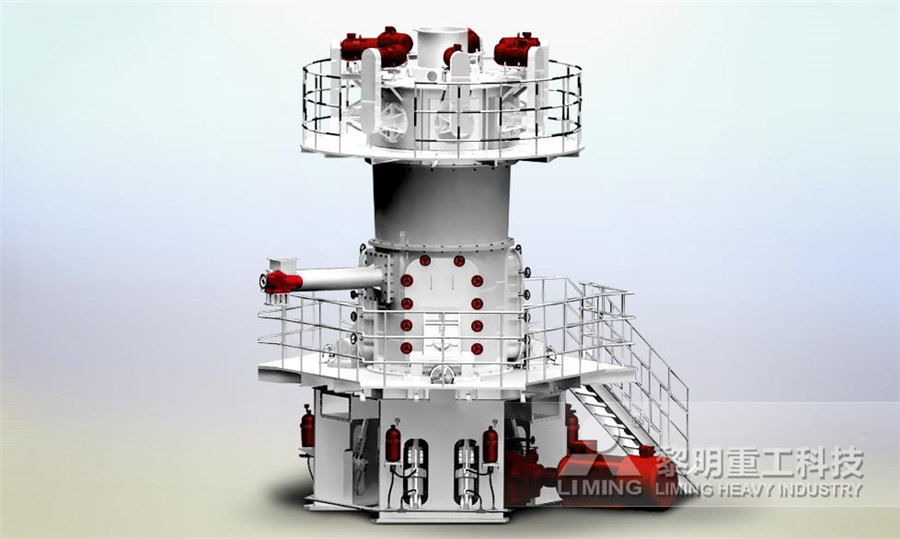

HOME→Stator pressure regulating European version mill Stator pressure regulating European version mill Stator pressure regulating European version mill

Stator pressure regulating European version mill Stator pressure regulating European version mill Stator pressure regulating European version mill

.jpg)

Influence of rotorstator axial clearance on compressor rotating

2023年8月1日 The strengthening of stator suction surface separation leads to the increase of pressure on the pressure surface leading edge Meanwhile, the fluctuation caused by the Results of numerical investigations based on a 3D RANS solver FlowER, explaining the effects of geometrical and flow parameters on the development of endwall flows are presented The Pressure distribution at the stator (left) and rotor (right) profile In this study a full three dimension numerical simulation verified by LDA measurements of instantaneous velocity distribution was employed to investigate the flow pattern, the pumping Characterisation of Flow Pattern in a Rotor Stator High Shear Mixer2018年4月1日 Transitioning to continuous production requires an indepth understanding of how each unit operation is affected by the shift This contribution reviews the scientific (PDF) RotorStator Mixers: From Batch to Continuous Mode

.jpg)

A comparison of power and flow characteristics between batch

2019年7月20日 Batch and inline rotorstators share the same power characterisation Pipe flow in Inline rotorstators is not the true flow through the mixing head Stators with larger holes The circumferential compressive stress, which is measured by eight biaxial strain gages installed on the surface of the backiron for the stator core, is changed linearly with respect to the Development of Variable Stress Applying System for Shrink Fitting 2018年1月1日 In these cases, rotorstator devices are capable of generating much smaller droplets than, eg, highpressure homogenizers This chapter presents different rotorstator Fabrication of Nanoemulsions by RotorStator Emulsification2021年10月28日 Understand the principles of rotorstator technology Hockmeyer provides a comprehensive guide to effective mixing and dispersion techniques If you’re considering Rotor Stator Principles Explained Hockmeyer

.jpg)

Influence of Upstream and Downstream Compressor Stators on

2014年10月8日 The rotor wakes are measured at different circumferential locations across the vane passage, and the influence of Stator 1 wake on the suction side of the rotor wake is 2021年6月26日 While rotating, the rotor induces periodic perturbations on the pressure and velocity field in the stator–rotor gap, altering the evolution of the total quantities and the flow Influence of the RotorDriven Perturbation on the StatorExit Flow Explore Hockmeyer’s rotorstator mills for efficient blending and dispersion Ideal for achieving consistent results in various industrial applications Machine Features Sizes from 2 horsepower to 100 horsepower Hoist or tankmounted RotorStator Hockmeyer Hockmeyer Equipment There are also a number of automated, higherthroughput rotorstator homogenizers These are generally more expensive than a bead mill of equivalent throughput, but allow for processing larger samples There are also a number of rotorstator homogenizers which allow semicontinuous inline processing, and can therefore handle very large volumesRotorStator Homogenization Homogenizers

