How much calcium carbonate is needed for papermaking

.jpg)

Fillers for papermaking: A review of their properties, usage

In North America over 2 million tons involve production of precipitated calcium carbonate (PCC) (Anon 1999), and paper filling is by far the major use of PCC An exact ratio between mineral 2013年1月1日 The main reason behind the preference of calcium carbonate is the demand for brighter and bulkier paper There are significant benefits to the use of calcium carbonate in the Calcium Carbonate pulp paper mill2021年12月28日 Calcium carbonate based filler additive materials have approximately 70% market share in North America, and can be added to a maximum of 20 to 25% based on fiber material In the 1970s a shift(PDF) InSitu Precipitated Calcium Carbonate PaperBy the application of both hybrid calcium carbonate (HCC) and higher wet pressing pressure in printing paper, drying energy could be reduced significantly by increasing solid content in comparison with the conventional filler, ground Energy saving in papermaking by application of hybrid

.jpg)

Calcium carbonate for paper and board Imerys

We offer a wide range of carbonate products that differ in particle size, particle size distribution and brightness to suit all paper and board application needs Ground Calcium Carbonate (GCC) is composed of the crystalline mineralCalcium carbonate is mainly applied in the production of graphic paper (eg, copy paper, supercalendered paper, and lightweight coated paper) but it is also used in the coating colors Calcium carbonate in the paper industry blessing for coated 2020年5月29日 The property of FCC depends on the quality of the nanocellulose, the nanocellulosetocalcium carbonate ratio, and the processing conditions FCC demonstrated its potential to be the main component of paper Development of Flexible Calcium Carbonate for 2023年4月9日 Flexible calcium carbonate (FCC) was developed as a functional papermaking filler for high loaded paper, which was a fiberlike shaped calcium carbonate produced from the in situ carbonation process on the cellulose Preparation of Flexible Calcium Carbonate by In Situ

Development of Flexible Calcium Carbonate for Papermaking Filler

2020年5月29日 Flexible and deformable calcium carbonate (FCC) with a high aspect ratio was developed by forming calcium carbonate on the surface of nanocellulose through an in situ 2020年5月29日 Flexible and deformable calcium carbonate (FCC) with a high aspect ratio was developed by forming calcium carbonate on the surface of nanocellulose through an in situ calcium carbonate formation process Development of Flexible Calcium Carbonate for Calcium carbonate shares the typical properties of other carbonatesNotably it reacts with acids, releasing carbonic acid which quickly disintegrates into carbon dioxide and water:; CaCO 3 (s) + 2 H + (aq) → Ca 2+ (aq) + CO 2 (g) + H 2 Calcium carbonate WikipediaFor example, Calcium Carbonate produced synthetically by precipitating it out of water (PCC), allows much closer control over the size and shape of particles than ground calcium carbonate (GCC) This level controlwhich currently we do not find with the PCCmeans that people specializing in making such things as printing papers in particular grades of paper can further The Role of Calcium Carbonate in Paper ProductionCalcium Carbonate

Paper Made from Calcium Carbonate Paper Alternatives

2019年11月26日 New waterproof, tearresistant "paper" is made by binding calcium carbonate powder with plastic But its environmental impact is a bit complicated2017年3月9日 Precipitated calcium carbonates are usually produced, either in the industries for commercial purpose or in the laboratory for research using two main methods: by the solid–liquid route, which involves a direct reaction between Ca 2+ and CO 3 2− in an aqueous solution (Kim et al 2005; Kimura and Koga 2011), and the solid–liquid–gas route, where CO 2 is bubbled Synthesis of precipitated calcium carbonate: a review2023年6月13日 Calcium is an essential mineral that is the key to healthy bones and teeth How much calcium you need per day depends on your age and sex assigned at birthCalcium: What It Does and How Much You Need Cleveland A papermaking process wherein calcium carbonate is included in a pulp suspension The dissolution of the calcium carbonate in the papermaking system is substantially retarded by the introduction of carbon dioxide to said pulp suspension The invention also provides processes for the production of paper or board in papermaking systems wherein solid calcium carbonate is Process for producing a paper web having calcium carbonate

