List of fly ash processing equipment

Fly Ash Processing Equipment FEECO International Inc

FEECO provides custom, highquality agglomeration and bulk material handling equipment for dedusting fly ash and turning it into a more 展开The fly ash processing plant produced by AGICO includes a ball mill grinding system, conveying system, dust collecting system, ash classifying system and ash storing system It helps our customers realize reasonable solid waste Fly Ash Processing Plant Cement Equipment Maximize fly ash utilization with STET's highrate, dry fly ash separation equipment Unlock highquality ash for concrete productionFly Ash Separation Equipment ST Equipment2023年8月16日 There are two primary types of fly ash: Class C, derived from burning lignite or subbituminous coal, contains higher amounts of calcium and is often used in cement and concrete Class F, produced from burning harder, Fly ash processing: Tailored solutions for reclaimed fly

.jpg)

Ash Pond Rehabilitation and FlyAsh Processing Vortex IS

VIS Processed Fly Ash The VIS machine is a quality option for the milling of fly ash on a like for like basis compared to existing mechanical milling plant options When you also factor in the 2024年11月26日 UCC has nearly a century of experience and expertise in the design, engineering and installation of pneumatic fly ash handling systems The NUVEYOR® Dry Vacuum transfer System is the industry standard for efficient Fly Ash Handling Systems Vacuum Material Ash We have installed complete ash handling systems for power plants, pulp and paper mills, waste to energy facilities, etc Dry Drag Chain Conveyors The dry drag chain conveyor can be applied to precipitators, fabric filters, boiler Mechanical Ash Handling Systems Brochure Metso Here at ProcessBarron, we specialize in ash handling solutions that facilitate the transport and disposal of fly ash in an efficient, environmentallyfriendly way We accomplish this through our stateoftheart fly ash conveying systems that Powerful, HeavyDuty Fly Ash Drag Conveyor, Handling

Vaccuum, Pressure, and Combination Fly Ash Handling

BW's ASH fly ash handling systems are a reliable, low maintenance, costeffective way of collecting and conveying boiler and emissions control system fly ashList of flyash companies Over 55 in China FREE Listing Home; Tianjin Shida Electric Power Equipment Co, Ltd The company was set up in the year of 2001 Inspection and Quarantine comprehensive foreign trade Currently operates five cenosphere processing factory, List of Fly Ash companies in ChinaCoal combustion products (CCPs), also called coal combustion wastes (CCWs) or coal combustion residuals (CCRs), [1] are categorized in four groups, each based on physical and chemical forms derived from coal combustion methods and emission controls: Diagram of the disposition of coal combustion wastes Fly ash is captured after coal combustion by filters (), Coal combustion products Wikipedia2015年11月23日 In 2007, the United States produced over 131 million tons of coal combustion products from the nation’s 1,308 coalfired power plants This 131 million tons of residuals must go somewhere, and has to be handled in a A Primer on Coal Ash Handling Systems

ReEngineering Fly Ash SCM For Green Cement

2023年11月14日 There’s more fly ash available for construction than contractors might think Now we need to mine that and recycle the ash with innovative engineering to allow use of even greater volumes2019年10月26日 Ash is discharged in wet form or dry form Dry fly ash is generally preferred when used for cement manufacturing Dry Ash Disposal: Dry extraction system is adapted for handling and management of ash in dry formIn this system, ash is collected in dry form in the hoppers of electrostatic precipitator; it is then disposed of using a vacuum or a pressure pumpHandling and Utilisation of Fly Ash from Thermal Power Plants2023年12月13日 Fly ash can be turned into more than just an industrial byproduct With economically effective and environmentally sound strategies for processing, like those provided by Economy Ball Mill and our stateoftheart ball mills, fly ash can become a valuable commodity in the industrial and construction marketplaceUsing Ball Mills for Fly Ash Processing Economy Ball Mill2021年9月1日 Fly ash wastewater treatment methods are economical, environmentally friendly, and efficient (Mushtaq et al, 2019) As mentioned earlier, unburned carbon in fly ash allows the adsorption of organic compounds such as phenols, dyes, toxic metals, herbicides, petroleum constituents, and other inorganic pollutants from wastewater Fly ash properties, characterization, and applications: A review

