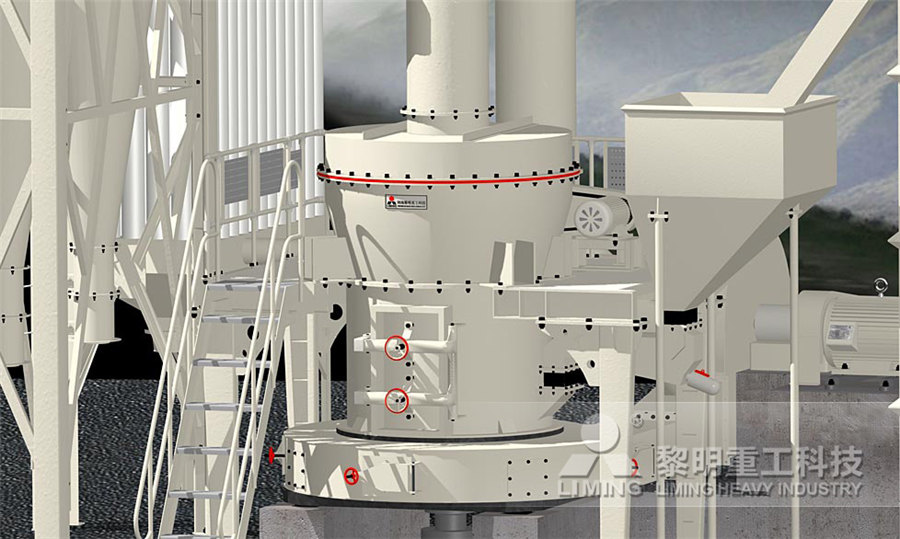

Calcite ore crushing equipment

.jpg)

Calcite Ore Crushing Solutions DSMAC

We develop calcite crusher in stationary, portable, mobile series to meet the different calcite crushing demands As calcite (calcspar) occurs in a number of massive forms such as aragonite, marble, limestone, chalk, fibrous etcFTM Machinery offers various stone crushing equipment at an affordable price for large, medium, or small mining companies, especially for artisanal miners, junior miners, and amateur mining enthusiastsStone Crushing Equipment Fote MachineryCalcite processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout designCalcite Processing Equipment, Process Flow, CasesCalcite crusher, as an essential machine for crushing calcite ore, has become increasingly important in the mining industry This paper introduces the working principle, structure, and Calcite Crusher

Calcite crushers for calcite quarrying, crushing, powder making

Calcite crushing process with crushers, pulverizer machine SBM provide best calcite crushers including primary, secondary crusher used as calcite powder making machinery for sale2023年4月21日 For calcite crushing, SBM provides jaw crushers, impact crushers, cone crushers, and other mining calcite crushing equipment If your final particle size need is greater, you may also use our calciterelated equipment, Calcite Processing SBM Mill CrusherDesigns and manufactures crushing and screening plants with different configurations and capacity values as per clients’ needs and preferences Production capacity values of our Stone Crushing and Screening Plants CM Mining MachineryMining machinery is mainly used for crushing and gridning various materials, such as river pebbles, granite, basalt, limestone, quartzite, calcite, dolomite, silica ore, basalt, etc Common GMG Group® Official Website Mining Crushing and Screening

.jpg)

Pebble Ore Crushing Solutions DSMAC

A pebble is a clast of rock with a particle size of 4 to 64 millimetres based on the Krumbein phi scale of sedimentology Pebbles are generally considered to be larger than granules (2 to 4 millimetres diameter) and smaller than cobbles (64 to 256 millimetres diameter)Crushing is one of the key stages to process sandstone DSMAC Machinery supply primary crushing, secondary crushing to tertiary crushing, fineness crushing equipment in the sandstone crushing plant In the construction industry, the manufacturing of cement, lime, the important raw materials are sandstonesSandstone Ore Crushing Solutions DSMAC2021年10月29日 After the magnesiumcontaining solution acts on calcite, it will turn the calcite into magnesite, so magnesite also belongs to the calcite family Jaw crushers are widely used as crushing equipment in the magnesite Magnesite Grinding Equipment Production Line2016年4月12日 Crushing Calcite Ore: In the flowsheet a 2stage open circuit crushing section is provided to reduce the limerock to approximately minus ¾” for feed to the ball mill The size of the crushing equipment depends largely upon the quarrying operation and the size of the largest pieces delivered to the crusherCalcite Processing by Flotation for Beneficiation

