Magang slag powder

Fabrication of a Sulfur/Steel SlagBased Filter and Its

2024年2月27日 Steel slag powder (400 mesh) was purchased from Magang (Group) Holding Company Ltd, Ma’anshan, China The potassium nitrate, ammonium chloride, potassium dihydrogen phosphate, and sodium GradeS95 slag powder with a density of 290 g/cm3 and a specific surface area of 410 m2/kg was taken from Anhui Magang Jiahua New Building Materials Co, Ltd of China Its quality Fabrication of BakingFree Bricks Using Gold Tailings and 2020年11月1日 Slag powder is a process with characters of multivariables, strongly coupling and nonlinearity The material layer thickness plays an important role in the process It can Analysis and multiobjective optimization of slag powder process2018年1月30日 Steel slag powder has hydraulic properties, and its hydration process is similar to that of cement [15, 16] Studies have shown that concrete that contains steel slag powder Applications of Steel Slag Powder and Steel Slag Aggregate in

Fabrication of BakingFree Bricks Using Gold Tailings and

2021年11月1日 The slag powder, cement and fly ash can fill the spaces between the grains of gold mine tailings and therefore make the sample obtain a better size distribution, leading to a 2022年1月1日 Blast furnace slag is often used as aggregate into concrete after air cooling and crushing of the solidified slag (Pang et al, 2015; Ozbakkaloglu et al, 2016; Rios et al, 2019) A review on characteristics of silicomanganese slag and its 2023年5月15日 On this basis, steel slag and slag composite micro powder (SSCM) technology was proposed, which realized the high added value and utilization rate of steel slag in Comprehensive utilization of steel slag: A review ScienceDirect2021年9月24日 The engineering characteristic test of manganese slag shows that the particle size distribution characteristics and critical moisture content of manganese slag are similar to Analysis of Basic Physical and Chemical Characteristics of

Preparation of waterquenched manganese slag and fly ash

2023年3月20日 In this paper, S95 grade ultrafine mineral admixture (UMA) was prepared by water quenched manganese slag and fly ash 1:1 compound mechanical ball milling to a 2024年4月28日 Zhang et al investigated the carbonation of steel slagbased mortar prepared from the mixture of steel slag powder mixed with mineral materials, including MgO, CaO and A Review on the Carbonation of Steel Slag: Properties, Mechanism 2022年11月11日 Steel slag is generally regarded as a supplementary cementitious material in cementbased materials, which is conducive to the realization of the goal of carbon peak and carbon neutralization However, the Laboratory Preparation and Performance 2024年9月1日 The findings revealed that the addition of seashell powder and calcined slag improved the material’s toughness and promoted the formation of cementitious products such as carboaluminate phases, CASH gel, and ettringite, with a 15% mixture of seashell powder and calcined slag increasing the compressive strength ratio of SCSC to ordinary Portland cement Seashell powder calcined slag cement: A novel green lowcarbon

