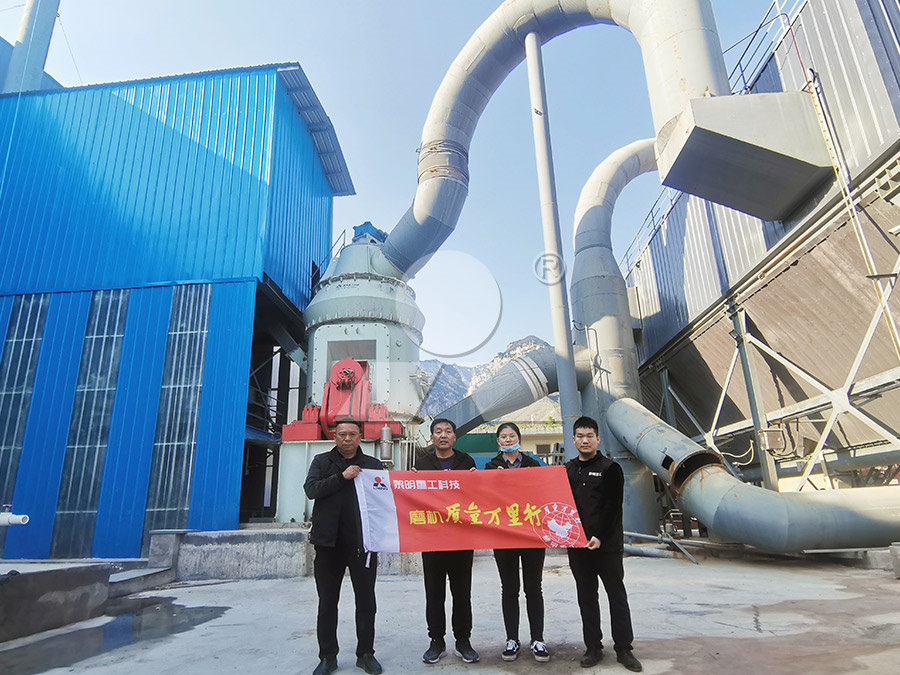

Universal pulverizer for lithium ore

.jpg)

Bulk Material Handling Processing Solutions for Lithium

Whether your lithium originates in ore or a brine deposit, Schenck Process offers a wide range of bulk material handling and dust collection systems that allows us to provide equipment solutions through various stages of lithium processingImpurity removal from the salar brine is a critical step in the process flowsheet for production of batterygrade lithium Our MaxRTM technology provides the most advanced method in the Lithium processing technology Complete solutions that FLSmidthBico Pulverizer features efficient operation, minimal power consumption, and long service life It has a compact design and is effective for pulverizing hard rock, ores, and minerals The grinding chamber is easily accessible for cleaning, Bico Pulverizer Gilson Co2021年5月1日 In modern Russian realities, roasting and hydrometallurgical processing of ores and concentrates using sulfuric acid and limesoda methods seem to be practically Processing of lithium ores: Industrial technologies and case studies

Lithium Processing Equipment, Process Flow, Cases JXSC Machine

2019年8月23日 Over 12 to 18 months, the concentration of the brine increases to 6,000 ppm Li through solar evaporation When the lithium chloride reaches optimum concentration, the 2021年5月1日 In modern Russian realities, roasting and hydrometallurgical processing of ores and concentrates using sulfuric acid and limesoda methods seem to be practically Processing of lithium ores: Industrial technologies and case studies Several different routes for spodumene processing are under development to reduce costs to compete with brine projects This paper will give an overview of the strengths and weaknesses Lithium Ore Processing – an Overview of the Current and New 2021年2月1日 The latest enhancements of the sulfation method significantly increase its overall technological efficiency: sulfuric acid treatment of spodumene is the most costeffective for Processing of lithium ores: Industrial technologies and case studies