.jpg)

Calcite Processing Equipment, Process Flow, Cases JXSC Machine

Calcite is the mineral component of limestone which is used primarily as construction aggregates, and in production of lime and cement Limestone also is used in a variety of commercial applications including: road construction, riprap and jetty stone, filter stone, railroad ballast, poultry grit, mineral food, sugar processing, flux stone in steel production, glass manufacture, sulfur The high copper prices of recent years are producing a substantial supply response Copper ore a valuable mineral source for all countries The biggest copper mines are in Chile and North America, every year many thousands of tonnes of copper ore were produced, The copper ores are extracted by either traditional mining (open pit or underground) or by leaching, and 90 Copper Ore Ore Crushing Solutions DSMAC2023年4月21日 Calcite Mill For calcite crushing, SBM provides jaw crushers, impact crushers, cone crushers, and other mining calcite crushing equipment If your final particle size need is greater, you may also use our calciterelated equipment, such as ball mills and vertical roller millsCalcite Processing SBM Mill Crusher2022年8月17日 Iron ore crusher is a kind of mechanical equipment that crushes iron ore raw ore step by step, from large pieces of raw iron ore (about 500mm) to millimeterlevel fine materials +17 [ protected] Iron ore crushing material characteristics Characteristics of Iron ore crushing equipment and process flow

.jpg)

Limestone crushing technology and equipment SBM Ultrafine

2023年12月8日 After being processed by the coarse crushing equipment, the secondary crushing equipment is used for secondary crushing to break the stones into stones between 20100mm The particle size of the discharged stones can also be controlled by adjusting the size of the discharge port of the media crushing equipment Get finished gravel2023年4月26日 So how is calcite processed? What equipment is needed for processing? Calcite crushing process There are three main technologies in calcite processing: crushing, sand making, and milling, and crushing is the primary stage Calcite has a Mohs hardness of 3 It is easily broken, often breaking into small square pieces along its cleavage 13 Incredible Flows to Win Calcite Processing (Without Failing)Calcite is a calcium carbonate mineral, widely distributed, usually white or colorless Common shapes are granular, massive, fibrous, earthy, and so on The calcite mill can grind calcite into a fine powder of 1503000 mesh, which is widely used Generally, calcite is used as industrial raw material such as chemical industry and cementCalcite Ultrafine Grinding Mill2024年7月13日 A 120 TPH stone crushing production line typically consists of a vibrating feeder, It has a high reduction ratio and is capable of handling various types of rocks and ores Optimized equipment configuration ensures efficient operation and high production rates120 TPH stone crushing production line – Mining Equipment

Gypsum Ore Crushing Solutions DSMAC

Jaw crusher is used to crush gypsum ore into small size less than 8 mm in the primary crushing process The vibrating screen screens out the suitable particles into the next step, while the unsuitable go back for the coarse crushing2021年10月14日 High energy consumption in ore crushing brings great challenges to the mining industry Microwave irradiation provides a promising solution for rock breakingStudy on Magnetite Ore Crushing Assisted by Microwave IrradiationSBM has been focusing on the field of mining ore crushing and grinding machinery Crushing and sand making equipment can process 1000+ kinds of raw materials GRINDING The grinding equipment independently developed and produced by SBM can grind nonflammable and explosive nonmetallic ores Calcite Marble Magnesite Limestone Kaolin Processing Materials SBM Ultrafine Powder Technology2016年12月20日 Find Crushing Equipment manufacturers, Product Description The structure of Crushing Iron Ore Equipments includes Main Frame, Main Axle, Roller Bearings, Eccentric Shaft, Jaw This is an effective Unit mainly for Calcite Dolomite Minerals which carries out the process right from crushing of Stones Up to the Sizes of 6 mm to Crushing Equipment Manufacturers, Suppliers, Dealers Prices