Value in Waste: Fly Ash Reuse and Recovery Opportunities

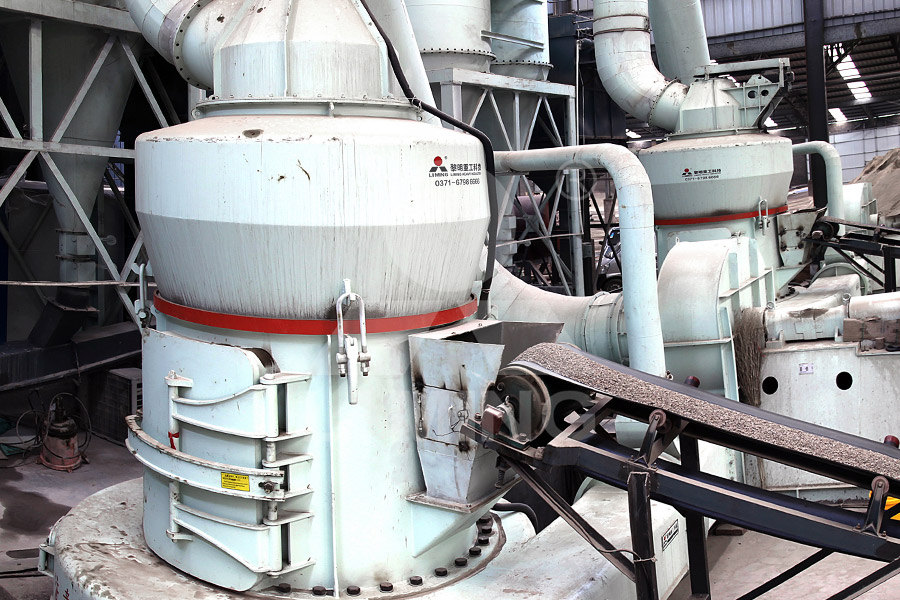

In 2016, the American Coal Ash Association announced that for the first time in history, the amount of coal ash (a combination of fly ash and bottom ash) reuse in the United States exceeded 50% ACAA Executive Director Thomas H Adams, had this to say:Below is the list of chemical compositions of fly ash from various coal types [5] Key compositions/coal types Bituminous Subbituminous Lignite SiO 2 (%) 2060 4060 1545 Al 2 O 3 (%) 535 the power plant processing conditions and the ash collection system The glassy content can be > 90% for an IGCC Fly Ash Separation Technology and its Potential Applications2014年1月24日 Fly ash (FA) is a byproduct of power, and incineration plants operated either on coal and biomass, or on municipal solid waste FA can be divided into coal fly ash, obtained from power plant burning coal, flue gas desulphurisation FA, that is, the byproduct generated by the air pollution control equipment in coalfired power plants to reduce the release of SO2, biomass Review of fly ash inertisation treatments and recyclingFly Ash Processing Process There are different equipment configurations and processes for grinding fly ash On the market, ultra fine ball mill grinding, Raymond mill grinding, and vertical roller mill grinding all exist SINOMA Fly Ash Processing Plant Superfine Final Product

Ash Handling Systems Sumitomo Heavy

Information on Ash Handling Systems from Sumitomo Heavy Industries We are a comprehensive heavy machinery manufacturer with a diverse range of businesses, including standard and massproduction machines, such as 2021年6月17日 It is shown that the reason behind the low interest of the Russian private sector in the processing of coal fly ash is the lack of stimulating market mechanisms for manufacturers and consumers of Recycling of Coal Fly Ash as an Example of an Efficient We provide high performance parts and upgrades for our AllenShermanHoff® line of ash handling equipment, as well as most other brands Inventory is maintained for a wide range of critical parts, including bottom ash components, fly ash components, and piping and fittings This means fast delivery of the parts you need mostAllenShermanHoff (ASH) Ash Handling EquipmentFly ash processing equipment plays a critical role in making this possible Fly ash is a fine, powdery material that is carried out of coalfired power plants with flue gases It is a complex mixture of inorganic and organic materials that can be used in a variety of applications, The Benefits of Utilizing Fly Ash Processing Equipment

