Crushing large pieces of quicklime

Limestone Crushing Solution Eastman Rock Crusher

Introduce how to crush limestone, whole limestone crushing plant flow layout (with photo), and related rock crusher machine Contact us to do free flow 2023年12月8日 In the limestone crushing production line, the coarse crushing equipment can crush the large pieces of limestone mined into stones of 125400mm in size Medium crushing equipment: Commonly used equipment are Limestone crushing technology and equipment SBM In the context of quicklime production, jaw crushers are essential for the initial stage of size reduction, breaking down large raw materials into more manageable pieces The production of The Role of Jaw Crushers in Quicklime Production2022年6月2日 In the process of limestone production and processing, the following equipment is mainly used: pulverizer (Raymond mill or high pressure mill), jaw crusher, hammer crusher, Limestone grinding and processing equipment Shanghai Clirik

.jpg)

Limestone Crushing Process JXSC Mineral

Limestone can be directly processed into stone using crushing equipment and fired into quicklime Quicklime absorbs moisture or adds water to become hydrated lime The main component of hydrated lime is calcium hydroxide 2021年3月3日 Limestone rocks with sizes of around 1 m in diameter are commonly crushed in primary crushers such as jaw crushers, gyratory crushers, or impact crushers The main goal Lime SpringerLinkLimestone can be made into limestone powder by treatment of limestone crusher and limestone grinding mill Limestone powder can produce quicklime by calcination Quicklime can be widely used for desulfurization in power plants, LIMESTONE CRUSHING GRINDING ball mills supplierCrushing: Breaking large pieces of limestone into small pieces for subsequent processing Commonly used crushing equipment includes jaw crusher, impact crusher, cone crusher, etc How to process limestone? clirik ultrafine grinding mill