.jpg)

The VRS Rotor Stator Mixer SCHOLD

A rotor stator is a highly efficient device used for highspeed dispersing, mixing, size reduction, and deagglomerating It works by utilizing a rotor that spins within a stationary slotted stator at very high speeds This setup acts like a The investigations were conducted for the blade apsect ratio of 075 (stator), 13 (rotor), pressure drop in the stage from 7908 to 7116 bar, stator exit Mach number of Ma = 04Pressure distribution at the stator (left) and rotor (right) profile Stator, SIL30 High Pressure Valve Stator Stator, SIL30 High Pressure Valve Stator Toggle navigation Sign In; Compare; 1300 032 032 Quick Order Capillary Electrophoresis Capillaries and Cartridges Capillaries; Cartridges; Chemistries and Kits Chemistries; Kits; Detectors and Accessories Accessories; Detectors Stator, SIL30 High Pressure Valve Stator Valve Parts SCIEX2017年9月30日 The statorrotor interaction is an important issue in turbomachinery design when the highest performances are targeted Different characters mark the interaction process in highpressure or lowpressure turbines depending both on the blade height and on the Reynolds number For small blade heights, being the stator secondary flows more important, a more StatorRotor Interaction in Axial Turbine: Flow Physics and

Evaluation and scaleup of miniaturized rotor–stator impact mills

2016年1月31日 Two recently marketed, miniaturized rotorstator impact mills of 70 mm and 35 mm rotor diameter were evaluated and compared to a conventional small scale model of 110 mm rotor diameter, in order This phenomenon is known as droop Pressure regulator accuracy is defined as how much droop the device exhibits over a range of flows; less droop equals greater accuracy The pressure versus flow curves provided in the graph “Direct Acting Pressure Regulator Operating Map”, indicates the useful regulating capacity of the regulatorThe Basics of Pressure Regulators Beswick Engineering2011年10月31日 The pin mill is a type of rotor–stator mill; therefore, one of the disks is the stator and the other one rotates with a high peripheral speed of up to 150 m/s An additional modification of the design consists of having two counterrotating pin disks, which allow for peripheral speed of up to 250 m/s (Nied 2007)Mechanical ParticleSize Reduction Techniques SpringerLink2021年10月28日 Rotor Stators are high shear mixers that incorporate both a rotor and a stationary stator As the rotor (or rotors) turns at high speeds within the stationary stator, it creates a vortex circulating the product through the gap between the rotor and stator, mechanically shearing the contents at high speeds and creating a very homogenous blendRotor Stator Principles Explained Hockmeyer

.jpg)

Rotorstator Dispermill

The Rotorstator shaft is interchangeable with your Discovery or Xproof shaft and comes with flange included There are two versions available The short version can be connected on the Discovery 100, and the XProof FR 075 The long 2017年6月1日 In the present study, the rotational pressure loss at the entrance of rotorstator gap is characterised Based upon dimensional analysis, the coefficient of entrance loss can be correlated with a An experimental study of rotational pressure loss in rotorstator 2005年1月1日 The most frequent ones are the rotor–stator systems (colloid mill, Comparison between high pressure jet and rotor stator process European Journal of Pharmaceutics and Biopharmaceutics, Volume 126, 2018, pp 140148 Sandra Gehrmann, Heike parison of emulsification efficiency of proteinstabilized 2004年6月1日 Conference: Proceedings of the ASME Turbo Expo 2004; At: Vienna, Austria; Volume: ASME Paper GT200453463Effect of Clocking on the Second Stator Pressure Field of a One

