Land price for mineral powder processing plant contract

Guidelines for mineral process plant development studies AusIMM

Scoping study testwork would typically cost USD30 000 to USD50 000 including sample collection and freight Results of testwork would provide the basis on which to develop process optionsAs a result of ever increasing complexity, alternatives of process and remoteness of site, there is an ever increasing emphasis on accurate estimating and the attendant cost control systems in Capital Cost Estimating for Mineral Processing PlantsESFC, an international company, offers financing and engineering design for mining and processing plants under an EPC contract, including research, development of individual Mining and Processing Plants ESFC Investment GroupThe Spanish company ESFC Investment Group offers financing and construction of mining and processing plants under EPCcontract • From €50 million and more • Investments up to 90% of the project cost • Loan term from 10 to 20 Mining and processing plant construction ESFC

.jpg)

» Aya Gold Silver Announces Fixed Price EPC Contract for

2022年12月1日 A multicurrency fixed price EPC Contract of USD $78 million1 for the construction of a new 2,000 tonne per day ("tpd") processing plant This will bring the total To address these considerations, the World Bank’s Sustainable Energy, Gas, Oil and Mining Department developed this paper to provide guidance and good practice examples to Mineral Resource Tenders and Mining Infrastructure Projects 2017年2月8日 Ausenco’s low capital cost design and build process helped add $800M to the feasibility study NPV of this US$175 billion CAPEX project Our work achieved: 50% smaller footprint than the original DFS layout; 35% Cost effective mineral process plant design Ausenco2018年3月2日 The cost approach, also known as the appraised value method, is based on the premise that an exploration property, or a mineral resource property, is worth an amount equivalent application to past exploration Mineral Property Valuation: Principles and Procedures

CIM Practice Guidelines for Mineral Processing Canadian

The PGMP deal primarily with the description of leading practice as it applies to the mineral processing and extraction of base metals, precious metals, and other mineral products by the 2017年8月24日 In mineral processing, ores must go through a number of different operations to obtain the final products Thus, mineral processing involves four major steps or stages: (1) comminution or size reduction, (2) size separation, (3) concentration or beneficiation by taking advantage of physical properties, and (4) dewateringMineral Processing SpringerLink2024年8月7日 Mineral processing involves key stages to extract valuable minerals from ores, including crushing to reduce ore size for further processing, grinding to further refine particle size and liberate minerals, classification to Mineral Processing Equipment for Mining Industry2023年4月8日 Developing a Mineral Processing Plant Capital Risk and Analysis Blueprint involves the following steps: Define project objectives: Determine the project's objectives, including the desired production capacity, target markets, Towards developing a Mineral Processing Plant

.jpg)

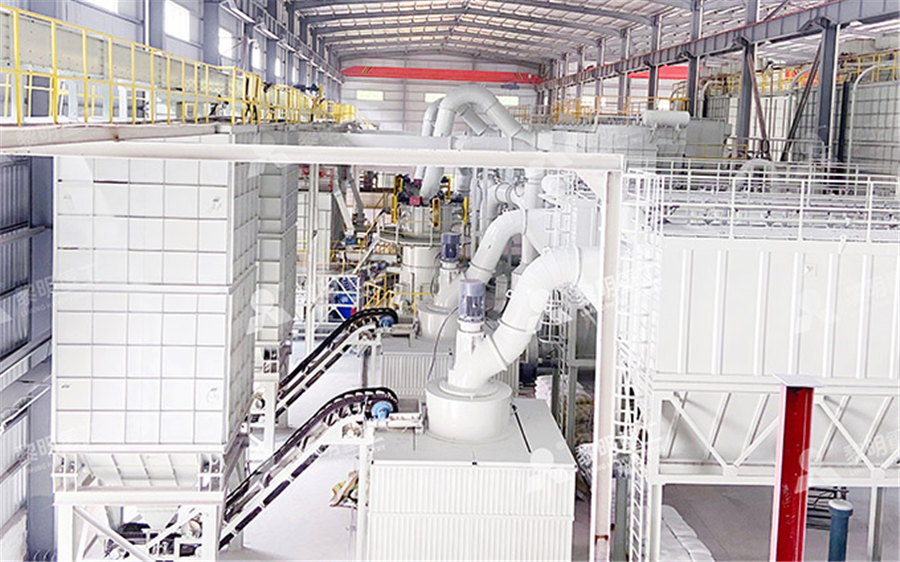

Lingshou County TeYuan Mineral Processing Plant

Lingshou teyuan mineral products processing plant is a manufacturer of wollastonite powder, cat litter, clay balls, hollow glass beads, calcium carbonate, titanium dioxide, quartz sand series, carbon black series, volcanic stone, Maifan stone, tourmaline, iron oxide pigment, composite pigment, kaolin, diatomite, talc powder, vermiculite, bentonite and other mineral products, Our We’re not just experts in powder processing, we are a globally recognised market leader in the concept, design and manufacture of bespoke powder, particle, liquid and vapour processing equipment and systems for multiple purposes, such as size reduction, drying, grinding, mixing, blending, agglomeration and compactionPowder Processing Hosokawa Micron Ltd2023年5月3日 Mineral processing plants can be classified in many ways Depending on the types of ore to be processed, they can be classified into nonferrous metal mineral processing plant, ferrous metal mineral processing plant, nonmetal mineral processing plant; depending on the production capacity, they can be classified in large, medium, and small mineral processing Mineral Processing Plant SpringerLink2022年4月1日 Consequently, the degree to which a metal, mineral or material is considered critical, is determined by geopolitical factors that change with time (Spooren et al, 2020)For example, Australia has 24 “critical minerals” (Austrade, 2020) compared to the EU's 30 “critical raw materials” (European Commission, 2020)The EU has also seen an increase in the Review on advances in mineral processing technologies suitable