Is Fly Ash Dangerous? Dealing with Hazardous Fly Ash Heyl

2023年5月5日 Thus, proper fly ash removal, processing, and storage are vital for safety Is fly ash dangerous? Understanding the risks and implementing suitable measures can transform fly ash from a hazard to a valuable resource Fly Ash – Composition and Traditional Treatment Fly ash is a byproduct of burning carbonaceous materials such as coal in 2018年11月2日 Increased agglomeration for reclaim ash Agglomeration observed in landfilled ash particles Ref: McCarthy, M J and Dhir, R K, Exploiting short and longterm, wet stored fly ash as a cement component in concrete Proceedings International Conference, United Kingdom Quality Ash Association (UKQAA), Birmingham, 15–17 MISBN 09550, 2006Fly Ash Reclamation and2024年8月16日 Fly ash washing: cleaning fly ash to remove harmful components and extract valuable materials Zinc recovery: Extraction of pure zinc from fly ash, which can then be resold Bottom ash processing: Processing and recycling of bottom ash produced during waste incineration Phosphorus recovery: Recovering phosphorus from sewage sludge incinerationProcesses for Waste Incineration and Bottom Ash Treatment2022年1月26日 Class F Fly Ash The flaming of harder, older anthracite bituminous coal typically produces Class F fly ash This fly ash is pozzolanic contains less than 10% lime (CaO) and possesses pozzolanic properties The glassy silica alumina of Class F fly ash require a cementing agent, such as Portland cement, quicklime, or hydrated lime Class C What is Fly Ash? Physical and Chemical Properties of Fly Ash

Fly Ash Handling: Challenges and Solutions Power Engineering

2012年2月1日 By Jayant Khambekar, PhD and Roger A Barnum, Jenike Johanson, Inc, USA Fly ash is a general name used for the residual products of combustion that rise with flue gases More than 100 million Abstract Fly ash (FA) is a byproduct of power, and incineration plants operated either on coal and biomass, or on municipal solid waste FA can be divided into coal fly ash, obtained from power plant burning coal, flue gas desulphurisation FA, that is, the byproduct generated by the air pollution control equipment in coalfired powerReview of fly ash inertisation treatments and recyclingJAYCEE is the market leader in Fly Ash, Slag, GBFS, Cement products supply and exports from India JAYCEE owns and operates South Asia’s biggest, independent Fly Ash processing plant with a capacity of 12 million tons per JAYCEE: Fly Ash, Slag, GBFS, Cement Supply and Fly ash grinding mill, also called fly ash Raymond mill, is a device for grinding, processing and reusing fly ash This equipment has good grinding products, stable work, and reliable operation It is mainly responsible for the preparation Fly Ash Production ProcessFly Ash Processing

Fly Ash Ashtech

Our 27+ years of experience in processing and distribution of Fly Ash keeps us at the spearhead of the industry Fly Ash (pulverized fuel ash) is a byproduct of a coalbased thermal power station generated by the combustion of pulverized coal Fly Ash is a fine, grey amorphous powder, rich in silica alumina and spherical in shape2023年5月24日 Environmental Impact of Fly Ash and Bottom Ash Like many industrial processing byproducts, fly ash and bottom ash can negatively impact the environment if not managed properly Both fly ash and bottom ash can contain heavy metals and other toxic substances that can contaminate the surrounding environment Special caution must be taken Fly Ash vs Bottom Ash Powder Bulk Solids Process EquipmentONSITE PROCESSING PLANT IS USED TO PREPARE STORED ASH FOR COMMERCIAL USE The onsite processing plant is being utilized to dry and beneficiate the harvested fly ash for commercial use FLY ASH MEETS OR EXCEEDS REQUIREMENTS OF ASTM C618 AND AASHTO M295Harvested Fly Ash Eco Material2024年6月18日 Elevate your recycling operations with cuttingedge industrial systems, equipment, components, and accessories Explore our categories for the latest innovations in recyclable material processing Upgrade sustainability todayThe FAW (Acid Fly Ash Washing) Process RecyclingInside

.jpg)

