Which manufacturer has better quality highpressure mill

.jpg)

Highpressure mill, Highpressure grinding mill All

Find your highpressure mill easily amongst the 16 products from the leading brands (LONGI, Hosokawa, Metso, ) on DirectIndustry, the industry specialist for your professional purchasesAt Weir, we are specialised in high tonnage, hard rock HPGRs to satisfy the need in mining to process higher volumes of ore Our Enduron® HPGR portfolio ranges from pilot machines to Enduron® High Pressure Grinding Rolls (HPGR) WeirWith low energy consumption, low maintenance requirements, excellent throughput capacity and high availability, Enduron® high pressure grinding rolls (HPGR) are a proven way to improve the efficiency of aggregate and mineral Our Dynamic HPGR Technology for Mineral Grinding2019年8月19日 Whether you’re designing a brandnew mill circuit or optimising an existing site for longterm efficiency, High Pressure Grinding Rolls offer a range of advantages over conventional milling techniques, including ball mills, How HPGRs compare to conventional milling Weir

.jpg)

FLS High Pressure Grinding Rolls – Efficient grinding

High Pressure Grinding Rolls (HPGR) are the most efficient comminution product for milling Robust and reliable heavyduty process pumps for efficient handling of abrasive slurries Full Backed by years of experience and indepth knowledge within the field, CITIC HIC has successfully developed high pressure grinding roll (HPGR) suited to meet global customers' needs of safe, reliable, energysaving and high High Pressure Grinding Roll Grinding Mill SupplierOur mills offer a broad range of roll materials and concepts to meet all your applications, including cleanroom production to international standards Threeroll mills (triple mills) from Bühler provide reliability, high raw material yield and ThreeRoll Mills Grinding and Dispersing Bühler GroupHighpressure grinding roll presses (HPGRs) are emerging as an important comminution technology in the minerals processing industry The technology has found its key application in HighPressure Grinding

.jpg)

High pressure grinding rolls HRC™ 8 HRC™ 800 Metso

Robust HRC™ high pressure grinding rolls (HPGR) HRC™ 8 and HRC™ 800 are based on a highpressure grinding roll (HPGR) technology and are optimized for the demanding Roll cooling is performed with sprays attraditionally high pressure mance Perfor improvement and reduction of cost are reported for a new type of low pressure cooling called High Turbulence Roll ooling (HTRC)C [8]This type of cooling module is presented in figure 5 Figure 5: High Turbulence Roll cooling module [8]2020 Technology and Operation of a Hot Rolling Mill DA clear example is the work of Hadizadeh et al (2017), who classified the mill power draw and bearings pressure in levels such as very low, low, good, high, and very highRelationship between SAG mill power draw, bearing High pressure grinding mill, also known as high pressure roller mill, can grind nonflammable and explosive materials with Mohs hardness not greater than 93 and humidity below 6%Its main components include main engine, reducer, YGM High Pressure Grinding Mill

High Pressure Pump Manufacturers High Pressure Water

High Pressure Water Pump suppliers exporters offer Multistage Industrial High Pressure Pump D7, Industrial Area, Delhi Road, Saharanpur, Uttar Pradesh, India Office Hours: Monday Saturday 9 am to 5 pm2019年1月9日 Propolis has numerous biological properties and technological potential, but its low solubility in water makes its use quite difficult With the advent of nanotechnology, better formulations with Production of Nanopropolis Using High Pressure Ball Mill Barite ultrafine vertical roller mill is an industrial vertical grinding mill that can grind nonmetallic ore into fine powder The mill has a high production capacity, high fine powder content, high degree of automation, convenient maintenance, long service life, environmental protection, and energysaving, and is an ideal equipment for largescale production of ultrafine powderBarite Ultrafine Vertical Roller MillYGM series high pressure suspension grinding mill Breaking through the bottleneck of traditional pendulum mill production capacity, enjoy the advantages of large single production capacity at home and abroad, single processing capacity up to 50T/H, under the same power, the output is 20% higher than the traditional mill, 30% higher than the ball millYGM Series High Pressure Suspension Grinding Mill

.jpg)

