Normal temperature crushing and recycling production line

Automatic tire recycling production line Henan

This FullyAutomatic Tyre Recycling Line running in normal temperature, no need to add any other chemicals, no pollution to the environment This is the best way to recycling scrap tiresThe "modular automatic waste tire decomposition system at room temperature" adopts the normal temperature crushing method to recycle waste tires and carry out resource recycling and What are the main equipment components of the waste tire In most of the production lines the endproduct is a secondary raw material (crumbs, flakes, lumps and granules) and is meant for producers of (recycled) plastic products, in that case we put as A catalogue on machinery for recycling of plastic waste des The tire rubber powder production line operates at room temperature It can achieve tire crushing, tire wire separation, fiber separation, and tire powder making at one time During the process, no wastewater, waste gas, or dust is Tire Recycling Plant Gomine Recycling Machinery

The Complete Guide to Plastic Crusher: Essential Tips

The plastic crusher is a crucial piece of equipment for the recycling industry, as it is designed to break down solid plastic waste efficiently for further processing By crushing the plastic materials into smaller pieces, they can be easily and 2019年2月18日 Through review of the recycling technology of scrap tire at low temperature and the highvalue reuse of the regenerated rubber powder of domestic and abroad, the Overview of HighValue Reuse and Grinding at SubZero The Crushing and Cleaning Production Line is specifically designed for recycling PET beverage bottles (such as Coke and mineral water bottles) or PP/PE waste materials (such as Plastic Recycling Lines, Waste Crushing Production Line Granuwel 2024年8月12日 In order to recycle and dispose of plastic bottles more effectively, the plastic bottle crushing and cleaning recycling line came into being This paper will elaborate the Plastic bottle crushing cleaning recycling production line:working

