HOME→Fly ash floating bead equipment process Fly ash floating bead equipment process Fly ash floating bead equipment process

Fly ash floating bead equipment process Fly ash floating bead equipment process Fly ash floating bead equipment process

.jpg)

Effect of floating bead on the manufacturing process of fly ash

Semantic Scholar extracted view of "Effect of floating bead on the manufacturing process of fly ash ceramics" by Liqiang Qi et al2019年6月29日 The influence of the characteristics of floating beads on the properties of fly ash ceramics was discussed The best sintering conditions were determined through experiments The optimum floating bead content was Effect of floating bead on the manufacturing process The influence of the characteristics of floating beads on the properties of fly ash ceramics was discussed The best sintering conditions were determined through experiments The optimum Effect of floating bead on the manufacturing process of fly ash This article is published in International Journal of Applied Ceramic TechnologyThe article was published on It has received 3 citation(s) till now The article focuses on the Effect of floating bead on the manufacturing process of fly ash

Microstructure and performance of fly ash microbeads in

2014年2月15日 In this paper, the physical microconstitution of fly ash beads was investigated; the effects of micro crystalline phase and glassy noncrystalline phase inside fly ash beads on Abstract: Fly ash floating bead (FAFB) was modified by the nonionic surfactant polyethylene glycol (PEG) under various concentrations to improve its hydrophobility, and then PEG modified Fly Ash Floating Bead/polyaniline CompositesFly ash floating bead (FAFB) was modified by the nonionic surfactant polyethylene glycol (PEG) under various concentrations to improve its hydrophobility, and then PEG modified FAFB Synthesis and electric properties of polyethylene glycolmodified 2014年4月1日 In this paper, expanded perlite / fly ash floating beads insulation material was made of expanded perlite, fly ash floating beads, cement, fly ash and VAE emulsion by adding Preparation and Study on the Properties of Expanded Perlite / Fly

.jpg)

Sorting system and method for fly ash nonporous floating beads

A sorting system and fly ash technology, applied in chemical instruments and methods, wet separation, solid separation, etc, can solve the problems affecting the quality of float beads, For Peer Review Effect of Floating Bead on the Manufacturing Process of Fly Ash Ceramics Journal: International Journal of Applied Ceramic Technology Manuscript ID ACT5170R1 Manuscript Type: ArticleFor Peer Review ResearchGate2020年4月8日 Traditionally fly ash is thought to be glassy, spherical particle originating from pulverized coal combustion (PCC) at temperature up to 1700 °C However, nowadays fluidized bed combustion (FBC) technology is spreading Utilization of Fly Ashes from Fluidized Bed 2021年9月1日 The dispersion of fly ash in water results in an alkaline pH from 10 to 13 At high pH, the fly ash becomes negatively charged allowing the removal of heavy metal ions by precipitation and electrostatic adsorption from water (Cho et al, 2005) Fly ash can be modified or transformed into new materials for heavy metal ions adsorptionFly ash properties, characterization, and applications: A review

Preparation and Study on the Properties of Expanded Perlite / Fly Ash

2014年4月1日 In this paper, expanded perlite / fly ash floating beads insulation material was made of expanded perlite, fly ash floating beads, cement, fly ash and VAE emulsion by adding decent additives, like 2024年3月1日 SEM pictures of (a) highcalcium fly ash (Wang et al, 2022b), (b)–(c) short rodlike Ca 2 SiO 4 covering on the surface of fly ash after calcined and washed (Wang et al, 2022b), (d) tubular crystal ferric silicate on fly ash surface (Rodríguez et al, 2013), (e) crystalline particles with dendritic structure distributed on the surface of fly ash particles (Rodríguez et al, 2013), Review A review on fly ash highvalue synthesis utilization and its 2012年2月1日 By Jayant Khambekar, PhD and Roger A Barnum, Jenike Johanson, Inc, USA Fly ash is a general name used for the residual products of combustion that rise with flue gases More than 100 million Fly Ash Handling: Challenges and Solutions Power EngineeringA new type of ceramic material was prepared by adding flux with floating beads and kaolin The influence of the characteristics of floating beads on the properties of fly ash ceramics was discussedEffect of floating bead on the manufacturing process of fly ash

