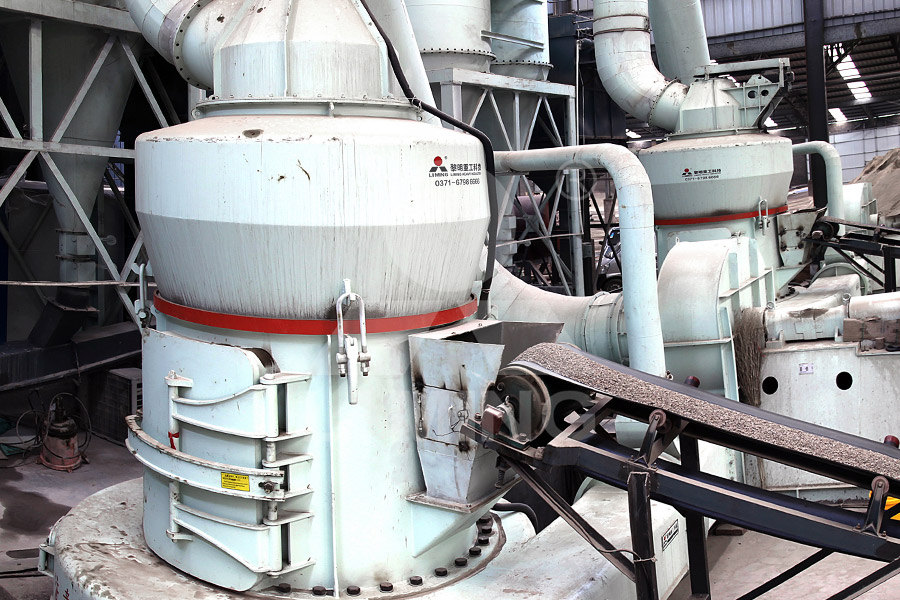

Dry grinding and iron removal equipment for potassium feldspar

How to Deironing and Mineral Separation of Potassium Feldspar

2024年10月21日 The equipment required for the potassium feldspar mineral processing process includes a jaw crusher, cone crusher, grinding machine, vibrating feeder, spiral classifier, ore color separator, artificial intelligence separator, magnetic separator, flotation machine, dryer, vibrating screen and conveyorThis article explores several common iron removal processes for potassium feldspar to help readers understand the advantages and applicable ranges of different methods 1 MagneticExploring Various Processes for Iron Removal from Potassium Magnetic separation is used as a backup process to remove any iron minerals present Following the drying process, dry grinding is sometimes performed to reduce the feldspar to less than 74 μm (200 mesh) for use in ceramics, paints, and tiles1127 Feldspar Processing2019年8月26日 Potash feldspar crushers include jaw crusher, cone crusher, and impact crusher The raw materials are fed into the silo via a dump truck, and the materials are evenly fed into the jaw crusher through a vibrating feeder to Potassium Processing Equipment, Process Flow, Cases

.jpg)

Iron removal process of potash feldspar SciSpace by Typeset

The iron removal process of the potash feldspar comprises the following steps of coarse grain ore washing, ore grinding, flotation and mica removal, magnetic separation and iron removal and filtering and drying2018年11月1日 Therefore, grinding equipment with iron medium is generally used in industrial plants As for sandy and weathered feldspars, scrubbing operation is quite important, which greatly helps reduce the harmful sandy components, improve the content of potassium oxide and sodium oxide, and decrease the iron oxide contentSystematic review of feldspar beneficiation and its comprehensive 2013年4月11日 A new permanent magnetic separator was introduced to treat the ores with the characteristics of weak magnetic iron minerals and in a fine size range The new machine was applied to the iron removal from potash feldspar The effects of the magnetic field intensity, pulp density and grinding fineness on the iron removal were investigatedRemoving iron by magnetic separation from a potash feldspar oreAbstract: A new permanent magnetic separator was introduced to treat the ores with the characteristics of weak magnetic iron minerals and in a fi ne size range The new machine was applied to the iron removal from potash feldspar The effects of the magnetic field intensity, pulp density and grinding fineness on the iron removal were investigatedRemoving Iron by Magnetic Separation from a Potash Feldspar Ore

.jpg)