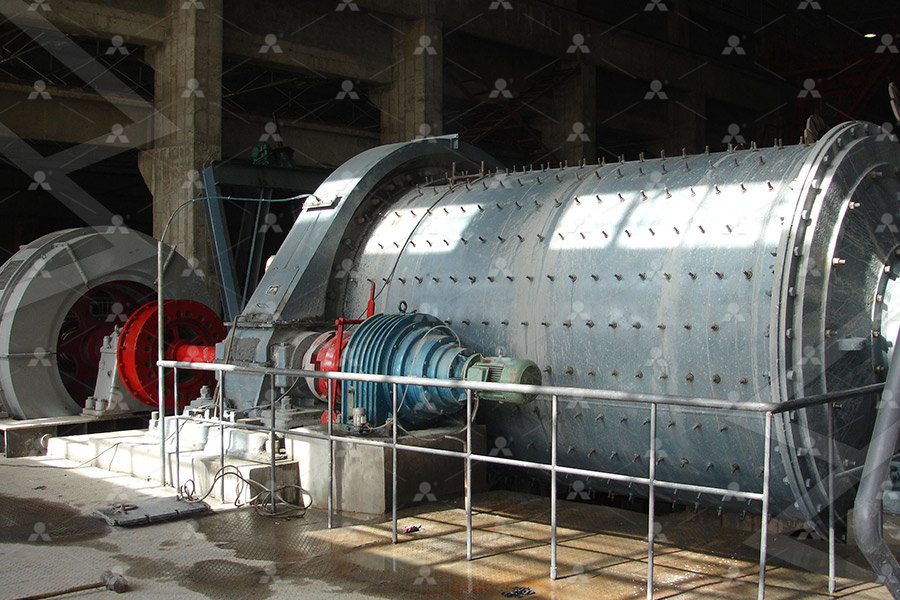

Resin Sand Reclamation Production Line ATHI

It is supplemented by falling sand, crushing, magnetic separation, cooling, conveying, and sand mixing equipment to form a complete set of resin sand recycling treatment equipment, which is mainly suitable for producing cast According to the production features of the different steel manufacturing enterprises,We developed “Dry method” and “Wet Method” comprehensive recycle equipment respectively The production capacity could be 300,000 tons – 2,000,000 tons per yearSteel slag recycling crushing and grinding production lineThe shredder production line can be controlled by a digital computer system to automatically control the speed, production situation, and material particle size information control system of the material storage and transportation production line The system technology is programmed according to production requirements to achieve automation work金属撕碎机production line金属破碎机production lineScrap 2020年4月1日 In addition, 5–10% of the waste (including unused quality fibers and yarns) during the production of raw polyester fibers can also be utilized in the production line Mechanical Recycling Complete recycling lines for the recovery of waste plastics include: washing, cleaning, chopping, drying, melting, and converting granulated plastic into plastic raw materials [ 7 ]Important Step in Sustainability: Polyethylene Terephthalate Recycling

1000kg/h Circuit Board PCB Recycling Machine WANROOETECH

PCB Recycling Machine Process flow: The whole PCB recycling machine adopts a 2stagecrushing step to get mixed metal and resin powder And then it separates metal and resin powder via air flow and high voltage electrostatic separator PCB Recycling Machine Components: PCB Recycling Machine Main Equipment:Tire Rubber Powder Production Line The tire rubber powder production line operates at room temperature It can achieve tire crushing, tire wire separation, fiber separation, and tire powder making at one time During the process, no wastewater, waste gas, or dust is generated, which meets environmental protection requirementsTire Recycling Plant Gomine Recycling Machinery2023年12月1日 Power consumption and therefore efficiency of crushing equipment are becoming increasingly important mainly due to the continuous and rapid increase of energy costs and efforts to minimise CO 2 emissions (Tromans, 2008, Legendre and Zevenhoven, 2014)In order to meet the Paris Climate Agreement goals, recycling should be maximized by 2050 Energy consumption of a laboratory jaw crusher during normal 2024年1月6日 Designed to revolutionize the recycling landscape, their cuttingedge crushing and sorting production line stands as a testament to innovation in metal reclamation and reuse Efficient Crushing Mechanism At the heart of this system lies an efficient crushing mechanism that processes scrap metal into manageable sizesMetal Recycling Solutions: GEP ECOTECH's CuttingEdge

-2.jpg)

plastic recycling production line KITECH

24/7 online with expert plastic recycling production line advice Multiprocess unit: including crushing, melting, extrusion, cutting and granulation, etc Adopt high wear resistant alloy material to ensure 15 times service life of normal one DegassingBSGH is one of the most professional PCB recycling machine manufacturers and suppliers in China, providing the best quality customized products with low price for distributors and dealers Welcome to buy or wholesale cheap PCB recycling machine for sale here from our factoryPCB Recycling Machine Manufacturers, Suppliers, FactoryTire to rubber granules through the tire recycling equipment is a mainstream type of tyre recoveryThere are more than three billion waste tires all over the world now and it +31 sunymachine@gmailTire Crushing And Recycling Production Line Suny GroupWe can customize metal crushing and recycling production line for you Shredding effect The output particles after shredding scrap metal can be customized Metal Crusher Metal Shredder The whole crushing line is controlled by PLC, which can realize microcomputer control and manual operation The main equipment of the scrap steel crushing Scrap metal crushing line, Scrap metal crushing plant, Metal Crushing

PP PE PVC Plastic Film Recycling Line Shuliy Machinery

Introduction of Plastic Granulating Line The whole waste film recycling line is suitable for crushing, washing, pelletizing, and packaging PE/PP film, woven bags, laminated film, cement bags, waste agricultural film, shrink wrap, drip 2018年3月20日 The melting temperature of tin is 232 °C, and the methods to melt soldering tin are several: the use of a tin melting furnace (CN; Circuit board crushing and recycling production line: CN: 2015: Hydrometallurgy process for the recovery of materials from electronic boards: WO:Printed circuit board recycling: A patent review ScienceDirectSales service Presale: we give customer the plastic recycling machinery detail technician offer, sign the sales contract etc; Insale: we supply the plastic film bag granulating machine (together with crushing washing machine if needed as a recycling Plastic Woven Bag Granulating Recycling Machine LineNew Design Pet Plastic Recycling Line offered by China manufacturer Haorui Machinery Buy New Design Pet Plastic Recycling Line directly with low price and high quality +86 +86 、 +86New Design Pet Plastic Recycling Line

