HOME→80 cubic meters of calcite per hour pregrinding sand powder vertical mill fine sand powder equipment

80 cubic meters of calcite per hour pregrinding sand powder vertical mill fine sand powder equipment

.jpg)

Effect of Operating Parameters on the Breakage Process of Calcite

As mentioned before, the effects of five different filling media ratios (55, 60, 65, 70, and 75%) on the performance of calcite for wet grinding were investigated in this study 展开Recently, the vertical roller mill having great grinding performance is widely applied to the raw material grinding process However, tube mill, which has about 30% poor grinding Vertical roller mill for raw Application p rocess materials2013年4月11日 In this study, the effects of various operating parameters, such as grinding time (min), stirrer speed (rpm), feed quantity (% of ball weight), and ball filling ratio (%) on fine Dry Fine Grinding of Calcite Powder by Stirred Mill2023年8月1日 Influences of three grinding aids on dry grinding of calcite were investigated The effect of different dosages was examined by changing the grinding time Particle size, energy Effective role of grinding aids in the dry grinding performance of

Energy Use of Fine Grinding in Mineral Processing

2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred The CLRM Enhanced Roller Mill adjusts for calcite powder from 80 to 500 mesh, ideal for materials under Mohs 6 It is energy efficient Home; About us It has a large output range of 05 to 30 tons per hour, catering to various production needs 3 Bucket Elevator Bucket elevator is a widely used vertical conveying equipment, Calcite Hardness Grinding Mill,Raymond Mill,Ball Mill,Ultrafine MillCalcium Carbonate Powder Mill for Limestone, Calcite, Dolomite, Talc and Clay, Super fine calcium carbonate grinding mill Production introduction Presale 1)Equipment sizing assistance based on customer's demand 2)Calcium Carbonate Powder Mill for Limestone, Calcite, Dolomite, 2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills It also discusses the factors, including the design, operating parameters, and feed material properties, EnergyEfficient Advanced Ultrafine Grinding of Particles Using

.jpg)

Talc Powder Ultrafine Vertical Roller Mill

Product advantage of talc powder ultrafine vertical roller mill 1 High quality powder size The fineness of the finished product is D97 545 microns Narrow particle size distribution, can produce 2 micron content of 20%70% products, greatly improving the added value of finished products and application areas 2A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal Energysaving and Efficient Vertical Roller Mill Fote MachineryLimestone Powder Ultrafine Vertical Roller Mill Modle : CLUM Series Finished Size: 4003000 mesh Processing Ability: 3 – 45t/h Max Feeding Size: 10 mm M 1 Set Price: $ Range Of Application: Limestone, Calcium Carbonate, Talc, Limestone Powder Ultrafine Vertical Roller MillOur main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected]SBM Ultrafine Powder Technology Industrial Grinding Mill,

Calcium Carbonate Grinding Mill Powder Modify SBM Ultrafine Powder

2022年5月5日 Heavy calcium carbonate is made by mechanical methods (using a fine powder mill or other industrial grinding mills) to directly crush natural calcite, limestone, chalk, shells, etc Light calcium carbonate is prepared by using limestone and other raw materials through a series of chemical reactions to obtain calcium carbonate precipitation, and finally through Independent research and development of Ultrafine vertical roller mill used Adopt multihead powder separator, SBM classifier perfect solved the particle cutting point height rate of screening questions, compared with the traditional Ultrafine vertical roller mill SBM Ultrafine Powder CLUM series calcium carbonate ultrafine vertical mill, a new type of ultrafine grinding equipment integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging, focusing on the largescale Calcium Carbonate Ultrafine Vertical Mill SBM The document presents a case study of Mangalam Cement in Kota, Rajasthan, India where a Vertical Roller Pre Grinding Mill (VRPM) system was installed to upgrade their existing cement mill Before the upgrade, the ball mill system Vertical Roller Pre Grinding Mill by AMCLMachinery

.jpg)

Sand Calculator (How much sand do I need?)