.jpg)

Chrome Processing plant JXSC Machinery

1 Feeding: Excavator or truck send raw ore into the raw material hopper, through vibrating feeder evenly feeds trommel screen The vibrating feeder with grizzly bar, gap 75mm, and over 75mm rock will be sent to the waste stockpile via belt conveyor 2 Washing stage: 075mm material is sent to trommel screen for sieving out 02mm and 275mm The belt conveyor sends 275mm Custom powder processing and milling services in Alabama Air classification, toll milling service Particle size analysis RSG Inc has a fully equipped pilot plant and laboratory for contract milling and toll air classification services Particle size analysis Read More 1 hr 120 US dollars $120 Let's Talkcontract powder processing contract milling toll air Ore processing is the process of separating valuable minerals from its ores by ore beneficiation equipment Mineral processing plant is recovers or extracts minerals through a range of ore dressing solutions, including washing, crushing, grinding, gravity concentration, flotation magnetic separation, electrostatic separation and more JXSC provide full mining process Mineral Processing Plant Beneficiation Solutions JXSC 2024年4月18日 IMARC Group’s report, titled “Mineral Water Processing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a mineral water processing plant The report covers various aspects, ranging from a broad market overview to intricate details like Mineral Water Processing Plant Project Report 2024: Raw

Mineral and metal processing Arkema Global

Greater value at every stage of the operation We help generate greater value from your operations at every stage of mineral processing including mineral suspension and slurry handling, flotation and other enrichment technologies, 2019年8月16日 Mining, mineral processing and metal extraction are undergoing a profound transformation as a result of two revolutions in the making—one, advances in digital technologies and the other, availability of electricity from renewable energy sources at affordable prices The demand for new metals and materials has also arisen concurrently This necessitates Future of Mining, Mineral Processing and Metal Extraction Solar photovoltaic (PV) power plant: construction under EPC contracts and project cost Today photovoltaic power stations dominate the field of renewable energy, and PV projects and technology is rapidly changing the landscape of the global Solar power plant construction services and EPC contract2022年8月13日 This includes a milk processing plant, milk powder, and containers to store the finished product You will need to set up the processing plant according to the manufacturer’s instructions Once the plant is set up, you can begin adding milk powder to the machine The machine will then process the milk powder and produce milk that is ready to Milk Processing Automatic Plant (Milk and Milk Powder) is the

.jpg)

Common Basic Formulas for Mineral Processing Calculations

2016年3月21日 By referring to the tables “Minerals and Their Characteristics” (pages 332339) it is seen that the perfect grade of a copper concentrate will be 633% when the copper is in the form of bornite, 798% when in the mineral chalcocite, and 346% when in the mineral chalcopyrite A common association is that of chalcopyrite and galenaWe offer a range of powder processing services including particle milling, air classifying mixing, available on a toll processing basis Learn more Call us on:+44 (0)1246 269 955 :knowhow@britishremaPowder Processing Services British RemaReport Overview: IMARC Group’s report, titled “Cocoa Processing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a cocoa processing plant It covers a comprehensive market overview to microlevel information such as unit operations involved, Cocoa Processing Plant Report 2024: Setup Cost IMARC GroupFigure 1 Sala Caravan Plant from the 1970s Abstract The concept of modular and mobile mineral recovery plants has been around for decades However, there is still some industry confusion about the best application for these versatile and costeffective plantsModular and Mobile Mineral Recovery Plants for High and Low

.jpg)

State of the art and challenges in mineral processing control

2001年9月1日 All content in this area was uploaded by SirkkaLiisa JamsaJounela on Jun 09, 年1月1日 The integration of mining and mineral processing technologies into new advanced mining systems is considered to offer several benefits, including selective mining, reduction in waste, increased Integrating mining and mineral processing for 2024年5月22日 IMARC Group’s report, titled “Mineral Water Processing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides Mineral Water Processing Plant Project Report 2024: CAPCOSTSA Handbook for Estimating Mining and Mineral Processing Equipment Costs , 1992, 2394 pp (Chapters 56 Chapter 6) Canadian Mining Taxation, latest edition, Price Waterhouse, Toronto 18 1998, 72 p CAPCOSTSA Handbook for Estimating Mining and

G[R.jpg)