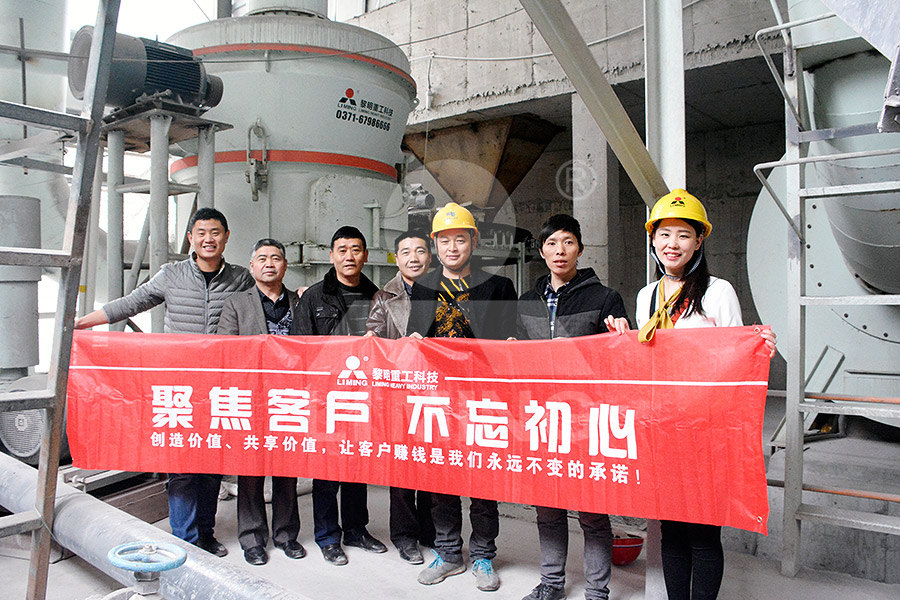

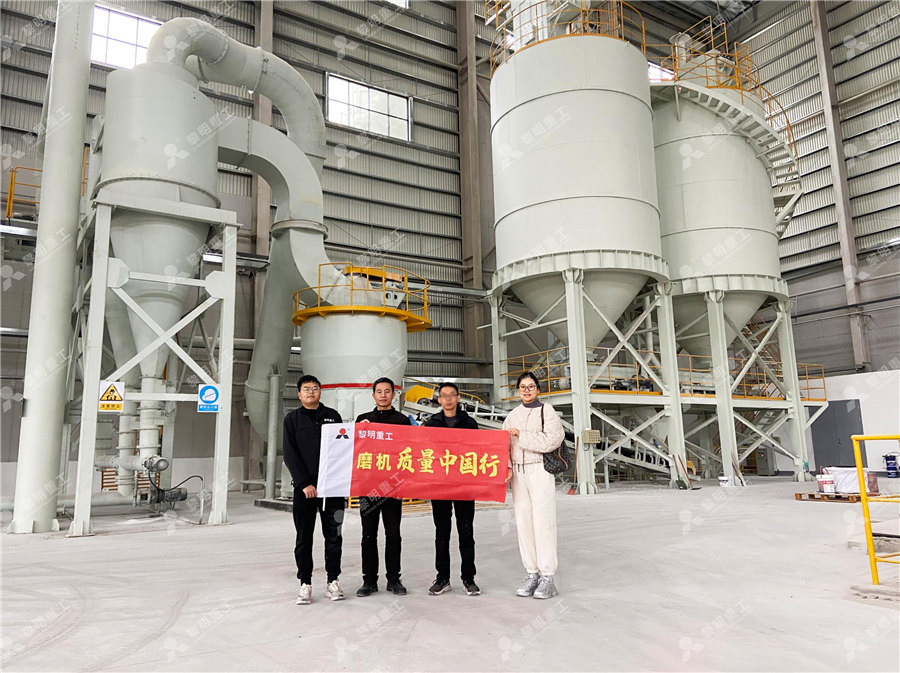

The Right Grinding Machines for Your Quicklime Industry Liming

Crushing Crush large pieces of limestone into small pieces to increase surface area and improve calcination efficiency This step includes preliminary crushing and screening to remove 2023年4月24日 Calcium oxide, also known as quicklime, is manufactured industrially by the thermal decomposition of calcium carbonate (limestone) in a lime kiln The process typically involves the following steps: Quarrying and How is calcium oxide manufactured industrially?Crushing: Breaking large pieces of limestone into small pieces for subsequent processing Commonly used crushing equipment includes jaw crusher, impact crusher, cone crusher, etc Screening: The crushed limestone is screened according to How to process limestone? clirik ultrafine grinding mill2024年5月16日 Some portable heaters use quicklimewater reactions You can categorize types of quicklime by size: Lump lime: large pieces up to eight inches in diameter; Pebble lime: small chunks from 025 to 25 inches in diameter; Lime vs Limestone Rock: Types and Uses of Each

Quick Lime Preparation, Properties and Uses Hebei Yayang

2023年10月11日 In systems that demand large quantities of lime, quicklime would be the preferred material as the density is twice the density of hydrated lime, which reduces the storage and transportation costs However, quicklime’s hydrophobic reaction with water requires a lime slaker to be used in the processQuicklime application instantly increases soil aggregate stability** Katharina M Keiblinger 1, Lisa M Bauer2, Evi Deltedesco , Franz Holawe2, Hans Unterfrauner3, Franz Zehetner1, and Robert Peticzka2* 1Institute of Soil Research, Department of Forest and Soil Sciences, University of Natural Resources and Life Sciences Vienna (BOKU), Peter JordanStrasse 82, 1190 Vienna, Quicklime application instantly increases soil aggregate stability**At Uma Lime Industry LLC, our Quicklime Lumps are produced through the precise calcination of highquality limestone in our advanced Cimprogetti kiln These large, solid pieces of quicklime are renowned for their purity and consistent quality, making them ideal for various industrial applications Key FeaturesQuicklime Lumps – Uma Lime Industry LLC2024年9月10日 When it absorbs rain or groundwater, it releases heat and bubbles that make it look alive That’s where the name comes from: quick means living Some portable heaters use quicklimewater reactions You can categorize types of quicklime by size: Lump lime: large pieces up to eight inches in diameterLime vs Limestone Rock: Types and Uses of Each

An Overview of Lime Slaking and Factors That Affect the Process

pebble quicklime is used Once the slaking tank is emptied, the water for the next batch is added to the slaking tank and the system goes to a standby mode waiting for an operator to start the next batch cycle Figure 4 shows a batch slaker for use with pulverized quicklime Batch slakers are used where only a few small batches are neededIn the context of quicklime production, jaw crushers are essential for the initial stage of size reduction, breaking down large raw materials into more manageable pieces The production of quicklime begins with limestone, a sedimentary rock abundant in calcium carbonate (CaCO₃)The Role of Jaw Crushers in Quicklime ProductionQuicklime was used in the infamous Holocaust The Nazis would place a thick layer of quicklime on the floor of the cattle cars before loading the Jews This would burn the skin of the victims on contact Quicklime, also known as burnt lime, is a chemical compound called The Amazing Uses of Quicklime You Probably Didn’t Know2014年5月1日 In 1932 Laudermilk [30] was the first to disprove this theory by using pieces of beef coated in quicklime and showed the preservatory effects of the chemicalLongterm effects of hydrated lime and quicklime on the decay of