Sand calculator online estimate the sand required for your construction or landscaping project in weight (pounds, kilograms, tons, tonnes) and volume (cubic ft, cubic yards, cubic meters) If you are wondering 'how much sand do I need', our free sand calculator is here to do the math for you Information about sand density, common sand types, sand grain sizes, how much a cubic yard 474 A paint manufacturing company uses a sand mill for fine grinding of paint with an output of 100 liters per hour using glass beads as grinding media Media load in the mill is 25 kg costing P20000 per kg and is fully replenished in 2 months time at MCQ in Engineering Economics Part 10 ECE Board ExamCLIRIK is China processional industrial grinding mill manufacturer, has established a whole production chain, the products cover micro powder grinding mill, high pressure grinding mill, vertical roller mill, Europe an version coarsegrinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and soonClirik calcite powder makingKefid 15tph limestone Grinding Plant in Spain Kefid Calcite Grinding Plant in Spain Raw Material: limestone Input Size: 1020mm Output Size: 500mesh Capacity: 15t/h Equipment: LUM series superfine vertical mill LUM1436X calcite 600mesh LUM series superfine vertical mill LUM1125 Related Case The analysis of largescale grinding plantLUM SERIES ULTRAFINE GRINDING MILL

High Quality Ultra Fine Calcium Carbonate Powder Grinding Mill

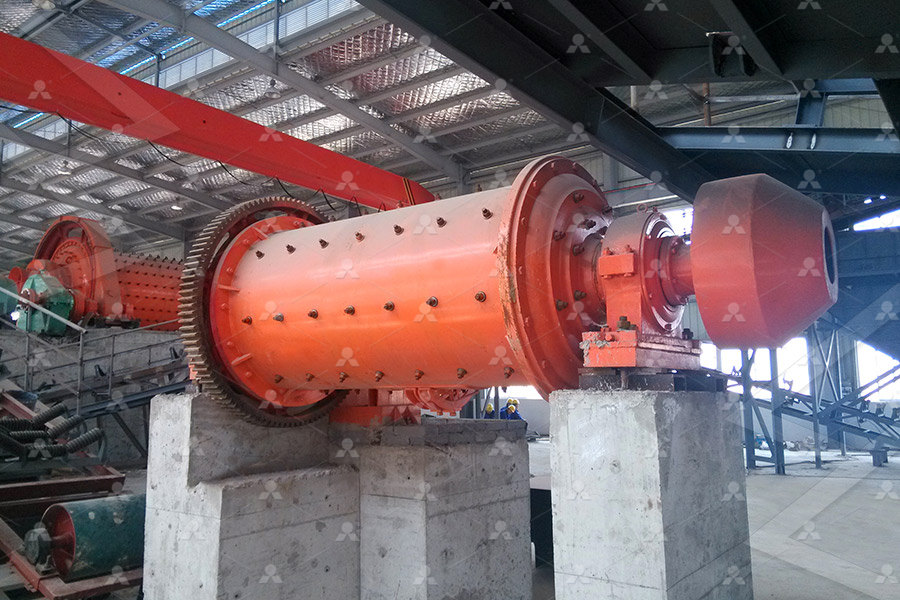

Features of Micro Powder Grinding Mill 1High Efficiency of micro powder grinding mill Under the same finished final size and the same motor power, the capacity of micro powder grinding mill is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30% 2Long lifecycle of spare parts of micro powder LM sand powder vertical mill is a kind of ultrafine sand making and powder grinding equipment, which is mainly suitable for the prefabricated sand powder process before the crushing of mineral products such as metallurgy, building materials, chemicals, and mines It is specially used for the preparation of special mortar fine aggregatesSand powder vertical mill, vertical mill price, vertical mill 2015年10月15日 A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Calculate Ball Mill Grinding Capacity 911MetallurgistDesign a trial mix having a specified compressive strength of 35 MPa This mix should have a slump of 75 mm, which will be pumped to place It will be exposed to the following classes based on ACI 31819: S0, F2, W1, and C0Concrete Mix Design Calculator (Based on the ACI

.jpg)

Dry Fine Grinding of Calcite Powder by Stirred Mill

2012年1月1日 Request PDF Dry Fine Grinding of Calcite Powder by Stirred Mill The demand for fine powder is increasing in the many fields such as chemical, pharmaceutical and material industries2009年7月1日 Furthermore, the energy requirements for grinding some materials, as for example, in the cement industry which requires the production of fines with surface area 3500 cm 2 /g, cannot be assessed Effect of grinding aids on the kinetics of fine grinding energy Apr 09, 2007 Concrete, Gravel 240 tonne/cubic meter Choose the above density that most closely matches your gravel, and calculate using the formulas below cubic meters * density = tonnes tonnes / density = cubic meters Thats the metric tonne Ok, need to convert 80,000 cubic meters of dry (premixed) cement to metric tons Read Moreaggregates weights per cubic meter Welcome to Tables ThymeModels of Ultrafine Mill: HGM80, HGM90, HGM100, HGM125and HGM1680L finished production fineness: 3003000mesh(574 micron) the capacity (ton/hour) ranges: 05 to 45 ton per hour Ultrafine Mill is a device that breaks solid materials into powder by grinding, Such comminution is an important unit operation in many processesHGM Series Grinding Mill,Stone Powder making machine ,UltraFine Mill

Benchmarking comminution energy consumption for the

2014年10月1日 Where P 80 and F 80 are the 80% passing si ze of the product and feed respectively (µm) Levin (1992) proposed a n ew method for calculating the s ize specific energy (SSE) requirements of1 cubic meter sand weight in kg The typical weight of 1 cubic meter of sand is range from 1,442 to 2,082kg (or 1442 to 2082 tonnes) A typical dry natural sand weighs about 1,600 kg (16 MT) per cubic meter while a typical wet sand weighs about 1 Cubic meter River M sand weight in kg ton Civil Sir2013年4月11日 In this study, the effects of various operating parameters, such as grinding time (min), stirrer speed (rpm), feed quantity (% of ball weight), and ball filling ratio (%) on fine grinding of calcite powder (CaCO 3) (d 50 = 3404 µm) were studied using a laboratory vertical stirred mill under dry conditionsDry Fine Grinding of Calcite Powder by Stirred Mill2017年9月11日 In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the circuit to evaluate the (PDF) Performance Evaluation of Vertical Roller Mill in Cement Grinding

The Effect of Stirred Mill Orientation on Calcite Grinding

2017年1月1日 For this study, Energex™ pelletized wood waste consisting of coniferous bark and wood was ground to fine sizes with a Szego Mill, a type of ring roller mill, at material rates up to about 500 kg 2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Energy Use of Fine Grinding in Mineral ProcessingThe CLRM Enhanced Roller Mill adjusts for calcite powder from 80 to 500 mesh, ideal for materials under Mohs 6 It is energy efficient Home; About us It has a large output range of 05 to 30 tons per hour, catering to various production needs 3 Bucket Elevator Bucket elevator is a widely used vertical conveying equipment, Calcite Hardness Grinding Mill,Raymond Mill,Ball Mill,Ultrafine MillCalcium Carbonate Powder Mill for Limestone, Calcite, Dolomite, Talc and Clay, Super fine calcium carbonate grinding mill Production introduction Presale 1)Equipment sizing assistance based on customer's demand 2)Calcium Carbonate Powder Mill for Limestone, Calcite, Dolomite,

EnergyEfficient Advanced Ultrafine Grinding of Particles Using

2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills It also discusses the factors, including the design, operating parameters, and feed material properties, Product advantage of talc powder ultrafine vertical roller mill 1 High quality powder size The fineness of the finished product is D97 545 microns Narrow particle size distribution, can produce 2 micron content of 20%70% products, greatly improving the added value of finished products and application areas 2Talc Powder Ultrafine Vertical Roller MillA vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal Energysaving and Efficient Vertical Roller Mill Fote MachineryLimestone Powder Ultrafine Vertical Roller Mill Modle : CLUM Series Finished Size: 4003000 mesh Processing Ability: 3 – 45t/h Max Feeding Size: 10 mm M 1 Set Price: $ Range Of Application: Limestone, Calcium Carbonate, Talc, Limestone Powder Ultrafine Vertical Roller Mill

SBM Ultrafine Powder Technology Industrial Grinding Mill,

Our main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected]2022年5月5日 Heavy calcium carbonate is made by mechanical methods (using a fine powder mill or other industrial grinding mills) to directly crush natural calcite, limestone, chalk, shells, etc Light calcium carbonate is prepared by using limestone and other raw materials through a series of chemical reactions to obtain calcium carbonate precipitation, and finally through Calcium Carbonate Grinding Mill Powder Modify SBM Ultrafine Powder