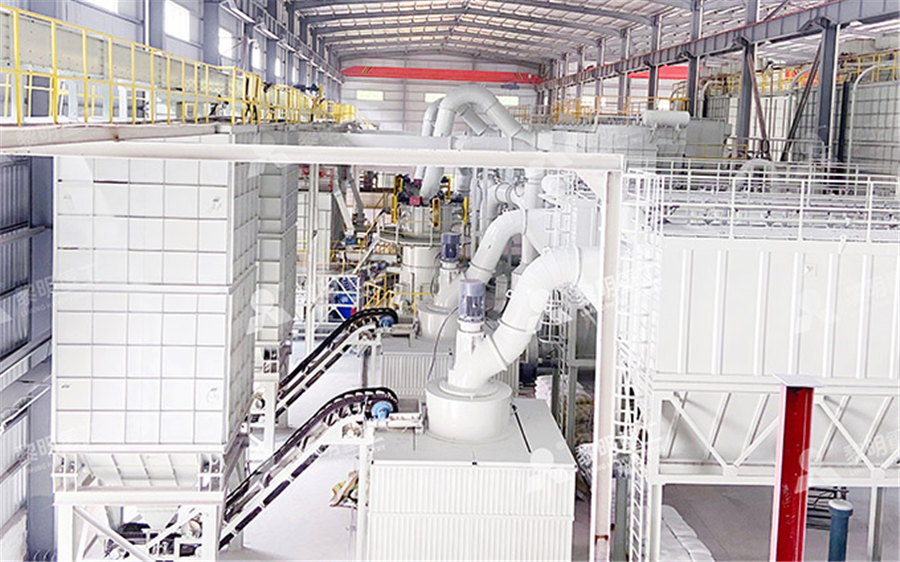

HOME→Steel slag toner mechanical equipment Steel slag toner mechanical equipment Steel slag toner mechanical equipment

Steel slag toner mechanical equipment Steel slag toner mechanical equipment Steel slag toner mechanical equipment

.jpg)

Comprehensive utilization of steel slag: A review ScienceDirect

2023年5月15日 Steel slag is the main solid waste generated in the steelmaking process, accounting for 15 to 20% of crude steel output [1] China's crude steel output in 2021 was Steel slag is the main waste product in the steelmaking process Because of its chemical coView Article2018年8月1日 Steel slag is the main waste product in the steelmaking process Because of its chemical composition and technical properties, it can be reused as raw material in steel plants Steel slag in China: Treatment, recycling, and management2023年11月20日 Some leading Indian steel industries, such as Jindal Steels and Tata Steels, first process the steel slag to recover valuable metals, then convert the remaining material into A Review on Environmental Concerns and Technological

Analyzing the Mechanical and Durability Characteristics of Steel

2023年12月20日 This paper conducts a systematic analysis of the physical and chemical properties of steel slag, specifically South Steel Electric Furnace slag, and compares it with 2021年10月1日 However, the direct use of untreated steel slag poses a great risk to the mechanical properties and durability of the steel slagderived composites In recent years, Use of steel slag as sustainable construction materials: A review of 2021年9月24日 Various approaches toward eliminating the inhibiting factors for recycling the SS in iron/steelmaking and blended cement manufacture are critically analyzed Based on the BOF Steel Slag: Critical Assessment and Integrated Approach for 2019年5月23日 Steel slag is the waste generated in the steelmaking process and includes ferric oxide and the impurities of some infusible matters It is the byproduct when slagforming Comprehensive Utilization Technology of Steel Slag

Physical and Chemical Properties of Steel Slag and Utilization

2019年3月1日 Based on the introduction of the element, composition and characteristics of steel slag, this paper expounds the application of steel slag in sintering and blast furnace 2024年4月28日 Steel slag is a byproduct of the steel industry and usually contains a high amount of fCaO and fMgO, which will result in serious soundness problems once used as a A Review on the Carbonation of Steel Slag: Properties, Mechanism, 2020年9月24日 In this paper, the common ways of resource utilization of steel slag in construction, agriculture, industry, and catalysis are reviewed Steel slag as a solid waste with Sustainable Utilization of Steel Slag from Traditional Industry and 2019年1月1日 However, to produce these steel productions not only release CO2 but also generate tons of solid wastes, namely, slag, dust, sludge, debris, etc Slag is the highest generated amount amongst these Recent trends in slag management utilization in

.jpg)