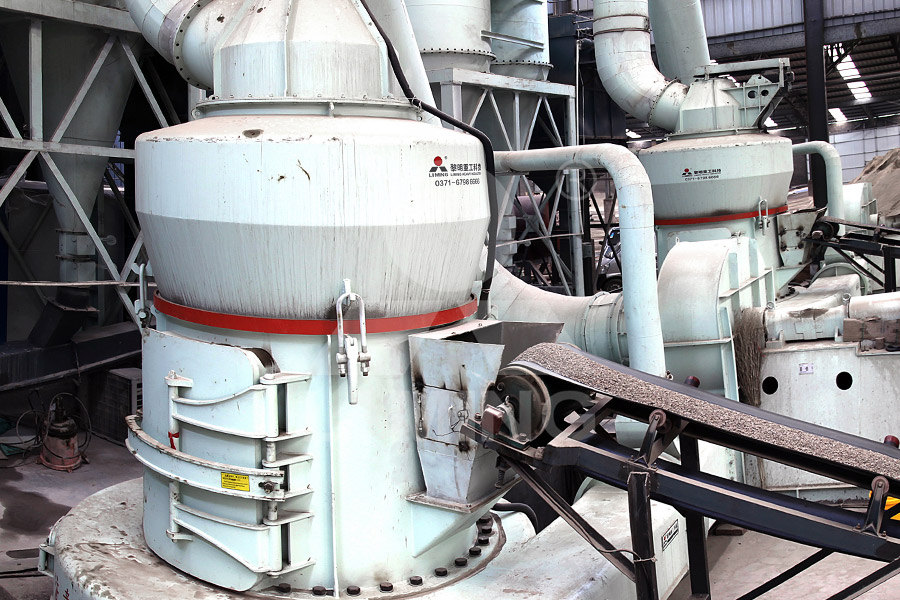

Slag Ultrafine Powder Processing Technology

2024年10月25日 In addition, slag powder, as a new admixture for highperformance concrete, has the advantage of improving various properties of concrete, which makes it have huge market potential in the construction industry The innovation of Clirik slag micro powder technology provides a new idea for the recycling of slag2017年12月15日 The chemical components of ferronickel slag primarily include SiO 2, MgO, CaO, Al 2 O 3, and Fe 2 O 3 [8], [11] and the crystalline minerals in ferronickel slag include enstatite, forsterite, and diopside [12]The content of amorphous minerals in ferronickel slag is usually greater than 50% [13]Ferronickel slag powder exhibits pozzolanic activity and hence is Characteristics and reactivity of ferronickel slag powder2023年10月15日 Steel slag powder is subsequently formed and causes considerably contaminate the land, and water resources, and degrade the air quality [9, 10] The compositions of steel slag depend on the way it is processed and they can be classified into basic oxygen furnace (BOF) slag, electric arc furnace (EAF) slag and ladle furnace (LF) slagInfluence of steel slag powder on the characteristics of 2023年6月27日 Steel slag powder and construction waste have received widespread attention for their resource utilization as solid waste This article uses steel slag powder and recycled concrete aggregates to prepare controlled lowstrength materials (CLSM) The study investigates the influence of steel slag powder replacing cement and recycled aggregates on the Effect of Steel Slag Powder on the Performance of Controlled Low

Influence of ferronickel slag powder on the sulfate attack

Granulated blast furnace slag powder being used to improve the resistance to sulfate attack of concrete performance research[J] Journal of Xinjiang Agricultural University, 2013, 36(4):340344 (in Chinese) [1] HAN Jianguo, YAN Peiyu, ZHANG 2024年9月1日 The mineral composition in steel slag powder is similar to that of cement, including C 3 S, C 2 S, etc, which can react with water, enabling steel slag powder to be used as supplementary cementitious material [3]However, deficiencies such as limited activity and poor stability of steel slag powder significantly restrict its applicability [4, 5]Insitu wet carbonation of steel slag powder paste made with 2020年2月3日 In view of the performance requirements of mass ultrahigh performance concrete (UHPC) for the Pang Gong bridge steel cable tower in China, the UHPC incorporating of steel slag powder and hybrid expansive agents is optimized and prepared The effects of steel slag powder and hybrid expansive agents on the hydration characteristics and persistent shrinkage Effects of Steel Slag Powder and Expansive Agent on the MDPI2023年9月20日 Previous studies have focused on using steel slag as an aggregate in asphalt mixtures, while neglecting the use of steel slag powder (SSP) instead of natural mineral powder The use of SSP in asphalt concrete is beneficial for improving its effective utilization rate, and the performance can be improved by increasing the stiffness of asphalt mortar ( Xie et al, 2023 ; Environmental hazard reduction and antiaging enhancement of steel slag

.jpg)

(PDF) Effects of Steel Slag Powder and Expansive

2020年2月3日 The results indicate that 15 wt% steel slag powder and 5 wt% hybrid expansive agents can effectively reduce the drying shrinkage deformation of UHPC with a slight decrease of strength2020年7月1日 The slag grinding system is the core of the slag powder control system, which con sists of batching station, conveyor belt, vertical mill, hot gas generator , dust collector and product warehouseAnalysis and multiobjective optimization of slag 2023年6月28日 The utilization rate of steel slag in China is far behind that of developed countries The annual output of steel slag is still increasing, resulting in a large amount of accumulation, causing environmental pollution This paper Effects of Steel Slag Powder as A Cementitious 2017年12月11日 Two different mould powders are used for casting peritectic steel grades at the voestalpine Stahl Linz GmbH slab casting machine Powder A forms significantly larger slag rims than Powder B, although their chemical compositions are very similarFor the clarification of the different performance during service, the melting and solidification behaviour as well as the Slag Rim Formation of two Mould Powders used for Casting of