THIS MINERAL PURCHASE CONTRACT (AGREEMENT), is made

2020年5月21日 other minerals and mineral rights lying in and under and that may be produced from the following lands situated in Ellis County, State of Oklahoma, described as follows, towit: [An undivided (1/2?) interest in and to all of the oil, gas and other minerals and mineral rights lying in, under and that may beFind here online price details of companies selling Mineral Processing Plants Get info of suppliers, manufacturers, Magnesite ore processing calcination plant machines; Aluminum oxide powder production plant machines, Mineral processing plant, output capacity: 2 tons/day; Modular Mineral Processing Plants: Mineral Processing Plants at Best Price in India India Business Gold mineral processing plant Why Is Mineral Processing Important? The profitability of a mine is based on how much concentrate of the desirable mineral can be extracted from the ore As a result, mineral processing is designed to yield the maximum amount of mineral concentrate possible before products hit the marketEssential Guide to Mineral Processing Equipment Flyability2022年1月26日 These lawyers collectively have 15 reviews to help you choose the best lawyer for your needs Customers rate lawyers for mineral lease agreement matters 497 What is a Mineral Lease Agreement? A mineral lease agreement is a legal contract that grants an individual or company the right to extract minerals from a specific location for a set periodWhat is a Mineral Lease Agreement? (Key Terms + Sample) Contract

.jpg)

Lithium Processing Plant, Equipment JXSC Machinery

Lithium processing plant malinly includs crushing, grinding, gravity separation, The lithium beneficiation process is mainly used for three lithiumcontaining minerals processing: (suspension made by mixing ferrosilicon powder and water), and enters the dense medium cyclone for separation and separation2002年1月1日 The paper discusses the special mixing requirements for Metallurgical Plant Design and outlines the problems associated with the agitation in Mineral Processing Industry todayMineral Processing Plant Design, Practice, and Control: Bullion 2024年9月30日 Gold and copper miner Barrick Gold has awarded mineral processing technology company Metso an order for the supply of copper concentrator plant equipment to its Lumwana expansion project in the Barrick awards Metso €70m contract for copper processing 2017年8月24日 In mineral processing, ores must go through a number of different operations to obtain the final products Thus, mineral processing involves four major steps or stages: (1) comminution or size reduction, (2) size separation, (3) concentration or beneficiation by taking advantage of physical properties, and (4) dewateringMineral Processing SpringerLink

.jpg)

Mineral Processing Equipment for Mining Industry

2024年8月7日 Mineral processing involves key stages to extract valuable minerals from ores, including crushing to reduce ore size for further processing, grinding to further refine particle size and liberate minerals, classification to 2023年4月8日 Developing a Mineral Processing Plant Capital Risk and Analysis Blueprint involves the following steps: Define project objectives: Determine the project's objectives, including the desired production capacity, target markets, Towards developing a Mineral Processing Plant Lingshou teyuan mineral products processing plant is a manufacturer of wollastonite powder, cat litter, clay balls, hollow glass beads, calcium carbonate, titanium dioxide, quartz sand series, carbon black series, volcanic stone, Maifan stone, tourmaline, iron oxide pigment, composite pigment, kaolin, diatomite, talc powder, vermiculite, bentonite and other mineral products, Our Lingshou County TeYuan Mineral Processing PlantWe’re not just experts in powder processing, we are a globally recognised market leader in the concept, design and manufacture of bespoke powder, particle, liquid and vapour processing equipment and systems for multiple purposes, such as size reduction, drying, grinding, mixing, blending, agglomeration and compactionPowder Processing Hosokawa Micron Ltd

.jpg)

Mineral Processing Plant SpringerLink

2023年5月3日 Mineral processing plants can be classified in many ways Depending on the types of ore to be processed, they can be classified into nonferrous metal mineral processing plant, ferrous metal mineral processing plant, nonmetal mineral processing plant; depending on the production capacity, they can be classified in large, medium, and small mineral processing 2022年4月1日 Consequently, the degree to which a metal, mineral or material is considered critical, is determined by geopolitical factors that change with time (Spooren et al, 2020)For example, Australia has 24 “critical minerals” (Austrade, 2020) compared to the EU's 30 “critical raw materials” (European Commission, 2020)The EU has also seen an increase in the Review on advances in mineral processing technologies suitable 1 Feeding: Excavator or truck send raw ore into the raw material hopper, through vibrating feeder evenly feeds trommel screen The vibrating feeder with grizzly bar, gap 75mm, and over 75mm rock will be sent to the waste stockpile via belt conveyor 2 Washing stage: 075mm material is sent to trommel screen for sieving out 02mm and 275mm The belt conveyor sends 275mm Chrome Processing plant JXSC MachineryCustom powder processing and milling services in Alabama Air classification, toll milling service Particle size analysis RSG Inc has a fully equipped pilot plant and laboratory for contract milling and toll air classification services Particle size analysis Read More 1 hr 120 US dollars $120 Let's Talkcontract powder processing contract milling toll air

.jpg)

Mineral Processing Plant Beneficiation Solutions JXSC

Ore processing is the process of separating valuable minerals from its ores by ore beneficiation equipment Mineral processing plant is recovers or extracts minerals through a range of ore dressing solutions, including washing, crushing, grinding, gravity concentration, flotation magnetic separation, electrostatic separation and more JXSC provide full mining process