Suspension roller ore mill structure

Roller Mill Springer

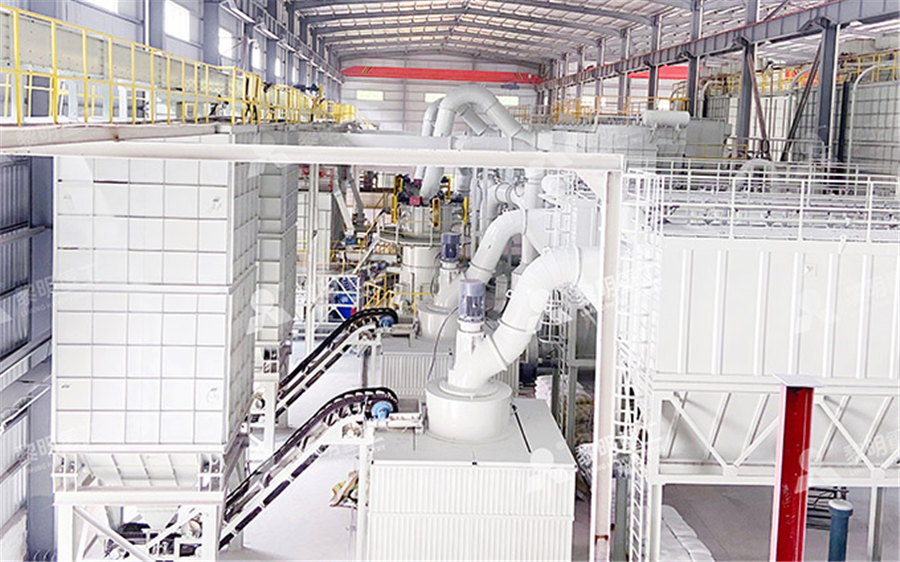

The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, and the device for easy replacement It can Vertical roller mills are traditionally airswept mills A VRM applies a compressive force using fixed rollers pressing downwards on a rotating grinding table The material to be ground is fed into Vertical Roller Mills used for the comminution of mineral oresThe roller mill’s ability to reduce materials to a uniform particle size provides more control of product characteristics and minimizes waste, as shown in Figure 1 The mill’s controlled Roller mills: Precisely reducing particle size with greater efficiencyIn the main machine of highpressure suspension roller mill, a highpressure spring with a pressure of 10001500kg is fastened on the grinding roller hanger After working, the grinding YGM HighPressure Grinding Mill Shanky Machinery

.jpg)

Latest Installations And Developments Of Loesche Vertical Roller

2012年9月1日 The paper is giving an overview about successful operating Loesche Vertical ? Roller ? Mills (VRM) installations and summarises the main benefits of the dry compressive The highpressure suspension roller mill mainly has the following characteristics: 1 The output of the highpressure suspension roller mill is 1020% higher than that of other mills under the Structural features of ore mill2019年4月12日 结合当前研究成果及工业现场数据,本文对比了高压辊磨机在金属矿山和球团预处理行业中的工艺流程,以及辊面比压力、辊面线速度、辊缝几个工艺参数,为高压辊磨机在 高压辊磨机在金属矿选矿与球团预处理领域的工艺和 2001年10月1日 LOESCHE vertical roller mills are widely used for the comminution of raw materials in the cement industry, for the comminution of clinker and blast furnace slag and for Loesche vertical roller mills for the comminution of ores and

.jpg)

Optimization of working parameters of highpressure roller mill

based on the properties of the ore itself, the structural parameters of the highpressure roller mill and the working condition parameters Daniel et al6 analyzed the roller pressure2024年11月15日 Schematic diagram of highpressure roller mill structure The main structure of the highpressure roller mill is shown in Fig 1, which mainly includes the frame, hydraulic Optimization of working parameters of highpressure roller mill Jemelon high pressure suspension mill is a new RD mill It is designed by engineers based on many years’ industrial mill research and the needs of mill industry The adoption of world leading powder processing technology makes Jemelon high pressure suspension mill start a new era of mill industry with high efficiency and low consumption It is the ideal substitute of the traditional YGM HighPressure Grinding Mill2022年10月21日 1 Difference of grinding system: Raymond mill adopts centrifugal pendulum suspension roller device for rolling, impact crushing The number of rollers is generally 37, and the number of grinding rings is one How to choose ring roll mill and Raymond mill SBM