Systematic review of feldspar beneficiation and its comprehensive

2018年11月1日 China is the second largest producer of feldspar and the largest feldspar consumer in the world (Tanner, 2012)Unfortunately, most of feldspar resources in China reportedly are characterized with fine liberation size consisting quartz, mica, and iron minerals (Hu et al, 2005, Zhou et al, 2013)Owing to the lack of advanced processing and mechanism to flotation to remove iron oxide minerals for its little floatability to feldspar [15] Furthermore, there are other methods to remove iron from feldspar, for example, the selective flocculation of the starch and iron to change the particle settling rate has been performed by DOGU et al [16] to achieve the separation of the iron and potash feldsparBenzohydroxamic acid to improve iron removal from potash feldspar 2023年4月2日 Therefore, dry magnetic separation experiments were carried out to remove the iron content from feldspar ore in the Wadi umm harjal area in Egypt to meet the specifications required for different Removing Iron Impurities from Feldspar Ore Using an 85% iron removal under conditions of 70°C, 1000 rpm, 5% S/L ratio, 20 g/l oxalic acid, and 90 minutes The kinetics of iron dissolution exhibited a reasonable fit with the shrinking core model with a mixed control mechanism The present study aims at removing iron oxide from Egyptian feldspar to get a feldspar product withOptimizing the removal of iron oxide from Egyptian feldspar ore

Optimizing the removal of iron oxide from Egyptian feldspar ore

3 Physicochem Probl Miner Process, 59(6), 2023, 21 Feldspar ore preparation The feldspar sample was, first, primary crushed in a “5x6 Denver” Jaw crusher followed by secondaryminutes Magnetic separation is used as a backup process to remove any iron minerals present Following the drying process, dry grinding is sometimes performed to reduce the feldspar to less than 74 µm (200 mesh) for use in ceramics, paints, and tiles Drying and grinding are often performed simultaneously by passing the1127 Feldspar ProcessingApplication It is used for iron removal and purification of nonmetallic minerals in wet processing, especially for wet iron removal of nonmetallic minerals such as quartz sand, potassium feldspar, and soda feldsparIn addition, it has a good separation performance for weak magnetic minerals such as hematite, limonite, specularite, siderite, manganese ore, and tantalumniobium oreIron Separator, Magnetic Stirrer, Magnetic Separator HuateThe properties of potassium feldspar ore were analyzed, and the technology for iron removal from potash feldspar ore was expounded The optimum parameters were determinedExperimental study on removal of iron from potash feldspar

Feldspar Processing Plant JXSC Machinery

Raw feldspar ore information: contains iron, calcium, mica, and other impurities, so the feldspar ore dressing process including magnetic separation, flotation or gravity separation, so as to remove iron, mica and other impurities to obtain highgrade feldspar 1 Crushing section: Utilize coarse jaw crusher, fine jaw crusher and vibrating screen to form a closed crushing circuit, so The grinding of feldspar is mainly divided into dry grinding and wet grinding The efficiency of wet grinding is higher than that of dry grinding, and the phenomenon of “overgrinding” is not easy to appearGrinding equipment are mainly ball mill, rod mill, tower mill, sanding mill, vibration mill, airflow mill, etcBasic knowledge and impurity removal method of feldspar2024年2月23日 2 Flotation process The flotation process can effectively remove iron from clay and finegrained ironcontaining minerals, but the effect is not good for hard ores For severely weathered ores, secondary sludge may Beneficiation Process For Removing Impurities From 2024年3月12日 Weathered granite contains a high concentration of feldspar, quartz, and kaolin However, while it becomes rich in clay due to strong physical weathering, the granite minerals that are not fully weathered are still very Efficient Recovery of Feldspar, Quartz, and Kaolin from

