Coal powder preparation heating and drying process

Fundamentals of pulverised coal combustion ICSC

Drying and heating are the first steps in the coal combustion process When coal particles approach a flame, they are first dried and then rapidly heated It appears that drying is Coal preparation, also called washing, cleaning, processing, and beneficiation of coal, is a physical process where coal is upgraded by the reduction of ash, sulfur, and moisture content Coal Preparation an overview ScienceDirect Topicspertinent information to dry coal processing globally, and aid in understanding the applicability, performance, success or failure thereof Over the years, numerous dry techniques have been Dry processing for coal preparation: a review2024年1月11日 Processing raw coal into pulverized coal involves several intricate steps that ultimately convert raw coal into fine powder primed for energy generation However, it is crucial to handle pulverized coal carefully due to its How to Process Coal into Pulverized Coal in 5 Steps?

Dry processing for coal preparation: a review

Dry coal processing benefits downstream utilizations through possible cost and energy savings along with a reduction in water pollution As a result, dry processing has inspired interest in the Coal preparation, which may also be called washing, cleaning or processing, is the methodology by which coal feedstocks are upgraded in order to reduce freight costs, improve utilization Coal Preparation SpringerLinkMost coal requires some preparation before use Preparation may range from simply crushing to provide a size consist suitable for certain types of boilers to extensive size reduction and CHAPTER 3 Coal Preparation and Cleaning2019年9月5日 A modular and efficient dry coal preparation system was established for raw coal preparation, drying, separation, medium purification and recovery, density steadystate control, Research Progress in Dry Beneficiation University of Pittsburgh

.jpg)

A review of stateoftheart processing operations in coal

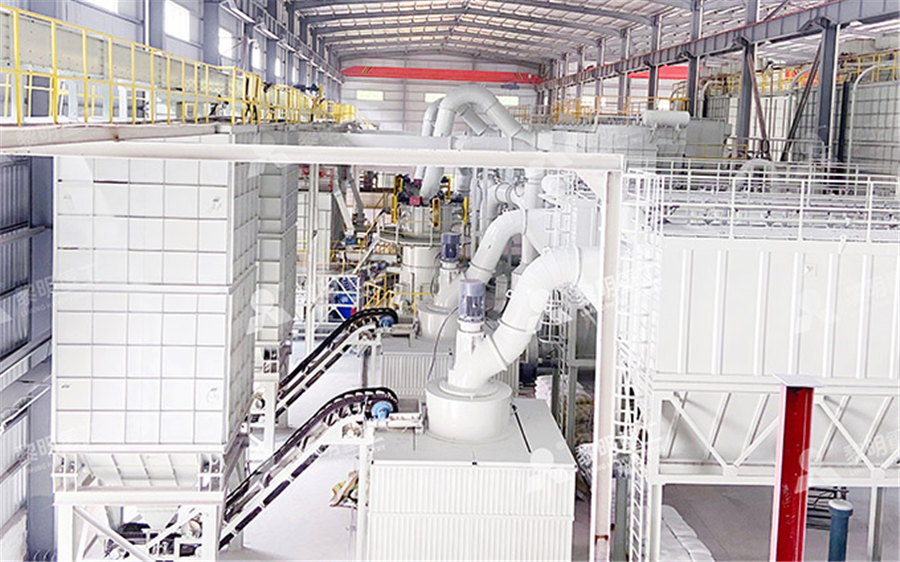

2015年7月1日 Coal preparation is an integral part of the coal commodity supply chain This stage of postmining, preutilization beneficiation uses lowcost separation technologies to 2019年9月5日 is formed in the airdense medium fluidized bed with magnetite powder and pulverized coal as the 13 Modular highefficiency dry coal preparation process system Raw coal Prescreening A modular and efficient dry coal preparation system was established for raw coal preparation, drying, separation, medium Research Progress in Dry Beneficiation University of PittsburghCoal preparation is defined as the process of removing the undesirable elements from runofmine (ROM) coal by employing separation processes to achieve a relatively pure, uniform product These separation processes are based on the differences between the physical and surface properties of the coal and the impuritiesCoal Preparation an overview ScienceDirect Topics2020年2月5日 This paper presents the results of research describing the thermokinetics of brown coal’s (lignite) drying process in a fountainbubble fluidized bed dryer The drying medium was atmospheric air of a variable Thermokinetics of Brown Coal during a Fluidized

.jpg)