.jpg)

SIZE REDUCTION BY CRUSHING METHODS By ResearchGate

3 Size reduction of ores is normally done in order to liberate the value minerals from the host rock This means that we must reach the liberation size, normally in the interval 100 – 10 micron The production of quicklime is one of the oldest chemical processes developed by mankind But there is often a lot of confusion between terms like lime and quicklime Are you wondering what quicklime is, and what it is made of? Then you've come to the right page! ScienceStruck gives you a lot of information about quicklime, and explains how it is industrially madeWhat is Quicklime and How is it Made? Science StruckAfter crushing,theparticlesused mustbebetween 10and20 mm in size as the heat does not quite penetrate to the core of larger sized stones; therefore, the centre of these pieces remains asFactors influencing the reactivity of quicklime ResearchGaterequirements for the crushing work of single roll crusher The single roll crusher is one of the key pieces of equipment for sintering production, and its main role is to crush the large pieces of sintered ore unloaded from the sinter to make its granularity Optimization of roller teeth based on the analysis of the crushing

Activation of fly ash cementitious systems in the presence of quicklime

2006年12月1日 For other substitute materials, such as marble waste and coconut shells, some studies revealed that crushing waste materials into small pieces improves concrete mechanical properties [23][24][25]Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ftlbf/ft 3 (2,700 kNm/m 3)) 1 This standard is issued under the fixed designation D1557; the number immediately following the designation indicates the year of original Standard Test Methods for Chemical Analysis of Limestone, Quicklime 2 Crushing and Screening Crushing: Large chunks of limestone are fed into crushing machines where they are broken down into smaller, more manageable pieces Screening: The crushed limestone is then screened to separate it into different size fractionsTypically, the desired particle size for calcination is between 1050 mm Uniform particle size ensures consistent heat Guide to Calcination of LimeLime Calcination Lime Kiln Calcination2007年7月1日 In this study cement and quicklime are examined as binders to enhance the ripening process and immobilize contaminants in dredging sludge Ripening comprises the drying in the open air till a dry Use of cement and quicklime to accelerate ripening and

Limestone crushing machine, limestoneZhengzhou Vanguard

Cement plant can break and break large pieces of limestone through Zhengzhou Vanguard limestone crushing production line equipment, so as to meet the national standards and customer requirements Easy to use, the particle size of broken products is more uniform, long service life, low noise, small dust, easy maintenance and repair, low vibration and so on2017年3月4日 pieces of ore are broken once, and then fall to a lower position Large feesing size ,high crushing cavity,w ide range of the highhardness of the materials ,large SIZE REDUCTION BY CRUSHING METHODS2020年10月29日 The preparation of the dolomite for calcining includes crushing, usually with rolls, to reduce the amount of fines, and mixing with the sized dolomite a small percentage of iron ore, boiler scale, or other iron ingredient The mixture is Lime Quicklime Limestone 911Metallurgist2016年7月7日 In steelmaking process, quicklime is used to produce CaObased slag Although rapid dissolution of quicklime is required for highefficiency refining, it is known that the rate decreases when dicalcium silicate (C2S) layer forms around the quicklime by reacting with slag The equation that driving force is the difference of CaO content between in slag and a liquid Rapid Dissolution of Quicklime into Molten Slag by Internally

Calcium Oxide: From Ancient Warfare to Modern Industry

2021年5月20日 Calcium oxide (and calcium hydroxide) is also an important chemical for raising the pH of potable water and wastewater during its treatment However, there are different methods used to utilize quicklime during the different stages of water softening, neutralization, and stabilization, so it is important to adhere to the types of lime recommended by ASTM C1529 quicklime particle, so some cores are large compared with the weight estimated from 2 pctCO 2, and weight of some core are zero The average decreasing ratio measured in this study is 43 pct, though the grade of CO 2 content in the quicklime is 2 pct It is well known that CaO isRapid Dissolution of Quicklime into Molten Slag by Springer2021年3月25日 It is the first stage in the crushing process that can sometimes include secondary, tertiary and even quaternary crushing stages, depending on the material and the end product requirements Types of Primary Crushers There are several types of primary crushers, including: Gyratory Crushers Jaw Crushers HammermillsWhat Type of Crusher Is Best for Primary Crushing? McLanahan2024年3月27日 The main limestone processing techniques are as follows:Crushing: Breaking large pieces of limestone into small pieces for subsequent processing Comm +86How to process limestone?