Hard Rock Lithium Processing SGS

Flotation is used to generate a high grade spodumene concentrate (7585% spodumene) suitable for lithium extraction Minimize the cost of roasting Lithium can be extracted from spodumene 2018年2月5日 The highspeed universal pulverizer not only shares the advantages of the hammer pulverizer, but also shows unique characteristics such as light weight, small size, Thermal optimization and experimental research of highspeed 2023年1月1日 Lithium resources in nature are mainly stored in lithium deposits of brine, pegmatite, and sedimentary rocks (Talens PL et al, 2013; Liu LJ et al, 2017)Among them, brine mainly includes underground and salt lake brine, and pegmatitetype lithium ore is stored in spodumene, lepidolite, petalite, and zinnwaldite (Xi WW et al, 2022; Yu F et al, 2019), while Lithium extraction from hard rock lithium ores (spodumene, 2014年1月1日 Minerometallurgical processes have been developed for lithium recovery from pegmatitic ore deposits, involving physical concentration, thermal treatment, digestion and/or leaching in order to Minerometallurgical processes for lithium recovery

Universal Pulverizer UPMACH

Universal pulverizer uses the relative movement between the active fluted disc and the fixed fluted disc to impact, grind and crush the target materials The size of granules can be achieved by changing of the screen The machine has the 2023年10月6日 The conventional methods of lithium extraction include mining lithium from ore deposits and extracting lithium from brine sources These methods have been used for decades and have undergone continuous improvements to increase efficiency, reduce environmental impacts , and enhance the quality of the extracted lithiumSustainable Lithium Extraction: How is Lithium Mined and Regarding reserves, the globally confirmed lithium resources have significantly increased, totaling approximately 98 million tons Bolivia boasts the highest reserves, accounting for 2157 % of the global total, followed closely by Argentina and Chile (Fig 1 d) [6]Among these, salt lake brine resources make up 723 % of the reserves, while ores account for 203 %, with nearly 50 % of Advances and promotion strategies of processes for extracting lithium Hammer Mill Pulverizer Benefits Investing in a laboratory or pilot plant pulverizer for your industrial facility means reaping all of the following operational benefits: Easy maintenance: Pulverizers from Pulva are easy to install and maintain, with removable door covers that enable greater accessibility for cleaning and wear part replacementReliable Pulverizers for Various Industries Pulva

The lithium ore crushing machine

A lithium ore crusher, also known as a lithium ore crushing machine or lithium ore pulverizer, is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust This type of crusher is commonly used in the mining industry to break down large chunks of lithium ore into smaller pieces, making it easier to transport and process2021年2月1日 Request PDF Processing of lithium ores: Industrial technologies and case studies – A review Recently, there has been a steady increase in demand for lithium (Li) and its compounds Processing of lithium ores: Industrial technologies and case studies lithium ore • Fast detection of impurities or offspec ore mineralogy • BT XRD in laboratories or containers or an automated environment 46 Title of the presentation 21 October 2020 Mineralogical monitoring of lithium ores and brines Fast decision making and counteractions on changing conditions, reduced operational costsAccurate mineralogical analysis for lithium ore processing Lithium ore, also known as hardrock lithium, is derived from mining and is one of the major raw material sources for lithium production for industrial applications – the other source is lithium brines Hardrock lithium deposits are found in countries like Australia, Brazil, Canada, Ireland, Lithium Ore and Concentrates for Battery Production and Beyond

43.jpg)

The beneficiation of lithium minerals from hard rock ores: A

2019年1月15日 There are two economic sources of lithium; brines and hard rock ores The majority of the global lithium production, greater than 60%, is produced from brines while lithium ores accounted for the remaining production (Ebensperger et al, 2005)Table 1 summarises the world’s major lithium producers from ores and brines, and the total reserves2022年10月11日 The beneficiation and flotation process of lithium ore flotation technology mainly includes crushing, grinding, and sorting Crushing is to change the large pieces of lithium ore into small pieces to meet the requirements of Lithium Ore Flotation Technology JXSC Machine2023年2月11日 The elemental EDXRF analysis shows the presence of lithium across the selected pegmatite ore deposit range 352–953% with Panda in Nasarawa State having the highest presence of lithium oxide in the lithiumbearing pegmatite []Also, the beneficiation of the identified deposit was done using frothflotation technique to achieve an improved lithium Characterization and Beneficiation of Nigerian Lithium Ore: An The Pulverisette 19 Universal Cutting Mill System has been optimized for Cannabis Processing Quantity Add to Quote request Quick View Liste de souhaits Quick View The Laboratory Disc Pulverizer Pulverisette 13 Premium Line is designed for batch or continuous fine grinding of hardbrittle to mediumhard solids, down to 50µm QuantityCrushers, Pulverizers, Grinders Lavallab

