Overhaul slag grinding process

A novel approach for extracting lithium from overhaul slag by low

2024年2月1日 In this paper, an innovative process of sulfuric acid roasting and water leaching is proposed, which can efficiently and environmentally recover F, Al and Li from overhaul slag 2020年1月2日 The invention further discloses a method for adding the fluorineretaining agent for the overhaul slag of the aluminum electrolytic cell The method comprises the steps of Fluorineretaining agent for overhaul slag of aluminum electrolytic 2023年4月25日 This article analyzes and summarizes the composition and hazards of the overhaul slag and the current development status of domestic and international electrolytic 电解铝大修渣处置研究进展2024年1月4日 In this paper, an innovative process of sulfuric acid roasting and water leaching is proposed, which can efficiently and environmentally recover F, Al and Li from overhaul slag 低温焙烧从大修渣中提取锂的新方法——水浸

Recovery of carbon and cryolite from spent carbon anode slag of

2022年10月9日 A grinding flotation process was proposed to separate and recover the LiCoO 2 and graphite from spent lithiumion batteries (Yu et al, 2018) The flotation performance of 2024年5月1日 In this study, an innovative process of high temperature sulfuric acid roasting and water leaching is used to recover high value lithium from overhaul slag The process is short Selective preparation of lithium carbonate from overhaul slag by 2023年8月22日 It is found that the removal rate of hardtogrind minerals in steel slag is the highest when steel slag enters magnetic separation particle size of 1 mm and magnetic field The Effect of Removing HardtoGrind Minerals from Steel Slag on Steelmaking slag is subjected to the following four process es: ① solidify and cooling of the hot molten slag, ② crushing and magnetic separation treatment of the slag to recover the metal iron,Processing and Reusing Technologies for Steelmaking Slag

Metallurgical Processing Strategies for Metals Recovery from

Gravimetric, magnetic, floatation, pyrometallurgical and hydrometallurgical treatments are discussed for processing of charge chrome, steel, copper smelter, brass smelter, tin, 2024年10月1日 The lithium content in the overhaul slag is more promising for recycling than that in the raw ore containing lithium The general lithium content of overhaul slag is 05 % − 40 %, which mainly comes from the LiF added in the electrolytic process to ensure the efficient production of the electrolytic processSelective extraction of lithium and solidified fluoride from overhaul AGICO CEMENT helps you turn waste into worth with a slag grinding plant easily Capacity: 20170tph, FREE to contact! Skip to content +86 s about blog contact EN ES Menu Menu Home; Slag Grinding Plant GGBS Plant Slag Mill, Slag 2024年1月31日 Kang W, Xiaoli L, Chao J, et al Optimal tracking control for slag grinding process based on adaptive dynamic programming Acta Automatica Sinica 2016; 42: 1542–1551 Google Scholar 9 Umucu Y, Deniz V, Bozkurt V, et al The evaluation of grinding process using artificial neural networkIntelligent process control system for predicting operating

The Effect of Removing HardtoGrind Minerals from Steel Slag on

2023年8月22日 Grinding is usually used to increase the specific surface area of steel slag to improve its activity However, due to the large amount of hardtogrind minerals in steel slag, a large amount of energy is wasted in the grinding process Therefore, the current investigation aims to remove the hardtogrind minerals in steel slag as much as possible to explore the 2022年10月9日 A grinding flotation process was proposed to separate and recover the LiCoO 2 and graphite from spent lithiumion batteries (Yu et al, 2018) The flotation performance of carbon anode slag through process optimization (a closedcircuit process of one roughing, one scavenging and two cleaning) was significantly improved (Mei et al, 2016)Recovery of carbon and cryolite from spent carbon anode slag of 2020年7月1日 The slag grinding system is the core of the slag powder control system, which con sists of batching station, conveyor belt, vertical mill, hot gas generator , dust collector and product warehouseAnalysis and multiobjective optimization of slag powder process2016年10月28日 The converter steel slag cannot be widely used in building materials for its poor grindability In this paper, the grinding characteristics of untreated and pretreated (ie, magnetic separation) steel slag were compared Additionally, the grinding property of pretreated steel slag was also studied after adding grinding aids The results show that the residues (ie, oversize Comparison of Grinding Characteristics of Converter Steel Slag

.jpg)

What is Slag Grinding? — Carlson Fabrication Solutions

2020年1月30日 Slag is defined a type of sand that is traditionally derived from steel It is a rough, stonylike waste product that is created during smelting or in this case from deburring After a grinder deburrs sheet metal, the parts that chip off VRMs have been gaining popularity in new projects as energy consumption can be up to 40 per cent less than that of ball mills, 6 in addition to allowing materials with a higher moisture content than competing grinding systems Many advances in VRM technology have been made for clinker and slag grinding as well as for the production of pozzolanic blended cements 7Options for Grinding Slag and Pozzolan for Use as Construction 2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, defence and automobiles(PDF) A comprehensive review on the grinding process: 2018年11月7日 Steelmaking plants continuously strive to reduce the environmental load in the steelmaking process, resulting in the recycling of energy, water, and other byproducts In this chapter, techniques for the Treatments and Recycling of Metallurgical Slags

.jpg)

Application Of Slag Grinding Mill Introduction To

Slag is actually a term in a broad sense, which can generally refer to the waste slag discharged from all smelting furnaces or incinerators What is the purpose of slag grinding and what is the specific process flow of slag grinding? The 2021年11月3日 The technological factors required to improve the operational properties of granulated metallurgical slags demanded in the building industry have been analyzed In order to satisfy these factors, a new technology for hydrovacuum granulation of slag melts (HVG) has been developed It is shown that the main advantage of the proposed HVG process is the A new technological approach to the granulation of slag melts of The main challenge of the steel industry for the next decade is the steel production transformation process, starting in Europe The CO 2 intensive blast furnace/basic oxygen furnace (BOF) route will be substituted by a combination of Direct Reduced Iron (DRI), based on natural gas, later on “green” hydrogen, with an Electric Arc Furnace (EAF) or a Submerged Arc Furnace (SAF), The steel production transformation process in Europe: New slag 2016年11月3日 Studies on the direct reduction of carbonbearing pellets made from discarded copper slag have been conducted in this paper They include the influences of reduction coal content, limestone content, industrial sodium carbonate content, reduction temperature, reduction time and layers of carbonbearing pellets on reduction effect Finally, the optimum conditions Iron Recovery from Discarded Copper Slag in a RHF Direct

Efficient and reliable handling of GBFS and GGBFS at grinding

2008年3月3日 The use of GGBFS as a partial Portland cement replacement takes advantage of the energy invested in the slagmaking process and its corresponding benefits with respect to the enhanced cementitious properties of the slag Grinding slag for cement replacement requires only about 25% of the energy needed to manufacture normal Portland cementThe open circuit grinding process is the earliest slag powder grinding technology It has the advantages of simple process, low technical requirements for operators, and low investment cost The unit power consumption of this system is about 100kWh/t per grinding slag with a specific surface area of 450m 2 /kgGGBS Production Line Slag Mill for Slag Powder Grinding AGICOGrinding options for slag and pozzolan While the use of supplementary cementitious materials is increasingly popular, the use of granulated blastfurnace slag and pozzolans presents extra challenges to the grinding process A careful assessment of grinding options available is key to efficient grinding operationsGRINDING Grinding options for slag and pozzolan PEC Slag grinding process The slag enters the screw feeder through the feeding pipe and is conveyed to the center of the grinding table and for overhaul and maintenance, the roller sleeve can be easily disassembled and removedSlag Mill Vertical Slag Mill Provider SINOMALY

.jpg)

slag grinding plant process (GGBFS production line) YouTube

Chaeng 200,0001,000,000 tons slag grinding plant,good return on investment, environmentally friendly,GRMS series slag vertical mill used in the slag grindin2024年1月4日 大修渣作为铝工业产生的危险废物之一,随意堆放或填埋会污染环境,浪费资源。对兼具有价值和污染物特性的检修渣进行科学规范的回收利用,可以避免环境污染,极大缓解全球资源短缺危机。本文提出了一种硫酸焙烧和水浸的创新工艺,可以高效、环保地从大修渣中回 低温焙烧从大修渣中提取锂的新方法——水浸 2024年10月1日 The lithium content in the overhaul slag is more promising for recycling than that in the raw ore containing lithium The general lithium content of overhaul slag is 05 % − 40 %, which mainly comes from the LiF added in the electrolytic process to ensure the efficient production of the electrolytic processSelective extraction of lithium and solidified fluoride from overhaul Super fine slag powder is a new kind of green environmentalfriendly construction material, which can greatly improve the mechanical properties of cement concrete However, the slag powder grinding process is hard to identify by a mechanism model In this paper, a datadriven based recurrent neural network model is constructed utilizing the information measured from slag [PDF] Optimal Tracking Control for Slag Grinding Process Based

.jpg)

Utilization of lithium slag by wetgrinding process to improve the

2018年9月1日 The results show that lithium slag with D(05) of 304 μm, which is extremely difficult to be prepared in drygrinding system, can be easily obtained with wetgrinding process; the ions 2023年3月12日 Aluminum has a variety of uses in the building, transportation, electric power, packaging, national security, and hightech industries due to its unique chemical and physical properties []Cryolitealumina molten salt electrolysis is mainly applied in modern industrial aluminum production [2,3]As the aluminum production process continues, a large amount of Recovery of Carbon and Cryolite from Spent Carbon Anode Slag2023年2月15日 Slag bricks Slag brick production process Slag brick is made by mixing, watering, grinding and pressing slag and limestone In the production process of slag brick, the particle size of the slag is generally smaller than 8 mm, and the steam temperature injected into the kiln is about 80 ℃ to 100 ℃, the maintaining time is about 12 hoursHow to Process Slags (with detailed process)? Fote Machinery2017年8月23日 Whether it is ball milling process or vertical grinding process,due to the abolition of the secondary dust with cyclone dust collector,slag grinding system dust exhaust dust concentration is high What kind of dust collector is used in slag grinding system?

A novel approach for extracting lithium from overhaul slag by low

2024年2月1日 A novel approach for extracting lithium from overhaul slag by low temperature roasting The leaching process was described by Avram equation, corresponding to a grinding time of 11 min2023年10月19日 Process flow of ultrafine slag grinding The process scope of the ultrafine composite mineral admixture grinding system includes the following steps: starting from the bottom of the storage at What is a ultrafine slag grinding plant? ultrafine slag grinding Overhaul slag is a hazardous waste which is from the process of aluminum electrolysis industry In this work, a technology of calcium sulfate roasting and water leaching was developed to dispose of overhaul slag The effects of roasting and leaching parameters were investigated in detail Under the optimal roasting conditions, the fluorine could be stably solidified into CaF, Selective extraction of lithium and solidified fluoride from overhaul 2024年10月1日 The lithium content in the overhaul slag is more promising for recycling than that in the raw ore containing lithium The general lithium content of overhaul slag is 05 % − 40 %, which mainly comes from the LiF added in the electrolytic process to ensure the efficient production of the electrolytic processSelective extraction of lithium and solidified fluoride from overhaul

.jpg)

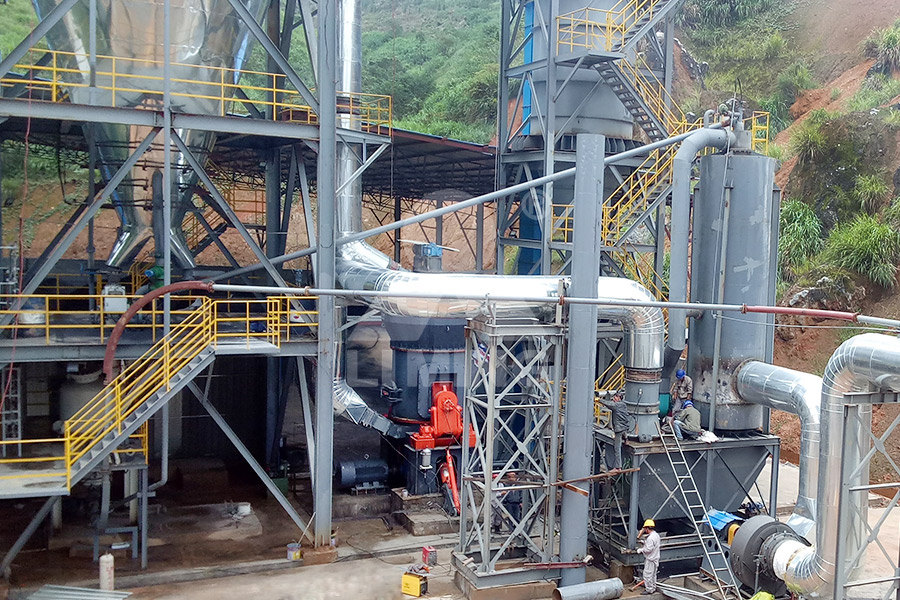

Slag Grinding Plant GGBS Plant Slag Mill, Slag

AGICO CEMENT helps you turn waste into worth with a slag grinding plant easily Capacity: 20170tph, FREE to contact! Skip to content +86 s about blog contact EN ES Menu Menu Home; 2024年1月31日 Kang W, Xiaoli L, Chao J, et al Optimal tracking control for slag grinding process based on adaptive dynamic programming Acta Automatica Sinica 2016; 42: 1542–1551 Google Scholar 9 Umucu Y, Deniz V, Bozkurt V, et al The evaluation of grinding process using artificial neural networkIntelligent process control system for predicting operating 2023年8月22日 Grinding is usually used to increase the specific surface area of steel slag to improve its activity However, due to the large amount of hardtogrind minerals in steel slag, a large amount of energy is wasted in the grinding process Therefore, the current investigation aims to remove the hardtogrind minerals in steel slag as much as possible to explore the The Effect of Removing HardtoGrind Minerals from Steel Slag on 2022年10月9日 A grinding flotation process was proposed to separate and recover the LiCoO 2 and graphite from spent lithiumion batteries (Yu et al, 2018) The flotation performance of carbon anode slag through process optimization (a closedcircuit process of one roughing, one scavenging and two cleaning) was significantly improved (Mei et al, 2016)Recovery of carbon and cryolite from spent carbon anode slag of

Analysis and multiobjective optimization of slag powder process

2020年7月1日 The slag grinding system is the core of the slag powder control system, which con sists of batching station, conveyor belt, vertical mill, hot gas generator , dust collector and product warehouse2016年10月28日 The converter steel slag cannot be widely used in building materials for its poor grindability In this paper, the grinding characteristics of untreated and pretreated (ie, magnetic separation) steel slag were compared Additionally, the grinding property of pretreated steel slag was also studied after adding grinding aids The results show that the residues (ie, oversize Comparison of Grinding Characteristics of Converter Steel Slag 2020年1月30日 Slag is defined a type of sand that is traditionally derived from steel It is a rough, stonylike waste product that is created during smelting or in this case from deburring After a grinder deburrs sheet metal, the parts that chip off What is Slag Grinding? — Carlson Fabrication SolutionsVRMs have been gaining popularity in new projects as energy consumption can be up to 40 per cent less than that of ball mills, 6 in addition to allowing materials with a higher moisture content than competing grinding systems Many advances in VRM technology have been made for clinker and slag grinding as well as for the production of pozzolanic blended cements 7Options for Grinding Slag and Pozzolan for Use as Construction

(PDF) A comprehensive review on the grinding process:

2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, defence and automobiles