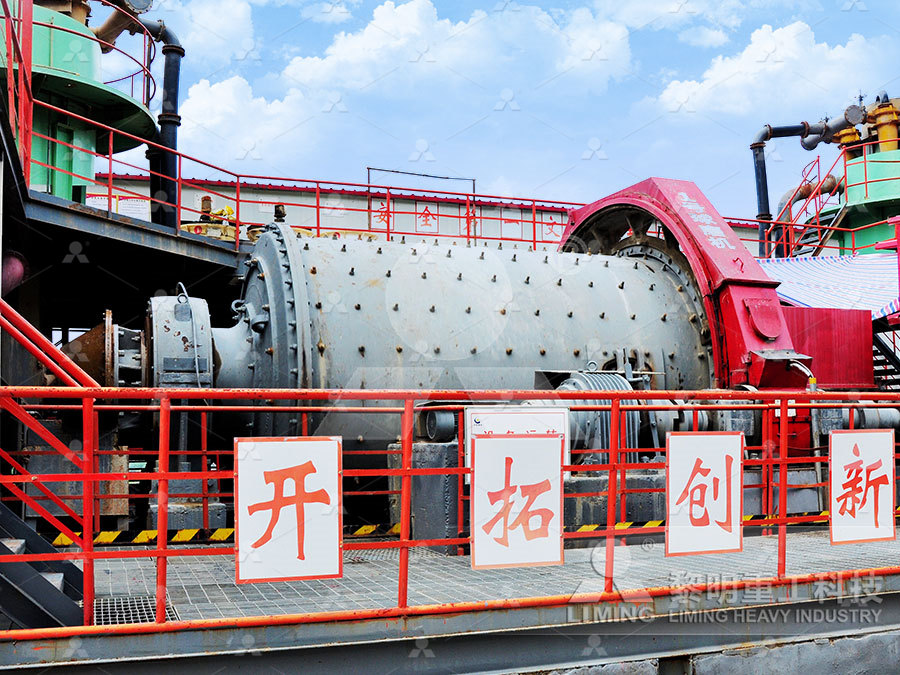

The most aluminumsmelting electrolyte waste slag grinding machine in China

.jpg)

Efficient lithium recovery from electrolytic aluminum slag via an

2024年2月1日 The electrolytic aluminum industry generates a large amount lithium (Li)containing electrolytic aluminum slag (EAS) annually, and this can result in severe 2023年4月25日 This article analyzes and summarizes the composition and hazards of the overhaul slag and the current development status of domestic and international electrolytic Research Progress of Electrolytic Aluminum Overhaul Slag Disposal2022年10月10日 One of the main electrolytic aluminum production costs is the consumption of carbon anodes, and carbon anode slag is a common hazardous waste in the aluminum Recovery of carbon and cryolite from spent carbon anode slag of 2024年7月24日 First, the spent aluminum electrolyte slag phase was reconstructed through a calcium sulfate roasting process, which solidified fluorine into CaF 2 and transformed lithium Cleaner Process for the Selective Extraction of Lithium from Spent

.jpg)

The recycling of carbonrich solid wastes from aluminum

2024年5月23日 Here, we review carbonrich solid wastes with focus on sources and hazards, detoxification, separation, recovery, recycling and disposal Treatment techniques include 2021年10月31日 Spent carbon anode (SCA) is a dangerous solid waste that is continuously discharged from the aluminum electrolysis industry and has a large number of valuable Advances in the Safe Disposal and Comprehensive Utilization of Slag of aluminum is a residue which results during the melting process of primary and secondary aluminum production Salt slag of aluminum is hazardous solid waste according to theRecovery of Aluminum from Industrial Waste (Slag) by Melting and About 2 million tons of aluminum slag are generated during the process of primary aluminum smelting, fabrication and processing, and waste aluminum recycling in China The main Technical Report International Aluminium