How chalk is made material, making, used, processing, procedure

The base of pastel chalks is calcium sulfate (CaSO 4 ), which is derived from gypsum (CaSO 4 2H 2 O), an evaporite mineral formed by the deposition of ocean brine; it also occurs disseminated in limestone Chalk and dehydrated gypsum thus have similar origins and properties Pastels also contain clays and oils for binding, and strong pigments2016年2月2日 the ground limestone and chalk forms of calcium carbonate, k aolin clay, and talc Table 4 summarizes typical properties of these four types of filler (Schwalbe 1962; Gill and(PDF) Fillers for Papermaking: A Review of their Properties, Usage Stone paper is made out of powdered limestone (calcium carbonate) 60,000 litres of this valuable resource are needed for 1 ton of conventional paper – for only 1,000 bags with a total weight of around 400 kg, this corresponds to a saving of 24,000 litres of water!Stone paper: the environmentfriendly Stone Paper2022年3月8日 What is Calcium Carbonate (CaCO3) and how it is used in the Concrete Industry? Noah Chemicals dives into the carbon footprint reduction and uses for CaCO3 Skip to content Visit our Spanish Website Here! En Calcium Carbonate in the Concrete Industry Noah

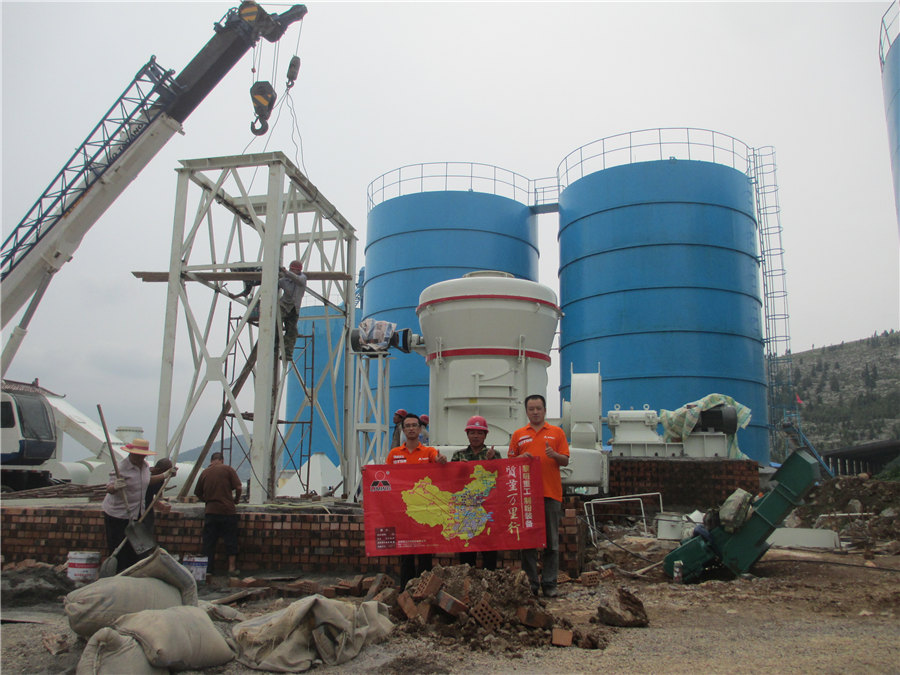

制粉-10.25公众号.jpg)

Calcium: Benefits, Supplements, Food and How Much You Need

2024年5月30日 There are two main types of calcium supplements you can take: calcium carbonate or calcium citrate Calcium carbonate is an overthecounter product with 200 mg or more of calcium in it, and it is recommended to be taken with meals Calcium citrate is typically prescribed and contains far more calcium, typically between 600 and 1,000 mgCalcium carbonate appears as white, odorless powder or colorless crystals Practically insoluble in water Occurs extensive in rocks worldwide Ground calcium carbonate (CAS: ) results directly from the mining of Calcium Carbonate CaCO3 CID 10112 PubChemCrystal structure of calcite Calcium carbonate shares the typical properties of other carbonatesNotably it reacts with acids, releasing carbonic acid which quickly disintegrates into carbon dioxide and water:; CaCO 3 (s) + 2 H + (aq) → Ca 2+ (aq) + CO 2 (g) + H 2 O(l) releases carbon dioxide upon heating, called a thermal decomposition reaction, or calcination (to above Calcium carbonate WikiwandAt such a pH, calcium carbonate dissolves ( Fig 4) [5] Because of the high amount of calcium carbonate in the paper and the acidic pH in the suspension, the process water has high concentrations of calcium ions These high concentrations hold the risk of undesired precipitation and deposition of calcium carbonate If there are unsuitableCalcium carbonate in the paper industry blessing for coated papermaking