Overcoming Challenges with Fly Ash Handling ProcessBarron

2019年1月3日 When correctly engineered, fly ash handling systems can avoid the flow problems that often plague incorrectly designed or constructed equipment ProcessBarron engineers, constructs, and installs fly ash handling systems for a variety of plants and industries Contact the team for more informationRWE npower Aberthaw ash processing facilities 3 ST ASH PROCESSING FACILITIES Controlled low LOI fly ash is produced with ST’s technology at twelve power stations throughout the US, Canada, the UK and Poland The processed fly ash is marketed under the ProAsh® brand throughout these market areas ProAsh® fly ash has been approved forSeparation Technologies’ 17 Years of Commercial Experience in Fly Ash Manufacturer of Fly Ash Processing System offered by Aesha Conveyors And Crushing Equipment, Ahmedabad, Gujarat Aesha Conveyors And Crushing Equipment Odhav, Ahmedabad, Gujarat GST No 24AKQPP5648D1ZV TrustSEAL Verified Call 61% Response Rate SEND Fly Ash Processing System Manufacturer from AhmedabadList of flyash companies Over 55 in China FREE Listing Home; Tianjin Shida Electric Power Equipment Co, Ltd The company was set up in the year of 2001 Inspection and Quarantine comprehensive foreign trade Currently operates five cenosphere processing factory, List of Fly Ash companies in China

Coal combustion products Wikipedia

Coal combustion products (CCPs), also called coal combustion wastes (CCWs) or coal combustion residuals (CCRs), [1] are categorized in four groups, each based on physical and chemical forms derived from coal combustion methods and emission controls: Diagram of the disposition of coal combustion wastes Fly ash is captured after coal combustion by filters (), 2015年11月23日 In 2007, the United States produced over 131 million tons of coal combustion products from the nation’s 1,308 coalfired power plants This 131 million tons of residuals must go somewhere, and has to be handled in a A Primer on Coal Ash Handling Systems2023年11月14日 There’s more fly ash available for construction than contractors might think Now we need to mine that and recycle the ash with innovative engineering to allow use of even greater volumesReEngineering Fly Ash SCM For Green Cement2019年10月26日 Ash is discharged in wet form or dry form Dry fly ash is generally preferred when used for cement manufacturing Dry Ash Disposal: Dry extraction system is adapted for handling and management of ash in dry formIn this system, ash is collected in dry form in the hoppers of electrostatic precipitator; it is then disposed of using a vacuum or a pressure pumpHandling and Utilisation of Fly Ash from Thermal Power Plants

Using Ball Mills for Fly Ash Processing Economy Ball Mill

2023年12月13日 Fly ash can be turned into more than just an industrial byproduct With economically effective and environmentally sound strategies for processing, like those provided by Economy Ball Mill and our stateoftheart ball mills, fly ash can become a valuable commodity in the industrial and construction marketplace2021年9月1日 Fly ash wastewater treatment methods are economical, environmentally friendly, and efficient (Mushtaq et al, 2019) As mentioned earlier, unburned carbon in fly ash allows the adsorption of organic compounds such as phenols, dyes, toxic metals, herbicides, petroleum constituents, and other inorganic pollutants from wastewater Fly ash properties, characterization, and applications: A reviewIn 2016, the American Coal Ash Association announced that for the first time in history, the amount of coal ash (a combination of fly ash and bottom ash) reuse in the United States exceeded 50% ACAA Executive Director Thomas H Adams, had this to say:Value in Waste: Fly Ash Reuse and Recovery OpportunitiesBelow is the list of chemical compositions of fly ash from various coal types [5] Key compositions/coal types Bituminous Subbituminous Lignite SiO 2 (%) 2060 4060 1545 Al 2 O 3 (%) 535 the power plant processing conditions and the ash collection system The glassy content can be > 90% for an IGCC Fly Ash Separation Technology and its Potential Applications

Review of fly ash inertisation treatments and recycling

2014年1月24日 Fly ash (FA) is a byproduct of power, and incineration plants operated either on coal and biomass, or on municipal solid waste FA can be divided into coal fly ash, obtained from power plant burning coal, flue gas desulphurisation FA, that is, the byproduct generated by the air pollution control equipment in coalfired power plants to reduce the release of SO2, biomass