Rotor Stator Homogenizers – Definition, Principle, Parts, Uses

2024年3月22日 Bear in mind that not all rotorstators are equipped with a probe, which is necessary for operating a rotorstator homogenizer Although the phrase “highshear homogenizer” is commonly used to describe rotorstator homogenizers, this can be misleading because other types of homogenizers, such as highpressure homogenizers, also function in 2016年12月1日 The fluid then enters the diffuser stage where the stators turn this dynamic pressure into static pressure by slowing down the flow So to summarize, the compressor adds velocity to the flow by doing work (adding energy) to the flow This energy is then converted from dynamic pressure to static pressure by the diffuser as it slows down the fluidHow does a stator convert velocity into pressure?The pressure rings and the superimposed pressure fingers are sprung into place during the pressing to maintain the necessary pressure in the stator core Stator Winding The stator winding is a diamond winding installed in open slots with two coil sides per slot The coils are manufactured in two halves that are brazed togetherStator Coil an overview ScienceDirect TopicsDiscover the key differences between High Shear Wet Mills and Traditional RotorStator Mixers in industrial processing Explore their design, functionality, and performance to make informed equipment choices for optimal mixing and dispersion results Chicago: 6309241208High Shear Wet Mills vs Traditional RotorStator Mixers in

.jpg)

Influence of rotorstator axial clearance on compressor rotating

2023年8月1日 Graf [5] investigated the effects of the stator pressure field on upstream rotor performance in a highpressure compressor stage through steady simulation and quantified the timeaveraged loss, blockage and pressure rise caused by the downstream stator Sirakov [6] studied the rotor performance affected by the interaction between rotor tip clearance flow and 2018年12月31日 The use of high purity water results in relatively few chemistry and materials issues in generator water cooling Of the few problems that arise, flow restrictions by copper oxide deposits have Corrosion and Deposits in WaterCooled Generator Stator Windings: Part Rotorstator homogenizers are also sometimes referred to as highshear homogenizers, although this term may be somewhat confusing as other types of homogenizers, such as highpressure homogenizers, also operate in whole or Rotor Stator Homogenizersnot an option for a 42ft Gearless Mill Drive The ring motor is not selfsupported and needs the mill to fix the rotor poles to and it needs the mill foundation to support the stator Finally you would need a few thousand tons of ore and possibly even an earthquake would be needed to have a realistic test environment representative of a mine siteThe Siemens 42ft gearless mill drive, still an evolutionary design

(PDF) RotorStator Mixers: From Batch to Continuous

2018年4月1日 Since the same rotorstator heads are often used in both modes of operation, it is sometimes assumed that transitioning from batch to continuous rotorstator mixers is straightforward2021年6月26日 In stator–rotor interaction studies on axial turbines, the attention is commonly focused on the unsteady rotor aerodynamics resulting from the periodic perturbations induced by the stator flow structures Conversely, less interest has been historically attracted regarding the influence of the rotor on the flow released by the stator, correlated to propagation of the blade Influence of the RotorDriven Perturbation on the StatorExit Flow Typically installed in a process line between tanks or in a truly continuous process with no tanks, inline mixers provide focused, singlepass, rapid mixing Our inline rotor stator mills and pumps take up less space than other kinds of tank mixer systems, are easy to maintain, and simple to operate Applications: Powder wetting and dispersionHigh Shear Rotor Stator Pump Mill Inline Rotor Stator Mills Stator Résistant 200°C Haute Performance Rotor Volant Magnétique VOIR LES PRODUITS Haute Performance Rotor Volant Magnétique VOIR LES PRODUITS VOIR LES PRODUITS EFS RMSTATOR EUROPE 15 Ruelle du Puits 38270 Revel Tourdan France 09 67 59 45 76 eRmStatorEurope

.jpg)