High Quality SingleDrive HighPressure Roller Mill

Singledrive high pressure grinding roll is specially designed to pregrind the cement clinkers, the mineral dross, the steel clinkers and so on into small granules, to ultracrush the metallic minerals (iron ores, manganese ores, copper ores, leadzinc ores, vanadium ores and others) and to grind the nonmetallic minerals (the coal gangues, feldspar, nepheline, dolomite, limestone, quartz 2024年4月18日 Grand Design RV has a reputation for tough, solid, and reliable RVs Their RVs have no problem standing up to rough terrains and extreme weather They also provide an efficient and responsive customer service team, a 3year limited structural warranty, and a lifetime warranty on the roof membrane12 Best RV Brands Of 2024 (And How To Identify A Good Brand)2021年6月22日 Both bead mill homogenizers and high pressure homogenizers are useful tools for a variety of applications Typically, a bead mill is used for smaller samples, particularly where high throughput is required Laboratory bead mill homogenizers can only handle sample sizes of 1 Bead Mill Homogenizers vs High Pressure Homogenizers2022年7月7日 A recent investigation into the effect of highpressure processing (400 and 600 MPa, for two or five min, 20 °C) compared to conventional autoclave, or thermal, processing (96°C for 45 minutes) on cauliflower found that the technology has clear potential in increasing shelf life, while preserving a high level of qualityHigh pressure processing: Evaluating the uses and benefits for

High Pressure Mill, High Pressure Roller Mill, High Pressure

The HGM High Pressure Mill is improved on the basis of Raymond mill The machine is pressurized by a highpressure spring, Bellian mining machinery manufacturer provides you with a complete set of mine crushing, milling, mineral processing solutions and Cement with a steep PSD is one with a high water demand To address this issue, VRM manufacturers have come up with a more conventional raw mill VRM design Investment Cost VRM has been a more compact unit is quite smaller Ball Mills Or Vertical Roller Mills: Which Is Better For 6 天之前 The problem of high temperatures in ball mills is a prevalent problem that needs to be addressed to improve their performance and efficiency By implementing the solutions discussed in this article, such as proper lubrication, regular maintenance, and the use of cooling devices, the temperature of a ball mill can be effectively controlledFour Ways To Improve The High Temperature Problem Of Ball Mill2016年10月5日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study performed on a EnergyEfficient Technologies in Cement Grinding IntechOpen

.jpg)

Which RV Manufacturer Has the Best Quality? [2024]

2024年2月21日 Quick Answer: When it comes to RV manufacturers, it’s important to consider various factors such as build quality, reliability, customer satisfaction, and overall value While there are several reputable manufacturers in the market, our team of RV enthusiasts at RV Brands™ has conducted extensive research and analysis to determine the RV manufacturer 2021年11月3日 Compared with other mills, it has a high passing rate – 99% The main drive device of the highpressure mill adopts an airtight gearbox and belt pulley, the transmission is stable and the operation is reliable Important components are made of highquality castings and profiles, ensuring the durability of the whole equipmentPhosphate Mineral Powder Grinding Mill SBM Ultrafine 2023年8月5日 The main motor is the main power source for the entire high pressure roller mill Two highvoltage threephase asynchronous motors are used, which can be purchased by the user or commissioned by the manufacturer The transmission system adopts the internationally advanced planetary reducer suspension transmissionIntroduction to the structure of high pressure roller mill2016年7月14日 Thus, some of the finish grinding work is handled by the highpressure grinding roll The throughput of the existing grinding system can be increased by 50 to 70%, while power consumption can be cut by 20 to 30% Additional options for highpressure grinding roll use in gold ore comminution circuits are illustrated in Figure 11HPGR 911Metallurgist

.jpg)