.jpg)

Lithium Ore Beneficiation Process Overview JXSC Machine

Lithium Ore Beneficiation Equipment Lithium ore beneficiation equipment includes crushers, ball mills, jigs, flotation machines, and auxiliary equipment to form a complete production line Lithium Ore Beneficiation Methods 1 Manual Selection MethodHosokawa Micron Powder Systems recently introduced the Universal Mikro® Pulverizer (UMP) From the inventors of the original high speed pulverizer comes a new line of pharmaceutical impact mills that provide the next level of performance and versatility to the IndustryThe Universal Mikro Pulverizer is now available2019年8月23日 Mining for Lithium: Lithium is often recovered from brine, or water with a high concentration of lithium carbonate Subsurface brines trapped in the Earth’s crust are major source material for lithium carbonate These sources are less expensive to mine than from rock such as spodumene, petalite, and other lithiumbearing mineralsLithium Processing Equipment, Process Flow, Cases JXSC MachineThe Bico Pulverizer has a compact design and is highly effective for handling hard rock, ores, and other similar materials Log in; Favorites List; Shopping Cart Universal Sample Splitters Starting at $91750 Models: SP0, SP1, SP2, SP25 MiniJaw CrusherBico Pulverizer Gilson Co

Transformations of Critical Lithium Ores to BatteryGrade MDPI

2024年10月28日 The escalating demand for lithium has intensified the need to process critical lithium ores into batterygrade materials efficiently This review paper overviews the transformation processes and cost of converting critical lithium ores, primarily spodumene and brine, into highpurity batterygrade precursors We systematically examine the study findings 21 Working principle of the pulverizer The highspeed universal pulverizer used in this research pulverizes the material by imposing strong impact, crush, and shear forces on the material through highspeed spinning blades During the pulverizing process, the material endures the following forces: (i) shear and impact forces ofThermal optimization and experimental research of highspeed universal 2020年6月1日 This data release provides the descriptions of approximately 20 US sites that include mineral regions, mines, and mineral occurrences (deposits and prospects) that contain enrichments of lithium (Li) This release includes sites that have a contained resource and (or) past production of lithium metal greater than 15,000 metric tonsLithium Deposits in the United States US Geological Surveyglass for lithium battery chip for cables coarse powder for plastics (13) for rubber for EPS for powders (9) mineral (9) stone silicon for limestone sulfur silica potassium manganate graphite talc kaolin mica quartz for solid fuels (8) for Disc mill, Disc pulverizer All industrial manufacturers

.jpg)

Lithium Ore Grinding Mills SBM Ultrafine Powder

2024年7月9日 Lithium ore is mainly used to extract lithium, which is widely used in batteries, ceramics, glass, lubricants, aerospace, medicine and other fields In recent years, due to the increasing demand for lithium batteries in electric 2015年1月13日 I've found Tungstate Ore in the overworld, but there's no Tungsten in Tungstate Ore You get Manganese (which is important for making Stainless Steel) and a few other dusts from it, but no Tungsten There is an actual Tungsten Ore listed in NEI, however there is no entry for Tungsten in the Ore Chart found in The GuideGregtech Survival Guide Page 6 Feed the Beast4 The grinder set consists of grinder, EXC collector of raw material and ESC collective duster It solves the problem, ie the dust is flying during the period of crushing raw material 5 The principle of work is as follows: after raw material is fed into the crushing chamber, it undertakes the comprehensive actions such impacted by teeth, shearing force, friction force, impacted Universal Pulverizer Crusher Grinder Milling Machine for Making Lithium Ore is a Tier 3 item obtained using Lithium Ore Drill, which requires 2 Machine Oil to function It is used to make Lithium Battery Packs The Lithium Production line (LIPL) Lithium Ore is extracted by Lithium Ore Drill Lithium Ore + Sulfuric Acid + Sodium Carbonate In a ChemicalReactor = Lithium Sulfate Then back into the chemical reactor, with water + lithium Lithium Ore Industrialist Wiki Fandom

.jpg)

