Vertical roller mill ore mill discharge port

.jpg)

Roller Mill Springer

material is discharged from the discharge port The biggest difference between the horizontal cylinder roller mill and other grinding equipment is that the inner wall of the rotating hollow Vertical roller mills are traditionally airswept mills A VRM applies a compressive force using fixed rollers pressing downwards on a rotating grinding table The material to be ground is fed into Vertical Roller Mills used for the comminution of mineral oresThe CLUM series ultrafine vertical roller mill combines grinding, centrifugal force, and airflow to achieve the desired fineness of the final product It is designed to produce ultrafine powders efficiently and is commonly used in industries such CLUM Series Ultrafine Vertical Roller MillThe disc of vertical mill rotated by the main motor driving gear, while hot air from the air inlet into the vertical mill body, the central disc material falls from the LM Vertical Mill

.jpg)

LM Vertical Roller MillGrinding mill machine, mineral mill,

The material falls through the screw feeder's discharge port and falls in the center of the grinding table When grinding the roller table area, it is crushed by the grinding roller, and the bulk 2016年9月1日 This paper brings together two separate studies, in which the vertical roller mill was used to grind two different precious metal ores, an epithermal gold deposit hosted in Operational parameters affecting the vertical roller mill 2017年4月1日 Pilot plant test results with various ores showed that low energy consumption feature of vertical roller mills is applicable to the ore industry Grinding test results for zinc ore Operational parameters affecting the vertical roller mill SBM Ore Ultrafine Grinding Mill Discharge fineness: 1503000 mesh Feed size: 20 mm Output: 120 T/H Models: HGM ultrafine grinding mill, CLUM vertical roller mill, LXMC ultrafine wet stirring mill etc Send us an Inquiry If you have SBM Ore Ultrafine Grinding Mill

.jpg)

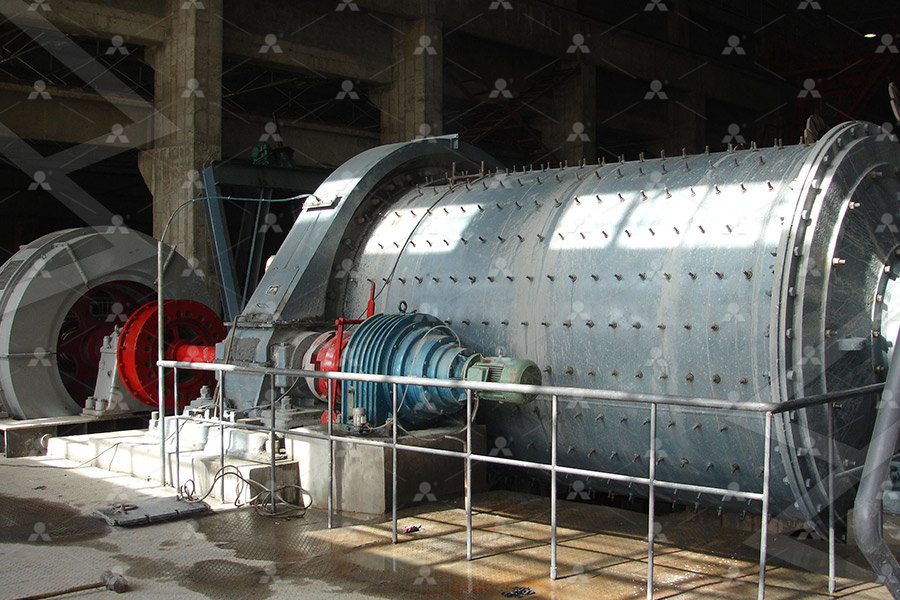

Copper ore grinding in a mobile vertical roller mill pilot plant

2015年3月10日 Vertical roller mill (VRM) technology was developed based on that and attracted interests of both manufacturers and researchers Characterization of chalcopyrite ore under high voltage pulse discharge: Particle size distribution, fractal dimension, specific energy consumption, grinding kinetics2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot PlantSBM Micro Powder Technology Co, Ltd designs and manufactures highquality ultrafine vertical roller mills, which can grind any ore materials with a Mohs hardness below 6 +17 [ protected] language Ultrafine vertical roller mill Discharge fineness: 1503000 mesh Feed size: 20mm Output: 120 t/hUltrafine vertical roller mill SBM Ultrafine Powder TechnologyA vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal Energysaving and Efficient Vertical Roller Mill Fote Machinery