Steel Slag Utilization — Overview in Indian

2016年8月31日 PDF Current total productions of steel slag in India, are around 12 million tonnes per annum (Indian Minerals Yearbook, May 2016), which is far behind Steel slag is an industrial byproduct of steel production which is obtained during the pyrometallurgical process Technological dissemination on effective utilization of steel slag in vast quantities globally is essential as the generation of steel is escalating year by year and the availability of steel slag is also in millions of tons Though steel slag has been used for various Recent applications of steel slag in construction industry2024年11月1日 Steel Slag (SS) mainly comes from the waste slag produced in the steelmaking process (Zhang et al, 2022a, Zhang et al, 2022b)The global production of steel slag can reach 150 to 250 million tons per year (Liu, G et al, 2023)The accumulation of large quantities of SS will not only occupy a large amount of land resources, but also cause serious pollution of soil Exploration of steel slag by lignin and sodium citrate modification 2019年5月23日 At present, the main grinding equipment of steel slag at home and abroad include ball mill the highpressure rolling mill, vertical mill, tube mill with internal powder selecting, rolling mill, The excellent angularity and mechanical property of slag make it a possible substitute for natural building prehensive Utilization Technology of Steel Slag

.jpg)

Effect of the combination of polyvinyl chloride (PVC) and steel slag

2024年10月14日 Steel slag, a waste produced by the steel manufacturing process, exhibits considerable potential in improving the efficacy and longterm viability of cementbased composites Steel slag can enhance certain characteristics of concrete, such as its mechanical strength, durability, and ability to endure adverse environmental situations [24, 25]2024年9月5日 SelfCompacting Concrete (SCC) is a highly flowable concrete that can spread into place, fill formwork, and encapsulate reinforcement without mechanical consolidation This study investigates the use of steel slag as a partial replacement for fine aggregate in SCC, with replacement levels ranging from 0 to 70% Eight different mixes were prepared and tested for Innovative enhancement of selfcompacting concrete using 2023年7月2日 Alkaliactivated cement (AAC) is either clinkerless or free, and it is also environmentally friendly due to its low carbon footprint and wide range sources Industrial wastes, like steel slag and blastfurnace slag, usually have latent hydraulic reactivity, and can be used as precursors of AAC Both clinkerless and clinkerfree AAC were prepared from the mixture of Mechanical properties and durability of alkaliactivated steel slag 2023年12月20日 Steel slag is a solid byproduct of the steelmaking process, widely generated in the metallurgical industry Due to its alkaline nature and excellent adhesive properties with asphalt, it represents a potential road construction material with outstanding road performance, making it wellsuited for utilization in highway construction This paper conducts a systematic Analyzing the Mechanical and Durability Characteristics of Steel Slag

Effect of CO2 wet mineralized steel slaggranulated blast furnace slag

Effect of CO 2 wet mineralized steel slaggranulated blast furnace slag composite admixture on mechanical properties and chloride corrosion resistance of mortar Hydration activity and mechanical properties of steel slag used as cementitious materials Environ Prog Sustain Energy, 41 (2021), 101002/ep13756 Google Scholar [24]SLAG IRON AND STEEL 57th Edition SLAG IRON STEEL (FINAL RELEASE) GOVERNMENT OF INDIA MINISTRY OF MINES INDIAN BUREAU OF MINES Indira Bhavan, Civil Lines, NAGPUR – 440 001 PHONE/FAX NO (0712) PBX : (0712) , , EMAIL : Website: ibmgov January, 2020 Indian SLAG IRON AND STEEL IBMDownload Table Physical and mechanical properties of steel slag from publication: Steel Slag as A Road Construction Material Steel slag is a byproduct obtained from steel industryTable 3 Physical and mechanical properties of steel slag2017年3月5日 Steel slag is an inevitable solid waste of the steel manufacturing industry charac environmental and mechanical properties of iron/steel slags appears to be highly desirable CO 2(PDF) Iron and Steel Slags ResearchGate