Gas turbine engine compressor variable stator vane arrangement

USA1 US12/458,539 USA USA1 US A1 US A1 US A1 US A US A US A US A1 US A1 US A1 Authority US United States Prior art keywords compressor variable stator pressure gas turbine turbine engine Prior art date 2008 2021年7月19日 Colloid mills are rotorstator mixers that are commonly used to make emulsions and dispersions It can also be used to make solids in suspension smaller A highspeed rotor inside the colloid mill forces the fluid through small holes in a stationary stator, resulting in significant mechanical shear The user can manage the level of shear []What Is a Colloid Mill and How Is It Different From a Homogenizer2018年4月3日 Although continuous production processes are often desired, many processing industries still work in batch mode due to technical limitations Transitioning to continuous production requires an indepth understanding of how each unit operation is affected by the shift This contribution reviews the scientific understanding of similarities and differences between RotorStator Mixers: From Batch to Continuous Mode of 2007年10月9日 John Stuart Mill (18061873) was the most famous and influential British moral philosopher of the nineteenth century He was one of the last systematic philosophers, making significant contributions in logic, metaphysics, epistemology, Mill's Moral and Political Philosophy Stanford Encyclopedia of

.jpg)

RotorStator Hockmeyer Hockmeyer Equipment

Explore Hockmeyer’s rotorstator mills for efficient blending and dispersion Ideal for achieving consistent results in various industrial applications Machine Features Sizes from 2 horsepower to 100 horsepower Hoist or tankmounted There are also a number of automated, higherthroughput rotorstator homogenizers These are generally more expensive than a bead mill of equivalent throughput, but allow for processing larger samples There are also a number of rotorstator homogenizers which allow semicontinuous inline processing, and can therefore handle very large volumesRotorStator Homogenization HomogenizersA rotor stator is a highly efficient device used for highspeed dispersing, mixing, size reduction, and deagglomerating It works by utilizing a rotor that spins within a stationary slotted stator at very high speeds This setup acts like a The VRS Rotor Stator Mixer SCHOLDThe investigations were conducted for the blade apsect ratio of 075 (stator), 13 (rotor), pressure drop in the stage from 7908 to 7116 bar, stator exit Mach number of Ma = 04Pressure distribution at the stator (left) and rotor (right) profile

.jpg)

Stator, SIL30 High Pressure Valve Stator Valve Parts SCIEX

Stator, SIL30 High Pressure Valve Stator Stator, SIL30 High Pressure Valve Stator Toggle navigation Sign In; Compare; 1300 032 032 Quick Order Capillary Electrophoresis Capillaries and Cartridges Capillaries; Cartridges; Chemistries and Kits Chemistries; Kits; Detectors and Accessories Accessories; Detectors 2017年9月30日 The statorrotor interaction is an important issue in turbomachinery design when the highest performances are targeted Different characters mark the interaction process in highpressure or lowpressure turbines depending both on the blade height and on the Reynolds number For small blade heights, being the stator secondary flows more important, a more StatorRotor Interaction in Axial Turbine: Flow Physics and 2016年1月31日 Two recently marketed, miniaturized rotorstator impact mills of 70 mm and 35 mm rotor diameter were evaluated and compared to a conventional small scale model of 110 mm rotor diameter, in order Evaluation and scaleup of miniaturized rotor–stator impact millsThis phenomenon is known as droop Pressure regulator accuracy is defined as how much droop the device exhibits over a range of flows; less droop equals greater accuracy The pressure versus flow curves provided in the graph “Direct Acting Pressure Regulator Operating Map”, indicates the useful regulating capacity of the regulatorThe Basics of Pressure Regulators Beswick Engineering

.jpg)

Mechanical ParticleSize Reduction Techniques SpringerLink

2011年10月31日 The pin mill is a type of rotor–stator mill; therefore, one of the disks is the stator and the other one rotates with a high peripheral speed of up to 150 m/s An additional modification of the design consists of having two counterrotating pin disks, which allow for peripheral speed of up to 250 m/s (Nied 2007)2021年10月28日 Rotor Stators are high shear mixers that incorporate both a rotor and a stationary stator As the rotor (or rotors) turns at high speeds within the stationary stator, it creates a vortex circulating the product through the gap between the rotor and stator, mechanically shearing the contents at high speeds and creating a very homogenous blendRotor Stator Principles Explained Hockmeyer