Ore mill, Ore grinding mill All industrial manufacturers

Find your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch The POITTEMILL pendulum roller mill is a vertical mill that works by compressing the material The overflow type ball mill is a new type of ball mill equipment with simple structure and selfflow discharge of ore It is often used to grind 2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from Find, read and cite all the research (PDF) Performance Evaluation of Vertical Roller Mill in Cement 2022年6月24日 Ball mills and vertical roller mills are common mining machinery that can grind ore into powder and are used in all walks of life CLUM vertical roller mill series mainly consists of grinding roller assembly, grinding disc assembly, and the material falls into the middle of the grinding disc from the discharge portHow to choose between ball mill and vertical roller mill?2021年11月3日 Phosphate mineral powder grinding mills includes ultrafine mills, vertical roller mills, highpressure mills, etc can grind ores into a fine powder +17 [ protected]Phosphate Mineral Powder Grinding Mill SBM Ultrafine

.jpg)

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

2019年4月16日 Research of iron ore grinding in a verticalrollermill, Minerals Engineering 73 (2015), 109–115 The vertical roller mill (VRM) is a comminution device in which crushing, Reliable roller air seals eliminate unnecessary airflow into the mill The special sealing design of the roller bearing prevents dust from penetrating A robust gear reducer is used to ensure efficient and stable power transmission Brief Vertical roller mill Hengtu MachineryThe Pfeiffer pilot mill used in this study is a semiindustrial vertical roller mill of type MVR with a table diameter of 400 mm The mill can be equipped with different classifiers for specific applications The process layout of the plant (Figure 2) corresponds to that of an industrial plantVertical Roller Mills used for the comminution of mineral oresFIGURE 4 Particle size distributions of collected samples (Survey 2) Bond work indices and breakage characteristics under compression were determinedPerformance Evaluation of Vertical Roller Mill in Cement

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc The VRM cement mill has a 2023年9月21日 This article aims to compare and contrast the key aspects of vertical roller mill and ball mill, highlighting their advantages, disadvantages, and They are commonly used in the mining industry for grinding ores, reducing its particle size The final product exits through a discharge grate or trommel screen at the opposite A Comparative Analysis: Vertical Roller Mill Vs Ball MillThe material falls from the discharge port to the center of the grinding disc Under the action of centrifugal force, it moves to the edge of the grinding disc and is crushed by the grinding roller Air ring) The highspeed upward hot air is brought to the highefficiency separator integrated with the industrial vertical grinding millIndustrial Vertical Grinding MillHRM1700MVRM Free download as PDF File (pdf), Text File (txt) or read online for free The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for Operation Manual: HRM1700M Vertical Roller Coal Mill

.jpg)

Barite Ultrafine Vertical Roller Mill

Barite ultrafine vertical roller mill is an industrial vertical grinding mill that can grind nonmetallic ore into fine powder The mill has a high production capacity, high fine powder content +17 Barite Ultrafine Vertical Roller Mill Discharge fineness: 1503000 meshesLM Vertical Roller Mill LM vertical mill adopts new milling devic Gypsum Applications: cement, electricity, metallurgy, chemical, nonmetallic mineral ore and other industries, focus on non and at the same time, the wind enters the mill from the air inlet The material falls through the screw feeder's discharge port and falls in LM Vertical Roller Mill, slag vertical mill, coal vertical mill 2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Copper ore grinding in a mobile vertical roller mill pilot plantThe CLUM ultrafine vertical roller mill is mainly composed of a host, a feeder, a classifier, a blower, a pipeline device, a storage hopper, an electric control system, and a collection system The main motor drives the grinding disc to rotate through the reducer, and at the same time, the wind enters the mill from the air inletQuartz Ultrafine Vertical Mill

.jpg)

What is the difference between vertical mill and Raymond mill?