Roller Mill SpringerLink

2024年1月1日 The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, nonmetallic ore, glass, ceramics, cement, gypsum, pesticide, chemical fertilizer, and other materials The product particle size is 0045–0125 mm Column Mill2022年10月15日 YGM high pressure suspension roller mill The highpressure suspension roller mill can be used to crush nonflammable and explosive materials such as barite, limestone, ceramics, slag, etc with Mohs hardness not greater than 93 and humidity below 6%Sepiolite 80600 Mesh High Pressure Suspension Roller MillAdopting a new sealing structure design, the grinding roller device can be filled with grease once in 300500 hours MILL STRUCTURE 1The Models above can be equiped with Hongcheng patented certical pendulum sturcture,suspension pendulum structure is also avaible to material character and product finenessHC series pendulum mill HCM Grinding MillCLIRIK perlite mill has obvious advantages, performance characteristics, scientific and reasonable structure, and is widely used in the field of perlite grinding processing by virtue of advanced powder making technology CLIRIK's highpressure suspension roller Raymond mill is a common equipment for perlite processingPerlite Ore Processing EquipmentNewsultramillindustrial

Micronizer Roller Mill Working Principle Crusher Mills, Cone

NewsMicronizer,Micronizer Mill,Micronization Equipment Installation of micronizer mill Working principle: during the work, the edge of the rotary roller pin drive dozens of roller in the roll of ring 2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Copper ore grinding in a mobile vertical roller mill pilot plant2023年7月4日 The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, nonmetallic ore, glass, ceramics, cement, gypsum, pesticide, chemical fertilizer, and other materials The product particle size is 0045–0125 mm Column MillRoller Mill SpringerLink2022年6月1日 Working principle of high pressure grinding mill The overall structure of the highpressure suspended roller mill is composed of the main engine, the analyzer (powder separator), the piping device, the blower, the finished product cyclone, the jaw crusher, the elevator, the electromagnetic vibration feeder, and the electric control motorHigh pressure grinding mill suspension roller mill for sale

MB5X158 Pendulum Suspension Grinding Mill Kefid

MB5X series pendulum suspension grinding mill has high efficiency, low cost and long life 5 3 1Thin oil lubricating grinding roller device, low maintenance cost Grinding roller device adopts thin oil lubrication, which is a technology initiated domestically, and it is maintenancefree and easy to operate 2Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermillThe CLRM Enhanced Roller Mill adjusts for powder from 80 to 500 mesh, ideal for materials under barite, limestone, talc, ceramics, iron ore, emery, bauxite, phosphate rock, coal, and more, encompassing approximately 400 different CLRM Enhanced Roller Mill Grinding Mill,Raymond Clean Utilization of Limonite Ore by Suspension Magnetization Roasting Technology Jianping Jin 1,2, Xinran Zhu 1,2, Pengchao Li The limonite ore was first crushed to 2 mm using a double roller crusher and then ground to 60 wt% passing 74 μm by a ball mill A suspension magnetization roastingClean Utilization of Limonite Ore by Suspension Magnetization

Vermiculite Industrial Milling Equipment SBM Ultra Mill

2021年11月12日 This vertical mill can also produce 1503000 mesh ore powder Compared with the ultrafine grinding mill, Through the reversible structure and hydraulic adjustment system, Highpressure Suspension Roller Mill Processing ability: 050tph Max feeding size: 35mm Product Fineness: 80325MeshThe YGM highpressure suspension roller mill has the advantages of compact structure, easy operation, and convenient maintenance Its application fields are wide, including large and mediumsized mining, chemical industry, building materials, metallurgy, refractory materials, pharmaceuticals, cement, and other industriesYGM160 High Pressure Grinding Mill Baichy Heavy IndustryYGM Series High Pressure Suspension Grinding Mill can produce powder from various nonflammable and nonexplosive mineral materials with Mohs hardness below 93 and humidity below 6%, there are mainly applied in the industries of metallurgy, construction materials, chemical, and mining, etcYGM Series High Pressure Suspension Grinding Mill2013年8月1日 This article reviews the principle and structure features of high pressure roller mill Moreover, the major progress in structure and technology parameters is summarized For the effect of application in nonferrous and ferrous ores, the high pressure roller mill will be widely applied in the futureA Review on the Development of High Pressure Roller Mill

.jpg)

LOESCHE vertical roller mills for the comminution of ores and minerals

2001年10月1日 LOESCHE vertical roller mills are widely used for the comminution of raw materials in the cement industry, for the comminution of clinker and blast furnace slag and for the production of 2024年8月29日 Shanghai Clirik Machinery Co, Ltd Is excellent ore mill supplier Our main products include ultrafine powder grinding mill, vertical roller mill, roller grinding mill, stone powder production equipment, Welcome to consultClirik Grinding Mill Clirik Enterprise Focuses On The Production 2022年5月26日 In the later crushing and grinding process, feeder, jaw crusher, iron remover, impact crusher, vibrating screen, YGM Raymond suspension roller mill, etc are generally used +17 [ protected]Construction waste crushing and grinding reprocessing What Is YGM Highpressure Suspension Mill Used For? CFTC YGM highpressure suspension roller mill is used for grinding and processing a wide range of nonflammable and nonexplosive mineral materials This mill is particularly effective for producing fine powders for various industrial applications Grinding Powder Plant Cement Processing PlantYGM Highpressure Suspension MillGrinding MachineMobile