The positive contributions of steel slag in reducing carbon dioxide

2024年10月15日 However, due to the uneven particle size of the steel slag generated by mechanical crushing methods, posing challenges for industrial utilization, and the high temperature of the cooled steel slag (500–900 °C), which significantly diminishes the efficiency of steel slag waste heat recovery, research and application of mechanical crushing methods The influence of steel slag was evaluated in concrete in this study and the following findings are concluded : • The aggregate produced from cooled steel slag meets criteria for the use in concrete mixes • Furthermore, According to ASTM D5106 experiments, steel slag meets the requirements to be used in concrete mixes,EFFECT OF USING STEEL SLAG AGGREGATE ON MECHANICAL 2023年11月25日 In response to the pressing global issue of reducing carbon emissions and the crucial technical challenges of fully utilizing steel slag, researchers have been studying an accelerated carbonation process that entails the carbonation of basic oxides in steel slag to store CO2 However, despite its promising potential, the process has yet to see widespread A review of use of metallurgical slag for its carbonation products 2020年2月1日 In order to study the effects of steel slag on the mechanical properties and microstructure of geopolymers, the compressive strength and flexural strength of a flyash steel slag–based Effects of Steel Slag on Mechanical Properties and

Greener phosphogypsumbased allsolidwaste ScienceDirect

2024年3月1日 Steel slag powder (SSP), with similar minerals components to cement (Jiang et al, 2018), is potentially practicable as the activator, thus resulting in greener allsolidwaste EPSCBut steel slag is often named the “overburnt Portland cement clinker” (> 1600 °C) (G et al, 2013), which means it owns coarse crystalline and consequent much lower activity than cement2018年1月25日 Figure 3 Slag aggregate pile Source: National Slag Association Compositionally, there are two main types of ferrousbased slags – steel slag and blast furnace slag (BFS) Steel slag, such as electric arc furnace slag (EAFS) or steel furnace slag (SFS), results from steelmaking processes EAFS or steel slags are always aircooledHigh Performance Slag Materials – A Steel Industry Byproduct2020年2月20日 Steel slag is a rocklike material which is produced in chorus with the steel from steelmaking industry Presently, India is the second largest steelmaking country (up from eighth in 2003) in the world as per Indian Minerals Yearbook 2018 []According to New Steel Policy2017, Indian steel industry produced 1014 million tons (MT) steel in 2016–17 and targets to PhysicoChemical and Mechanical Characterization of Steel Slag 2011年1月1日 Steel slag is a byproduct of the steelmaking and steel refining processes This paper provides an overview of the different types of steel slag that are generated from basicoxygenfurnace (BOF Chemical, Mineralogical, and Morphological

Recycling of iron and steel slag for carbon reduction and low

2024年6月12日 1 INTRODUCTION Blast furnace slag (BFS) and steel slag (SS), as industrial solid wastes produced in the process of steelmaking, account for 80%–90% of the total smelting slag [] BFS accounts for about 30% of pig iron output, [] while SS accounts for 10%–15% of the crude steel output [] SS comprises various slags, including basic oxygen furnace slag (BOFS) 2024年11月4日 In modern construction, increasing the sustainability of materials without sacrificing performance is crucial UltraHighPerformance Concrete (UHPC) is known for its exceptional strength and durability However, incorporating waste and optimizing the mix is still a key focus The main goal of this article is to evaluate the enhancement of the mechanical Enhancing the Mechanical Properties of UltraHighPerformance 2024年5月1日 Effect of steel slag powder and stone powder byproduct from manufactured sand on the mechanical properties and microstructure of cementitious materials Influence of mixed steel slag and stone powder on mechanical properties of concrete J North China Univ Sci Technol (Nat Sci Ed), 42 (4) (2020), pp 8186Effect of steel slag powder and stone powder byproduct from 2020年5月12日 From their experimental results it was evident that the crushing strength of the HPC containing steel slag and crystallized steel slag aggregates were 18–34% and 11–21% greater than of the HPC containing limestone aggregate 31–35% and 11–18% increase in modulus of rupture was reported for the HPC containing steel slag and crystallized steel slag Steel Slag—A Strong and Sustainable Substitute for Conventional

}@~3SRDG`IA1KP_ICWAA.jpg)