.jpg)

Graphite Grinding Machine Powder Mill Equipment

2021年10月26日 Graphite Production Line Equipment Intro – Crushing Grinding Link The equipment configuration of the complete graphite powder production line is complicated, and the equipment selection can be planned and adjusted according to the actual production needs of customers, and the production line has a high degree of automationCalcitefluorite type ore: The main minerals are fluorite and calcite (the content is as high as 30%), some of which contain a small amount of quartz, and sometimes quartzcalcitefluorite type ore can be formed, which is a refractory ore—(Main process: crushing – grading – jigging – grinding – roughing – multiple flotation);Fluorite Flotation Process, Equipment JXSC Machinery2021年9月10日 High energy consumption in ore crushing brings great challenges to the mining industry Microwave irradiation provides a promising solution for rock breaking However, there is currently a lack of detailed understanding of the microwave parameters regarding magnetite ore The purpose of this study is to fully understand the potential value of microwave irradiation Study on Magnetite Ore Crushing Assisted by Microwave Irradiation 【Feeding Size】: 65300mm 【Cone Crusher Output Size】: 5 10 mm; 1040 mm 【Capacity】: 20 1000T/h 【Applicable materials】: limestone, granite, pebbles, basalt, dolomite, bluestone, calcite, iron ore, etc 【Applicable Fields】: primarily used in mining, quarrying, and construction to efficiently crush and size a variety of materials, including hard rocks and aggregatesCone Crusher For Sale Secondary Crushing Equipment

Iron ore crushing and screening process SBM

2022年8月3日 The iron ore processing and production process mainly includes three processes: crushing, grinding and beneficiation In the crushing process, the threestage closedcircuit crushing is more modern and suitable for high AIMIX has jaw crusher, impact crusher, cone crusher and sand making machine as the core crushing equipment,with a full range of models to meet the customer’s tonnage and cobblestone, basalt, granite, iron ore, feldspar, calcite, talc, fluorite, construction waste, etc Production capacity 15600 t/h Feed particle size ≤500 mm Power Aimix Group Stone Crushing SolutionsLead ore crushers are used widely in such ore curshing industry Since the establishment, DSMAC has grown to become the largest crusher and screening equipment dealer in the China Lead Ore Cursher Working Details Jaw crusher for lead ore: Jaw crusher is used in primary crushing station Lead ore jaw crusher can crush lead ore into small sizesLead Ore Ore Crushing Solutions DSMACCalcite in the processing equipment in accordance with the the processing fineness of different, can be divided into: calcite sand 610 mesh,1020 mesh equipment used is the European version of the mill; calcite powder below 325 mesh, mainly used in the device is Raymond; purpose of more than 325 calcite ultrafine powder uses the most widely used, mainly used in calcite Calcite Crushing Process Design Mining, Crushing, Grinding,

.jpg)

Exceptional Barite Processing Methods and Machines

2023年3月20日 When processing barite ore with a particle size greater than 2mm, use the jigs When processing barite ore with a particle size smaller than 2mm, use shaking tables or spiral chutes Here is a case of barite gravity beneficiation Barite Ore Flotation Flotation is an important way to recover barite from lowgrade ores, associated ores and tailingsThe stone crusher machine is the machine used for crushing ore, concrete, FTM Machinery offers various stone crushing equipment at an affordable price for large, medium, or small mining companies, such as cement, limestone, marble, talc, calcite, dolomite, kaolin, coal, gypsum, etc Capacity: 5–260 t/h Output size: 0–10 mmStone Crushing Equipment Fote MachineryEquipment: Jaw crusher, impact crusher, sand maker Limestone is a sedimentary rock composed mostly of the mineral calcite and comprising about 15% of the Earth’s sedimentary crust Limestone is the main concrete, etc Impact crusher is widely used in various ore crushing, railway, highway, energy, cement, chemical, construction Limestone Aggregate Crushing JXSC MachineThe gangue of copper ore is mainly quartz, followed by calcite, feldspar, mica, chlorite, barite, etc SANME, as a famous supplier of mining crushing solutions, can offer complete set of copper ore crushing equipment and comprehensive technical support to every customerCopper Ore Crushing SHANGHAI SANME MINING MACHINERY

