgrinding, a 10% grinding concentration, and a period of grinding 90 min, at pH = 7 However, the Discover the Hammer Mill, the ultimate industrial grinding equipment designed for efficient material processing, including coal, coke, biomass, and waste Learn how its advanced features and working principle make it ideal for precise carbon and sulfur measurement, ensuring accurate results for both environmental and industrial analysis"Top 5 Benefits of Hammer Mill for Carbon and Sulfur Industrial Grinder now yields up to 100 items of a type per grind 24592: Fixed a crash that would occur with the Industrial Grinder 24599: Fixed an issue with Industrial Grinders 2492: Fixed an Industrial Grinder exploit 2502: Changed the Industrial Grinder to have only 1 stack, and retroactively applied this to help deal with an Industrial Grinder ARK Official Community Wiki2021年1月1日 The deployed primary machines in the sulfur melter heating coil fabrication process are the plasma cutting machine, the bending pipe machine, the welding machine, and the granty crane as illustrated in Fig 1 At the same time, the auxiliary machines in the fabrication process are hand grinding machines and drilling machinesInvestigation of Sulfur Melter Heating Coil as an Industrial

DETERMINATION OF SULFUR CONTENT IN WASTE MATERIALS BY

grinding the material in two steps: first a reduction of the particles to diameters passing a 10mm sieve and secondly to diameters passing a 2mm sieve The sulfur extraction from the homogenized 2023年8月31日 Active sulfur directly affects the performance and longevity of cutting oils in industrial applications This method involves precise chemical reactions that unveil the concentration of active sulfur By understanding active sulfur content, industries can optimize cutting processes and minimize wear and tearRemove Sulfur from Oil: Efficient Desulfurization Methods2003年10月11日 Cogrinding nonferrous metal (Cu, Pb, and Zn) oxides with sulfur and iron stimulate solidstate reactions to form nonferrous metal sulfides and iron oxideMechanochemical Sulfidization of Nonferrous Metal Oxides by Grinding 2014年9月17日 Sulfur mining takes place in countries such as Poland, Russia, Ukraine, United States and Turkmenistan Ijen, a quiet but active volcano in East Java, Indonesia contains a one kilometer wide crater lake; a well known site of Sulfur Mining Processing: What to Know

.jpg)

Application fields of different specifications of

2023年11月14日 The functions of industrial sulfur powder are diverse and have different functions in various fields Whether it is rubber manufacturing, explosives, papermaking, food processing, medicine, planting, animal 2014年12月31日 PDF As dust explosion is a major risk factor threating the safety of sulfur production, in the industrial proces s because of the high ignition energy and ignition temperatu re, (PDF) Research on Explosion Characteristics of Sulfur Dust and 2021年5月11日 Elemental sulphur combustion is traditionally used to generate SO 2 to produce sulphuric acid that is consumed in chemical industries, but is now also being considered as an energy vector for power generation Despite the fact that sulphur combustion has been practiced for decades, there are limited reaction mechanisms for its combustion chemistry, which is A detailed reaction mechanism for elemental sulphur combustion Although, the quantity of sulfur emitted into atmosphere and sulfur cycle due to human activities is very easy to quantify as compared to natural sources , the majority of manmade sulfur resources are due to fossil fuel (like coal, natural gas and petroleum) burning, smelting of ores (nonferrous metals) and various industrial/burning processes [31,32,33,34]A Critical Review on the Properties and Applications of Sulfur

.jpg)

Recent advances in the devulcanization technologies of industrially

2023年7月1日 Much more desirable is devulcanization, ie, the selective cleavage of the intermolecular sulfidic bonds, such as carbonsulfur (C–S) and/or sulfursulfur (S–S) bonds, which breaks down the tridimensional network without main chain scissions and degradation of the polymer (Fig 2) [22]2013年4月1日 Mechanochemical sulfidization of zinc oxide by grinding with sulfur and reductive additives Author links open overlay panel SAITO F Mechanochemical sulfidization of nonferrous metal oxides by grinding with sulfur and iron [J] Industrial Engineering Chemistry Research, 2003, 42(23): 5813 5818 [2] CHENG Yi, GUO Zhaohui, LIU Mechanochemical sulfidization of zinc oxide by grinding with sulfur Sulfur dust ignites easily in air Grinding sulfur may produce an explosion hazard Static discharge may ignite sulfur dust Hygiene Measures: Handle in accordance with good industrial hygiene and safety procedures Wash hands and other exposed areas with mild soap and water before eating, drinking, Sulfur Hess CorporationThe Industrial Grinder is a multiblock machine that allows better grinding of items It is a medium tier machine with 40000FE internal energy buffer and 256FE input Also it has internal tank for 16 buckets which store fluid used to grind oreIndustrial Grinder [Tech Reborn]