YGM Series High Pressure Suspension Grinding Mill

YGM Series High Pressure Suspension Grinding Mill can produce powder from various nonflammable and nonexplosive mineral materials with Mohs hardness below 93 and humidity below 6%, there are mainly applied in the industries of metallurgy, construction materials, chemical, and mining, etc2024年9月25日 Like many other quality manufacturers, Doma builds their LVP with an SPC (StonePlastic Composite) core, which is a sturdy and reliable choice known to last for decades When it comes to sizes, you’ll find their planks mainly in 7″ x 48″ dimensions, though some collections offer larger 9″ x 60″ planks if you’re looking to make a bigger statement in your spaceTop 11 Best Luxury Vinyl Flooring Brands For 年2月26日 The industry has failed to fully adapt to this technological development, which offers significant energy savings, as it did with other technical developments such as the precalciner kiln or high efficiency coolers Mill operation and maintenance Operation of a ball mill is relatively simple, with no moving mechanical parts within the mill paring ball mills and VRMS for cement grindingtraditional SAG mill, ball mill, and crusher circuits, as repo rted by Daniel, Lane and McLe an (2010) For this reason, original equipment manufacturers like Weir have increased the size of HPGRs to effectively process larger volumes of ore in a more energyefficient manner (Figure 2) Figure 2—Enduron 26 Metre (m) Diameter x 26 m HPGR,Flowsheet of the Future: HighPressure Grinding Rolls, Vertical

BALL MILLS Ball mill optimisation Holzinger Consulting

in combination with a ball mill for cement grinding applications and as finished product grinding units, as well as raw ingredient grinding equipment in mineral applications This paper will focus on the ball mill grinding process, its tools and optimisation possibilities (see Figure 1) The ball mill comminution process has a high electrical2021年11月12日 HIGHPRESSURE MILL; The industrial milling equipment produced by SBM runs stably, which can guarantee your production process and output; The fineness can be adjusted to meet a variety of milling needs, which can expand your market competitiveness; Simple operation and convenient maintenance can save you labor; Energy saving and Vermiculite Industrial Milling Equipment SBM Ultra MillDonghua is high pressure homogenizer manufacturer in China since 1984, offer colloid mill, industrial and laboratory homogenizer for food, beverage, chemical and pharmaceutical industry Our homogenizer is up to 150Mpa, we use Nanometer technology in making homogenizer, we are Chinese large homogenizer supplier, our homogenizer also applied in petroleum chemical and High Pressure Homogenizer Manufacturer Colloid Mill in China 2020年6月8日 Some pellet machine manufacturers says that they have manufactured a new type of wood pellet ring die pellet mill, which called high efficient centrifugal ring die pellet mill When we saw name, we may be tempted by the phrases like “high efficient” and centrifugal, and we may think that the ring die pellet mill seems like quality equipmentWhich is better to choose between vertical pellet mill and

.jpg)