.jpg)

Lime/quicklime for metallurgy – how producing and briquetting

2023年2月4日 What is lime Lime, also known as quicklime or burnt lime, is mainly composed of calcium oxide, molecular formula CaO, which is a white block or powder cubic crystal The lime commonly used in industry will be dark gray due to impurities such as magnesium oxide, aluminum oxide and ferric oxide The relative density is 325338g/cm3, the true density is The quality of quicklime is affected by several factors related to the limestone feed and the calcination process These include the chemical composition and crystalline structure of the limestone, as well as operating conditions in the kiln such as temperature, particle size of the limestone, rate of temperature rise, retention time, and CO2 concentration Controlling these Factors Affecting The Quality of Quicklime2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each Stage2023年4月24日 Calcium oxide, also known as quicklime, is manufactured industrially by the thermal decomposition of calcium carbonate (limestone) in a lime kiln The process typically involves the following steps: Quarrying and How is calcium oxide manufactured industrially?

How to process limestone? clirik ultrafine grinding mill

Crushing: Breaking large pieces of limestone into small pieces for subsequent processing Commonly used crushing equipment includes jaw crusher, impact crusher, cone crusher, etc Screening: The crushed limestone is screened according to 2024年5月16日 Some portable heaters use quicklimewater reactions You can categorize types of quicklime by size: Lump lime: large pieces up to eight inches in diameter; Pebble lime: small chunks from 025 to 25 inches in diameter; Lime vs Limestone Rock: Types and Uses of Each2023年10月11日 In systems that demand large quantities of lime, quicklime would be the preferred material as the density is twice the density of hydrated lime, which reduces the storage and transportation costs However, quicklime’s hydrophobic reaction with water requires a lime slaker to be used in the processQuick Lime Preparation, Properties and Uses Hebei Yayang Quicklime application instantly increases soil aggregate stability** Katharina M Keiblinger 1, Lisa M Bauer2, Evi Deltedesco , Franz Holawe2, Hans Unterfrauner3, Franz Zehetner1, and Robert Peticzka2* 1Institute of Soil Research, Department of Forest and Soil Sciences, University of Natural Resources and Life Sciences Vienna (BOKU), Peter JordanStrasse 82, 1190 Vienna, Quicklime application instantly increases soil aggregate stability**

Quicklime Lumps – Uma Lime Industry LLC

At Uma Lime Industry LLC, our Quicklime Lumps are produced through the precise calcination of highquality limestone in our advanced Cimprogetti kiln These large, solid pieces of quicklime are renowned for their purity and consistent quality, making them ideal for various industrial applications Key Features2024年9月10日 When it absorbs rain or groundwater, it releases heat and bubbles that make it look alive That’s where the name comes from: quick means living Some portable heaters use quicklimewater reactions You can categorize types of quicklime by size: Lump lime: large pieces up to eight inches in diameterLime vs Limestone Rock: Types and Uses of Eachpebble quicklime is used Once the slaking tank is emptied, the water for the next batch is added to the slaking tank and the system goes to a standby mode waiting for an operator to start the next batch cycle Figure 4 shows a batch slaker for use with pulverized quicklime Batch slakers are used where only a few small batches are neededAn Overview of Lime Slaking and Factors That Affect the ProcessIn the context of quicklime production, jaw crushers are essential for the initial stage of size reduction, breaking down large raw materials into more manageable pieces The production of quicklime begins with limestone, a sedimentary rock abundant in calcium carbonate (CaCO₃)The Role of Jaw Crushers in Quicklime Production

.jpg)

The Amazing Uses of Quicklime You Probably Didn’t Know

Quicklime was used in the infamous Holocaust The Nazis would place a thick layer of quicklime on the floor of the cattle cars before loading the Jews This would burn the skin of the victims on contact Quicklime, also known as burnt lime, is a chemical compound called