.jpg)

vertical roller mill clirikultrafine vertical mill, Raymond vertical

Nonmetallic ore grinding equipment manufacturer About us The company's products mainly include ultrafine grinding mills, highpressure suspension roller pulverizers, coarse powder pulverizers, hammer and the production time is not the same, the internal structure is not the same See details case Cement vertical roller mill Grinding Mills Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 71 Introduction Grinding is the last stage in the comminution process where particles are reduced in size by a combination of impact and abrasion, either dry, or more commonly, in suspension in waterGrinding Mill an overview ScienceDirect TopicsDownload scientific diagram Drawing of the basic structure of a roller mill with two rotating/counterrotating rollers (crosssection) from publication: A study of operating parameters of a Drawing of the basic structure of a roller mill with two rotating RollerMill has been chosen over alternative technologies for the comminution process (Benzer, Gerold, Schmitz, 2018) Hoberg, Loesche, and Schneider (1985) investigated the flotation behavior INVESTIGATION ON FLOTATION BEHAVIOR OF A COPPER SULFIDE ORE

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

2019年4月16日 Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like limestone, clinker, phosphate, manganese, magnesite, feldspar and titaniumRaymond Mill Working Principle In the Raymond mill, a Raymond mill spring with a pressure of 10001500 kg is fastened to the grinding roll hanger After starting work, the grinding roller rotates around the main shaft and rolls close to the grinding ring under the action of the Raymond mill spring and centrifugal forceRaymond Roller Grinding MillRequest PDF On Sep 1, 2016, Deniz Altun and others published Operational parameters affecting the vertical roller mill performance Find, read and cite all the research you need on ResearchGateOperational parameters affecting the vertical roller mill 2019年8月1日 iron fines into suspension can Gerold C, Schmitz C (2018) First application of a VerticalRollerMill in a sulphide CopperGold ore depending on the ore type and mineral structureINVESTIGATION ON FLOTATION BEHAVIOR OF A COPPER SULFIDE ORE

YGM HighPressure Grinding Mill

Jemelon high pressure suspension mill is a new RD mill It is designed by engineers based on many years’ industrial mill research and the needs of mill industry The adoption of world leading powder processing technology makes Jemelon high pressure suspension mill start a new era of mill industry with high efficiency and low consumption It is the ideal substitute of the traditional 2022年10月21日 1 Difference of grinding system: Raymond mill adopts centrifugal pendulum suspension roller device for rolling, impact crushing The number of rollers is generally 37, and the number of grinding rings is one How to choose ring roll mill and Raymond mill SBM 2024年1月1日 The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, nonmetallic ore, glass, ceramics, cement, gypsum, pesticide, chemical fertilizer, and other materials The product particle size is 0045–0125 mm Column MillRoller Mill SpringerLink2022年10月15日 YGM high pressure suspension roller mill The highpressure suspension roller mill can be used to crush nonflammable and explosive materials such as barite, limestone, ceramics, slag, etc with Mohs hardness not greater than 93 and humidity below 6%Sepiolite 80600 Mesh High Pressure Suspension Roller Mill

HC series pendulum mill HCM Grinding Mill

Adopting a new sealing structure design, the grinding roller device can be filled with grease once in 300500 hours MILL STRUCTURE 1The Models above can be equiped with Hongcheng patented certical pendulum sturcture,suspension pendulum structure is also avaible to material character and product finenessCLIRIK perlite mill has obvious advantages, performance characteristics, scientific and reasonable structure, and is widely used in the field of perlite grinding processing by virtue of advanced powder making technology CLIRIK's highpressure suspension roller Raymond mill is a common equipment for perlite processingPerlite Ore Processing EquipmentNewsultramillindustrial NewsMicronizer,Micronizer Mill,Micronization Equipment Installation of micronizer mill Working principle: during the work, the edge of the rotary roller pin drive dozens of roller in the roll of ring Micronizer Roller Mill Working Principle Crusher Mills, Cone 2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Copper ore grinding in a mobile vertical roller mill pilot plant

Roller Mill SpringerLink

2023年7月4日 The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, nonmetallic ore, glass, ceramics, cement, gypsum, pesticide, chemical fertilizer, and other materials The product particle size is 0045–0125 mm Column Mill2022年6月1日 Working principle of high pressure grinding mill The overall structure of the highpressure suspended roller mill is composed of the main engine, the analyzer (powder separator), the piping device, the blower, the finished product cyclone, the jaw crusher, the elevator, the electromagnetic vibration feeder, and the electric control motorHigh pressure grinding mill suspension roller mill for sale