Recycling, Management, and Valorization of Industrial Solid Wastes

2021年5月10日 Three approaches for recycling solid wastes are known : (1) Recycling is a procedure of dealing with solid waste and recycling of secondary materials (2) Conversion is making new forms of substances from waste, such as asphalt materials using rubber and waste glass, construction materials using blast furnace slag and fly ash as starting materials, and BEIER Machienry, thanks to its worldwide experience in the field of PET bottle washing recycling line,can provide its customers with proper technical solutions and stateofthe art recycling technologies Through input high temperature and high pressure steam, add chemical Medicament, like NAOH, cleaner and etc, PET Bottle Recycling Washing Line and Machine Beier MachineryThe Resin Sand Reclamation Production Line comprises a magnetic separation belt conveyor, vibration crusher regeneration machine, centrifugal rotor secondary regeneration machine, sand storage, bucket elevator (3 sets), mobile twoarm continuous resin sand mixing machine, pulse bag dust collector, and other equipmentResin Sand Reclamation Production Line ATHI2024年3月13日 Assessment of Plastic Waste Management in Bangladesh: A Comprehensive Perspective on Sorting, Production, Separation, and Recycling(PDF) Assessment of Plastic Waste Management in Bangladesh: A

Pet Bottle Crushing Washing Drying Recycling Line

Pet Bottle Crushing Washing Drying Recycling Line offered by China manufacturer Haorui Machinery Buy Pet Bottle Crushing Washing Drying Recycling Line directly with low price and high quality +86 +86 、 +86 haoruishirley@petjixie 、 haorui006@petjixie 、 haorui005@petjixie2024年9月6日 Recycling steps: removing bottle labels — removing bottle trademarks — crushing — cleaning — drying — storage 500kg/h PET bottle recycling machines display plastic bottle recycling line 1000kg plastic bottle PET Plastic Bottle Recycling Line Recycling MachineModel NO: XYWPET500, XYWPET1000, XYWPET2000, XYWPET3000 Aftersales Service: Provide Warranty: 1 Years Material Processed: Plastic Bottle Plastic Type: PET Automation: AutomationPet Bottle Cleaning/Washing Recycling Production Line2020年7月7日 The nominal recycling rate, which is the ratio of the statistical recycling volume of postconsumer titanium products to the production volume of titanium sponge, is quite low (less than 1 pct) This value is miniscule compared with the recycling rates for steel (25 pct in 2013 in Japan), aluminum (36 pct in 2016 in Japan), and copper (30 pct in 2016 in Japan)[ 66 ]Recent Progress in Titanium Extraction and Recycling

.jpg)

Industrial Glass Processing and Fabrication SpringerLink

The hot end corresponds to the part of the furnace where melting, forming and annealing processes occur The cold end, downstream of the forming and annealing processes, is where postprocessing such as coating, cutting and inspection take place An example of an industrial float glass production line is shown in Fig 3482023年12月1日 In uence of the temperature (a) and solids content (b) on the recovery yield (black line) and copper impurities (red line) for anodes with a process time of 5 min (15coloum tting image)Direct recycling of lithiumion battery production scrap Solvent 2019年11月29日 With the increasing amount of electronic waste (ewaste) generated globally, it is an enormous challenge to recycle printed circuit boards (PCBs) efficiently and environmentally friendly However Recycling Waste Circuit Board Efficiently and Environmentally Friendly Shredwell's scrap tyre recycling line is designed to turn scrap car tires, truck tires and OTR tires into 50100mm, 20mm, 15mm or 30120 mesh rubber powder according customer request with most advanced recycling technologies Call us to get best tyre recycling solution to Scrap Tire Recycling Line Reliable Rubber Powder Plant for