Sorting system and method for fly ash nonporous floating beads

[0078] Based on the sorting system of fly ash nonporous floating beads in the first embodiment, a sorting method for nonporous floating beads is realized, including the following steps: [0079] 1 The fly ash in the ash hopper 1 enters the friction charging chamber 3 under the action of the ash hopper fan 2, so that the carbon particles and the ash particles have different polarities and 2022年9月1日 According to Xray diffraction spectra (Fig 2), the mineral composition of the coal fly ash is quartz, mullite, and maghemiteDuring the combustion process, minerals in the raw coal such as kaolinite, montmorillonite, pyrite, and calcite are almost completely melted and decomposed at high temperature, forming an amorphous glass body predominantly composed Separation of unburned carbon from coal fly ash: Pre 2021年5月11日 Fly ash is used as a cementitious material as well as a partial cement replacement It also serves as a fine aggregate in concrete (Khan et al 2017; Xu and Shi 2018)According to American Coal Ash Association 2020, around 37% of 38 million tons of fly ash produced in the USA are used in concreteThe use of fly ash in construction as cementitious Coal Fly Ash Utilisation and Environmental ImpactBy carbonremoval flotation and superfine classification process,ultrafine fly ash beads with D50 =466 μm were selectedAfter particle ratio optimization with fractal theory model on ultrafine beads,cement and silica fume,the low density cement slurry of 140 g/cm3 was developedThe results showed that ultrafine beads lightened cement stone,cured either at 50 ℃ or 80 ℃,has Preparation of Lowdensity Slurry Lightened with Ultrafine Fly Ash

Synthesis and electric properties of polyethylene glycolmodified fly

Fly ash floating bead (FAFB) was modified by the nonionic surfactant polyethylene glycol (PEG) under various concentrations to improve its hydrophobility, and then PEG modified FAFB composited with polyaniline (FAFBPEG/PAn) by emulsion polymerization method using different feed ratios of FAFBPEG The chemical structure, phase structure, microstructure, 2016年7月1日 The fly ash floating beads were covered by polyaniline ( FAFB/PAn ) by using in situ polymerization method Sol gelhydrothermal method was introduced to prepare FAFB/PAn/BaTi03 compositesSynthesis and electrorheological property of fly ash floating bead The utility model relates to a float pearl technical field, and disclose a fly ash floats pearl sorting unit, comprising a base plate, the spacing seat of top fixedly connected with of bottom plate, the top fixedly connected with motor cabinet of bottom plate, the top fixedly connected with motor of motor cabinet, the spout has been seted up at the top of spacing seat, the inner wall swing Fly ash floating bead sorting device Google Patents2020年4月8日 Traditionally fly ash is thought to be glassy, spherical particle originating from pulverized coal combustion (PCC) at temperature up to 1700 °CUtilization of Fly Ashes from Fluidized Bed Combustion: A Review