Feldspar Powder Crushing Grinding Production Line

2023年12月14日 Jaw Crusher( feldspar production line equipment) It is necessary to crush big feldspar stones into small pieces before the grinding process The crushing equipment usually uses a jaw crusherIt has 2017年5月25日 The choice between wet and dry milling is, in general, unimportant in smallscale milling but is a major technical problem when largescale milling in the metallurgical industries is involved On purely mechanical grounds it is difficult to see any great difference in fundamental principles between wet and dry milling, since dry milling may be regarded as wet milling with a Dry Grinding VS Wet Grinding 911MetallurgistFeldspar, as one kind of aluminum silicate minerals containing calcium, sodium, potassium, is an important industrial raw material ceramic With the higher requirement for the quality of ceramic products in society, the whiteness of feldspar is low, produced by the traditional processing technology, like “Crushing+Ball Milling+Weak Magnetism”, which is far from the demand of the Feldspar HGMS for Iron RemovalApplication It is used for iron removal and purification of nonmetallic minerals in wet processing, especially for wet iron removal of nonmetallic minerals such as quartz sand, potassium feldspar, and soda feldsparIn addition, it has a good separation performance for weak magnetic minerals such as hematite, limonite, specularite, siderite, manganese ore, and tantalumniobium oreIron Separator, Magnetic Stirrer, Magnetic Separator Huate

.jpg)

Production, Reserves, and Processing of Feldspar and Feldspathoid Rocks

2020年8月17日 Subsequent dry grinding and multistage screening are prerequisites for final electromagnetic separation to remove unwanted ironcontaining minerals Potassiumsodium feldspars are another logical type of feldspar raw material used in the ceramic and glass industries (merged to KNafeldspar category in Figure 10 )As a major component in the glass industry, feldspar is also used as a raw material in the manufacture of ceramic articles, paints, rubber latex, fiberglass, fertilizer, and other products [25] in Egypt, highquality sodium feldspar (nafeldspar) is produced from South Sinai, whereas potassium feldspar (Kfeldspar) is produced from the pegmatites and granitic rocks of the Removing Iron Impurities from Feldspar Ore Using Dry Magnetic The use of precrusher for coarse crushing and fine crushing, in order to prevent the pollution of iron to potassium feldspar in the processing process, so it is easy to use a turbine, gravel mill or porcelain ball mill, ultrafine laminating automill, etc as grinding equipment in the selection of milling equipment, the use of spiral classifier potassium feldspar product particle sizeThe PTMS Electromagnetic Separator of potassium feldspar ore 2022年5月7日 Therefore, potassium feldspar iron removal is the key to purification Iron is a magnetic substance, while potassium feldspar is a nonmagnetic substance, As a grinding equipment, a spiral classifier is used to ensure the particle size of the product The process is simple and the investment is lowWhat are the uses of potassium feldspar? What equipment is

Removing iron by magnetic separation from a potash feldspar

2013年4月1日 Therefore, dry magnetic separation experiments were carried out to remove the iron content from feldspar ore in the Wadi umm harjal area in Egypt to meet the specifications required for different 2009年2月1日 tests of grinding were performed at dry and wet mill and finally removing the iron impurities by desliming, Results of iron removal from feldspar by flotation without deslim ingIron Removal from Choghaie Feldspar Mine by Flotation2024年2月4日 The Kfeldspar mineral is an insoluble potassium resource with a high potassium content and the most extensive and abundant reserves To address the insufficient supply of soluble potassium fertilizers in China, the Review on KFeldspar Mineral Processing for 2024年7月30日 Iron is not only iron oxide, but also mechanical iron, etc what is magnetic separation method? To remove iron, it is to remove quartz ore and potassium sodium feldspar heavy iron, iron containing impurity minerals generally include: needle ore, hematite, limonite, ilmenite, magnetite pyrite, calcium carbide, amphiblite, biotite and so onPurpose and classification of the iron removal method for potassium

Potash Feldspar Beneficiation Explained

2021年9月26日 Potash feldspar beneficiation equipment mainly includes jaw crusher, ball mill, spiral chute, shaking table, magnetic separator, flotation machine, thickener, filter, etc The main function of the magnetic separator is to remove iron metal, and can use a permanent magnet drum type magnetic separator2005年12月31日 The kinetics of batch dry grinding of binary mixtures of ceramic raw materials, namely quartz–kaolin, quartz–potassium feldspar and kaolin–potassium feldspar, from the feed sizes of −3350 Dry grinding kinetics of binary mixtures of ceramic raw materials To recover potassium from feldspar, a biowaste, ie, eggshell, was used The chief composition of eggshells is calcite As it is a rich source of Ca, hence it is used with HCl to produce calcium chloride Feldspar is an aluminosilicate mineral that bears potassium in the interstitial sites To unlock the potassium from the interstitial sites, it was roasted with calcium chloride prepared by Sustainable Process for the Extraction of Potassium from Feldspar Feldspar, as one kind of aluminum silicate minerals containing calcium, sodium, potassium, is an important industrial raw material ceramic With the higher requirement for the quality of ceramic products in society, the whiteness of feldspar is low, produced by the traditional processing technology, like “Crushing+Ball Milling+Weak Magnetism”, which is far from the demand of the Feldspar HGMS for Iron Removal