Characterization and kinetic modeling of the drying process of

2024年5月1日 In recent years, highgrade iron ore resources are increasingly depleted, the use of lowgrade iron ore such as limonite has become an unstoppable trend, the development of lowgrade iron ore pelletizing process and supporting technology has become a key scientific issues in the field of ironmaking at home and abroad [8], [9], [10]The main characteristics of limonite 2016年8月31日 To enhance the combustion efficiency of high moist coal, it is important to reduce its moisture contents For reduction of moisture contents, the selection of efficient and lowcost drying (PDF) Evaporative Drying of LowRank Coal ResearchGate2016年8月31日 Lowrank coals including the brown and the subbituminous coals are commonly known to contain high moisture content (up to 65%, wet basis), which limits their utilization around the world in spite of their low cost Today, the most of the drying technologies are based on the evaporation of the water from the moist product In this chapter, the most effective parameters Evaporative Drying of LowRank Coal IntechOpen2023年9月5日 Therefore, powder preparation technology is continuously evolving and innovating to meet the requirements for particle size and performance 2 Preparation Methods of Metal Powder: 21 Physicochemical Methods 211 Reduction Method The reduction of metal oxides and salts is a widely used method for powder preparationMetal Powder Preparation Methods and Principles: A

Process flow diagram of coal rotary drying ResearchGate

Download scientific diagram Process flow diagram of coal rotary drying from publication: DualStage Drying Process of Lignite Using Pilot Scale Coal Rotary Dryer In conventional rotary drying 2023年1月15日 With the increase of gas velocity, vibration frequency and amplitude, the activation energy E a of fine coal drying process decreases first and then increases, and then the activation energy E a in the separation process of fine coal is the lowest under the conditions of N = 14, f = 20 Hz, A = 2 mmStudy on fluidization characteristics and drying characteristics of 2022年6月16日 Background In this study, turmeric (Curcuma longa L) powder was prepared with various extraction and drying methods Extractions were performed using three solvents (water, 50% ethanol, and 70% (PDF) Preparation of turmeric powder with various extraction and drying 2024年6月24日 Impact of external moisture on quantitative analysis of coal and rapid drying by a CO2 laser to improve prediction accuracy based on laser induced breakdown spectroscopyImpact of external moisture on quantitative analysis of

A green and efficient lignitefired power generation process

2024年5月1日 Nowadays coal supplies over a third of global electricity generation In China, Coal accounts for around 70% of primary energy consumption Statistics show that China's coalfired power generation in 2022 were 573 trillion kWh, accounting for 584% [1]With continued consumption of coal resources, the available highgrade coal is decreasing and the proportion 2021年10月11日 The preparation of silica aerogel by solgel method [20], [21] is divided into three processes: solgel, aging and drying The drying process usually adopts supercritical drying or atmospheric drying Supercritical drying is carried out under the critical temperature and pressure conditions of the drying mediumAtmospheric drying preparation and microstructure characterization of 2006年11月8日 Drying of lowrank coal The nal moisture content requirement for coal is different depending on the process in which it is hightemperature heating (and fluidizing) medium, 10 16 18 15 (PDF) 43 Drying of Coal ResearchGatePhoto 1 Briquetted UBC Photo 2 Lowrank coal upgrading demonstration plant 1) Toru Sugita et al, UBC (Upgraded Brown Coal) Process Development, Kobe Steel Engineering Reports, 53, 42, 20034D2 Lowrank Coal Upgrading Technology (UBC Process)

.jpg)

Production of Fruit Juice Powders by Spray Drying Technology

2018年8月26日 The spray drying process is considered a conventional method to convert fruit juices to powder form Process of spraydrying consists of three basic steps, including atomization, droplethot air 2013年1月1日 The effect of oven drying (OD) at 50±5°C, sun drying (SD), and fresh leaves (control) of seven selected herbs used in herbal preparation as herbal baths were evaluatedDifferent Drying Methods: Their Applications and Recent PDF On Jan 1, 2007, Zdzisław Pakowski and others published Basic Process Calculations and Simulations in Drying Find, read and cite all the research you need on ResearchGate(PDF) Basic Process Calculations and Simulations in DryingDry Coal Process Gas Recirculation Fan Dry Product Dust Collector Water Out Condensing Coils Heating Coils Coal Fines Surge Hopper Pneumatic Transfer System Cyclones Process Gas Recirculation Fan Coal Fines Fired Process Gas Heater Cumbustion Air Fan CVEMiningBrochureqxd:Layout 1 7/30/08 1:31 PM Page 1Thermal Coal Drying and Beneficiation Systems Carrier Vibrating

.jpg)

Coal briquetting technology process, binder and the briquette

2018年11月26日 Coal briquetting process A simple coal briquetting process normally follow the way below Coal dust picking (making) – Mixing (with or without binder) – Briquetting – Drying Every step we should make things specific in order to make high quality coal briquette Raw coal quality inspection and testingProcess layout, coal drying equipment and impact of fuel moisture on plant performance and emissions are discussed As fuel moisture content decreases, its heating value increases and, assuming constant electric power output of a power plant, less coal needs to be fired This reduces the burden on the coal handling system, Coal Drying Improves Performance and Reduces EmissionsDOI: 101016/jjaap2021 Corpus ID: ; Promotion effect of activated carbon, coal char and graphite on lignite microwave dehydration process @article{Ge2021PromotionEO, title={Promotion effect of activated carbon, coal char and graphite on lignite microwave dehydration process}, author={Lichao Ge and Xiaoyan Liu and Hongcui Feng and Hantao Promotion effect of activated carbon, coal char and graphite on 2010年6月30日 dewatering = drying process employed in the mineral proces ventional hot ai r used in coal drying b ecause it elimin ates fire hazard to 4 bar and 150 C for heating t he fluidize d Dewatering and Drying in Mineral Processing

