Fly ash decarbonization feasibility study report

Effects of fly ash properties on carbonation efficiency in CO2

2019年6月1日 CO 2 mineralisation by fly ash can not only reduce CO 2 emissions, but also increase the stability of fly ash by reducing the alkaline contents through carbonation 2020年6月11日 The article presents the results of research on mineral sequestration of CO 2 (suspensionCO 2) using fluidized bed combustion (FBC) fly ashes from hard coal The potential of FBC fly ashes to reduce CO 2 emissions Nature2024年5月15日 Huang et al [83] recently conducted an intriguing experimental study, demonstrating the feasibility of protonated amines as solvents for Ca 2+ leaching and Accelerated CO2 mineralization technology using fly ash as raw 2014年6月21日 This paper discusses some possible avenues where fly ash can be further positively utilized, especially in coal mining industry The paper covers feasibility study of (PDF) A Critical Study on Feasibility of Fly Ash Utilization in

.jpg)

Large CO2 reduction and enhanced thermal performance of agro

2024年4月10日 According to a report published by CEA (2022), the total utilisation of fly ash in manufacturing of bricks and tiles is 3162 million tons which is 1168% of total fly ash utilisation 2023年10月29日 The results indicated that flotation decarbonization treatment could remarkably reduce the water demand ratio and increase the intensity activity index of fly ash Moreover, Effect of decarbonization of high carbon fly ash on workability 2024年9月12日 To address this environmental impact, fly ash geopolymer concrete (FAGC) has emerged as a promising lowcarbon alternative This study establishes a robust compressive Compressive strength prediction and lowcarbon optimization of 2 天之前 This study focuses on reducing pollution and promoting sustainability by exploring the use of fly ash (FA), an industrial byproduct, in polymer composites through rotational molding Transforming fly ash into value: Sustainable LLDPEfly ash

.jpg)

[PDF] Effective carbon emission reductions from using upgraded

2015年9月15日 The greatest contribution of CO2 to the environment is attributed to cement production, responsible for 5 to 8% of global emissions On the other hand, fly ash (FA) is During this webinar, seven companies presented their fly ash treatment solutions, all offering (different degrees) of valorisation and/or reuse Some of these technologies are commercially WastetoEnergy fly ash valorisation2014年6月21日 A Critical Study on Feasibility of Fly Ash Utilization in Overburden Dumps of Opencast Coal Mines June 2014; Report 2012", International EnergyAgency “World Energy 0utlook2013",(PDF) A Critical Study on Feasibility of Fly Ash 2023年10月29日 The carbon content of fly ash (FA) influences the performance of concrete In this paper, the flotation decarburization treatment was carried out on high carbon fly ash (HCFA) to obtain flotation decarburized fly ash (FDFA) The effects of flotation decarbonization treatment of fly ash on workability, mechanical properties, chloride penetration, carbonation, and Effect of decarbonization of high carbon fly ash on workability

.jpg)

Characterisation of LD slag of Bokaro Steel Plant and its feasibility

Characterisation of LD slag of Bokaro Steel Plant and its feasibility study of manufacturing commercial ‘fly ash–LD slag’ bricks August 2013 International Journal of Environmental Technology Detailed Project Reports Profiles on Bricks From Fly Ash Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost Bricks From Fly Ash Manufacturing Plant, Detailed Project Report 2023年12月20日 The test result is in agreement with the fly ash column flotation decarbonization results conducted by Cao et al [19], who carried out experiments on the decarbonization of fly ash by column flotation with different operating variables and showed that the LOI of tailings ash would gradually decrease and the carbon rejection would gradually increase with increasing An investigation of nanobubble enhanced flotation for fly ash Central Electricity Authority’s ‘Report on fly ash generation at coal / lignite based thermal power stations and its utilization in the country for the year 2021 22 7 Authorization of auditors to undertake the compliance audit for ash disposal by the coal and lignitebased thermal power plants and the user agencies as per Ash Utilization Notification No548l(E) dated 31122021Fly Ash Management and Utilization Mission

.jpg)