A Review of Secondary Aluminum Production and Its Byproducts

2021年7月30日 Aluminum is the second mostconsumed metal in the world, only outranked by steel Primary aluminum is produced through the HallHeroult process1 In this process, alumina dissolves in a sodium cryolite melt, and aluminum is reduced at the aluminum liquid cathode pool while the anode products are significant amounts of \({\mathrm{CO}}{2}\) and other 2021年5月1日 Aluminum Slag Separation Process Analysis Through a Vibratory Machine in the Foundry Process May 2021 International Journal for Innovation Education and Research 9(5):104120Aluminum Slag Separation Process Analysis Through 2018年8月1日 Steel slag is the main waste product in the steelmaking process Because of its chemical composition and technical properties, it can be reused as raw material in steel plants and can serve as a Steel slag in China: Treatment, recycling, and management2014年5月1日 The beginnings of human civilization can be traced to the Jiahu settlement, China (ca 7000–5700 BC, 500 inhabitants) However, if we are to accept the view of historians, who generally clock (PDF) The Aluminum Smelting Process ResearchGate

(PDF) The History and Future Challenges of Calcined Petroleum

2014年12月20日 Calcined petroleum coke is obtained by calcining petroleum coke at high temperatures under the condition of 1250 • C to 1350 • C Because of its low cost, high carbon content, and easy 2018年12月14日 Results are provided for a study of porous ceramic materials prepared in the course of chemical and exothermic reactions based on a system containing secondary resources (chamotte scrap, mullite (PDF) THE USE OF ALUMINUM SLAG RECYCLING PRODUCTS IN 2014年2月19日 Slags are byproducts of the metallurgical industry It is of importance to recycle materials and recover heat from metallurgical slags to reduce the energy consumption and environmental impact of steel industry China is the largest iron and steelmaking slag producer in the world, and intensive efforts have been made during last decades for slag valorisation, Current Development of Slag Valorisation in China Waste2023年4月4日 Copper metal occurs naturally, although minerals such as chalcopyrite and bornite are by far the most abundant sources Smelting, leaching, and electrolysis are used to extract copper from these ores and minerals Chile, Peru, and China are the three biggest copperproducing countries It is found in both its native and combined statesExtraction of Copper: Detailed Process Science Info

.jpg)

Environmental impact of typical zinc smelting that implements

2022年10月10日 Purpose Large stocks of many kinds of zinc smelting solid waste have been generated; moreover, the disposal process consumes high amounts of energy and takes low output rate of metal resources, which seriously endangers regional ecological environment and human health The purpose of this study is to compare the environmental impact of the Aluminum processing Smelting, Refining, Alloying: Although there are several methods of producing aluminum, only one is used commercially The Deville process, which involves direct reaction of metallic sodium with aluminum chloride, was the basis of aluminum production in the late 19th century, but it has been abandoned in favour of the more economical electrolytic Aluminum processing Smelting, Refining, Alloying BritannicaLow Pollution IGBT 30kg Aluminum Smelting Machine (JLZ70) US$ 10010000 / Piece 1 Piece Jig Cleaning Machine for Mineral Smelting Slag US$ 100050000 / set 1 set Upgrade your Metal Recycling Machine with the elegant and durable Smelting MachineryIn China, Smelting Machinery MadeinChina2021年9月19日 Nickel smelting slag contains valuable metals including nickel and copper Failure to recycle these metals wastes resources, and disposal of nickel slag in stockpiles results in environmental pollution Nickel slag Recovery of Valuable Metals from Nickel Smelting

The Study of Carbon Recovery from Electrolysis Aluminum

Regarding the problem of aluminum electrolysis solid waste recycling, Vasyunina et al [31] adopted a grinding–classification–reverse flotation–concentration process using2023年8月1日 So, very high energy is consumed in grinding the slag samples to a particle size suitable for froth flotation Shamsi et al [80] investigated the influence of grinding time on the liberation of copper values in the smelter slag A grinding time of 65 min resulted in a ground product having a particle size of 80% finer than 70 μmA comprehensive review on the recovery of copper values from copper slag2024年5月23日 16 Million metric tons of spent carbon electrodes modify carbonrich solid wastes from aluminum electrolysis are produced annually, threatening ecosystems by cyanide and fluoride pollution Here, we review carbonrich solid wastes with focus on sources and hazards, detoxification, separation, recovery, recycling and disposal Treatment techniques The recycling of carbonrich solid wastes from aluminum 2020年1月30日 Slag is defined a type of sand that is traditionally derived from steel It is a rough, stonylike waste product that is created during smelting or in this case from deburring After a grinder deburrs sheet metal, the parts that chip off What is Slag Grinding? — Carlson Fabrication Solutions