Trona Crush Calcite Manufacturing Machines Crusher Mills, Cone

Gold Ore Crushing,Gold Ore crushing Equipment,Gold Ore Gold: Gold is usually found associated with the mineral quartz It is sometimes connected with other minerals too, including iron and manganese oxides, calcite 2024年6月14日 Granite quarrying is the process of extracting granite from the earth for use in construction, landscaping, and other applications Crushing equipment plays a vital role in this process, breaking down large pieces of granite into smaller, more manageable sizes Types of Crushing Equipment There are several different types of crushingGranite Quarrying Operations Crushing Equipment CM A pebble is a clast of rock with a particle size of 4 to 64 millimetres based on the Krumbein phi scale of sedimentology Pebbles are generally considered to be larger than granules (2 to 4 millimetres diameter) and smaller than cobbles (64 to 256 millimetres diameter)Pebble Ore Crushing Solutions DSMACCrushing is one of the key stages to process sandstone DSMAC Machinery supply primary crushing, secondary crushing to tertiary crushing, fineness crushing equipment in the sandstone crushing plant In the construction industry, the manufacturing of cement, lime, the important raw materials are sandstonesSandstone Ore Crushing Solutions DSMAC

.jpg)

Magnesite Grinding Equipment Production Line

2021年10月29日 After the magnesiumcontaining solution acts on calcite, it will turn the calcite into magnesite, so magnesite also belongs to the calcite family Jaw crushers are widely used as crushing equipment in the magnesite 2016年4月12日 Crushing Calcite Ore: In the flowsheet a 2stage open circuit crushing section is provided to reduce the limerock to approximately minus ¾” for feed to the ball mill The size of the crushing equipment depends largely upon the quarrying operation and the size of the largest pieces delivered to the crusherCalcite Processing by Flotation for BeneficiationCalcite is the mineral component of limestone which is used primarily as construction aggregates, and in production of lime and cement Limestone also is used in a variety of commercial applications including: road construction, riprap and jetty stone, filter stone, railroad ballast, poultry grit, mineral food, sugar processing, flux stone in steel production, glass manufacture, sulfur Calcite Processing Equipment, Process Flow, Cases JXSC MachineThe high copper prices of recent years are producing a substantial supply response Copper ore a valuable mineral source for all countries The biggest copper mines are in Chile and North America, every year many thousands of tonnes of copper ore were produced, The copper ores are extracted by either traditional mining (open pit or underground) or by leaching, and 90 Copper Ore Ore Crushing Solutions DSMAC

Calcite Processing SBM Mill Crusher

2023年4月21日 Calcite Mill For calcite crushing, SBM provides jaw crushers, impact crushers, cone crushers, and other mining calcite crushing equipment If your final particle size need is greater, you may also use our calciterelated equipment, such as ball mills and vertical roller mills2022年8月17日 Iron ore crusher is a kind of mechanical equipment that crushes iron ore raw ore step by step, from large pieces of raw iron ore (about 500mm) to millimeterlevel fine materials +17 [ protected] Iron ore crushing material characteristics Characteristics of Iron ore crushing equipment and process flow2023年12月8日 After being processed by the coarse crushing equipment, the secondary crushing equipment is used for secondary crushing to break the stones into stones between 20100mm The particle size of the discharged stones can also be controlled by adjusting the size of the discharge port of the media crushing equipment Get finished gravelLimestone crushing technology and equipment SBM Ultrafine 2023年4月26日 So how is calcite processed? What equipment is needed for processing? Calcite crushing process There are three main technologies in calcite processing: crushing, sand making, and milling, and crushing is the primary stage Calcite has a Mohs hardness of 3 It is easily broken, often breaking into small square pieces along its cleavage 13 Incredible Flows to Win Calcite Processing (Without Failing)