(PDF) StateoftheArt Review on Utilization of Fly Ash

2023年10月19日 The use of fly ash in construction has been on the rise, yet its application in pavement construction remains relatively underexplored This study addresses this gap by critically reviewing 70 Power Utility wise fly ash generation utilization for the year 2021 22 4 V Statewise fly ash generation utilization during the year 2021 22 9 VI Targets for fly ash utilization for Thermal Power Station in operation as on 03112009 11 VII Targets for fly ash utilization for Thermal Power Station commissioned after 03112009 12 VIIIREPORT ON FLY ASH GENERATION AT COAL / LIGNITE BASED 2022年3月10日 Nowadays, geopolymers, which are more environmentally friendly than cement due to the high energy requirements and high carbon dioxide (CO 2) emissions of cement production, emerge as alternative bindersIn this study, the mechanical and durability properties of geopolymer concrete (GC) based on ground granulated blast furnace slag (GGBS) Performance evaluation of fly ash and ground granulated blast 2024年11月26日 Fly Ash Brick Project: Feasibility Study Using CVP Analysis is a Harvard Business (HBR) Case Study on Finance Accounting , Texas Business School provides HBR case study assignment help for just $9 Texas Business School(TBS) case study solution is based on HBR Case Study Method framework, TBS expertise global insightsFly Ash Brick Project: Feasibility Study Using CVP Analysis

Effects of fly ash properties on carbonation efficiency in CO2

2019年6月1日 In this study, five fly ashes from China and Australia were selected for carbonation The experiments were first performed in a batch reactor at 40 and 140 °C, 20 bar initial CO 2 pressure, 200 g/L solid to liquid ratio, 450 rpm stirring rate to compare the carbonation characteristics of the five fly ashes and investigate the effects of fly ash properties on 2014年4月1日 Onho [12] has made the feasibility study of using fly ashbased geopolymer concrete as a binder material in ECC (instead of cement) thereby making it as Engineered Geopolymer Composites (EGC)A feasibility study of strain hardening fiber reinforced fly ash 2023年11月28日 Fly ash was chosen as the primary precursor, and the effect of BOF slag replacement was studied The percentage replacement of fly ash in this study by BOF slag varies from 0 to 50% (6 levels), whereas in the case of fine aggregates, IOT replaces Msand from 0 to 45% (5 levels) The steel fibre addition varied from 08 to 2% (5 levels)Fly Ash and BOF Slag as Sustainable Precursors for Engineered • Pond ash Fly ash and bottom ashes are combined with water to create a slurry that is piped to the ash pond The ash settles in the ash pond, and the surplus water is decanted The ash that has been deposited is pond ash 12 FLY ASH Fly ash is a fine glass powder that is collected fromOPTIMIZING FLY ASH USE IN INDIA: CHARACTERIZATION AND

.jpg)

Effect of decarbonization of high carbon fly ash on workability

2023年10月29日 The performance of alkaliactivated slag (AAS) under thermal treatment has received particular attention In this study, the effect of five elevated temperatures (25, 200, 400, 600, and 800 °C Request PDF On Oct 1, 2023, Hao Huang and others published An Investigation of Nanobubble Enhanced Flotation for Fly Ash Decarbonization Find, read and cite all the research you need on An Investigation of Nanobubble Enhanced Flotation for Fly Ash Fly Ash Brick Project The brainchild of Rajiv Sharma (“Sharma”), which involves themanufacturing and selling of bricks made out of fly ash, a residue obtained from combustion of coal which is widely available in India due to the high utilisation of coalin the production of thermal power, its major power generation source 50% 40% 32% 10%FLY ASH BRICK PROJECT: FEASIBILITY STUDY USING CVP Bentonite, sand and 4 Fly ash and its mixes were characterized for sorption study 2 The class C fly ash was found to be more effective for adsorbing Pb2+ 3 Pb2+ adsorption was correlated by two power relationship to Atterberg limits 4 The utility A feasibility study of Indian fly ashbentonite as an alternative

.jpg)