BOF Steel Slag: Critical Assessment and Integrated Approach for

2021年9月24日 During steel production, the impurities in the hot metal react with the fluxes forming the steel slag Chemical constituents of this steel slag (SS) are relevant to iron/steelmaking or blended cement manufacture Harmful impurities present in it, however, limit its recycling to these applications Japan, Europe, and the US consume a significant amount of 2020年11月20日 The most common types of steel slag are Basic Oxygen Furnace (BOF) slag, Electric Arc Furnace (EAF) slag, and ladle slag (Thomas et al, 2019) Studies on the properties of slagcontaining asphalt mixtures show improvement in their mechanical properties including durability, tensile strength, stiffness, and resilient modulus ( Hunt and Boyle, 2000 ; Oluwasola Evaluating the effect of electric arc furnace steel slag on dynamic 2023年5月15日 Steel slag is the main solid waste generated in the steelmaking process, accounting for 15 to 20% of crude steel output [1]China's crude steel output in 2021 was 1035 billion tons [2], more than half of the global crude steel output (19505 billion tons) [3], and the steel slag output exceeded 120 million tonsIn contrast, the comprehensive utilization rate of Comprehensive utilization of steel slag: A review ScienceDirect2022年4月30日 A novel technology has been developed to recycle steel slag as a flux for the submerged arc welding process The chemical, mechanical, and metallurgical properties of welds produced using recycled slag have been evaluated and compared with that of Waste to wealth: Recycling of steel slag as flux for the submerged

Analyzing the Mechanical and Durability Characteristics of Steel Slag

2024年3月4日 In terms of fatigue characteristics, SMA13 exhibits a longer fatigue life than AC13C, indicating superior fatigue performance for steel slag SMA13 Steel slag enhances the abrasion resistance 2019年1月1日 However, to produce these steel productions not only release CO2 but also generate tons of solid wastes, namely, slag, dust, sludge, debris, etc Slag is the highest generated amount amongst these Recent trends in slag management utilization in 2016年8月31日 PDF Current total productions of steel slag in India, are around 12 million tonnes per annum (Indian Minerals Yearbook, May 2016), which is far behind Steel Slag Utilization — Overview in Indian Steel slag is an industrial byproduct of steel production which is obtained during the pyrometallurgical process Technological dissemination on effective utilization of steel slag in vast quantities globally is essential as the generation of steel is escalating year by year and the availability of steel slag is also in millions of tons Though steel slag has been used for various Recent applications of steel slag in construction industry

Exploration of steel slag by lignin and sodium citrate modification

2024年11月1日 Steel Slag (SS) mainly comes from the waste slag produced in the steelmaking process (Zhang et al, 2022a, Zhang et al, 2022b)The global production of steel slag can reach 150 to 250 million tons per year (Liu, G et al, 2023)The accumulation of large quantities of SS will not only occupy a large amount of land resources, but also cause serious pollution of soil 2019年5月23日 At present, the main grinding equipment of steel slag at home and abroad include ball mill the highpressure rolling mill, vertical mill, tube mill with internal powder selecting, rolling mill, The excellent angularity and mechanical property of slag make it a possible substitute for natural building prehensive Utilization Technology of Steel Slag2024年10月14日 Steel slag, a waste produced by the steel manufacturing process, exhibits considerable potential in improving the efficacy and longterm viability of cementbased composites Steel slag can enhance certain characteristics of concrete, such as its mechanical strength, durability, and ability to endure adverse environmental situations [24, 25]Effect of the combination of polyvinyl chloride (PVC) and steel slag 2024年9月5日 SelfCompacting Concrete (SCC) is a highly flowable concrete that can spread into place, fill formwork, and encapsulate reinforcement without mechanical consolidation This study investigates the use of steel slag as a partial replacement for fine aggregate in SCC, with replacement levels ranging from 0 to 70% Eight different mixes were prepared and tested for Innovative enhancement of selfcompacting concrete using

Mechanical properties and durability of alkaliactivated steel slag

2023年7月2日 Alkaliactivated cement (AAC) is either clinkerless or free, and it is also environmentally friendly due to its low carbon footprint and wide range sources Industrial wastes, like steel slag and blastfurnace slag, usually have latent hydraulic reactivity, and can be used as precursors of AAC Both clinkerless and clinkerfree AAC were prepared from the mixture of 2023年12月20日 Steel slag is a solid byproduct of the steelmaking process, widely generated in the metallurgical industry Due to its alkaline nature and excellent adhesive properties with asphalt, it represents a potential road construction material with outstanding road performance, making it wellsuited for utilization in highway construction This paper conducts a systematic Analyzing the Mechanical and Durability Characteristics of Steel Slag Effect of CO 2 wet mineralized steel slaggranulated blast furnace slag composite admixture on mechanical properties and chloride corrosion resistance of mortar Hydration activity and mechanical properties of steel slag used as cementitious materials Environ Prog Sustain Energy, 41 (2021), 101002/ep13756 Google Scholar [24]Effect of CO2 wet mineralized steel slaggranulated blast furnace slag