However, the initial investment cost of the vertical mill is much higher than that of Raymond mill Therefore, the vertical mill can not completely replace the status of Raymond mill in nonmetallic ore processing Customers can choose flexibly according to their needs If you have a vertical mill or Raymond mill procurement needs, welcome to Should We Choose Raymond Mill or Vertical Roller Mill For Aluminum Powder Processing? Aluminum powder is widely used and in great demand Since the 19th century, it has been produced by a single ball millVertical Roller Grinding Mill Machine CLIRIK Machinery Vertical Roller Mill is a kind of highefficiency grinding equipment, which is widely used in cement, 85tph Cement Ball Mill In Indian Cement Plant; Ore Dressing Line; and the fine powder that meets the requirements is discharged from the discharge port, Vertical Roller Mill VRM Vertical Roller Mill For Sale2019年8月1日 investigation on flotation behavior of a copper sulfide ore after dry grinding by loesche vertical roller mill August 2019 Conference: 58th Annual Conference of Metallurgists (COM 2019)INVESTIGATION ON FLOTATION BEHAVIOR OF A COPPER SULFIDE ORE

Dolomite Ultrafine Vertical Roller Mill

The vertical roller mill integrates crushing, drying, grinding, and conveying +17 [ protected] Dolomite Ultrafine Vertical Roller Mill Discharge fineness: 1503000 meshes It can produce a variety of different highquality ore Request PDF On Sep 1, 2016, Deniz Altun and others published Operational parameters affecting the vertical roller mill performance Find, read and cite all the research you need on ResearchGateOperational parameters affecting the vertical roller mill Calcium Carbonate Ultrafine Powder Vertical Mill Discharge fineness: 3253000 mesh Feed Clum series calcium carbonate ultrafine powder vertical mill adopts the latest grinding roller technology from Taiwan and powder selection copper and other minerals These powders are then used in various applications such as ore processing and Calcium Carbonate Ultrafine Powder Vertical Mill2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and energetic

PREDICTING THE PRODUCT PARTICLE SIZE DISTRIBUTION FROM A VERTICAL

The Colorado School of Mines offers courses in chemistry, geology, and physics, with a focus on mining geology and astroparticle physicsSBM Ore Ultrafine Grinding Mill Discharge fineness: 1503000 mesh Feed size: 20 mm Output: 120 T/H Models: HGM ultrafine grinding mill, CLUM vertical roller mill, LXMC ultrafine wet stirring mill etc Send us an Inquiry If you have SBM Ore Ultrafine Grinding Mill2015年3月10日 Vertical roller mill (VRM) technology was developed based on that and attracted interests of both manufacturers and researchers Characterization of chalcopyrite ore under high voltage pulse discharge: Particle size distribution, fractal dimension, specific energy consumption, grinding kineticsCopper ore grinding in a mobile vertical roller mill pilot plant2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant

Ultrafine vertical roller mill SBM Ultrafine Powder Technology

SBM Micro Powder Technology Co, Ltd designs and manufactures highquality ultrafine vertical roller mills, which can grind any ore materials with a Mohs hardness below 6 +17 [ protected] language Ultrafine vertical roller mill Discharge fineness: 1503000 mesh Feed size: 20mm Output: 120 t/hA vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal Energysaving and Efficient Vertical Roller Mill Fote MachineryFind your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch The POITTEMILL pendulum roller mill is a vertical mill that works by compressing the material The overflow type ball mill is a new type of ball mill equipment with simple structure and selfflow discharge of ore It is often used to grind Ore mill, Ore grinding mill All industrial manufacturers2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from Find, read and cite all the research (PDF) Performance Evaluation of Vertical Roller Mill in Cement

36.jpg)

How to choose between ball mill and vertical roller mill?

2022年6月24日 Ball mills and vertical roller mills are common mining machinery that can grind ore into powder and are used in all walks of life CLUM vertical roller mill series mainly consists of grinding roller assembly, grinding disc assembly, and the material falls into the middle of the grinding disc from the discharge port2021年11月3日 Phosphate mineral powder grinding mills includes ultrafine mills, vertical roller mills, highpressure mills, etc can grind ores into a fine powder +17 [ protected]Phosphate Mineral Powder Grinding Mill SBM Ultrafine 2019年4月16日 Research of iron ore grinding in a verticalrollermill, Minerals Engineering 73 (2015), 109–115 The vertical roller mill (VRM) is a comminution device in which crushing, (PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM