Vertical spiral mill manufacturing

Byard Ltd Home

Byard, with operations based in the UK and Singapore, are the world's leading spiral mill design, manufacture and installation company We have been manufacturing both spiral pipe and our advanced Byard Spiral pipe mills since SINOMALY has rich experience in manufacturing spiral vertical mills Our spiral vertical mills have complete specifications and are widely used, which can well Supply Spiral Vertical Mill Customized FactoryShandong Dorco Heavy Industry Machinery Co, Ltd is mainly engaged in the design, manufacturing, and installation of largescale equipment such as heavy industry machinery, ring rolling machines, spiral welded pipe machines, Shandong Dorco Heavy Industry Machinery Vertical 2019年8月15日 Mini spiral millthread tools Gear deburring; Machining software; All four stations use CNC for vertical, tangential, automotive, and turbomachinery manufacturing, offers automated and usercontrolled toolpath Mini spiral millthread tools Aerospace

Spiral jet mill All industrial manufacturers

Other Manufacturing Equipment > Spiral jet mill Spiral jet mills 4 companies 5 vertical (1) Submit Product applications for plastics (1) for rubber waste (1) coarse powder food (1) The ConJet®® High Density Bed Jet Mill combines 2023年5月18日 As the most commonly used stirred mill, the vertical spiral type is provided with agitator of spiral blade, and the grinding media are usually steel balls with a diameter of 12–30 mm Running at 30–120 revolutions per minute (rpm), the vertical spiral type is extensively applied in the regrinding, fine grinding, and ultrafine grinding of iron, copper, leadzinc, molybdenum, Stirred Mill SpringerLink2016年12月8日 Drilling tapping with vertical mill Thread starter DynMetalworks; Start date May 19 use a spiralpoint tap EPAIII Diamond Joined Nov 23, 2003 Location Beaumont, TX Register for the world’s largest manufacturing technology forum for free today to stay in the know Learn more about us STAY CONNECTED Become a forum Drilling tapping with vertical mill Practical MachinistThe ConJet®® High Density Bed Jet Mill combines a spiral jet mill with an integrated classifier wheel This combination allows the ConJet®® to produce materials with the highest fineness independent of the product load, and with higher throughput capacities In the past, the fineness was controlled by adjusting the feed rateSpiral jet mill ConJet® NETZSCH Grinding Dispersing vertical

quiet revolution vertical axis wind turbines

Global Renewable Energy Partners Limited 11 Edison Road StIves Cambridgeshire PE27 3LF United Kingdom TEL No +44 (0) 1480 Mobile No +44(0) 7407 info@vwtpower visit our blog vwtpower2024年1月1日 As the most commonly used stirred mill, the vertical spiral type is provided with agitator of spiral blade, and the grinding media are usually steel balls with a diameter of 12–30 mm Running at 30–120 revolutions per minute (rpm), the vertical spiral type is extensively applied in the regrinding, fine grinding, and ultrafine grinding of iron, copper, leadzinc, molybdenum, Stirred Mill SpringerLinkSSAW Spiral Pipe Plant produce driven and water tubes as well as oil and gas pipes from coiled, hot rolled steel strip The pipes range in diameter from 15 to 100 inches and in wallthickness from 5 to 25 Millimeters They are mainly used in tap water engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation and urban construction such Spiral pipe plant (SSAW) SMS group GmbH1 Spiral vertical mill is a world recognized lowcost grinding technology, which has the advantages of energy saving and environmental protection, fine product particle size and low total investment cost 2 It is widely used in secondary module, regrinding, fine grinding, limestone maturation and other fields 3 The spiral vertical mill we have carefully built has the Supply Spiral Vertical Mill Customized Factory SINOMALY

Anyone mount a vertical mill head on a Cincinati

2012年12月5日 I put in new spindle bearings then gave up on the project due to lack of time If you ever decide to tackle your project again l would consider an even trade: Bridgeport head for Cincinnati 2M vertical head I just want to do China Spiral Pipe Mill Machinery wholesale Machinery For Manufacturing suppliers, wholesalers and factory on MadeinChina Home Manufacturing Processing Machinery Vertical Diameter: 30 40 50 60 70mm etc Range: 254762mm Customized 1 / 6 FavoritesSpiral Pipe Mill Machinery MadeinChinaVertical Spiral Conveyor Manufacturing; Retail; Transportation Warehousing; Solutions; All Solutions; Fulfillment; Packaging; Storage; Robotic Integration; 450 W Hanes Mill Rd Ste 226 Winston Salem, NC 27105 9699 Enterprise Dr Painted Post, NY 14870 Vertical Spiral Conveyor Adaptec Solutions2023年9月9日 Definition and overview of Vertical Axis Wind Turbines (VAWTs) The overview and definition of VAWTs can help us understand how these turbines function A verticalaxis wind turbine (VAWT) is a type of wind turbine where the main rotor shaft is set vertically Unlike horizontalaxis wind turbines (HAWTs), VAWTs can operate regardless of wind The Ultimate Guide To Vertical Axis Wind Turbines Green Life Zen

Vertical Roller Mill Manufacturer in India – Shalimar Engineering

Spiral Classifiers; Vibrator Screen; Centrifugal Screen; Roto Shifter; Mixing Equipments Leading the Way as India’s Premier Vertical Roller Mill Manufacturer Introduction: Shalimar Engineering boasts an extensive track record of expertise and experience in the manufacturing of vertical roller mills2021年9月9日 #WRDTubeMillSolutionSpiral pipe mill lineSpiral steel pipe manufacturing technology: it is a spiral seam steel pipe, which is formed by warm extrusion andSpiral pipe mill show/ SSAW Pipe Mill/Sprial pipe production lineThe verticaltype spiral stirring mill has the advantages of simple structure, convenience in operation and maintenance, small occupied area, small vibration, low noise, energy conservation, high efficiency and the like CNU Verticaltype spiral stirring mill Google Patents Verticaltype spiral CNU Verticaltype spiral stirring mill Google Patents2009年1月22日 A vertical turret mill can do a few things better than a horizontal but when it comes to very satisfying metal removal, they can't beat a horizontal That doesn't mean I never use my verticals, there are little jobs with small metal removalGeneral Horizontal vs Vertical Mill? Practical Machinist

.jpg)

How spiral welding is revolutionizing windturbine manufacturing

2023年8月15日 This increase in domestic manufacturing capacity is coming online at a critical time with a significant expansion in need for windturbine components driven by the passage of the Inflation Reduction Act Keystone’s tapered spiral welding process brings the speed, quality, and consistency of automated manufacturing to windtower manufacturingA 3axis clone of a Bridgeportstyle vertical milling machine Milling is the process of machining using rotary cutters to remove material [1] by advancing a cutter into a workpieceThis may be done by varying directions [2] on one or several axes, cutter head speed, and pressure [3] Milling covers a wide variety of different operations and machines, on scales from small individual Milling (machining) WikipediaMLY Series: 2 Stage, 1 Stage Spiral Bevel Gear Pair + 1 Stage Planetary Gear Pair; MLXSD Series: 3 Stage, 1 Stage Spiral Bevel Gear Pair + 1 Stage Helical Gear Pair + 1 Stage Planetary Gear Pair; MLXSS Series: 3 Stage, 1 Stage Vertical Mill GearboxesBecause coilchanging and endcutting welding need some time while the main mill produces pipe continuously, the Hydraulic Vertical accumulator in pipe line some length of strip to ensure continuous production Main Structure: 1 Low turnover bracket Consisted of bracket,horizontal roller and vertical roller 2 Angel adjusttable flip bracketHorizontal/Vertical/Cage/Disc Type Steel Strip Spiral Accumulator

vertical spindle mill KOOKS

Used CNC Mill For Sale 60% Off CNC Milling Machines With Find 150+ Used CNC mill for sale with PRICES! Make purchasing your next Used CNC Milling Machine, Call Our CNC Mill Experts 8442626789 The world's tallest verticalaxis wind turbine, in CapChat, Quebec Vortexis schematic Vertical axis wind turbine offshore A verticalaxis wind turbine (VAWT) is a type of wind turbine where the main rotor shaft is set transverse to the wind while the main components are located at the base of the turbine This arrangement allows the generator and gearbox to be located close to the Verticalaxis wind turbine WikipediaChina Spiral Pipe Mill wholesale Vertical Diameter: 30mm Range: 254762mm Thickness: 0530mm Motor Power: 11kw*2 1 / 6 Visiting their manufacturing facility and requesting samples can help you assess their production quality Spiral Pipe Mill MadeinChinaMANUFACTURING METHOD OF SPIRAL BEVEL GEARS BASED ON CAD/CAM AND 3AXIS MACHINING CENTER vertical machining centre semifinish cut using a 2 mm flatend mill, and (3) finish cut using a 2 mm ballend mill The teeth surfaces of spiral bevel gears are slanted and complicated surfaces They can be considered as sculptured surfaces MANUFACTURING METHOD OF SPIRAL BEVEL GEARS BASED

.jpg)

Spiral Jet Mill Hosokawa

Spiral jet mill for fine comminution of soft materials (approximately up to a Mohs hardness of 3) with brittle crystalline fracture behavior in the fineness range of 10 – 150 µm Designed as a flatcylindrical grinding chamber without rotating components2022年6月28日 The existing vertical spiral ditching machine mainly works in flat orchards, and the structural design of ditching components does not match the design of power transmission system, which leads to (PDF) Design and Optimization of Working Parts of Vertical Spiral EIRICH TowerMill Vertical agiated media mill to contact form Facebook; Linkedin; Mail; Maschinenfabrik Gustav Eirich GmbH Co KG Walldürner Str 50 74736 Hardheim Germany +49 6283 510 +49 6283 51 325 eirich@eirich Fairs; News; Contact; myEirich; Partner Login; Facebook YouTube Linkedin TowerMill Eirich2023年7月4日 Vertical Roller Mill in Cement Manufacturing Plant 10:16:27 Author: Zenith A cement manufacturing plant is an industrial facility that produces cement, a key binding material used in various construction applications, such as concrete, mortar, and stuccoVertical Roller Mill in Cement Manufacturing Plant