The 5 Most Useful Methods Of Lithium Mining Beneficiation

2019年8月29日 As for the supply of lithium carbonate, there will be a gap in the supply and demand of global lithium carbonate by 2019 3 Lithium mining equipment Lithium ore beneficiation equipment includes crushers, ball mills, jigs, flotation machines, etc, as well as some auxiliary equipment to form a complete production line2022年12月26日 Typical lithium ore is divided into spodumene, diathene, lepidolite and so on With the development of science and technology, HGM calcium carbonate pulverizer is mainly suitable for medium and low hardness, Mohs hardness ≤ 6 grade nonflammable superfine powder processing of brittle materials, suchLithium ore is how to process crushing, grinding equipment?2022年7月5日 Lithium is an element valuable for the production of glass, aluminum products, and batteriesWith the development of technology, electronic equipment, and new energy industries, the demand for lithium ore has increased rapidly Therefore, lithium ore is known as the “energy metal that drives the progress of the world”Lithium Processing Plant JXSC MachineWeed Warrior Pulverizer Twist Universal Trimmer Line, 0080" Diameter x 100' Weed Warrior Pulverizer Twist 080 in x 100 ft bicomponent twistshaped trimmer line is designed for heavyduty use The unique aerodynamic twist design reduces Skil BY870500 PWRCore 40 25Ah 40V Lithium Battery Weed

Lithium extraction from hard rock lithium ores (spodumene,

2023年1月1日 Lithium resources in nature are mainly stored in lithium deposits of brine, pegmatite, and sedimentary rocks (Talens PL et al, 2013; Liu LJ et al, 2017)Among them, brine mainly includes underground and salt lake brine, and pegmatitetype lithium ore is stored in spodumene, lepidolite, petalite, and zinnwaldite (Xi WW et al, 2022; Yu F et al, 2019), while 2014年1月1日 Minerometallurgical processes have been developed for lithium recovery from pegmatitic ore deposits, involving physical concentration, thermal treatment, digestion and/or leaching in order to Minerometallurgical processes for lithium recovery Universal pulverizer uses the relative movement between the active fluted disc and the fixed fluted disc to impact, grind and crush the target materials The size of granules can be achieved by changing of the screen The machine has the Universal Pulverizer UPMACH2023年10月6日 The conventional methods of lithium extraction include mining lithium from ore deposits and extracting lithium from brine sources These methods have been used for decades and have undergone continuous improvements to increase efficiency, reduce environmental impacts , and enhance the quality of the extracted lithiumSustainable Lithium Extraction: How is Lithium Mined and

Advances and promotion strategies of processes for extracting lithium

Regarding reserves, the globally confirmed lithium resources have significantly increased, totaling approximately 98 million tons Bolivia boasts the highest reserves, accounting for 2157 % of the global total, followed closely by Argentina and Chile (Fig 1 d) [6]Among these, salt lake brine resources make up 723 % of the reserves, while ores account for 203 %, with nearly 50 % of Hammer Mill Pulverizer Benefits Investing in a laboratory or pilot plant pulverizer for your industrial facility means reaping all of the following operational benefits: Easy maintenance: Pulverizers from Pulva are easy to install and maintain, with removable door covers that enable greater accessibility for cleaning and wear part replacementReliable Pulverizers for Various Industries PulvaA lithium ore crusher, also known as a lithium ore crushing machine or lithium ore pulverizer, is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust This type of crusher is commonly used in the mining industry to break down large chunks of lithium ore into smaller pieces, making it easier to transport and processThe lithium ore crushing machine2021年2月1日 Request PDF Processing of lithium ores: Industrial technologies and case studies – A review Recently, there has been a steady increase in demand for lithium (Li) and its compounds Processing of lithium ores: Industrial technologies and case studies

.jpg)

Accurate mineralogical analysis for lithium ore processing

lithium ore • Fast detection of impurities or offspec ore mineralogy • BT XRD in laboratories or containers or an automated environment 46 Title of the presentation 21 October 2020 Mineralogical monitoring of lithium ores and brines Fast decision making and counteractions on changing conditions, reduced operational costsLithium ore, also known as hardrock lithium, is derived from mining and is one of the major raw material sources for lithium production for industrial applications – the other source is lithium brines Hardrock lithium deposits are found in countries like Australia, Brazil, Canada, Ireland, Lithium Ore and Concentrates for Battery Production and Beyond