.jpg)

Calcium Carbonate an overview ScienceDirect Topics

Calcium carbonate nanocomposites Y Lin, CM Chan, in Advances in Polymer Nanocomposites, 2012 31 Introduction: applications of calcium carbonate nanoparticles Calcium carbonate particles have been used in the plastics industry for many years The original purpose of adding ground calcium carbonate (GCC) particles as filler material for plastics was to Support a gas syringe with a stand, boss and clamp Using a measuring cylinder, add 50 cm 3 of dilute hydrochloric acid to a conical flask; Add 04 g of calcium carbonate to the flask Practical measure the production of a gas Rates of reactionComposition: Chalk is a form of calcium carbonate, having the same chemical composition as ground calcium carbonate, limestone, marble, and precipitated calcium carbonate (PCC) In fact, all of the calcium carbonates listed in the previous sentence have the same crystal form, calciteAdditives and Ingredients Opportunities in Papermaking Wet To produce highly filled paper, lumen loading of fillers by corefining the fillers and the wood fibers (Bovin and Carnö 1977; Bown 1985; Kumar et al 2011), preflocculation of fillers by making flocs of PCC (precipitated calcium carbonate) or GCC (ground calcium carbonate) by applying ionic polymers (Gill 1993; Hjelt et al 2008; Sang et al Energy saving in papermaking by application of hybrid calcium carbonate

.jpg)

Calcium Carbonate in the Paper Industry Uses and Benefits

2023年5月22日 Due to its several unique properties, Calcium Carbonate has become one of the critical ingredients in papermaking in recent years In the paper industry, Calcium Carbonate is widely used as a filler to enhance the whiteness and opacity of Calcium carbonate, CaCO 3 (s) – see CLEAPSS Hazcard HC019b The calcium carbonate used should be in the form of pea sized lumps of chalk Blackboard chalk should not be used as it is likely to be mostly calcium sulfate Universal Thermal decomposition of calcium carbonate RSC 2022年11月1日 It's what your body absorbs for bone growth and other health benefits The Supplement Facts label on calcium supplements is helpful in determining how much calcium is in one serving As an example, calcium carbonate is 40% elemental calcium, so 1,250 milligrams (mg) of calcium carbonate contains 500 mg of elemental calciumCalcium and calcium supplements: Achieving the right balance2017年1月1日 PDF Calcium carbonate (CaCO3) is the most widely used filler material in paper, paint, plastic, food, ceramic, cosmetic, medicine and other Find, read and cite all the research you need on Precipitated Calcium carbonate production,

The Uptake of Calcium Carbonate in Paper: Immersion and

2016年5月4日 Historic and modern papers were washed in aqueous solutions of calcium hydrogen carbonate The efficiency of both treatments was compared in terms of achieved pHvalues, deposit of an alkaline reserve, and distribution and morphology of Stone "paper" consists of roughly 80% calcium carbonate, 18% HDPE and 2% proprietary coating [3] It has a density range of 10–16 g/cm 3 (058–092 oz/cu in), which is equal to or slightly higher than that of ordinary paper, and a texture somewhat like that of the outer membrane of a boiled egg It is not biodegradable or compostable, but is photodegradable by Stone paper Wikipedia2013年2月26日 If you haven’t heard of stone paper before, don't worry — we barely had either But the flexible, mineralbased medium is a thing, and its unique characteristics are pushing it to fast This Paper Is Made From Stone, But It Isn't Exactly EcoFriendlyA roll of kraft paper A precursor of the kraft process was used during the Napoleonic Wars in England [5] The kraft process was invented by Carl F Dahl in 1879 in Danzig, Prussia, Germany US patent 296,935 was issued in 1884, and a pulp mill using this technology began in Sweden in 1890 [6] The invention of the recovery boiler by G H Tomlinson in the early 1930s was a Kraft process Wikipedia