.jpg)

AP42 Background Document for Section 1127 Feldspar Processing

potassium, sodium, and calcium, and it is the most abundant mineral of the igneous rocks The two types of feldspar are soda feldspar (7 percent or higher Na 2O) and potash feldspar (8 percent or higher K 2O) Feldsparsilica mixtures can occur naturally, such as in sand deposits, or can be obtained from flotation of mined and crushed rockPotassium feldspar beneficiation process and beneficiation equipment October17,2022 The raw potassium feldspar ore mined from the mine is transported to the ore dressing plant, and the storage volume of the ore on the ore floor is generally more than 5 Potassium feldspar beneficiation process and beneficiation equipment2018年11月1日 China is the second largest producer of feldspar and the largest feldspar consumer in the world (Tanner, 2012)Unfortunately, most of feldspar resources in China reportedly are characterized with fine liberation size consisting quartz, mica, and iron minerals (Hu et al, 2005, Zhou et al, 2013)Owing to the lack of advanced processing and mechanism to Systematic review of feldspar beneficiation and its comprehensive flotation to remove iron oxide minerals for its little floatability to feldspar [15] Furthermore, there are other methods to remove iron from feldspar, for example, the selective flocculation of the starch and iron to change the particle settling rate has been performed by DOGU et al [16] to achieve the separation of the iron and potash feldsparBenzohydroxamic acid to improve iron removal from potash feldspar

Removing Iron Impurities from Feldspar Ore Using

2023年4月2日 Therefore, dry magnetic separation experiments were carried out to remove the iron content from feldspar ore in the Wadi umm harjal area in Egypt to meet the specifications required for different an 85% iron removal under conditions of 70°C, 1000 rpm, 5% S/L ratio, 20 g/l oxalic acid, and 90 minutes The kinetics of iron dissolution exhibited a reasonable fit with the shrinking core model with a mixed control mechanism The present study aims at removing iron oxide from Egyptian feldspar to get a feldspar product withOptimizing the removal of iron oxide from Egyptian feldspar ore3 Physicochem Probl Miner Process, 59(6), 2023, 21 Feldspar ore preparation The feldspar sample was, first, primary crushed in a “5x6 Denver” Jaw crusher followed by secondaryOptimizing the removal of iron oxide from Egyptian feldspar oreminutes Magnetic separation is used as a backup process to remove any iron minerals present Following the drying process, dry grinding is sometimes performed to reduce the feldspar to less than 74 µm (200 mesh) for use in ceramics, paints, and tiles Drying and grinding are often performed simultaneously by passing the1127 Feldspar Processing

Iron Separator, Magnetic Stirrer, Magnetic Separator Huate

Application It is used for iron removal and purification of nonmetallic minerals in wet processing, especially for wet iron removal of nonmetallic minerals such as quartz sand, potassium feldspar, and soda feldsparIn addition, it has a good separation performance for weak magnetic minerals such as hematite, limonite, specularite, siderite, manganese ore, and tantalumniobium oreThe properties of potassium feldspar ore were analyzed, and the technology for iron removal from potash feldspar ore was expounded The optimum parameters were determinedExperimental study on removal of iron from potash feldsparRaw feldspar ore information: contains iron, calcium, mica, and other impurities, so the feldspar ore dressing process including magnetic separation, flotation or gravity separation, so as to remove iron, mica and other impurities to obtain highgrade feldspar 1 Crushing section: Utilize coarse jaw crusher, fine jaw crusher and vibrating screen to form a closed crushing circuit, so Feldspar Processing Plant JXSC MachineryThe grinding of feldspar is mainly divided into dry grinding and wet grinding The efficiency of wet grinding is higher than that of dry grinding, and the phenomenon of “overgrinding” is not easy to appearGrinding equipment are mainly ball mill, rod mill, tower mill, sanding mill, vibration mill, airflow mill, etcBasic knowledge and impurity removal method of feldspar