.jpg)

Effect of Steel Slag Powder Content and Curing Condition on the

2023年4月10日 The results illustrate that the incorporation of steel slag powder can significantly delay the setting time and improve the flowability of AAMUHPC, making it possible for engineering applications2024年8月9日 Steel slag powder (SSP) was finely ground and has a relatively small particle size ranging from 015 to 186 μm, with a median size of 332 μm and a specific surface area of 6553 m 2 /kg GBFS has an average diameter of 15 μm and a specific surface area of 801 m 2 /kgModification of magnesium phosphate cement with steel slag powder 2024年9月20日 While steel slag powder can effectively enhance the mechanical strength of soil and significantly reduce its waterinduced swelling behavior [34], due to the weak activity and adsorption of SSP itself, it exhibits poor impact toughness, is prone to cracking and brittle damage as a cementitious material, and undergoes low hydration at room temperatureDisintegration characteristics and mechanism of red clay improved 2022年6月27日 After thermal braising and magnetic separation, steel slag is often ground into steel slag powder (SSP), which contains active silica (SiO 2) and can be used as a cementitious material to replace part of the cement and applied in concreteHowever, there have been relatively few studies on the influence of SSP on the performance of pavement cement concrete (PCC)Characteristics of Pavement Cement Concrete Incorporating Steel Slag Powder

.jpg)

Spectroscopic Analysis of Weak Acid Modified Steel Slag Powder

Spectroscopic Analysis of Weak Acid Modified Steel Slag Powder: ZHANG Hao 1, 2, 3, ZHANG Xinyu 3, LONG Hongming 1, 2, 3* 1 School of Metallurgical Engineering, Anhui University of Technology, Ma’anshan , China 22021年2月22日 Slag, as shown in Fig 1, is the 16th ingredient of highperformance concrete production [22], called supplementary cementitious materials (SCM) [23], that can enhance the strength and durability of concrete [2]The highly fine slag powder, with a surface area of 400–600 m 2 /kg and a bulk density of 1200 kg/m 3, can be mixed with free lime to replace 40% to 65% Slag uses in making an ecofriendly and sustainable concrete: A 2024年7月30日 Steel manufacturers around the world are looking for ways to produce higher quality, lowersulfur steel This requires an additional desulfurization step using the Kambara reactor (KR) during steel production As a side effect, the Kambara reactor’s slag processing generates emissions that are captured and concentrated in dust collectors such as bag filters, Recycled Kambara reactor slag powder as a sustainable stabilizer The calculated K value of the slag powder was 1808 (its chemical composition is shown in Table 1), which is larger than 12 According to the provisions of the Chinese standard GB/T 2032008, K ≥ 12 is needed Generally, the larger the K value, the higher the potential activity of the slag powder Therefore,Fabrication of BakingFree Bricks Using Gold Tailings and

Influence of slag powder on the mechanical and electrical

2024年3月29日 On the one hand, the slag powder’s “dilution effect” increased the CCS’s porosity, while on the other, the powder’s “secondary hydration” consumed Ca(OH) 2 and formed CSH, which led ultimately to the gradual reduction of the slag powderincorporated composite cementitious material’s electrical resistivity2024年2月28日 11 Raw Materials The raw materials used for the test included P•MH 425 mediumheat Portland cement meeting the requirements of Chinese standard GB/T 2002017 [], granulated blast furnace phosphorus slag produced as a byproduct of the yellow phosphorus industry in Guizhou, China, phosphate slag powder with a specific surface area of 200, 340, SelfSimilar Fractal Characteristics of Phosphorus Slag Powder 2022年3月18日 The influence of different replacement ratios of steelslag powder as cementreplacement material on the fracture performance of concrete is studied in this paper A threepoint bending fracture test is carried out on slag powdercementbased concrete (SPC)notched beams with steelslag powder as cementitious materials, partially replacing cement (0%, 5%, Fracture Behavior of Steel Slag PowderCementBased Concrete 2018年1月30日 The applications of steel slag powder and steel slag aggregate in ultrahigh performance concrete (UHPC) were investigated by determining the fluidity, nonevaporable water content, and pore Applications of Steel Slag Powder and Steel Slag Aggregate in

.jpg)