Shandong Dorco Heavy Industry Machinery Vertical

Shandong Dorco Heavy Industry Machinery Co, Ltd is mainly engaged in the design, manufacturing, and installation of largescale equipment such as heavy industry machinery, ring rolling machines, spiral welded pipe machines, 2019年8月15日 Mini spiral millthread tools Gear deburring; Machining software; All four stations use CNC for vertical, tangential, automotive, and turbomachinery manufacturing, offers automated and usercontrolled toolpath Mini spiral millthread tools Aerospace Other Manufacturing Equipment > Spiral jet mill Spiral jet mills 4 companies 5 vertical (1) Submit Product applications for plastics (1) for rubber waste (1) coarse powder food (1) The ConJet®® High Density Bed Jet Mill combines Spiral jet mill All industrial manufacturers2023年5月18日 As the most commonly used stirred mill, the vertical spiral type is provided with agitator of spiral blade, and the grinding media are usually steel balls with a diameter of 12–30 mm Running at 30–120 revolutions per minute (rpm), the vertical spiral type is extensively applied in the regrinding, fine grinding, and ultrafine grinding of iron, copper, leadzinc, molybdenum, Stirred Mill SpringerLink

.jpg)

Drilling tapping with vertical mill Practical Machinist

2016年12月8日 Drilling tapping with vertical mill Thread starter DynMetalworks; Start date May 19 use a spiralpoint tap EPAIII Diamond Joined Nov 23, 2003 Location Beaumont, TX Register for the world’s largest manufacturing technology forum for free today to stay in the know Learn more about us STAY CONNECTED Become a forum The ConJet®® High Density Bed Jet Mill combines a spiral jet mill with an integrated classifier wheel This combination allows the ConJet®® to produce materials with the highest fineness independent of the product load, and with higher throughput capacities In the past, the fineness was controlled by adjusting the feed rateSpiral jet mill ConJet® NETZSCH Grinding Dispersing vertical Global Renewable Energy Partners Limited 11 Edison Road StIves Cambridgeshire PE27 3LF United Kingdom TEL No +44 (0) 1480 Mobile No +44(0) 7407 info@vwtpower visit our blog vwtpowerquiet revolution vertical axis wind turbines2024年1月1日 As the most commonly used stirred mill, the vertical spiral type is provided with agitator of spiral blade, and the grinding media are usually steel balls with a diameter of 12–30 mm Running at 30–120 revolutions per minute (rpm), the vertical spiral type is extensively applied in the regrinding, fine grinding, and ultrafine grinding of iron, copper, leadzinc, molybdenum, Stirred Mill SpringerLink

Spiral pipe plant (SSAW) SMS group GmbH

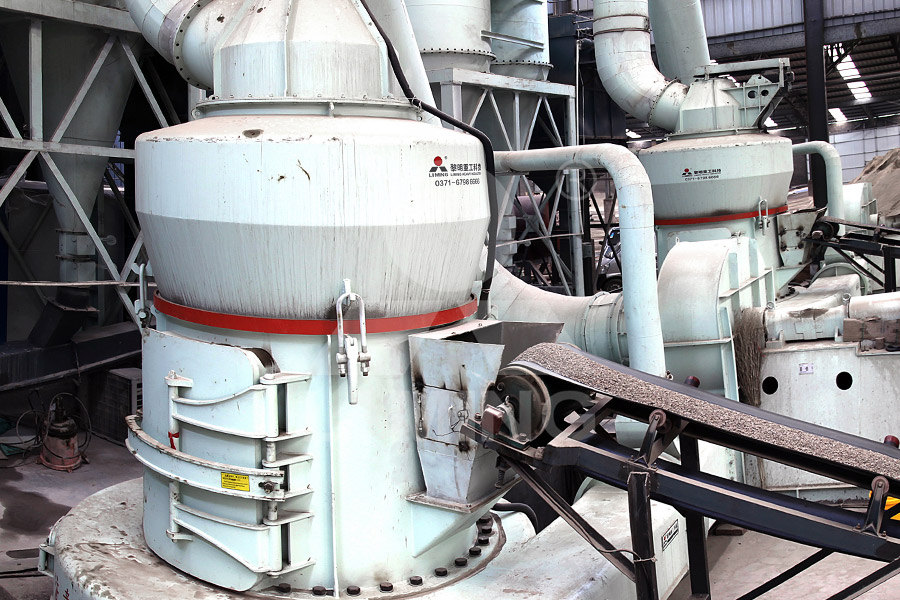

SSAW Spiral Pipe Plant produce driven and water tubes as well as oil and gas pipes from coiled, hot rolled steel strip The pipes range in diameter from 15 to 100 inches and in wallthickness from 5 to 25 Millimeters They are mainly used in tap water engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation and urban construction such 1 Spiral vertical mill is a world recognized lowcost grinding technology, which has the advantages of energy saving and environmental protection, fine product particle size and low total investment cost 2 It is widely used in secondary module, regrinding, fine grinding, limestone maturation and other fields 3 The spiral vertical mill we have carefully built has the Supply Spiral Vertical Mill Customized Factory SINOMALY