PP/PE Film Bags Washing Recycling Line Greenlandplast

The film bags washing recycling line is mainly used for waste HDPE/LDPE/PP film, bags, woven bag crushing, washing recycling The production line includes conveyor ,crushing (with water), rinsing, highspeed friction washing, dewatering, drying, collection and packaging systems; The drying part can also be equipped with our latest film squeezing compactor machine or film 2024年11月7日 The waste tire recycling line (also rubber powder production line) uses advanced tire recycling technology, and used tire recycling equipment, making the waste tires into rubber powder The waste tyre recycling line mainly includes a tire ring cutter, strip cutter, lump cutter, and rubber granules machineWaste tire recycling line rubber granules making machineOur PP PE flake recycling line is a production facility designed to process and recycle a wide Precise control of melt temperature, extrusion pressure, and cutting speed on our Below you will find a detailed description of the plastic pelletizing process Crushing: Waste plastics are crushed into small pieces in a waste Waste PVC PP PE Flake Recycling LineAccording to the production features of the different steel manufacturing enterprises,We developed “Dry method” and “Wet Method” comprehensive recycle equipment respectively The production capacity could be 300,000 tons – 2,000,000 tons per yearSteel slag recycling crushing and grinding production line

.jpg)

金属撕碎机production line金属破碎机production lineScrap

The shredder production line can be controlled by a digital computer system to automatically control the speed, production situation, and material particle size information control system of the material storage and transportation production line The system technology is programmed according to production requirements to achieve automation work2020年4月1日 In addition, 5–10% of the waste (including unused quality fibers and yarns) during the production of raw polyester fibers can also be utilized in the production line Mechanical Recycling Complete recycling lines for the recovery of waste plastics include: washing, cleaning, chopping, drying, melting, and converting granulated plastic into plastic raw materials [ 7 ]Important Step in Sustainability: Polyethylene Terephthalate Recycling PCB Recycling Machine Process flow: The whole PCB recycling machine adopts a 2stagecrushing step to get mixed metal and resin powder And then it separates metal and resin powder via air flow and high voltage electrostatic separator PCB Recycling Machine Components: PCB Recycling Machine Main Equipment:1000kg/h Circuit Board PCB Recycling Machine WANROOETECHTire Rubber Powder Production Line The tire rubber powder production line operates at room temperature It can achieve tire crushing, tire wire separation, fiber separation, and tire powder making at one time During the process, no wastewater, waste gas, or dust is generated, which meets environmental protection requirementsTire Recycling Plant Gomine Recycling Machinery

.jpg)

Energy consumption of a laboratory jaw crusher during normal

2023年12月1日 Power consumption and therefore efficiency of crushing equipment are becoming increasingly important mainly due to the continuous and rapid increase of energy costs and efforts to minimise CO 2 emissions (Tromans, 2008, Legendre and Zevenhoven, 2014)In order to meet the Paris Climate Agreement goals, recycling should be maximized by 2050 2024年1月6日 Designed to revolutionize the recycling landscape, their cuttingedge crushing and sorting production line stands as a testament to innovation in metal reclamation and reuse Efficient Crushing Mechanism At the heart of this system lies an efficient crushing mechanism that processes scrap metal into manageable sizesMetal Recycling Solutions: GEP ECOTECH's CuttingEdge 24/7 online with expert plastic recycling production line advice Multiprocess unit: including crushing, melting, extrusion, cutting and granulation, etc Adopt high wear resistant alloy material to ensure 15 times service life of normal one Degassingplastic recycling production line KITECHBSGH is one of the most professional PCB recycling machine manufacturers and suppliers in China, providing the best quality customized products with low price for distributors and dealers Welcome to buy or wholesale cheap PCB recycling machine for sale here from our factoryPCB Recycling Machine Manufacturers, Suppliers, Factory

.jpg)

Tire Crushing And Recycling Production Line Suny Group

Tire to rubber granules through the tire recycling equipment is a mainstream type of tyre recoveryThere are more than three billion waste tires all over the world now and it +31 sunymachine@gmail