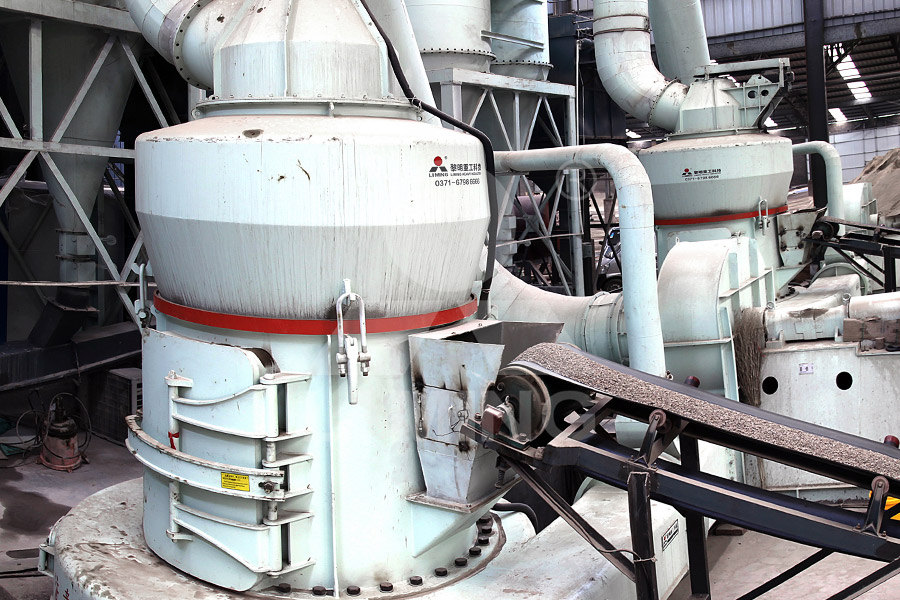

Power roller ore mill

Operational parameters affecting the vertical roller mill

2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants Vertical roller mill (VRM) is an established technology in cement and slag grinding applications and Boliden and Gebr Pfeiffer have been collaborating on the application of this technology in Vertical Roller Mills used for the comminution of mineral oresThe dry milling of ore in LOESCHE vertical roller mills has shown significant process advantages, as well as economic and ecological benefits To demonstrate these a mobile oregrinding plant the OGPmobile has been Mills for minerals and ores Loesche2023年7月4日 The vertical roller mill has the advantages of low energy consumption, high output, easy maintenance, etc, and has been widely applied in cement, steel and power Roller Mill SpringerLink

.jpg)

Copper ore grinding in a mobile vertical roller mill pilot plant

2015年3月10日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants The application of vertical roller mills (VRMs) for ore grinding is a part of the strategies against rising energy consumption (Reichert et al, 2015) The VRM technology was introduced in the Modeling and simulation of vertical roller mill using population 2012年9月1日 Mills (VRM) installations and summarises the main benefits of the dry compressive Loesche grinding technologies in Airflow and OverflowMode Some of these Latest Installations And Developments Of Loesche Vertical Roller The roller mill’s ability to reduce materials to a uniform particle size provides more control of product characteristics and minimizes waste, as shown in Figure 1 The mill’s controlled Roller mills: Precisely reducing particle size with greater efficiency

.jpg)

Review on vertical roller mill in cement industry its

2021年1月1日 Vertical Roller Mills (VRM), High Pressure Grinding Rolls (HPGR), Vertical Shaft Impact Crushers (VSI) and more recently, Horizontal Roller Mill (Horomill) have saved the specific power by 45–70% when compared with a ball mill circuit [8], [10]Vertical roller mill is an efficient industrial milling equipment, High grinding efficiency: save 20~30% power consumption compared with the ball mill 3 Strong drying capacity: Uses of vertical roller mill – in ore field Vertical Roller Mill SBM Ultrafine Powder TechnologyRoller Mill Xiao Xiao1, Huang Lilong2 and Xu Kuangdi3 1Changsha Research Institute of Mining and Metallurgy, Changsha, steel and power industry, manganese ore fine grinding, and other fields Horizontal Cylinder Roller Mill As for the horizontal cylinder roller, its roller surface and roller have a horizontal layout It wasRoller Mill Springer2015年3月10日 The mill power draw is measured by a torque rod situated in line with the main drive shaft Latest installations and developments of Loesche vertical roller mills in the ore industry Proc XXVI Int Min Proc Congr New Delhi (2012), pp 10181029 View in Scopus Google ScholarAn energy based comparison of vertical roller mills and

.jpg)