.jpg)

Coal Processing and Use for Power Generation ScienceDirect

2014年1月1日 The use of coal is negatively perceived, since the use of fossil fuels in power generation and other industry sectors contributes significantly to the CO 2 emissions worldwide Of the main fossil fuels, coal has the lowest H:C ratio, and consequently coal has the highest CO 2 footprint per unit of combustion energy produced Coal also contains percentage levels of Understanding the Powder Coating Process Steps Powder coating is a dry finishing process that involves the application of fine, electrostatically charged powder particles to a substrate's surface This application method ensures an even and consistent coating, free from drips, sags, or unevenness 1 Surface Preparation PretreatmentPowder Coating Process Explained – A Detailed Breakdown2023年6月5日 Charcoal briquette is a kind of fuel made from charcoal powder Step 3: Drying Then a drying process is needed If the water content exceeds the empirical upper limit, the temperature will rise and the volume will expand suddenly, which is easy to cause an explosionHow to Make Charcoal Briquettes:Components and Process2011年2月28日 Numerous drying technologies have been proposed for drying coal; they include pulse combustion, vacuum, fluid bed, rotary, flash, microwave, and superheated steam drying(PDF) A Critical Assessment of Industrial Coal Drying

Coal Sample Preparation Procedures Overview TopSampler

2018年7月2日 The procedures of coal sample preparation mainly include reduction, division, mixing, sieving and drying In article Coal Sample Preparation Procedures Overview (2), we introduce the sample division, mixing and sieving We’ll walk through coal sample drying and reduction in detail in an upcoming section Coal Sample DryingDrying and heating are the first steps in the coal combustion process When coal particles approach a flame, they are first dried and then rapidly heated It appears that drying is completely separate from the subsequent pyrolysis and does not impact pyrolysis products or pyrolysis times (Bryden and Hagge, 2003) However, the heating process is Fundamentals of pulverised coal combustion ICSC2019年9月5日 is formed in the airdense medium fluidized bed with magnetite powder and pulverized coal as the 13 Modular highefficiency dry coal preparation process system Raw coal Prescreening A modular and efficient dry coal preparation system was established for raw coal preparation, drying, separation, medium Research Progress in Dry Beneficiation University of PittsburghCoal preparation is defined as the process of removing the undesirable elements from runofmine (ROM) coal by employing separation processes to achieve a relatively pure, uniform product These separation processes are based on the differences between the physical and surface properties of the coal and the impuritiesCoal Preparation an overview ScienceDirect Topics

.jpg)

Thermokinetics of Brown Coal during a Fluidized

2020年2月5日 This paper presents the results of research describing the thermokinetics of brown coal’s (lignite) drying process in a fountainbubble fluidized bed dryer The drying medium was atmospheric air of a variable 2024年5月1日 In recent years, highgrade iron ore resources are increasingly depleted, the use of lowgrade iron ore such as limonite has become an unstoppable trend, the development of lowgrade iron ore pelletizing process and supporting technology has become a key scientific issues in the field of ironmaking at home and abroad [8], [9], [10]The main characteristics of limonite Characterization and kinetic modeling of the drying process of 2016年8月31日 To enhance the combustion efficiency of high moist coal, it is important to reduce its moisture contents For reduction of moisture contents, the selection of efficient and lowcost drying (PDF) Evaporative Drying of LowRank Coal ResearchGate2016年8月31日 Lowrank coals including the brown and the subbituminous coals are commonly known to contain high moisture content (up to 65%, wet basis), which limits their utilization around the world in spite of their low cost Today, the most of the drying technologies are based on the evaporation of the water from the moist product In this chapter, the most effective parameters Evaporative Drying of LowRank Coal IntechOpen

Metal Powder Preparation Methods and Principles: A

2023年9月5日 Therefore, powder preparation technology is continuously evolving and innovating to meet the requirements for particle size and performance 2 Preparation Methods of Metal Powder: 21 Physicochemical Methods 211 Reduction Method The reduction of metal oxides and salts is a widely used method for powder preparationDownload scientific diagram Process flow diagram of coal rotary drying from publication: DualStage Drying Process of Lignite Using Pilot Scale Coal Rotary Dryer In conventional rotary drying Process flow diagram of coal rotary drying ResearchGate2023年1月15日 With the increase of gas velocity, vibration frequency and amplitude, the activation energy E a of fine coal drying process decreases first and then increases, and then the activation energy E a in the separation process of fine coal is the lowest under the conditions of N = 14, f = 20 Hz, A = 2 mmStudy on fluidization characteristics and drying characteristics of 2022年6月16日 Background In this study, turmeric (Curcuma longa L) powder was prepared with various extraction and drying methods Extractions were performed using three solvents (water, 50% ethanol, and 70% (PDF) Preparation of turmeric powder with various extraction and drying