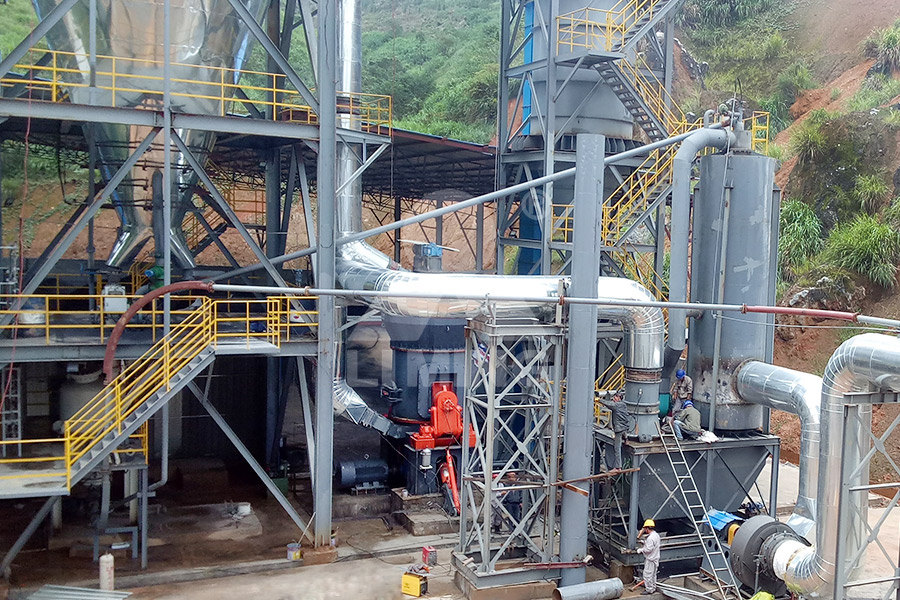

Optimization of working parameters of highpressure roller mill

2024年11月15日 The main structure of the highpressure roller mill is shown in Fig 1, which mainly includes the frame, hydraulic system, guide trough, pressure roller and other devicesThe two pressure rollers A world famous, reliable, and high quality valve manufacturer We manufacture valves using special materials like HASTELLOY (r), titanium alloys incoloy nickel alloys (r), monel (r) The Nai Lok High Pressure Metal Hose has an assortment which can be wide of It can be utilized in industries such as gas plus oils, construction, High pressure metal hose Manufacturer Supplier in ChinaEnduron® high pressure grinding rolls (HPGR) can handle a wide variety of ores and particle sizes from fine pellet feed all the way up to coarse grinding of 75mm magnetite iron ore When it comes to feed material characteristics, the specific ore type is not detected by an Enduron® HPGR, however ore hardness, size and bed compressibility are important considerationsOur Dynamic HPGR Technology for Mineral Grinding WeirRoll cooling is performed with sprays attraditionally high pressure mance Perfor improvement and reduction of cost are reported for a new type of low pressure cooling called High Turbulence Roll ooling (HTRC)C [8]This type of cooling module is presented in figure 5 Figure 5: High Turbulence Roll cooling module [8]2020 Technology and Operation of a Hot Rolling Mill D

.jpg)

Relationship between SAG mill power draw, bearing

A clear example is the work of Hadizadeh et al (2017), who classified the mill power draw and bearings pressure in levels such as very low, low, good, high, and very highHigh pressure grinding mill, also known as high pressure roller mill, can grind nonflammable and explosive materials with Mohs hardness not greater than 93 and humidity below 6%Its main components include main engine, reducer, YGM High Pressure Grinding MillHigh Pressure Water Pump suppliers exporters offer Multistage Industrial High Pressure Pump D7, Industrial Area, Delhi Road, Saharanpur, Uttar Pradesh, India Office Hours: Monday Saturday 9 am to 5 pmHigh Pressure Pump Manufacturers High Pressure Water 2019年1月9日 Propolis has numerous biological properties and technological potential, but its low solubility in water makes its use quite difficult With the advent of nanotechnology, better formulations with Production of Nanopropolis Using High Pressure Ball Mill

.jpg)

Barite Ultrafine Vertical Roller Mill

Barite ultrafine vertical roller mill is an industrial vertical grinding mill that can grind nonmetallic ore into fine powder The mill has a high production capacity, high fine powder content, high degree of automation, convenient maintenance, long service life, environmental protection, and energysaving, and is an ideal equipment for largescale production of ultrafine powderYGM series high pressure suspension grinding mill Breaking through the bottleneck of traditional pendulum mill production capacity, enjoy the advantages of large single production capacity at home and abroad, single processing capacity up to 50T/H, under the same power, the output is 20% higher than the traditional mill, 30% higher than the ball millYGM Series High Pressure Suspension Grinding MillSingledrive high pressure grinding roll is specially designed to pregrind the cement clinkers, the mineral dross, the steel clinkers and so on into small granules, to ultracrush the metallic minerals (iron ores, manganese ores, copper ores, leadzinc ores, vanadium ores and others) and to grind the nonmetallic minerals (the coal gangues, feldspar, nepheline, dolomite, limestone, quartz High Quality SingleDrive HighPressure Roller Mill 2024年4月18日 Grand Design RV has a reputation for tough, solid, and reliable RVs Their RVs have no problem standing up to rough terrains and extreme weather They also provide an efficient and responsive customer service team, a 3year limited structural warranty, and a lifetime warranty on the roof membrane12 Best RV Brands Of 2024 (And How To Identify A Good Brand)

Bead Mill Homogenizers vs High Pressure Homogenizers

2021年6月22日 Both bead mill homogenizers and high pressure homogenizers are useful tools for a variety of applications Typically, a bead mill is used for smaller samples, particularly where high throughput is required Laboratory bead mill homogenizers can only handle sample sizes of 1