Roller Mill Eastern Spreaders Pty Ltd

Roller Mill • Farm Commercial • Dry and High Moisture Rolling • Proven Performance • Reliability • Serviceability • PTO or Electric Auger Discharge ** Power requirement increases by 50% for differential drive units Capacity will change with moisture content, roll configuration, and particle size desired Roll WxD2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of Ball Mill Design/Power Calculation 911MetallurgistThe roller mill, when equipped with a variable speed mill drive, can be used in applications requiring adjustable capacity Power Mill Powermax Turbine Power Water Evaporation in mm acfm m3/hr hp kW hp kW hp kW 1000 lb/hr 30 760 3900 6600 30 22 30 22 25 18 07RAYMOND® ROLLER MILLS ThomasnetSuccessful inauguration of the New Steel Pilot Plant with a LOESCHE Ore Grinding Plant (OGPmobile) in Ouro Preto, MG, Brazil Ouro Preto – The company New Steel has developed a revolutionary new process for iron ore concentration for which New Steel has been awarded with the internationally highly esteemed Platts Global Metals Award for Innovation 2015Mills for minerals and ores Loesche

CRLM1300 Vertical MillVertical Roller Mill Raymond Mill

Shcronus has launched the CRLM1300 vertical roller mill which integrates drying and grinding with high efficiency and energy saving Focus CRLM1300 vertical mil can be widely used in cement, metallurgy chemical industry, nonmetallic ore, nonferrous metals ore powder grinding, and electric power Compared with the CRLM1300 vertical mill Avoid downtime with durable and dependable Flour Power roller mill belts Automated milling machines are widely used in foodprocessing Plants run 24 hours a day, seven days a week in adverse conditions Flour Power belts offer Roller Mill BeltRod Mill The rod mill is loaded with steel bars as grinding media and comprises five parts: cylinder shell, feeding system, discharge system, main bearing, and transmission system It is suitable for both dry and wet grinding to meet customer needs Materials with a Moh's Hardness of 5512 can all be handled by our millOre Grinding Mill2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and

Power Roller Conveyor Precision Millwright Machine

Powered Roller tables are typically built with variable speed electric drives and a joystick control The drive chain is wrapped rollertoroller and covered by removable formed chain guards Besides offering custom frame and roller sizes, we offer 2001年10月1日 PRINCIPLE OF THE LOESCHE MILL LOESCHE has been manufacturing vertical roller mills for cement raw materials, clinker and slag, indus trial minerais, and for coal for cement kilns, for power plants and for blast fumaces for more than 90 yearsLoesche vertical roller mills for the comminution of ores and minerals Vertical roller mills have numerous applications in many different industriesAlthough they are widely used in the cement sector, for example, you are just as likely to find a vertical roller mill being used to handle ores in mining processing plantsThere again, vertical roller mills also have uses within the context of power stations where they are primarily used to pulverize coalVertical Roller Mill Magotteaux3 The energy lost in power transmission system 4 The energy lost in the form of electrical losses in the motor etc, Torque and Power in Cold Rolling *Power is applied to the rolling mill by applying Torque to the rolls and by using roll strip tension*The total rolling load is distributed over the arc of contactPOWER IN ROLLING IDCOnline

How it Works Roller Mill

Roller Mill + Crusher: Complete package : Ksh 385,000/= Usually a single motor is used to power two rollers that will be rotating at a faster speed while a system of pulleys is used to allow easy rotation of the other rollers If the system has three rollers in line, the third pair of rollers in the system is operated using a different motorChina Roller Roller Mill wholesale Alum Powder Grinding Mill Vertical Mill Aluminum Hydroxide Grinding Roller Raymond Vertical Roller Mill for Aluminum Ore Powder US$ 15500 / Piece 1 Piece (MOQ) Zhengzhou General Mining Machinery Co, Motor Power: Cement Roller Press Rotationl Speed: 2022r/min Application: Roller Roller Mill MadeinChinaroller mill tests of your material in the manufacturer’s test facility with various roll corrugation styles and under conditions that duplicate your operating environment Figure 1 Particle size distributions: Roller mill versus other grinding methods Other grinding methods Roller mill Overs Target particle size Fines Figure 2Roller mills: Precisely reducing particle size with greater efficiencyThe Pfeiffer pilot mill used in this study is a semiindustrial vertical roller mill of type MVR with a table diameter of 400 mm The mill can be equipped with different classifiers for specific applications The process layout of the plant (Figure 2) corresponds to that of an industrial plantVertical Roller Mills used for the comminution of mineral ores

.jpg)

Roller Mills Milling Bühler Group

Roller mill Diorit The Diorit roller mill grinds wheat, durum, rye, barley, corn and spelt It comes in a wide range of sizes and options, including four and eight rollers It has a sturdy cast iron frame for 24/7 operation Roller mill DolomitChina Threeroll Mill wholesale Materials: Ore, Stone, Kaolin, Bauxite, and Others 1 / 6 Favorites Ceramics ThreeRoll Mill US$ 3600 Source cheap and high quality products of power tools, hand tools online from Chinese tools manufacturers suppliersThreeroll Mill MadeinChina2023年5月31日 Definition of a Rolling Mill Generally, a rolling mill refers to a machine used in metalworking works or projects to shape metal materials by passing them through a pair of rolls Similarly, these machines’ main objective is to reduce metal materials’ thickness and redesign them for use in different industrial projects Some of the byproducts produced by rolling A Definitive Guide to Rolling Mills: All You Need to Know Tuolian2012年11月17日 20 131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, 100, and 200 mesh A 70% coal sample passing through a 200 mesh screen indicates optimum mill performance The mill wear and Coal mill pulverizer in thermal power plants PPT SlideShare