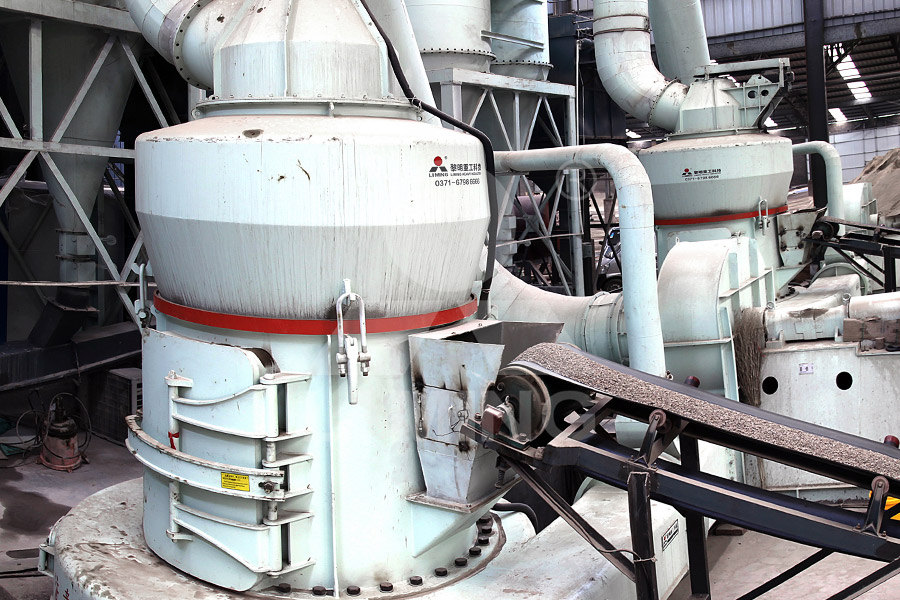

Fly Ash Production ProcessFly Ash Processing Equipment Clirik

Fly Ash Production ProcessFly Ash Processing Equipment What is fly ash? Fly ash generally refers to fly ash port fillers, and other materials The floating beads contained are also important fillers for thermal insulation materials and rubber, and their useful value is very large Uses of fly ash 12020年4月28日 The rapid economic development in China places a large demand for energy, and as a result, thermal power plants in China are producing an enormous amount of coal fly ash (CFA) which causes severe environmental pollution This paper briefly describes the current production and utilization status of CFA in China and identifies the challenges confronting Utilization of coal fly ash in China: a minireview on challenges 2024年5月29日 A novel method is introduced in this study for producing ceramisite coarse aggregates that are both lightweight and possess high strength The process involves utilizing fly ash as the primary material, along with coal ash floating beads (CAFBs) that have high softening temperature and a spherical hollow structure serving as the template for forming pores This A Novel Method for Preparing Lightweight and HighStrength2024年2月7日 Cenospherebased soundabsorbing materials have been investigated by some researchers 2228 For example, Zhang et al used fly ash cenosphere as a raw material, fabricated and produced a sound absorbing material with a lowfrequency sound absorption coefficient of 125 Hz greater than 034 and an average sound absorption coefficient greater Preparation and sound absorption performance of low‐carbon fly ash

2FD{P}PC]854]XQ.jpg)

Highvalued utilization of fly ash for preparing mechanically

2023年3月1日 Fly ash (FA) is the main solid waste produced after coal combustion or gasification, with small density and high specific surface area The particle size of FA is generally distributed in the range of 05 to 300 μm, while a small part of submillimeter float beads are usually contained in FA produced by coalfired power plants2014年12月1日 Fly ash (FA), the finetextured residue of coal combustion in power plants, is an amorphous ferroaluminosilicate enriched with oxides of aluminum, iron, and calcium that can strongly adsorb or precipitate P (Pengthamkeerati et al, 2008)The P sorption ability of FA has been demonstrated by laboratory batch (Agyei et al, 2000, Chen et al, 2007) and column Coal fly ash enhanced plantedfloating bed performance in 2012年2月1日 Download Citation Experimental Study of External Thermal Insulation Mortar Based on Fly Ash Floating Bead In this paper, the development and properties of floating bead insulation mortar were Experimental Study of External Thermal Insulation Mortar Based on Fly 2005年9月25日 Flyash floating beads (FAFB) are created in coalburning power stations and, when used in downhole working fluids such as well cementing slurries as lightening agent, bear in some cases a high Determination of bulk strength of flyash floating beads under

Physical, chemical, and geotechnical properties of coal fly ash:

2019年12月1日 Fly ash is used as a supplementary cementitious material (SCM) to produce Portland cement concrete Fly ash when used as SCM contributes to properties of hardened concrete through pozzolanic and/or hydraulic activity Fly ash has been used in concrete ranging from 15 to 25% by mass and high dosage of 40–60% can be used in structural uses [6]BFLY ASH The use of fly ash in concrete to making enhances workability and makes it easy to place and finish Fly ash helps to reduce the heat generated during the hydration process of concrete, which is especially advantageous where the mass concreting work is done, such as dams and foundations CEPS beadsAN EXPERIMENTAL STUDY OF FLOATING CONCRETE2020年3月9日 Taylor’s square root of time fitting method fly ash mixture; a without EPS beads, b with 1mm EPS beads, c with 2mm EPS beads, d with 3mm EPS beads, e with 4mm EPS beads and f with 6mm EPS beadsEffectiveness of Expanded Polystyrene (EPS) Beads Size on Fly Ash 2018年11月2日 Increased agglomeration for reclaim ash Agglomeration observed in landfilled ash particles Ref: McCarthy, M J and Dhir, R K, Exploiting short and longterm, wet stored fly ash as a cement component in concrete Proceedings International Conference, United Kingdom Quality Ash Association (UKQAA), Birmingham, 15–17 MISBN 09550, 2006Fly Ash Reclamation and