A feasibility study of strain hardening fiber reinforced fly ash

Mix proportion of fiber reinforced fly ashbased geopolymer Fly ash A Fly ash B Sand Na 2SiO 3 NaOH (pellet) Premix water Mix water Fiber (vol%) 08 02 03 0256 0056 0039 012 2 Table 2 Chemical compositions and physical properties of fly ash Fly ash A Fly ash B SiO 2 4606–4707 4339–4409 Al 2O 3 2255–2342 2321–2424 Fe 2O2021年9月23日 22 Manufacturing of bricks The mix proportions adopted in the manufacturing of the bricks are given in Table 1The mix proportion for casting the fly ash bricks is arrived by referring past studies [] and on a discussion in the field siteA total of 10 proportions were taken in this study and the bricks are casted as per the proportions given in Table 1Feasibility study on the development of fly ash bricks utilizing 2014年2月1日 Request PDF Experimental study of fly ash decarbonization on a circulating fluidized bed combustor Fly ash is a byproduct of coalfired power plants, whose production is huge As the coal Experimental study of fly ash decarbonization on a circulating times Since the 1930s, coal fly ash has been the primary pozzolan in US concrete The beneficial use of fly ash in concrete forms an important market for ash produced at electric power plants Data from the American Coal Ash Association (ACAA) indicates that the percentage of fly ash beneficially used continues to increase (Figure 1)Harvested Landfilled Fly Ash in Concrete: A Case Study EPRI

Decarbonization In Cement Plants With Waste Heat Recovery

Increased utilization of Fly ash 3 Increased utilization of Slag CARBON MANAGEMENT 1 Carbon Capture, Utilization Storage 2 Carbon Offset (Afforestation) 6 Role Of WHRS In Decarbonization Approx 40% of total plant electrical energy can be recovered from WHRS This electrical energy recovery • Feasibility study of WHRS2024年7月1日 Considering an ash content of 42 wt% and that 65% of the generated ash corresponds to fly ash, the combustion of one kg of petcoke produces 0027 kg of fly ash For a price of $50/t fly ash, the economic value of this product is $000135/kg petcoke, which represents 285% of the total economic value of the products from the steam generation operationLife cycle GHG emissions assessment of vanadium ScienceDirect2011年8月1日 Current annual production of Fly ash, a byproduct from coal based thermal power plant (TPPs), is about 112 million tonnes (MT) Some of the problems associated with Fly ash are large area of land Fly ash utilization in different sectors in Indian scenarioExecutive Summary: This report on the Feasibility Assessment of Rapid Decarbonisation Potential for a ‘Net Carbon Neutral’ Pune Metropolitan Region (PMR) presents an indepth study of the carbon emissions (CO 2 eq) in the PMR with a view to identify key areas of rapid carbon emission reductions in a various sector Following the PIC Policy Paper on ‘Making PMR NetCarbon 44 Rapid Decarbonization potential of Pune Metropolitan Region

.jpg)

The potential of FBC fly ashes to reduce CO 2 emissions

2020年6月11日 FBC fly ashes used in the study were obtained from the combustion of aqueous suspensions with the following fly ashes to water weight ratios: PF 1−09; PF 2−06; PF 3–08; PF 4–072023年9月25日 Meeting industrial decarbonization goals: a case study of and roadmap to a netzero emissions cement industry in California(PDF) Meeting industrial decarbonization goals: a case study of 2021年9月1日 The dispersion of fly ash in water results in an alkaline pH from 10 to 13 At high pH, the fly ash becomes negatively charged allowing the removal of heavy metal ions by precipitation and electrostatic adsorption from water (Cho et al, 2005) Fly ash can be modified or transformed into new materials for heavy metal ions adsorptionFly ash properties, characterization, and applications: A review2016年1月4日 Request PDF Feasibility Study of Loess Stabilization with Fly Ash–Based Geopolymer Loess, which primarily consists of windtransported silt and clay particles, is widely distributed around Feasibility Study of Loess Stabilization with Fly Ash–Based