Copper ore grinding in a mobile vertical roller mill pilot plant

2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of A roller flour mill plant serves the purpose of processing wheat to convert it into flour BANSAL Group has been involved in largest roller flour mill plant in India with latest technology – A free PowerPoint PPT presentation (displayed as an HTML5 slide show) on PowerShow Roller Flour Mill PowerPoint PPT Presentation2015年3月10日 Within the scope of the study ore grinding performance of the vertical roller mill was investigated with mobile pilot plant In this context, chalcopyrite ore of a plant having rod and ball milling circuit was ground under different operating modes eg, air swept and overflow, and process conditions, then samples were collected around the systemCopper ore grinding in a mobile vertical roller mill pilot plantNORMAL MILL PRACTICES Not to monitor lift of top roller It is assumed that top roller lifts only that value considered during mill setting calculations Normally actual lift of top roller during operation is higher than considered in mill setting calculation Higher thickness of cane/bagasse blanket passes through mills due to excessive lift of top rollerMILL DESIGN MILL OPERATION

.jpg)

Industrial Roller Mills Raymond Equipment for Sale Wabash Power

6058 Raymond High Side Roller Mill Horsepower 200/150 Manufacturer Raymond Add to Quote Cart View More 6659 Highside Roller Mill Horsepower 250/200 Manufacturer Raymond Add to Quote Cart For a confidential discussion about your next boiler rental or power gen project, contact us to schedule a meeting! Name * * Phone Number 2021年1月1日 Vertical Roller Mills (VRM), High Pressure Grinding Rolls (HPGR), Vertical Shaft Impact Crushers (VSI) and more recently, Horizontal Roller Mill (Horomill) have saved the specific power by 45–70% when compared with a ball mill circuit [8], [10]Review on vertical roller mill in cement industry its Vertical roller mill is an efficient industrial milling equipment, High grinding efficiency: save 20~30% power consumption compared with the ball mill 3 Strong drying capacity: Uses of vertical roller mill – in ore field Vertical Roller Mill SBM Ultrafine Powder TechnologyRoller Mill Xiao Xiao1, Huang Lilong2 and Xu Kuangdi3 1Changsha Research Institute of Mining and Metallurgy, Changsha, steel and power industry, manganese ore fine grinding, and other fields Horizontal Cylinder Roller Mill As for the horizontal cylinder roller, its roller surface and roller have a horizontal layout It wasRoller Mill Springer

.jpg)

An energy based comparison of vertical roller mills and

2015年3月10日 The mill power draw is measured by a torque rod situated in line with the main drive shaft Latest installations and developments of Loesche vertical roller mills in the ore industry Proc XXVI Int Min Proc Congr New Delhi (2012), pp 10181029 View in Scopus Google ScholarRoller Mill • Farm Commercial • Dry and High Moisture Rolling • Proven Performance • Reliability • Serviceability • PTO or Electric Auger Discharge ** Power requirement increases by 50% for differential drive units Capacity will change with moisture content, roll configuration, and particle size desired Roll WxDRoller Mill Eastern Spreaders Pty Ltd2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of Ball Mill Design/Power Calculation 911MetallurgistThe roller mill, when equipped with a variable speed mill drive, can be used in applications requiring adjustable capacity Power Mill Powermax Turbine Power Water Evaporation in mm acfm m3/hr hp kW hp kW hp kW 1000 lb/hr 30 760 3900 6600 30 22 30 22 25 18 07RAYMOND® ROLLER MILLS Thomasnet

.jpg)

Mills for minerals and ores Loesche

Successful inauguration of the New Steel Pilot Plant with a LOESCHE Ore Grinding Plant (OGPmobile) in Ouro Preto, MG, Brazil Ouro Preto – The company New Steel has developed a revolutionary new process for iron ore concentration for which New Steel has been awarded with the internationally highly esteemed Platts Global Metals Award for Innovation 2015Shcronus has launched the CRLM1300 vertical roller mill which integrates drying and grinding with high efficiency and energy saving Focus CRLM1300 vertical mil can be widely used in cement, metallurgy chemical industry, nonmetallic ore, nonferrous metals ore powder grinding, and electric power Compared with the CRLM1300 vertical mill CRLM1300 Vertical MillVertical Roller Mill Raymond Mill