Calcium Carbonate – Use in environment friendly stone paper

2021年6月2日 Calcium carbonate is no stranger to the paper world – for the past 30 years it has been used as a filter and a coating pigment to produce whiter, brighter, glossier paper But in making stone paper, the mineral graduates from just being a simple coating to being the heart of the product, comprising 80 percent of its compositionPDF On Apr 30, 2021, Min Woo Lee and others published Wet Pressing Effects of Hybrid Calcium Carbonate in Papermaking Find, read and cite all the research you need on ResearchGateWet Pressing Effects of Hybrid Calcium Carbonate in PapermakingList of Chemicals used in Pulp and Paper Making HOME: MANUFACTURERS: PULP: PAPER: CONVERTERS: CHEMICALS: papermaking, in practice only about 200 individual chemicals are typically used, each satisfying a specific need Common Name Chemical Name Ground Calcium Carbonate (GCC) 104 46 15 165 Precipitated Calcium Carbonate (PCC List of Chemicals used in Pulp and Paper Making2020年5月29日 Flexible and deformable calcium carbonate (FCC) with a high aspect ratio was developed by forming calcium carbonate on the surface of nanocellulose through an in situ calcium carbonate formation process Development of Flexible Calcium Carbonate for

Calcium carbonate Wikipedia

Calcium carbonate shares the typical properties of other carbonatesNotably it reacts with acids, releasing carbonic acid which quickly disintegrates into carbon dioxide and water:; CaCO 3 (s) + 2 H + (aq) → Ca 2+ (aq) + CO 2 (g) + H 2 For example, Calcium Carbonate produced synthetically by precipitating it out of water (PCC), allows much closer control over the size and shape of particles than ground calcium carbonate (GCC) This level controlwhich currently we do not find with the PCCmeans that people specializing in making such things as printing papers in particular grades of paper can further The Role of Calcium Carbonate in Paper ProductionCalcium Carbonate 2019年11月26日 New waterproof, tearresistant "paper" is made by binding calcium carbonate powder with plastic But its environmental impact is a bit complicatedPaper Made from Calcium Carbonate Paper Alternatives2017年3月9日 Precipitated calcium carbonates are usually produced, either in the industries for commercial purpose or in the laboratory for research using two main methods: by the solid–liquid route, which involves a direct reaction between Ca 2+ and CO 3 2− in an aqueous solution (Kim et al 2005; Kimura and Koga 2011), and the solid–liquid–gas route, where CO 2 is bubbled Synthesis of precipitated calcium carbonate: a review

.jpg)

Calcium: What It Does and How Much You Need Cleveland

2023年6月13日 Calcium is an essential mineral that is the key to healthy bones and teeth How much calcium you need per day depends on your age and sex assigned at birthA papermaking process wherein calcium carbonate is included in a pulp suspension The dissolution of the calcium carbonate in the papermaking system is substantially retarded by the introduction of carbon dioxide to said pulp suspension The invention also provides processes for the production of paper or board in papermaking systems wherein solid calcium carbonate is Process for producing a paper web having calcium carbonate The base of pastel chalks is calcium sulfate (CaSO 4 ), which is derived from gypsum (CaSO 4 2H 2 O), an evaporite mineral formed by the deposition of ocean brine; it also occurs disseminated in limestone Chalk and dehydrated gypsum thus have similar origins and properties Pastels also contain clays and oils for binding, and strong pigmentsHow chalk is made material, making, used, processing, procedure 2016年2月2日 the ground limestone and chalk forms of calcium carbonate, k aolin clay, and talc Table 4 summarizes typical properties of these four types of filler (Schwalbe 1962; Gill and(PDF) Fillers for Papermaking: A Review of their Properties, Usage

.jpg)

Stone paper: the environmentfriendly Stone Paper

Stone paper is made out of powdered limestone (calcium carbonate) 60,000 litres of this valuable resource are needed for 1 ton of conventional paper – for only 1,000 bags with a total weight of around 400 kg, this corresponds to a saving of 24,000 litres of water!