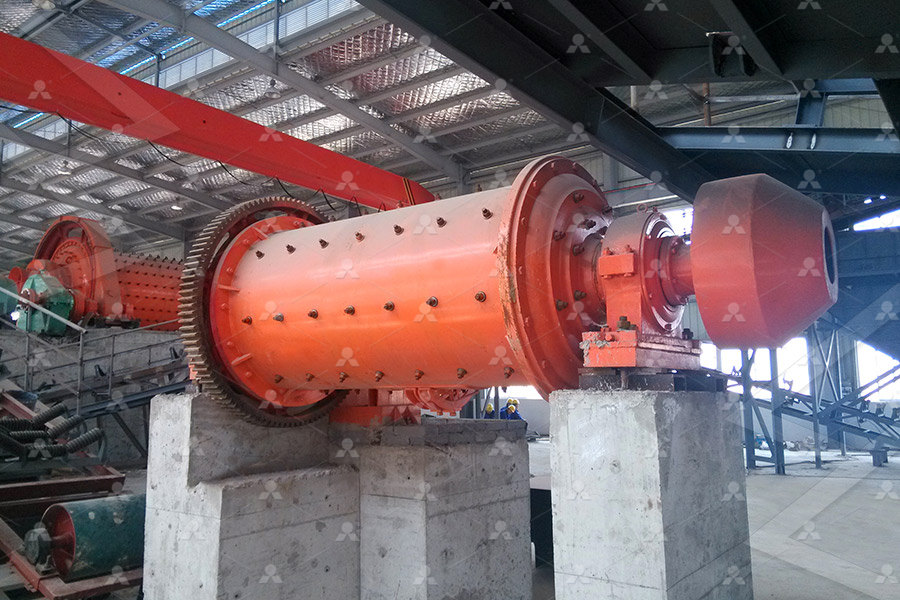

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

(PDF) A Critical Study on Feasibility of Fly Ash

2014年6月21日 A Critical Study on Feasibility of Fly Ash Utilization in Overburden Dumps of Opencast Coal Mines June 2014; Report 2012", International EnergyAgency “World Energy 0utlook2013",2023年10月29日 The carbon content of fly ash (FA) influences the performance of concrete In this paper, the flotation decarburization treatment was carried out on high carbon fly ash (HCFA) to obtain flotation decarburized fly ash (FDFA) The effects of flotation decarbonization treatment of fly ash on workability, mechanical properties, chloride penetration, carbonation, and Effect of decarbonization of high carbon fly ash on workability Characterisation of LD slag of Bokaro Steel Plant and its feasibility study of manufacturing commercial ‘fly ash–LD slag’ bricks August 2013 International Journal of Environmental Technology Characterisation of LD slag of Bokaro Steel Plant and its feasibility Detailed Project Reports Profiles on Bricks From Fly Ash Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost Bricks From Fly Ash Manufacturing Plant, Detailed Project Report

.jpg)

An investigation of nanobubble enhanced flotation for fly ash

2023年12月20日 The test result is in agreement with the fly ash column flotation decarbonization results conducted by Cao et al [19], who carried out experiments on the decarbonization of fly ash by column flotation with different operating variables and showed that the LOI of tailings ash would gradually decrease and the carbon rejection would gradually increase with increasing Central Electricity Authority’s ‘Report on fly ash generation at coal / lignite based thermal power stations and its utilization in the country for the year 2021 22 7 Authorization of auditors to undertake the compliance audit for ash disposal by the coal and lignitebased thermal power plants and the user agencies as per Ash Utilization Notification No548l(E) dated 31122021Fly Ash Management and Utilization Mission2023年10月19日 The use of fly ash in construction has been on the rise, yet its application in pavement construction remains relatively underexplored This study addresses this gap by critically reviewing 70 (PDF) StateoftheArt Review on Utilization of Fly AshPower Utility wise fly ash generation utilization for the year 2021 22 4 V Statewise fly ash generation utilization during the year 2021 22 9 VI Targets for fly ash utilization for Thermal Power Station in operation as on 03112009 11 VII Targets for fly ash utilization for Thermal Power Station commissioned after 03112009 12 VIIIREPORT ON FLY ASH GENERATION AT COAL / LIGNITE BASED

.jpg)

Performance evaluation of fly ash and ground granulated blast

2022年3月10日 Nowadays, geopolymers, which are more environmentally friendly than cement due to the high energy requirements and high carbon dioxide (CO 2) emissions of cement production, emerge as alternative bindersIn this study, the mechanical and durability properties of geopolymer concrete (GC) based on ground granulated blast furnace slag (GGBS) 2024年11月26日 Fly Ash Brick Project: Feasibility Study Using CVP Analysis is a Harvard Business (HBR) Case Study on Finance Accounting , Texas Business School provides HBR case study assignment help for just $9 Texas Business School(TBS) case study solution is based on HBR Case Study Method framework, TBS expertise global insightsFly Ash Brick Project: Feasibility Study Using CVP Analysis