Superfine Slag Powder Production Line FTM Machinery

Superfine slag powder production line is also called ultrafine slag micro powder plant or superfine slag powder making plant Superfine slag powder production line is used to crush non flammable materials of which Mohs hardness is no more than seven degree and water content is 2022年5月1日 Keywords Permeability Test, FerroNickel Slag Powder, Impermeability, Clean Water, Marine Environment, Pore Structure Permeability coefficient (fresh water) Investigation of ferronickel slag powder for marine applications 2017年2月25日 An experimental investigation has been carried to study about the effect of glass powder on high strength copper slag concrete The range of glass powder was 10%, 15% and 20% as a replacement of Utilisation of glass powder in high strength copper slag concrete2021年7月1日 rate of concrete with slag powder are the largest, and the loss rate of C30 concrete can reach 279 and 200%, respectively The addition of iron tailing powder can effectively reduce the loss rate(PDF) Effect of Iron Tailings and Slag Powders on Workability and

.jpg)

Laboratory Preparation and Performance

2022年11月11日 Steel slag is generally regarded as a supplementary cementitious material in cementbased materials, which is conducive to the realization of the goal of carbon peak and carbon neutralization However, the 2024年9月1日 The findings revealed that the addition of seashell powder and calcined slag improved the material’s toughness and promoted the formation of cementitious products such as carboaluminate phases, CASH gel, and ettringite, with a 15% mixture of seashell powder and calcined slag increasing the compressive strength ratio of SCSC to ordinary Portland cement Seashell powder calcined slag cement: A novel green lowcarbon 2024年10月25日 In addition, slag powder, as a new admixture for highperformance concrete, has the advantage of improving various properties of concrete, which makes it have huge market potential in the construction industry The innovation of Clirik slag micro powder technology provides a new idea for the recycling of slagSlag Ultrafine Powder Processing Technology2017年12月15日 The chemical components of ferronickel slag primarily include SiO 2, MgO, CaO, Al 2 O 3, and Fe 2 O 3 [8], [11] and the crystalline minerals in ferronickel slag include enstatite, forsterite, and diopside [12]The content of amorphous minerals in ferronickel slag is usually greater than 50% [13]Ferronickel slag powder exhibits pozzolanic activity and hence is Characteristics and reactivity of ferronickel slag powder

制粉-10.25公众号.jpg)

Influence of steel slag powder on the characteristics of

2023年10月15日 Steel slag powder is subsequently formed and causes considerably contaminate the land, and water resources, and degrade the air quality [9, 10] The compositions of steel slag depend on the way it is processed and they can be classified into basic oxygen furnace (BOF) slag, electric arc furnace (EAF) slag and ladle furnace (LF) slag2023年6月27日 Steel slag powder and construction waste have received widespread attention for their resource utilization as solid waste This article uses steel slag powder and recycled concrete aggregates to prepare controlled lowstrength materials (CLSM) The study investigates the influence of steel slag powder replacing cement and recycled aggregates on the Effect of Steel Slag Powder on the Performance of Controlled Low Granulated blast furnace slag powder being used to improve the resistance to sulfate attack of concrete performance research[J] Journal of Xinjiang Agricultural University, 2013, 36(4):340344 (in Chinese) [1] HAN Jianguo, YAN Peiyu, ZHANG Influence of ferronickel slag powder on the sulfate attack 2024年9月1日 The mineral composition in steel slag powder is similar to that of cement, including C 3 S, C 2 S, etc, which can react with water, enabling steel slag powder to be used as supplementary cementitious material [3]However, deficiencies such as limited activity and poor stability of steel slag powder significantly restrict its applicability [4, 5]Insitu wet carbonation of steel slag powder paste made with

Effects of Steel Slag Powder and Expansive Agent on the MDPI

2020年2月3日 In view of the performance requirements of mass ultrahigh performance concrete (UHPC) for the Pang Gong bridge steel cable tower in China, the UHPC incorporating of steel slag powder and hybrid expansive agents is optimized and prepared The effects of steel slag powder and hybrid expansive agents on the hydration characteristics and persistent shrinkage 2023年9月20日 Previous studies have focused on using steel slag as an aggregate in asphalt mixtures, while neglecting the use of steel slag powder (SSP) instead of natural mineral powder The use of SSP in asphalt concrete is beneficial for improving its effective utilization rate, and the performance can be improved by increasing the stiffness of asphalt mortar ( Xie et al, 2023 ; Environmental hazard reduction and antiaging enhancement of steel slag