China Fly Ash, Fly Ash Wholesale, Manufacturers, Price Madein

China Fly Ash wholesale Sell Wonderful Quality Cenosphere Beads and Cenosphere Fly Ash US$ 7001500 / Ton 10 Tons (MOQ) Hebei Jinheng New Material Technology Co, cenosphere, floater Here we are going to show you some of the process equipments for sale that featured by our reliable suppliers and manufacturers, • Pond ash Fly ash and bottom ashes are combined with water to create a slurry that is piped to the ash pond The ash settles in the ash pond, and the surplus water is decanted The ash that has been deposited is pond ash 12 FLY ASH Fly ash is a fine glass powder that is collected fromOPTIMIZING FLY ASH USE IN INDIA: CHARACTERIZATION AND Floating beads are aluminum silicate glass hollow beads floated from fly ash of thermal power plant It has light body, thin wall, hollow, smooth surface, high temperature resistance and good heat insulation performance Using these characteristics of floating beads, thermal insulation refractories with excellent thermal insulation performance are manufactured The production of Floating Bead Light Insulation Brick Tyreen Refractory Co,LtdFor Peer Review Effect of Floating Bead on the Manufacturing Process of Fly Ash Ceramics Journal: International Journal of Applied Ceramic Technology Manuscript ID ACT5170R1 Manuscript Type: ArticleFor Peer Review ResearchGate

Utilization of Fly Ashes from Fluidized Bed

2020年4月8日 Traditionally fly ash is thought to be glassy, spherical particle originating from pulverized coal combustion (PCC) at temperature up to 1700 °C However, nowadays fluidized bed combustion (FBC) technology is spreading 2021年9月1日 The dispersion of fly ash in water results in an alkaline pH from 10 to 13 At high pH, the fly ash becomes negatively charged allowing the removal of heavy metal ions by precipitation and electrostatic adsorption from water (Cho et al, 2005) Fly ash can be modified or transformed into new materials for heavy metal ions adsorptionFly ash properties, characterization, and applications: A review2014年4月1日 In this paper, expanded perlite / fly ash floating beads insulation material was made of expanded perlite, fly ash floating beads, cement, fly ash and VAE emulsion by adding decent additives, like Preparation and Study on the Properties of Expanded Perlite / Fly Ash 2024年3月1日 SEM pictures of (a) highcalcium fly ash (Wang et al, 2022b), (b)–(c) short rodlike Ca 2 SiO 4 covering on the surface of fly ash after calcined and washed (Wang et al, 2022b), (d) tubular crystal ferric silicate on fly ash surface (Rodríguez et al, 2013), (e) crystalline particles with dendritic structure distributed on the surface of fly ash particles (Rodríguez et al, 2013), Review A review on fly ash highvalue synthesis utilization and its

Fly Ash Handling: Challenges and Solutions Power Engineering

2012年2月1日 By Jayant Khambekar, PhD and Roger A Barnum, Jenike Johanson, Inc, USA Fly ash is a general name used for the residual products of combustion that rise with flue gases More than 100 million A new type of ceramic material was prepared by adding flux with floating beads and kaolin The influence of the characteristics of floating beads on the properties of fly ash ceramics was discussedEffect of floating bead on the manufacturing process of fly ash [0078] Based on the sorting system of fly ash nonporous floating beads in the first embodiment, a sorting method for nonporous floating beads is realized, including the following steps: [0079] 1 The fly ash in the ash hopper 1 enters the friction charging chamber 3 under the action of the ash hopper fan 2, so that the carbon particles and the ash particles have different polarities and Sorting system and method for fly ash nonporous floating beads2022年9月1日 According to Xray diffraction spectra (Fig 2), the mineral composition of the coal fly ash is quartz, mullite, and maghemiteDuring the combustion process, minerals in the raw coal such as kaolinite, montmorillonite, pyrite, and calcite are almost completely melted and decomposed at high temperature, forming an amorphous glass body predominantly composed Separation of unburned carbon from coal fly ash: Pre

.jpg)

Coal Fly Ash Utilisation and Environmental Impact

2021年5月11日 Fly ash is used as a cementitious material as well as a partial cement replacement It also serves as a fine aggregate in concrete (Khan et al 2017; Xu and Shi 2018)According to American Coal Ash Association 2020, around 37% of 38 million tons of fly ash produced in the USA are used in concreteThe use of fly ash in construction as cementitious