Control of slag formation in the electric furnace smelting of

2020年11月1日 Rotary kiln electric furnace (RKEF) is a wellproven technology for smelting nickel laterite into ferronickel [6] The process consisted of ore drying in a rotary dryer, as expressed in reaction 2016年12月2日 Air–water models have been widely applied as substitutes for CO2–cryolite systems in the study of the complex bubble dynamics and bubbledriven flow that occurs in the molten electrolyte phase in the aluminum electrolytic process, but the detailed difference between the two systems has not been studied This paper makes a numerical comparison between the Numerical Modeling of Flow Dynamics in The Aluminum Smelting in technologies coupled with energy and cost savings Aircraft capabilities have been greatly enhanced, and increases in size and capacity are made possible by advances in aluminum technology The metal's flexibility for shaping and extruding has led to architectural advances in energysaving building construction The high strengthtoweight ratio has meant a substantial The Aluminum Smelting Process : Journal of Occupational and2023年5月15日 Steel slag is the main solid waste generated in the steelmaking process, accounting for 15 to 20% of crude steel output [1]China's crude steel output in 2021 was 1035 billion tons [2], more than half of the global crude steel output (19505 billion tons) [3], and the steel slag output exceeded 120 million tonsIn contrast, the comprehensive utilization rate of Comprehensive utilization of steel slag: A review ScienceDirect

.jpg)

Grinding Slag Removal Apex Machine Group

What Is Grinding Slag Removal? Slag is a specific type of sand that’s traditionally made from steel It often forms as a coarse waste product resulting from deburring or smelting processes To remove slag, metal processing facilities require grinding and slag removal Slag grinding processes efficiently remove all of the heavy slag produced 2022年11月1日 China has the largest output of steel and iron in the world (Zhang et al, 2022)In 2021, China's average annual pig iron output arrived at about 869 million ton (Stewart et al, 2021) and crude steel arrived at about 103 billion tons (Zhao et al, 2022)Meanwhile, the output of steel solid waste keeps at a high level and generally the production of one ton steel will generate Life cycle assessment of melting reduction treatment for iron and 2023年3月1日 Nonferrous metals are indispensable basic materials, and they are strategically important for the national economy of China (Song et al, 2019; Xue et al, 2022), which greatly increases their demand and leads to increasing mining and smelting of metal oresThe productivity of ten different nonferrous metals in China reached approximately 58 million tons Soil heavy metal pollution from Pb/Zn smelting regions in China 2021年10月1日 To recover valuable elements such as lithium from waste aluminum electrolyte, Wu et al (2021) mixed Na 2 CO 3 with waste aluminum electrolyte and roasted them at 650 • C for 25 h, and Na 2 A novel approach for lithium recovery from waste lithium

.jpg)

Chapter 2 Production and Processing of Aluminum The

The starting material for electrolytic smelting of aluminum is pure, anhydrous aluminum oxide (Al 2 O 3) called alumina In the Western World, the Bayer 1 process, invented in the 19th century, is by far the most important process used in the production of aluminum oxide from bauxite The process has been refined and improved since its inception2023年2月22日 Sulfidation treatment of copper smelting slag In the sulfidation experiment, the particle size of the synthesized slag was controlled below 80 mesh (178 µm)The mixture of CaSO 4 and anthracite was pelletized at a pressure of 10 MPa in a Ø 4 mm pressing tool, and the weight of every pellet was roughly controlled to be 004 g Then the smelting slag and CaSO 4 The Phase Transition and Element Distribution of Copper Smelting Slag 2021年11月1日 This technology can alleviate the shortage of highquality petroleum coke resources in China’s carbon material industry and the high cost of raw materials in aluminum electrolysis industryAdvances in the Safe Disposal and Comprehensive Utilization 2024年2月3日 Fine slag (FS) is an unavoidable byproduct of coal gasification FS, which is a simple heap of solid waste left in the open air, easily causes environmental pollution and has a low resource utilization rate, thereby restricting the development of energysaving coal gasification technologies The multiscale analysis of FS performed in this study indicates typical grain size Multiscale analysis of fine slag from pulverized coal gasification in

Sustainable wastetreatment procedure for the spent potlining

2019年4月17日 Aluminium is produced by electrolysis using alumina (Al2O3) as raw material and cryolite (Na3AlF6) as electrolyte In this HallHéroult process, the energy consumption is relatively large, and 2023年3月12日 The aluminum electrolysis industry continually and unavoidably produces hazardous solid waste in the form of carbon anode slag Carbon anode slag poses a serious environmental pollution risk, and (PDF) Recovery of Carbon and Cryolite from Spent Carbon Anode Slag 2021年7月30日 Aluminum is the second mostconsumed metal in the world, only outranked by steel Primary aluminum is produced through the HallHeroult process1 In this process, alumina dissolves in a sodium cryolite melt, and aluminum is reduced at the aluminum liquid cathode pool while the anode products are significant amounts of \({\mathrm{CO}}{2}\) and other A Review of Secondary Aluminum Production and Its Byproducts2021年5月1日 Aluminum Slag Separation Process Analysis Through a Vibratory Machine in the Foundry Process May 2021 International Journal for Innovation Education and Research 9(5):104120Aluminum Slag Separation Process Analysis Through

Steel slag in China: Treatment, recycling, and management

2018年8月1日 Steel slag is the main waste product in the steelmaking process Because of its chemical composition and technical properties, it can be reused as raw material in steel plants and can serve as a 2014年5月1日 The beginnings of human civilization can be traced to the Jiahu settlement, China (ca 7000–5700 BC, 500 inhabitants) However, if we are to accept the view of historians, who generally clock (PDF) The Aluminum Smelting Process ResearchGate2014年12月20日 Calcined petroleum coke is obtained by calcining petroleum coke at high temperatures under the condition of 1250 • C to 1350 • C Because of its low cost, high carbon content, and easy (PDF) The History and Future Challenges of Calcined Petroleum 2018年12月14日 Results are provided for a study of porous ceramic materials prepared in the course of chemical and exothermic reactions based on a system containing secondary resources (chamotte scrap, mullite (PDF) THE USE OF ALUMINUM SLAG RECYCLING PRODUCTS IN

.jpg)

Current Development of Slag Valorisation in China Waste

2014年2月19日 Slags are byproducts of the metallurgical industry It is of importance to recycle materials and recover heat from metallurgical slags to reduce the energy consumption and environmental impact of steel industry China is the largest iron and steelmaking slag producer in the world, and intensive efforts have been made during last decades for slag valorisation, 2023年4月4日 Copper metal occurs naturally, although minerals such as chalcopyrite and bornite are by far the most abundant sources Smelting, leaching, and electrolysis are used to extract copper from these ores and minerals Chile, Peru, and China are the three biggest copperproducing countries It is found in both its native and combined statesExtraction of Copper: Detailed Process Science Info2022年10月10日 Purpose Large stocks of many kinds of zinc smelting solid waste have been generated; moreover, the disposal process consumes high amounts of energy and takes low output rate of metal resources, which seriously endangers regional ecological environment and human health The purpose of this study is to compare the environmental impact of the Environmental impact of typical zinc smelting that implements Aluminum processing Smelting, Refining, Alloying: Although there are several methods of producing aluminum, only one is used commercially The Deville process, which involves direct reaction of metallic sodium with aluminum chloride, was the basis of aluminum production in the late 19th century, but it has been abandoned in favour of the more economical electrolytic Aluminum processing Smelting, Refining, Alloying Britannica